Are you planning to gasify your house or modernize your gas supply? A gas pipeline is one of the most valuable and dangerous communications, so its reliable protection is extremely important.

Agree, damage to a gas pipe and leakage of this fuel can go unnoticed for quite a long time, and then lead to the most disastrous consequences. It’s better to study everything carefully in advance and play it safe when arranging protection, right?

If you are interested in the insulation of steel gas pipelines, in this article you will get answers to the following questions: why is it needed, what is it, in what cases and how each type of insulating material is used, how to check the quality of the coating. We will mention all types of gas pipelines: from main pipelines to low-pressure pipes, from aboveground to underwater, and we will answer all questions that arise.

Gas pipeline insulation functions

Today, almost every building in every locality is connected to the gas pipeline; it is difficult to imagine the life of a modern person without blue fuel. Just imagine how many pipes are needed to implement such a supply network!

They stretch above our heads, under our feet, deep in the earth, and even along the seabed. Every centimeter of this gas web must be reliably protected and absolutely safe, because a leak can lead to a large-scale accident, with destruction and sometimes casualties.

Modern underground gas pipelines are laid mainly in polymer pipes - they are not afraid of either corrosion or the effects of stray currents, and they retain temperature better

Polyethylene gas pipelines do not need additional protection, but they cannot be used everywhere, and replacement is expensive, so most gas pipes are made of steel.

To prevent steel from rusting and deteriorating, it is treated with special compounds and materials that isolate its surface from the environment. The main functions of such coatings are protection from moisture, chemical influences, mechanical influences, and dielectric protection.

Active electrochemical protection forms a cathodic charge on the surface of the pipe, ensuring its electrical stability and preventing the influence of external currents

In addition to the coating, for reliable protection from stray and direct currents, underground gas pipelines are equipped with electrochemical cathodic protection, which ensures the removal of these charges through a special conductor to the drainage substation.

For an above-ground pipeline, the protection is less solid, because it is easier to update, and the pipes are exposed only to atmospheric moisture, drying out regularly. For offshore gas pipelines, on the contrary, in addition to reliable protection from an aggressive environment, an additional layer of weighting is required so that the pipe lies motionless on the bottom, under the waves.

Pipe laying methods

On the street, insulation of heating pipelines is required both when installed above ground and when laid hidden - underground. The latter method is a channel method - a reinforced concrete trench is first laid in the trench, and pipes are already placed in it. Channelless placement method - directly in the ground. The insulating materials used differ not only in thermal conductivity, but also in steam and water resistance, durability and installation methods.

The need to insulate cold water supply pipes is not so obvious. However, you cannot do without it when the water supply is laid open above ground - the pipes must be protected from freezing and subsequent damage. But inside buildings, water supply pipes also have to be insulated - to prevent moisture condensation on them.

Hidden installation option

Based on the requirements of SNiP, joint construction of pipelines in the ground is unacceptable if at least one of them belongs to category I. When laying the system in a semi-through trench, you should know that its height cannot be less than 150 centimeters, and the minimum distance between insulated pipes must be 60 centimeters.

The areas where shut-off valves are installed should be located in thickened areas of the tunnel in order to periodically inspect and repair steam and hot water pipelines without effort.

When installing in walk-through trenches, the gap between the insulated elements must be at least 70 centimeters with a minimum tunnel height of 2 meters.

Materials for insulation of steel pipelines

The choice of the optimal solution depends on a number of factors: the operating temperature of the pipeline or gas pipeline, the transported medium, the type of pipeline installation (on-ground or underground), pipe diameter, etc.

The following materials can be used to insulate welded pipe joints:

- Primers or primers.

They are mainly applied before using heat-shrinkable cuffs. They reduce pipeline wear and increase its protection against corrosion. They are mainly used for insulating steel pipes for various purposes: oil pipelines, gas pipelines, water pipelines. - Adhesive tapes and films.

They can consist of a single material, such as PVC tapes, or of several anti-corrosion materials. They are used to fix waterproofing and increase the resistance of pipelines to various adverse factors. We should also highlight heat-shrinkable tapes. - Cuffs.

They are used to insulate welded pipe joints. Kits usually include additional elements in the form of locking plates, primers, etc. - Galvanized casing.

Quite often, pipe insulation requires additional coating with a steel casing. For this purpose, galvanized steel sheets are used. This material is especially relevant for insulating pipe joints. Insulation of pipelines with galvanized steel provides additional protection. - Coupling kit

It consists of a heat-shrinkable one-piece sleeve and a filler (applicator and adhesive tape). It is used for high-quality insulation of joints of thermally insulated PPU pipelines in a polyethylene sheath, providing high adhesion, shear strength, reliable and durable sealing of PPU joints. - Installation kits.

They most often include tape, clamps and self-tapping screws; they are used to tie together a set of thermal and waterproofing. - Thermal insulation materials.

Often, to insulate welded joints, PPU shells, PPS shells, foam glass shells, as well as fire-fighting material in the form of pierced mats or mineral wool cylinders can be used.

Types of insulation

Today, when laying pipelines, the following types of insulating materials are most often used:

- Bitumen;

- Folgoizol;

- Polyurethane foam shell;

- PPU shell;

- Glass wool;

- Mineral wool;

- Rubber shell;

- Polyethylene anti-corrosion insulation.

Now let's take a closer look at each of them.

Bitumen

Not so long ago, bitumen insulation of steel pipes was the most common. It consists of a thin layer of polyethylene, which is protected by a bitumen coating. In addition, fiberglass is often used on top of this coating.

Bitumen waterproofing of pipes is designed to protect the steel surface from corrosion, which can be caused by its contact with the soil and various chemical elements found in the soil. Most often, this method is used to cover routes that are laid in sandy, rocky or clayey soil.

Note! The average operating temperature of a bitumen-coated system should be between -40 and +65 degrees Celsius.

Roll of foil insulation

Folgoizol

Folgoizol can also be classified as bitumen coatings, since it consists of thin aluminum foil and bitumen-rubber binder.

Among the advantages of this material the following points can be highlighted:

- Low price, which ensures efficiency.

- Reliability;

- Simplicity and speed of application - the pipes are simply wrapped in foil insulation.

Most often, foil pipe insulation is used for channel and non-channel laying of water pipelines and heating mains.

Polyurethane foam shell

Polyurethane foam shell

This material is a collapsible cylinder that is put on the pipes, hence the name “shell”.

Among its advantages are:

- Reliability;

- Extremely simple installation instructions;

- Good thermal insulation properties, due to which such insulation is most often used for heating and hot water supply pipes;

- Durability;

- Can be used for both open and underground systems.

For these reasons, polyurethane foam pipe insulation has recently become one of the most common.

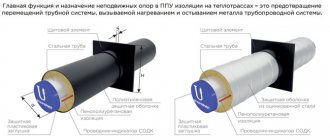

Pipes with PPU sheath

PPU shell

PPU insulation is applied to the pipes by the manufacturer, i.e. they go on sale already in a shell. Essentially, the product is a pipe within a pipe.

The technology for applying this coating is as follows:

- First of all, the surface of steel pipes is processed using a shot blasting machine. This allows for good adhesion of the coating to the steel surface, as it is cleaned of dirt, rust and welding scale.

- The pipe is then inserted into a polyethylene sheath.

- After this, liquid polyurethane is poured into the space between the inner wall and the outer insulation, which subsequently hardens.

It must be said that the shell can be not only polyethylene, but also galvanized. Its type depends on the operating conditions of the pipeline. In addition, in the case of laying an open pipeline, the polyethylene casing must be coated with acrylic or silicone paint, which will protect it from exposure to ultraviolet rays.

Note! The maximum operating temperature in the system where this technical pipe insulation is used should not exceed 130 degrees Celsius.

Mineral wool shell

Mineral wool

This material is most often used for thermal insulation of heating networks. As a rule, it consists of shells and mats made of mineral wool, which can be placed on pipes of a wide variety of diameters.

It should be noted that if it gets wet, mineral wool loses its properties, so it must be waterproofed and protected with galvanized casings. Therefore, despite the low cost of the material, it is not the most profitable, especially if it is necessary to insulate a large section of the pipeline.

Advice! Mineral wool is an excellent sound insulation for sewer pipes, especially for plastic risers.

Rubber shell

Rubber insulation

Rubber insulation for pipes is used as insulation. Most often it spreads in the form of empty tubes. To insulate large diameter pipes, rubber sheets with an adhesive layer are used to wrap the pipeline.

The scope of application of the rubber casing is quite extensive.

Most often it can be found in the following types of pipelines:

- Ventilation pipe systems;

- Heating networks;

- Water supply systems;

- Oil pipelines, etc.

This material is widely used due to the following properties:

- Water-vapour tightness;

- Low thermal conductivity;

- Fire safety;

- Elasticity;

- Resistant to all weather conditions;

- Easy to install, thanks to which you can insulate the pipeline yourself.

These properties determine the wide range of applications of the material. It must be said that rubber can also be used to soundproof sewer pipes.

The photo shows the application of polyethylene anti-corrosion insulation

Polyethylene anti-corrosion insulation

Polyethylene anti-corrosion insulation is a combined shell that consists of several layers. As in the case of polyurethane foam, protection of pipes with this material is carried out in production workshops. This is advisable, as it helps prevent corrosion if the structure is installed in bad weather.

As you might guess from the name, this material is designed to protect steel from corrosion. It is used for underground laying of pipelines.

As a rule, polyethylene insulation is used for oil and gas pipelines. To insulate household networks, it is more advisable to use a polyurethane foam shell or some other material, one of those discussed above.

These are, perhaps, all the main types of insulation that are most often used when laying pipelines in our time.

Coating Equipment

Application of the TERMA-ST coating must be carried out by trained workers. To prepare the surface to be coated, the following equipment is required:

- gas burner - 1 pc.;

- propane cylinder with reducer – 1 piece;

- connecting gas hose 1 Ohm - 1 pc.;

- contact thermometer with a measurement range from 0 to 150° C;

- press rollers;

- heat-resistant gloves, mittens, protective helmets, goggles;

- sander, file, sandpaper.

Why is this necessary?

- Condensation control: When the temperature is not maintained, condensation forms in the pipes, and over time, water accumulates. Proper insulation using appropriate cladding will minimize the likelihood of condensation.

- Corrosion protection. Over time, metal corrodes, but special coatings slow down this process.

- Noise control. During operation, pipes can create vibrations and even knock. If they are properly insulated, excessive operating sounds are kept to a minimum.

- Safety. As the temperature rises, there is a risk of accidents, and the protective layer minimizes the risks by maintaining the temperature within the acceptable range.

- Reducing costs associated with fuel losses. With high-quality insulation, there are practically no energy losses.

Glass wool, mineral wool

Insulating materials proven by practice. Meet the requirements of SP 61.13330.2012, SNiP 41-03-2003 and fire safety standards for any installation method. They are fibers with a diameter of 3-15 microns, close to crystals in structure.

Glass wool is made from waste from glass production, mineral wool from silicon-containing slag and silicate waste from metallurgy. The differences in their properties are insignificant. Available in the form of rolls, stitched mats, plates and pressed cylinders.

It is important to be careful with materials and know how to handle them correctly. Any manipulations must be performed in protective overalls, gloves and a respirator.

Installation

The pipe is wrapped or lined with cotton wool, ensuring uniform filling density over the entire surface. Then the insulation, without too much pressure, is fixed using a knitting wire. The material is hygroscopic and easily gets wet, so insulation of external pipelines made of mineral or glass wool requires the installation of a vapor barrier layer made of a material with low vapor permeability: roofing felt or polyethylene film.

A covering layer is placed on top of it to prevent the penetration of precipitation - a casing made of roofing tin, galvanized iron or sheet aluminum.

How to calculate insulation?

The choice of the required insulation is carried out on the basis of mathematical calculations, from which it is clear which material is better to take, its thickness, composition and other characteristics. If everything is done correctly, then it is quite possible to significantly reduce heat losses, as well as make the operation of systems reliable and absolutely safe.

Thermal insulation of pipes with foam plastic

What to pay attention to during calculations:

- difference in ambient temperatures where communications are used;

- the temperature of the surface that is supposed to be insulated;

- possible loads on the pipes;

- mechanical impacts from external influences, be it pressure, vibration, etc.;

- the value of the thermal conductivity coefficient of the insulation used;

- impact and corresponding magnitude from transport and soil;

- the ability of an insulator to resist various types of deformation.

It should be noted that SNiP 41-03-2003 is considered the main document on the basis of which materials for insulation and their thickness are selected, according to specific operating conditions. The same SNiP states that for networks in which the operating temperature of the pipes is less than 12 degrees, it is necessary to additionally lay a vapor barrier when treating the surface.

Thermal insulation of pipes can be calculated in two ways, and each option can be called reliable and convenient for specific conditions. We are talking about an engineering (formula) and online version.

In the first case, the actual thickness of the optimal insulating layer is determined by a technical and economic calculation, in which the main parameter is temperature resistance. The corresponding value should be within 0.86ºC m²/W in the case of pipes with a diameter of up to 25mm, and at least 1.22ºC m²/W - from 25mm and above. SNiP provides special formulas by which the total temperature resistance of the insulating composition of cylindrical pipes is calculated.

Please note that if you have any doubts about the correctness of the calculation, it is better to seek help and advice from specialists who will carry out the work reliably and efficiently, especially since the prices for their services are quite reasonable. Otherwise, a situation may arise where the scope of certain actions may be more costly in terms of money than doing everything from scratch.

When performing the work yourself, you should also understand that all calculations of the thickness of pipe insulation are made under certain operating conditions, which take into account the materials themselves, temperature changes, and humidity.

The second method is implemented through online calculators, of which there are countless today. Such an assistant is usually free, simple and convenient. Often it also takes into account all the norms and requirements of SNiP, according to which professionals perform calculations. All calculations are carried out quite quickly and accurately. Figuring out how to use the calculator will be easy.

Initially, the required task is selected:

- Preventing liquid freezing in utility pipelines.

- Ensuring a constant operating temperature of protective insulation.

- Insulation of communications of water heating networks of two-pipe underground channel laying.

- Protection of the pipeline from the formation of condensation on the insulator.

Then you need to enter the main parameters by which the calculation is carried out:

- Pipe outer diameter.

- Preferred insulation component.

- The time during which water crystallizes in an inert state.

- Temperature indicator of the surface to be insulated.

- Coolant temperature value.

- Type of coating used (metal or non-metal).

After entering all the data, the calculation result appears, which can be used as a basis for subsequent construction and selection of materials.

Thermal insulation of central heating pipes

Conditions of work.

2.1.

Insulation of the joints of polyurethane foam pipes begins after 100% inspection of the welds of the joints using a non-destructive method or after a hydraulic test of the pipeline. 2.2.. Work on insulating joints is carried out at an air temperature of at least -15 C°, as well as in the presence of technological pits of at least 1.4 m (0.7 m in each direction from the joint) and a depth of at least 400 mm, according to VSN 11-94 , VSN 29-95 and SP 41-105-2002

2.3. During precipitation (rain, snow), work is carried out only under temporary cover, which prevents moisture from entering the mounted elements.

2.4. When installing a heating main equipped with a system for online remote monitoring of the insulation condition (ODC), immediately before performing work on insulating the joint, it is necessary to connect the signal conductors and carry out control measurements in accordance with the “Instructions for connecting signal conductors” and “Instructions for carrying out control measurements”.

2.5. On pipelines with a steel pipe diameter of 273 mm and above, heat shrinkage of couplings is carried out using two gas burners simultaneously.

Features of selecting a pressure gauge

The purchase of a pressure gauge for a pipeline structure should be approached with the utmost responsibility, since the device is intended to monitor the pressure of steam and water in the system. The device provides information regarding the occurrence of an emergency.

Depending on the accuracy, the device may belong to a certain class:

- 2.5 - if the medium pressure is not more than 2.5 MPa;

- 1.5 – when the pressure value exceeds 2.5 MPa;

- 1.0 - at a medium pressure higher than 14 MPa.

The device scale has a red line indicating the permissible pressure in the pipeline. The pressure gauge is installed on a section of the structure located in an accessible area. It is installed either strictly vertically or with a slight (up to 30 degrees) slope forward.

Pipelines through which steam and hot liquid move belong to a special type of structure - they must be designed and operated in full compliance with the standards prescribed in SNiP. Such communications are laid from pipe products that have the necessary technical parameters.

VUS pipe insulation - parameters

| Pipe diameter | GOST R51164-98 | GOST 9.602-2005 | GOST 9.602-2016 | |||

| CS designs 1 and 2 | US Design 11 | VUS Design 1 | VUS Construction 2 polypropylene | US Design 1 and 2 | N Design 14 | |

| Insulation thickness in mm | ||||||

| 57 | 2,00 | 1,80 | 2,20 | 2,00 | 1,80 | |

| 76 | 2,00 | 1,80 | 2,20 | 2,00 | 1,80 | |

| 89 | 2,00 | 1,80 | 2,20 | 2,00 | 1,80 | |

| 108 | 2,00 | 1,80 | 2,50 | 2,00 | 1,80 | |

| 114 | 2,00 | 1,80 | 2,50 | 2,00 | 1,80 | |

| 127 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | |

| 133 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | |

| 146 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | |

| 159 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | |

| 168 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | |

| 219 | 2,00 | 2,00 | 2,50 | 2,00 | 2,00 | 2,00 |

| 273 | 2,00 | 2,20 | 3,00 | 2,20 | 2,00 | 2,20 |

| 325 | 2,20 | 2,20 | 3,00 | 2,20 | 2,20 | 2,20 |

| 377 | 2,20 | 2,20 | 3,00 | 2,20 | 2,20 | 2,20 |

| 426 | 2,20 | 2,20 | 3,00 | 2,20 | 2,20 | 2,20 |

| 530 | 2,20 | 2,20 | 3,50 | 2,50 | 2,20 | 2,20 |

| 630 | 2,50 | 2,50 | 3,50 | 2,50 | 2,50 | 2,50 |

| 720 | 2,50 | 2,50 | 3,50 | 2,50 | 2,50 | 2,50 |

| 820 | 2,50 | 2,50 | 3,50 | 2,50 | 2,50 | 2,50 |

| 920 | 3,00 | 2,50 | 3,50 | 2,50 | 3,00 | |

| 1020 | 3,00 | 2,50 | 3,50 | 2,50 | 3,00 |

To obtain information about the cost and price of steel pipes in anti-corrosion VUS or US type insulation based on extruded polyethylene, you must send an application on letterhead indicating the name of the product (pipe size, GOST, steel grade, type of anti-corrosion insulation), the ordered volume, terms and forms of product delivery.

All products comply with GOSTs, technical specifications and are an absolute analogue of:

- TU 1390−004−47966425−2007

- TU 1390−008−47966425−2009

- TU 1390−015−47966425−2011

- TU 1390-001-35349408-04

- TU 1390-002-35349408-06

- TU 1390-003-35349408

- TU 1390-005-35349408-2010

- TU 2458-065-05757848-2011

- TU 1390-044-05757848-2011

- TU 14-3R-75-2004

- TU 1394-015-05757848-2011

- TU 1390-063-05757848-2012

- TU 1390-011-45657335-2011

- TU 1390-020-45657335-2010

- TU 1394-001-45657335-2011

Supply of steel pipes to VUS insulation in all cities of the Russian Federation and the CIS.

Non-specialized information

The choice of pipeline casing greatly depends on the type of installation. There are three laying options:

| Underground in channels | In this case, the pipeline is most protected from the negative effects of the external environment. The only thing is that insulation of heating pipes and a warm water supply system are required to preserve the thermal energy of the transported liquid. If the channels are located above the soil freezing level, then thermal insulation is also required for a simple water supply system. |

| Underground ductless | It involves laying the system directly into the ground. Accordingly, the pipeline lacks protection from groundwater, etc. |

| Overground | In this case, the structure is exposed to all atmospheric influences, as a result of which it lacks anti-corrosion and, much more often, thermal insulation. |

If the coating is chosen incorrectly or applied in violation of the technology, this can lead to failure of the system, resulting in the need for urgent repair or even complete replacement.

Glass wool

Glass wool is very popular among insulation materials. It protects against heat loss and condensation. Rockwool, Isotek are the most popular manufacturers of such materials.

The use of such thermal insulation is only possible in conjunction with other compounds. For example, with fiberglass or rubyroid. You can also use simple fiberglass mats. To do this, you first need to wrap them around the reinforcement, secure it with wires, and protect it with polyethylene. The method requires a lot of effort and time, but it is reliable and safe.

How to choose thermal insulation

The selection process is important when constructing highways of any type, since the type of protection determines the long-term durability and speed of installation.

When choosing, it is important to consider the following criteria:

- location of the facility, operating conditions;

- permitted load;

- ambient temperature, rolling;

- level of thermal conductivity;

- resistance to deformation.

The main selection criteria: compressibility, density, flammability, vapor permeability, water absorption and water repellency.

In any case, the use of thermal protection will improve all performance indicators of highways, increasing their service life, therefore the use of such substances is necessary in highways of all types.

Features of insulation of underground gas pipelines

Insulation for underground gas pipelines is necessary to protect the pipeline from the effects of corrosive processes due to increased soil moisture, as well as to eliminate the effects of stray currents.

Production of pipes with PPU insulation

*

The impact of stray currents has a detrimental effect on metal pipes. They are capable of damaging the pipeline within the first year of operation. Currents are generated in places where power grids, highways and railways pass. If the gas pipeline is laid next to such communications, special protection should be used. The best insulator in this case is polyurethane foam (PPU).

The advantages of this insulator include:

- Low thermal conductivity coefficient.

- Low material density.

- Resistant to temperature changes and pressure fluctuations.

- Increasing the service life of the pipeline.

- Easy to install during repair work.

For insulation using polyurethane foam, two application methods are used:

- Application of material in the factory.

- Protection of communications after pipeline installation.

Pipes with factory-applied polyurethane foam insulation are regulated by GOST No. 30732. According to this standard, two types of pipes are produced: conventional and reinforced. They differ in technological characteristics and performance qualities. The production technology for pipes with PPU insulation is as follows:

- The upper shell is made of polyethylene using extrusion technology. For its production, a special press machine is used, into which liquid polyethylene is supplied under pressure, and then it hardens. After complete hardening, the shell is removed and the inside is inserted into the pipe.

- The gap between the pipe wall and the inner surface of the shell is filled with liquid polyurethane foam, which subsequently hardens.

Factory insulation of pipes is considered more reliable and durable. To enhance protection against moisture penetration, the shell is covered with polyethylene on top.

Polyurethane foam coating is an ideal solution for a gas system

This insulation has another advantage - the ability to install electronic gas pipeline monitoring sensors. It allows you to identify the slightest malfunctions in the system and quickly eliminate them.

During pipeline installation, the ends of the connected pipes are covered with asbestos fabric to protect the coating from damage when heated. It is better to use heat-shrinkable couplings to connect the ends of pipes. They are not inferior in performance to polyurethane foam and will perfectly protect the entire system as a whole.

Checking the quality of insulation application

The protection of steel gas pipelines is a responsible undertaking, therefore, each operation performed is subject to thorough inspection, with the drawing up of a report of hidden work performed and entering them into the pipeline passport. No matter how high-quality and correctly selected the insulation material is, it will not cope with the functions assigned to it if the technology for carrying out the work has been violated.

The main parameters of the finished coating to be checked are thickness, continuity and adhesion to the pipe. They are measured with special electronic devices: thickness gauges, spark flaw detectors and adhesive meters, respectively. They do not damage the coating, so they allow you to control all questionable points without extra costs.

In factory conditions

At factories and production bases, the thickness of the coating is checked on 10% of the pipes of each batch, in 4 places on different sides in a circle on each pipe, as well as in doubtful areas.

The insulation applied to pipes by the manufacturer is always more uniform, better quality and more reliable than that organized in the field, even when using similar materials

Adhesion, or the force of adhesion to metal and between layers, is also required by standards to be checked for 10% of the products in a batch or every 100 m.

The continuity of the coating, that is, the absence of punctures, scuffing and other through violations, is checked on all insulated products over the entire area.

In addition, dielectric continuity of the coating, impact strength, peel area after cathodic polarization and other tests can be checked. When insulating with bitumen coatings, a sample for physical properties is taken from each batch of mastic, at least daily.

At the installation or repair site

Under route conditions, the quality of insulation is also checked, for continuity - always and completely, and for thickness and adhesion - every 10th insulated weld.

In addition, the width of the overlap on the factory coating is checked, as well as the insulation relief - for the absence of corrugations, wrinkles, air cushions and other defects.

If the adhesion of the insulating tape to the pipe is weak, over time it will peel off and the pipe will be unprotected from the environment

In addition, the continuity of insulation on existing gas pipelines is regularly checked. To do this, you don’t even need to dig them up, and if damage is suspected, the pipes are exposed and not only the thickness, continuity and adhesion are checked, but also the dielectric properties of the insulation.

Insulation with mineral wool insulation

Such heat insulators have also proven their worth in ensuring the protection of main gas pipelines. Mineral wool insulation demonstrates:

- low thermal conductivity (due to the fibrous structure, air is retained inside the material);

- resistance to thermal loads;

- high fire resistance;

- resistance to water, biological organisms and chemical reagents;

- environmental friendliness (safe composition and additives used do not harm the environment or human health).

ZTI AMAKS offers enterprises highly reliable thermal insulation materials of its own production. We manufacture and sell a wide range of heat-insulating products, including mineral wool cylinders, tufted mineral wool mats, mounting tapes, extruded polystyrene foam segments, polyisocyanurate foam segments and much more.

Experienced specialists will select an effective insulator taking into account the characteristics and objectives of your facility and budget. Flexible pricing policy and individual conditions make cooperation with us economically profitable. We also offer delivery to any point in our country quickly and reliable transport (road, railway, special equipment).

Contact us in a way convenient for you: through the feedback form, by phone and receive comprehensive information on our production capabilities, assortment and terms of cooperation.

Expanded polystyrene (foam plastic, EPS)

It is produced in the form of shells, practically no different in appearance from polyurethane foam - the same dimensions, the same tongue-and-groove locking connection. But the temperature range of use, from -100 to +80 °C, with all this external similarity, makes its use for thermal insulation of heating pipelines impossible or limited.

SNiP 41-01-2003 “Heating, ventilation and air conditioning” states that in the case of a two-pipe heat supply system, the maximum supply temperature can reach 95°C. As for the return heating risers, not everything is so simple: it is believed that the temperature in them does not exceed 50 °C.

Foam insulation is more often used for cold water and sewer pipes. However, it can be used on top of other insulation materials with a higher permissible temperature of use.

The material has a number of disadvantages: it is highly flammable (even with the addition of fire retardants), does not tolerate chemical influences (dissolves in acetone), and crumbles into balls during prolonged exposure to solar radiation.

There are other non-polystyrene foams - formaldehyde, or phenolic for short. In fact, it is a completely different material. It is devoid of these disadvantages and is successfully used as thermal insulation for pipelines, but is not so widespread.

Installation

The shells are secured to the pipe using a bandage or foil tape; they can be glued to the pipe and to each other.

Fittings and other pipeline elements

According to regulatory documentation, all communications related to heating networks should be equipped with shut-off and control valves and the necessary measuring devices.

In this case, their settings must correspond to the required parameters. For example, the pressure level in a protective device cannot exceed the calculated value by more than 10%. If the pipeline operates at reduced pressure, it is necessary to configure safety devices in accordance with the operating conditions of the facility.

An important point is to equip the protective valves with diverting elements so that it is possible to redirect the medium when the protection is triggered. Discharge communications must be insulated in case of severe frosts and equipped with a structure for draining condensate. All fittings must have appropriate markings on their bodies.

The marking contains:

- trademark of the manufacturing company;

- diameter size (DN) of nominal bore;

- standard value of pressure and temperature of the transported medium;

- direction of movement of steam or water;

- steel grade.

How to spray PPU with your own hands?

Do-it-yourself equipment for PPU is a profitable purchase for work in small areas: insulation of chimneys, ventilation hatches. Installing a PPU with your own hands (assembling the components of the structure into one whole) is not cheap, approximately 120 thousand rubles. Therefore, it is better to purchase ready-made disposable kits for carrying out work.

When working, you should follow safety precautions:

- The room must have forced ventilation.

- Work should be performed in special clothing - a protective suit, and a respirator should be put on the face.

Insulation with polyurethane occurs in several stages:

- The surface on which the spraying will be applied is first prepared: cleaning from dirt, rust, degreasing.

- To obtain an effective layer of polyurethane foam, it is necessary to ensure the required temperature of the solution: 10-25 degrees.

- Equipment for spraying polypropylene resin with your own hands consists of a spray gun and two cylinders. They are intended for polyurethane components. One is for polyol with freon, the other is for isocyanate. The hoses with the gun are connected to the gearboxes. When the gun is pressed, the liquids are mixed.

- If necessary, an additional layer is applied.

The most effective self-made insulation is considered to be made in 3 layers. First, 14 mm thick polyurethane foam is applied, after drying, the surface is covered with 2 more layers at short time intervals.

Separation of pipelines according to category

According to the main operating characteristics of the transported medium, communications are divided into 4 categories.

The parameters according to which categories are determined are:

- For systems that transport steam from boilers - the value of its pressure and temperature at the exit point.

- For steam pipelines operating from turbines, the highest temperature and back pressure are observed when operating at idle speed.

- For designs of unregulated or adjustable types of extracting pairs - the highest value of pressure and temperature in the extraction.

- For communications that move the medium from reduction-cooling and pressure-reducing units - the highest pressure and temperature.

- For structures that move water after diaerators - the nominal pressure taking into account the system indicators.

- For supply and return communications of hot supply - the highest indicator of temperature and pressure, taking into account pumping facilities and terrain.

Purpose of insulation

Let's start with the fact that many insulation methods are applicable to different systems: water supply, sewerage, heating and ventilation. But in our article we will consider only those methods that are applicable to hot and cold water supply pipes. Pipeline insulation is divided into two types:

- thermal insulation measures;

- waterproofing.

The purpose of each type of insulation measures is as follows: Fastening materials for pipes

- Thermal insulation of the external cold water supply pipeline is needed to protect the system from freezing during the cold season. If the water in the pipe freezes in cold weather, it will not be able to get into the house, and finding the ice plug and eliminating it will be quite difficult.

- Thermal insulation of external hot water supply pipes is necessary to ensure that hot water does not cool down during transportation to the consumer. In addition, such protection helps to increase the service life of the system.

- Thermal insulation of hot water pipelines is also carried out, which will be located in grooves - channels cut into the wall. In this case, these pipe protection methods are needed because the temperature of the water in pipes in contact with cold brick or concrete walls may decrease.

- Waterproofing of external hot and cold water supply pipes is necessary to protect them from corrosion. The thing is that moisture present in the soil can cause steel pipes to rust. However, this does not apply to plastic products.

- Various types of waterproofing are used to protect pipeline joints from leakage.

- As for cold water supply systems inside the house, they are waterproofed to protect against condensation, which, collecting on the pipes, can cause corrosion. Again, this does not apply to plastic pipelines that are not subject to corrosion.

There are different types and methods of hydro- and thermal insulation of pipelines and their joints. Let's take a closer look at them.

Differences in pipelines according to design schemes

Depending on the diagram, the classification of steam and hot water pipelines is as follows:

- backbone networks;

- distribution systems;

- branches.

There is also a quarterly subtype, which is an intermediate segment of communications between the distribution system and consumers of thermal energy.

Trunk structures belong to transit pipelines; they do not have branches. They carry steam and water from the source to the distribution system. The temperature in them can range from 90 to 150 degrees with a pipe cross-section of 525–1020 millimeters.

In turn, distribution systems are designed to move heat from main structures to consumers, namely to apartments and houses. The diameter of these pipelines does not exceed 525 millimeters, and the permissible temperature for them is 85 - 110 degrees.

Branches are sections of heating networks that connect a heating point to the main line, or a residential building to the distribution system.