A clamp is a connecting element that looks like such a device - a rod. The ends of this product can be pulled together, creating a circle. This product is needed to reliably fasten and seal hoses, pipes, parts of pipelines, cables, and pipes.

There are types of clamps with temperature ranges and technical documents, which we have presented in the table.

| № | Clamp | Temperature | Technical document |

| 1. | worm | -60 to +450 | GOST 28191-89 DIN 3017 |

| 2. | power | -100 to + 350 | GOST 28191-89 DIN 3017 |

| 3. | with key | — 45 to + 100 | GOST 28191-89 DIN 3017 |

| 4. | wire | -80 to +160 | GOST 28191-89 DIN 3017 |

| 5. | screed | -40 to +80 | GOST R IEC 62275-2015 |

| 6. | muffler | -100 to +250 | GOST 28191-89 DIN 3017 |

| 7. | electrical staples | -40 to +120 | GOST 17679-80 |

| 8. | ventilation | -45and up to +120 | GOST 24137-80 |

| 9. | spring | -40 to + 200 | GOST 28191-89 DIN 3017 |

| 10. | tape | -45 to +120 | GOST 28191-89 DIN 3017 |

| 11. | pipe | -50 to +120 | GOST 24137-80 |

| 12. | CV joint boot | -60 to + 80 | GOST 28191-89 DIN 3017 |

| 13. | repair | -100 to + 100 | GOST 24137-80 |

Next, we will consider all types of clamps with their characteristics and applications.

Worm

This hardware is the most important fastening element. It is made from stainless, galvanized, carbon steel, as well as from passivated alloys. The worm clamp is used primarily to fix pipes on the surface, but also as a grounding device for metal hoses. Its design includes:

- ribbon

- screw part

- lock

The product in question is needed for joining the following items:

- ordinary wires

- electrical cables

- rubber hoses

Installation Tips

- Modern power products are easy to install, and there is no need to put in a lot of effort to get a good tightening. Moreover, over-tightening can reduce the life of the product and cause it to wear out quickly.

- If a single-bolt clamp is used, it simply needs to be unscrewed to the required pipe size, installed and tightened with a wrench and a screw.

- When attaching the clamp, you need to select the correct drill diameter for drilling the hole.

- The pipe should only be secured using the method specified for the selected clamp.

- If standard clamps are suitable for hermetically fastening cast iron pipes, then in areas of high pressure it is better to choose reinforced gear models.

- Do not forget to securely fix the pipes themselves after tightening with a clamp. To do this, you need to think in advance about additional fasteners.

Based on practice, with a correctly selected, high-tech clamp, there are usually no problems with its installation and further operation.

See below for an overview of power clamps.

Power

Power or reinforced clamps are used under severe vibration, high pressure and significant temperature changes. In addition to these technical features, it should be said that power clamps are made from two grades of steel: carbon and stainless.

There are two types of reinforced clamp: single-bolt and double-bolt.

Single bolt

The single-bolt power clamp is used to secure reinforced hoses, secure pipes, and also in pneumatic and hydraulic drives.

Double bolt

This type of fastening joints is used in highly specialized industrial sectors where it is necessary to ensure high-quality sealing of the joint.

Methods of application

The use of a wire clamp requires compliance with several conditions.

- This option is used for thick-walled elastic hoses. Long-term, cracked hoses that have lost their softness and elasticity cannot withstand the pressure of small-diameter steel wire. It destroys the structure of the material and can cut through, leading to leakage or even failure.

- When using a wire clamp, it is recommended to use a rubber gasket. This allows the pressure to be distributed more evenly and extends the life of the hose.

- Some products are initially equipped with a seal, which eliminates the need to use a gasket, ensuring the tightest possible fit.

- It is permissible to use this type of clamp only for fastening to solid bases - metal or plastic pipes, since at the junction of two soft-walled surfaces the wire will simply crush them.

The use of spiral steel wire provides the most reliable and tight connection. In addition to design differences, clamps have different methods of fixation. It depends on the purpose for which the device is used. On store shelves you can purchase products with a rigid fixation format. This type is most convenient in places where the pipeline branches and bends.

With key

This product is used like a worm clamp and their scope of application is the same. So, we take our clamp in our hands, crimp the desired section of the hose, then, thanks to tightening the hardware, you can notice a reliable fixation. This product attaches securely to the hose, but the downside is that it is not as strong as a regular worm-drive clamp.

The key or “lamb” has a plastic construction and comes in different colors. But some enterprises may also use steel ones.

Repair and fastening clamps: main differences

Fastening connectors and repair connectors are completely different products. Each of them performs a specific function and, accordingly, has its own distinctive properties. A repair type clamp is a multifunctional clamp that is designed to eliminate the following types of problems in pipeline systems:

- longitudinal and transverse cracks;

- violation of tightness in connecting parts (fittings);

- fistulas on the pipes formed due to stray currents.

Mostly for repairs, classic models of clamps in the form of metal plates with bent ends are used. It is at these places that the nuts and bolts for the tie are installed. Such devices do not come with a rubber gasket, so it must be selected individually.

Some clamps have convenient handles for fastening

Repair clamps have advantages over fastening clamps. They are characterized by simple and quick installation, are suitable for eliminating almost any malfunction, and do not require draining water to carry out work.

Wire

A wire clamp is a special fastening element, as well as one of the most common types of hardware for fastening. Its outer part is made as a ring, including a tightening mechanism in one area.

They are used to hold together spiral hoses that produce vibration waves. This type of clamp is reflected in almost all types of industry, but also in everyday life.

Connecting pipes of different diameters

To do this, you can use couplings, adapters, crosses and other connecting parts.

Water pipes can be joined using a coupling and a locknut if the pipe is straight and without corners. For a short connection, use one coupling; for a long connection, add a lock nut. The coupling must be marked with the diameters for which it is suitable. This method is applicable only for small pipes; for large diameters it is better to connect them by welding.

As you can see, there are many ways to connect pipes. It is possible to join pipes so that they cannot be disassembled in the future; such methods are used in hard-to-reach places to increase the strength and tightness of the connection.

Most methods do not require special knowledge and skills; even a beginner can handle some. What experience do you, our readers, have? Which pipe connection method do you use most often, and which do you consider the most unreliable?

Ventilation

A ventilation clamp is one of the types of fastening clamps. It is used to create a high-quality connection between round air ducts and vertical or horizontal surfaces.

There are two types of ventilation hardware:

- all-metal

- rubberized

They are also divided into crimped and non-crimped types.

Tape

This type of fastener is necessary to connect pipelines, hoses, and pipes. The band clamp is made from two types of steel:

- alloyed

- stainless steel

To protect hardware from rust, zinc or other anti-corrosion chemicals are applied to it.

It is used most of all in industry: automotive, construction, oil and gas industry, in everyday life and in housing and communal services.

Metal

First of all, it should be said that all existing pipes can be divided into two types:

- metal;

- plastic.

As a rule, the most problems arise with the joining of metal pipes, so first we will consider the methods of connecting them.

So, there are several options for hermetic docking:

Options for connecting metal pipes without welding

Below we will take a closer look at each of these options.

Threading dies

Using a threaded coupling

Most often, metal pipes can be joined without welding using a threaded connection. In this case, accordingly, thread cutting is required. It should be noted that this is not as complicated a procedure as many may think at first glance.

To cut threads, you will need an electric thread cutter or dies to perform this operation manually. Since the price of electric tools is very high, below I will tell you how to do the job manually:

- First of all, you need to clean the surface to be threaded from paint . If there are deposits of metal on it, for example, left after welding, they must be ground off;

- next you need to remove the outer chamfer from the end using a file;

- then you need to put a die (die) on the prepared end of the part and make half a turn . In this case, it is necessary to ensure that the die is put on strictly perpendicular to the axis;

- then you need to make a quarter turn back;

- Using this principle, the thread is cut to the required length . During the cutting process, the cutters must be lubricated with a special liquid or any other lubricant;

- then, according to the same scheme, threads are cut on the other connected part of the pipeline.

For coupling installation on one pipe, the thread length must be several times longer than on the other, so that a coupling with a nut can be screwed onto it.

Diagram of threaded installation using a coupling

After cutting the thread, you can make a coupling connection with your own hands, which is performed as follows:

- a nut is screwed onto a long thread and then a coupling;

- a nut is screwed onto the second end of the part;

- then the pipes are connected, and the coupling is rolled up with the length of the thread, as a result of which it begins to screw onto the second part with a short thread. This procedure must be performed until the joint is approximately in the middle of the coupling;

- then the nuts are screwed on both sides. Before tightening them, tow should be wound between the couplings and nuts to waterproof the connection.

This connection is reliable and durable. However, it is not always possible to cut threads. If, for example, the pipeline is located close to the wall, this operation is unlikely to be possible.

Therefore, next I will tell you how to reliably connect metal pipes without welding or threading.

In the photo - Gebo coupling

Gebo coupling connection

The Gebo coupling (“gebu” or “gebra”) is a special compression fitting. With its help, you can connect steel pipes without threading or welding very quickly, and you do not need any special tools for this.

Gebo coupling installation diagram

The scheme for its use is extremely simple:

- The parts are put on the pipe in the following sequence:

- screw;

- clamping ring;

- clamping ring;

- sealing ring;

- coupling;

- then you need to put the coupling halfway and tighten the nut;

- then the second part is connected to the fitting in the same sequence.

It must be said that this fitting exists both in the form of a coupling and in the form of a tee. This allows it to be used in cases where it is necessary to insert, for example, into a riser for wiring.

As for reliability, it depends on the quality of installation. If the work is done correctly, then this installation is reliable and durable.

Repair and installation clip

Repair and installation clip

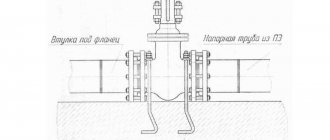

You can also connect pipes without welding and threading using a repair and installation clamp. This fitting is a coupling or tee, which consists of two parts. Both halves are tightened together using bolts.

It should be noted that repair and installation clips are intended primarily for temporary repairs, for example, in the event of cracks. However, in emergency situations, they can also be used to join pipes, especially if the pipeline will not operate under high pressure.

In this case, the installation instructions look like this:

- first of all, the areas of the pipeline parts on which the fitting will be put on must be cleaned of paint, rust and all kinds of irregularities so that their outer surface is absolutely smooth;

Installation diagram of the repair and mounting clip

- then you need to put a rubber seal on the pipe. The seal cut must be coated with silicone sealant. It should be noted that the seal must completely surround the pipes so that there is no gap left.

- then both halves of the fitting are put on the rubber seal and tightened with bolts, as shown in the diagram.

This method, as we see, is also extremely simple. The same principle applies to the connection with a clamp coupling. The only difference is that it is tightened on one side, not two.

It must be said that if you use pipe clamps, the connection of pipes without welding is even more reliable than using an installation and repair coupling.

If you need to connect profile pipes without welding to assemble any structure, you can also use special profile clamps.

Example of connecting profiles with a clamp

CV boot

This clamp is most familiar to motorists. Most often, car owners are interested in the CV joint boot for the following cars:

- VAZ

- Toyota

- Ford

- Renault

But the word “CV joint” comes from the components of the car. This name translates as a constant velocity joint. It is placed on a wheel drive system to transmit the moment of force when the wheels turn up to seventy degrees.