The clamp for the chimney braces, as well as the pipe crimp fasteners, is considered an important component and a mandatory part in the installation of a boiler, chimney and stove equipment operating on any type of fuel. It is important to know the differences and applications of these fasteners. The following recommendations are intended as a general guide to assist in selecting the chimney element required for installation.

Pipe crimp fastener

What problems do chimney clamps solve?

Most problems with heating equipment are due to the installation causing it to not work properly.

The purpose of the clamp is to hold the chimney pipe, and also to provide a reliable fastening for compression between other elements of the sandwich system.

In this article we will talk about the types of wall clamps and the structural necessity of installing a connection to pipes in order to avoid smoke escaping from them, as well as about production materials.

Types of clamps

The chimney clamp differs in purpose.

For wall mounting

For fastening to the wall

It differs in that in the tail part it has a flange with two holes for screwing to the wall.

This clamp is used when the pipe runs close to the wall. And if a large number of pipes are installed outside, a gust of wind will not be able to knock them down.

It is recommended to place one of these wall clamps every two meters to secure the pipe to the wall and maintain stability.

The crimp clamp consists of two parts:

- bolts the pipe

- tighten until the two parts fit tightly around the structure.

Built into the wall

Built into the wall

Another type of product for attaching a chimney is one that is mounted deep into the wall. Instead of a flat flange with a threaded hole, it has a long flange.

To place the clamp, you will need a guide on the wall so that the tail is held in place using building materials, plaster or cement.

This type of fastener is used when the pipe is separated away from the sunny side of the wall and a long tail will save the necessary distance.

A wall clamp for a chimney has two parts that wrap around the pipe and are secured with threaded screws to prevent the wind from knocking down the structure outside the house.

For gripping between pipes

For gripping between pipes

There are other types of clamps that perform different functions.

For gripping between pipes, holds and secures connection together.

This type of fastening is used in stainless steel pipes of sandwich systems.

Many brands have edges for using these clamps which, combined with the silicone compound inside, maintain a seal.

The party to such a connection is considered to be:

- odor prevention

- smoke leak

- outlet pressure

Because the stove has a smoke output pressure sensor. Pipes that do not have a clamp may be deformed by an impact during transportation, and will not be ideal for the system, and then the oven will signal a pressure failure on the stove.

Connection to furnace outlet

Connection to the outlet from the furnace

Failure to use a clamp when the pipe exits the furnace is considered the main malfunction of many chimneys.

The outlet inlet has a diameter thicker than the pipe itself and therefore does not fit together perfectly.

Typically, this is where you notice the smell of smoke when you turn on the stove.

And due to the fact that the pipes are not yet heated, the smoke comes out through the holes due to incorrect adjustment, between the outlet and the installed pipe.

To avoid these odors, it is recommended to use aluminum tape to surround the junction of these two elements, which have different thicknesses.

Then use a clamp to tighten this connection and avoid the inherent losses that occur when installation is not done properly.

This is a malfunction that causes people to complain about the smell of smoke but not be able to determine where the loss is occurring.

What is a sandwich chimney

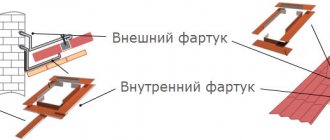

Attaching the chimney to the wall

The element got its name due to its layered structure. There is a filling that is placed between two bases. The first is insulation, and the base is metal pipes of different diameters. The entire system is a complete installation unit. By combining a certain number of such elements, chimneys of different heights are obtained. These are the basic parts; you also need fasteners for the chimney, various kinds of outlets and additional accessories.

Materials of construction

The three-layer structure, which is the basis of a single pipe element, consists of the following materials:

- Internal working casing for removal of combustion products. More often it is made of AISI 316 stainless steel.

- Filler intended for insulation.

- External or load-bearing casing of AISI 304 brand, which serves as a frame. It is fixed to the wall.

The peculiarity of the internal chimney is its ability to withstand gases whose temperature reaches 900 degrees Celsius. The outer shell has good resistance to aggressive environments.

Connection types

Sandwich elements for a chimney

Sandwich elements are connected to each other like elbows - on one side of the socket there is a joining cylindrical groove without insulation, into which the end of the other chimney is inserted up to the stop skirt. This is convenient and allows you to use only tightening clamps to tightly fix the cylinders together.

The chimney is fastened to the wall plane using support clamps of various diameters and holder lengths. Sometimes instead of them there is one stand, which at the end has the shape of a screw. This part is simply screwed into a plastic dowel inserted into the concrete.

Type of insulation and wall thickness

Basalt-based wool is used as insulation between the inner and outer casing in this type of construction. This is the only possible option for thermal insulation, since mineral wool is not a flammable material, and therefore can easily withstand high temperatures. The thickness of the basalt layer itself depends primarily on the diameter of the pipe. On average, this size ranges from 60 to 40 mm, and the density is 125 kilograms per cubic meter.

If we take the thickness of the stainless steel metal walls, then the standard for the internal casing is 1-0.5 mm, for the external casing, which is not subject to strong heating, 0.4 mm.

Tension clamp

A chimney guy clamp is a three-point clamp for securing rigid cables (coils) separated by 120 degrees from each other.

For reliable fixation, it is important that the flexible cable is secured in three directions.

A guy clamp is used to secure a chimney pipe that rises above the roof by more than 1.2 meters, or if the system runs along the external wall of the building, regardless of the height.

With each further meter, it is necessary to add another clamp for guy wires, no more than three. The maximum permissible level of the chimney above the roof, supported by guy wires, should not exceed 3.5 meters. It is allowed to use braces made of three steel rods or profiles.

Smoke exhaust device made from sandwich elements

Structural elements of a chimney Smoker

based on double-walled channels may contain the following standard elements:

- Sandwiches of various lengths. This is the main material that makes up the frame of the structure.

- Double-walled chimney starter. It is designed to connect the boiler or furnace output to the rest of the system components.

- Tee of double-wall construction with insulation. Performs the function of transition from a horizontal exit to a vertical section.

- End condensate collector. It is installed in the lower part of the tee to remove moisture flowing down the walls of the smoker.

- Support bracket for the chimney - holds the entire mass of the structure.

- Bend - this part allows you to shift the direction of the vertical if necessary to bypass a roof overhang or other obstacle.

- Clamps for fixation. They are used to compress the joints of sandwich elements.

- Cap. It is put on top to protect the channel from precipitation getting inside.

- Wall bracket.

All listed parts must be the same diameter.

If the distance of the channel from the last point of its attachment to the wall to the top exceeds 1.5 meters, a special clamp for guy wires should be installed on this segment. A structure that is not reinforced with cables can easily fall off in heavy winds.

Material selection

As a rule, the clamps should be metal, but depending on the type of pipe, it is matched to the selected material.

Galvanized

If you use a galvanized pipe to install a chimney, it would be logical to buy a galvanized clamp of the same diameter as the pipe.

In this way, we need to respect the aesthetics of the material and we will get a perfectly fitting installation.

Galvanized clamp

Glazed

If you use glazed pipes to install a chimney, it is wise to purchase clamps of the same material.

How unattractive it is to look at an installation with glass pipes on the wall held in place by galvanized clamps.

A different color will ruin the design of the finish

Glazed

From a functional point of view, it does not matter whether the function is the same, but to maintain aesthetics, it is recommended to purchase clamps according to the pipes used.

Stainless steel

Stainless steel clamps are selected for the chimney material.

This way there will be materials that are aesthetically equal and have the same coefficient of expansion.

Stainless steel

Advantages and disadvantages

Compared to brick chimneys, sandwich chimneys with wall brackets have the following advantages:

- speed of installation;

- high qualifications in stove work and masonry are not required;

- low cost;

- light weight, no capital foundation required.

The disadvantages include:

- shorter service life, after 5-8 years of constant use the metal chimney must be replaced;

- brackets are prone to sagging;

- dubious aesthetic value; a metal pipe does not harmonize with every architectural style.

Rules for using clamps

Depending on the purpose of the fastening, it is recommended to fasten the chimney clamp securely.

When assembling a chimney, it is worth following the rules, because mistakes can cause not only a fire, but also poisoning by combustion products. Proper use of the chimney will perform its functions for many years.

Installation of fasteners in itself requires compliance with the rules for reliable and durable operation. To avoid deviations from the line, the recommended distance between fasteners must be observed.

Installation of fasteners

If you install supports at a greater distance, there is a risk of the chimney falling. It is recommended to take into account that during installation, it is worthwhile to provide additional mounting brackets, before and after the connection point, as this guarantees reliable operation.

We recommend that you start assembling the chimney from the bottom up.

There are times when, when installing a system outside the house, an obstacle arises, such as a building or a tree, and we do not get stability, then it is possible to make a wall clamp with your own hands.

Homemade clamp

When there is no store nearby to buy a holder, there is a chance to make a fastening device on your own. Let's look at how to properly make a metal clamp.

Homemade clamp

The crimping part is easy to make from a strip of sheet steel. It is better to use galvanized sheet with a thickness of 1 mm. To align the edges you will need an M6 bolt

Required tools for making fasteners:

- metal scissors;

- pliers;

- calipers;

- hammer;

- wrench;

To drill holes, you will need an electric drill with a set of drills of a suitable diameter.

Using a caliper we measure the radius of the pipe that we are preparing to fix. If the size of the pipeline does not allow you to measure with a caliper, use a ruler and an angle, but the measurement may be inaccurate

We cut a strip of the required width from a piece of sheet metal. According to the rules, it is recommended to calculate the length of the strip as follows. The diameter of the pipe is multiplied by the number 3.14. We get the length of the product. However, in order to make ears for fastening, you need to add another 4-5 cm.

Cut out the blank of the required shape

Using metal scissors, cut out the workpiece of the required shape. Holes are drilled in the area where the ears are located.

The number of bolts directly depends on the width of the strip:

- width up to 6 cm requires 2 fasteners;

- width 6-8 cm, best option 3 bolts

You may have to increase the diameter of the holes if the bolt heads are large.

Ideally, it would be better to buy iron washers for fastening.

Having checked the alignment of the holes in the ears, all that remains is to thread the bolt and tighten the nut. With the bracket made, all that remains is to wrap the pipe and connect the ears with bolts.

The finished clamp is pulled onto the pipe and secured to the wall.