Brief overview of the main materials for thermal insulation of a gas chimney

To insulate the chimney, materials with a low thermal conductivity coefficient and high temperature resistance are used.

The second requirement is not met by most modern insulating materials, which include polystyrene foam, penoplex, foam rubber, cellulose porous insulation and materials based on polyethylene foam. The effectiveness of a heat insulator depends on the material from which it is made and its thickness; an important characteristic is the ability to absorb moisture

Rice. 9 Popular thermal insulators (glass and basalt wool)

Glass wool

It is a material made from thin glass fibers, has high heat resistance and low thermal conductivity, is not afraid of moisture and does not absorb water. The service life of glass wool is quite high, but the material has a low density - this makes it difficult to install. Although glass wool is mainly produced in rolls, for thermal insulation it is more convenient to use foiled hollow cylinders with a slot.

Rice. 10 Thermal conductivity of insulators

Mineral wool

Basalt insulation is widely used in the construction industry due to its high insulating qualities and environmental friendliness. Mineral wool is resistant to high temperatures, but can absorb moisture; for insulation it is better to use mineral wool in the form of hollow cylinders. Mineral insulation has a high density, so it is convenient to install and process - the material is the main type of insulation for pipe chimneys.

Chimney brick. The industry produces special types of hollow bricks with a hole for the chimney pipeline; the insulation is air cavities in its walls. Chimney brick is best used together with insulation, which prevents the pipeline from contacting the brick walls. In addition to its insulating qualities, brick provides a highly decorative appearance to a residential building, hiding unsightly chimney pipes in aesthetic stone columns.

Thermal insulation materials

Let's start the article with an analysis of insulation materials, because the modern building materials market today offers a fairly wide range of them. And the question of how to insulate heating pipes is relevant today.

There are both traditional materials and completely new ones, but they are all still in use, so it makes sense to consider at least the basic ones.

Mineral wool

This is a traditional insulation that has proven its relevance over many years of its use.

Things to note:

- Firstly, these are high thermal insulation characteristics.

- Secondly, the ability to use this material for finishing pipes through which coolant passes at a fairly high temperature.

- Thirdly, it is a non-flammable material.

- Fourthly, this heat insulator can come into contact with oils, acids and other aggressive environments, and at the same time it does not lose its qualities.

- Fifthly, the price of this material is quite low.

Various insulation materials for heating pipes

But it has, perhaps, only one drawback - it is hygroscopic. Mineral wool insulation quickly absorbs moisture, and at the same time sharply reduces its characteristics. That is why it is imperative to insulate it with waterproofing materials. For example, roofing felt or tin.

Expanded polystyrene

Expanded polystyrene has become an alternative to mineral wool insulation because it is quite cheap and at the same time easy to install. It is made in the form of two half-cylinders, which are used to compress the pipe.

The two parts are usually held together with clamps or self-adhesive tapes, or with wire. But, as in the case of mineral wool, polystyrene foam insulation must be waterproofed.

Expanded polystyrene - excellent thermal insulation

But if we compare these two insulation materials, then experts currently give preference to the second one. And the main reason is that the waterproofing process can be done with your own hands, without resorting to the services of specialists.

Penoizol

In its composition, this material is very similar to polystyrene foam, only it is used for application in liquid form. This heat insulator can be called this - insulation for heating pipes in the open air.

What are its advantages?

- Easy to apply.

- Seamless thermal insulation.

Insulation with penoizol

But it has one minus - it is impossible to apply without a special device. Therefore, you will not be able to insulate heating pipes yourself in this way. By the way, insulating the loggia in your own apartment with foam insulation is a very correct decision.

Foamed polyethylene

But this heating pipe insulation is extremely popular among home craftsmen. You don't even need instructions. The thing is that it is produced in rolls.

It is lightweight, convenient and easy to work with, there is no need to use any additional materials or devices, you simply wrap it around the pipes and fasten it with tape or wire.

The advantages include the durability of the product, its environmental friendliness, and let’s add that it is a non-flammable product, and this is of no small importance today. Thus, an insulated heating pipe is a guarantee of its effective thermal insulation.

Polyurethane foam

In this case, it is necessary to talk about two materials at once:

- Polyurethane foam. Many may doubt that it can be used as insulation for heating pipes. But practice has long proven that polyurethane foam can be used if there is a need to thermally insulate a small section of the pipeline.

- PPU shell. This insulation gets its name because it is produced in the form of two half-cylinders or in the form of several segments. By covering a pipe for insulation in this way, it is as if you were laying it in a shell.

Shell for insulation

Penofol with foil layer

This insulation appeared on the market recently, but immediately began to gain popularity. What is he like? There are two components used here. The first is aluminum foil, onto which the second component is applied - foamed polyethylene.

It is produced in rolls, it is perfectly protected by aluminum, foamed polyethylene is an excellent heat insulator. It is clear without words that using it to insulate pipes will not be difficult.

How to insulate an iron chimney pipe

To insulate a metal pipe outdoors, use basalt insulation and metal clamps - the rolled insulation must be wrapped around the pipe and secured with clamps after 30-40 cm. A tool that is useful for insulation:

- Hammer, pliers, screwdriver, clamp, and other plumbing tools;

- Tape measure, metal ruler or square, building level, pencil or marker;

- A cutter or scissors to cut the insulation for chimney pipes to size;

- A device for riveting and rivets that connect the casing. Instead of rivets, short press washers can be used;

- Screwdriver or electric drill, drills Ø 3-4 mm for rivets;

- If the chimney is being plastered, you will need: a spatula and a bucket for mortar;

- To seal cracks and joints - a construction gun and bitumen mastic.

Ways to fight

You can avoid emergency situations and prevent sewer pipes from freezing in the ground by using the following tips:

The laying of the sewerage pipeline must be carried out to a certain depth. It is recommended to place it below the freezing level. The fact is that temperatures at this level do not fall below 1-2°C. This indicator is optimal and allows work to be carried out without the use of insulating materials. If the work is carried out by non-professionals, then this rule is not observed. Pipes are laid above the freezing level, which can create an unusual situation during severe frosts and lead to a breakthrough. This method of deepening is needed when sewer insulation is carried out in a private house, and the owners do not live here permanently. Special materials designed for thermal insulation should be used. The pipes are carefully covered with material that has high thermal insulation properties. It slows down the cooling process and heat loss. Pipe heating is also used using an electric cable specially designed for this purpose. If it is necessary to insulate a device that is subject to freezing, then the pipes are sloped. It is at least 2 cm for every meter. In this case, an electric cable is laid outside the pipe, performing the functions of a heater. In its absence, the pipes freeze, and the frozen water in them forms ice jams.

As a result, the sewer system fails. It is important to properly insulate ventilation pipes. They are located outside, and are brought to the roof surface from the sewer riser. Some of them come from underground and serve to ventilate a septic tank or sewage tanks

When wastewater evaporates, it settles on the inner sides of the pipes. Over time, they freeze and fill the entire system. Residents begin to smell the stench due to a broken ventilation system. The situation can be corrected by pouring a bucket of water into the frozen riser. Only after this should it be insulated. If an electric cable is used for insulation, it must be packaged in corrugation. A plastic container will also work. This will ensure the longevity of the ventilation system.

Some of them come from underground and serve to ventilate a septic tank or sewer tanks. When wastewater evaporates, it settles on the inner sides of the pipes. Over time, they freeze and fill the entire system. Residents begin to smell the stench due to a broken ventilation system. The situation can be corrected by pouring a bucket of water into the frozen riser. Only after this should it be insulated. If an electric cable is used for insulation, it must be packaged in corrugation. A plastic container will also work. This will ensure the longevity of the ventilation system.

Base for chimney insulation

As smoke passes through the chimney, the warm flue gases inevitably cool. As a result, the heat from the flue gases heats the walls of the tube to remove the smoke into the atmosphere.

The draft in your stove is directly proportional to how quickly the chimney walls warm up. When the draft decreases, the smoke begins to follow the path of least resistance, and simply begins to move from the stove to the scrap, and this is fraught with carbon monoxide poisoning, especially if in a private house, the stove is located directly in a private house, and not in a boiler room designated for this.

Another important factor in favor of insulating the chimney and pipe. There is such a thing as the time during which the moment of condensation appears is overcome.

The time spent warming up the chimney duct largely depends on what it is made of.

Table for calculating the temperature regime of the chimney structure

A chimney made of brick can warm up in 15-30 minutes

Photo of a brick chimney

A chimney made of steel warms up much faster - in 2-5 minutes;

Steel chimney duct

Since a hot stove chimney is constantly in contact with cold atmospheric air, the appearance of condensation in the chimney duct cannot be avoided. Along with the appearance of condensation, due to the mixing of water with carbon dioxide and other combustion products, an acidic solution is formed, which, being absorbed into the walls of the chimney duct, gradually destroys it.

If the chimney is made of brick, then the condensate moisture is absorbed into the brick walls, and this most often leads to freezing of the brickwork of the pipe. A pipe that has cooled down overnight in the cold warms up again in the morning, and it is precisely from such frequent temperature changes that the brickwork of the chimney inevitably collapses.

Brick chimney after regular freezing

So why are chimney ducts insulated? Precisely because the appearance of condensation is practically unavoidable, but we can protect the chimney from freezing and destruction, it is imperative to insulate any chimney; the sooner you do this, the longer it will be used.

Influence of material on the occurrence of condensation

A gas boiler differs from an electric or solid fuel boiler in that it operates in such a way that some amount of moisture always forms in the system. Therefore, when purchasing and installing it, it is especially important to think about the issue of insulation and decide what the chimney will be made of. The service life and safety of heating equipment depends on the correct choice.

Brick

Well assembled (without cracks or crevices), it will be able to effectively retain heat, which will allow its walls not to cool down for a long time, and therefore will help maintain normal traction. On the other hand, it needs to be heated for a long time, and while the temperature remains low, the liquid accumulates relatively actively.

Basic requirements for chimney systems for gas boilers

When installing chimney ducts, to ensure their efficient operation and fire safety, the requirements specified in the regulatory documentation SNiP 2.04.05-91 and DBN V.2.5-20-2001 must be strictly followed. Their main provisions are the following points:

- The chimney cross-section (pipe diameter) should not be less than the boiler outlet pipe.

- The main pipe should be positioned vertically without inclined sections (let's say a slope of no more than 30 degrees), and there should be no curvatures or narrowed sections in its design.

- The maximum number of turns in the branch main is no more than three with the length of side branches up to 1 meter.

- The permissible distance between the walls of the chimney and non-combustible surfaces is at least 5 cm; if it passes through combustible walls and the roof, the permissible distance is more than 25 cm.

- The material used to make the chimney duct must be resistant to high temperatures and have a structure that prevents the passage of gases.

- All connections must be sealed, the insulation must not allow moisture and gases to pass through.

- Where the pipe duct passes through the roof, the structure must be solid and without joints.

Rice. 3 Boiler piping diagram

- At the bottom of the pipe there is usually an element for collecting condensate. The material used to make it must be resistant to moisture and gas combustion products.

- In places where turns are provided, inspection hatches must be located to clean the chimney from contaminants and condensate.

- The length of the chimney duct must provide good draft, the height of its outer part must be at least 50 cm above the roof ridge.

- When installing a smoke exhaust channel, it is necessary to have a protective canopy in its upper part to prevent the ingress of dirt and precipitation.

Do-it-yourself insulation installation

Before starting work, you need to learn the basic rules for applying insulation, and learn how to insulate an iron chimney pipe yourself. Insulation carried out according to the rules will allow the owner not to violate the construction technology and not worry about reducing the draft in the chimney.

Required tools and materials

For installation work on insulating a chimney pipe from the outside, you will need a set of tools that are available in every household: a tape measure, a screwdriver, a grinder, self-tapping screws, metal scissors, a knife for cutting insulation, and protective equipment.

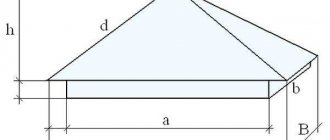

Calculation of the dimensions of the structure

To properly organize the work, you need to calculate the construction parameters and costs. The heating temperature of the inside of the outlet channel, as well as the insulating layer, depend on what type of fuel is used.

The amount of insulation is calculated according to the measurements taken:

- external parameters of the insulated surface;

- height of the structure;

- distance from the lower outlet of the pipe.

The insulation consumption for a chimney for a solid fuel boiler will be, for example, as follows: with its height of 5 m, diameter 219 cm, basalt cylinders need 5 linear meters with a layer thickness of 5 cm, parameters for the internal diameter. Sheet insulation will require 3.5 m². For the protective casing, buy galvanized steel, 2.7 cm thick.

The height of the protruding end depends on the distance of the channel to the roof ridge. Located at a distance of 1.5 m from the center of the house, the chimney should be 50 cm higher than the ridge. Two meters from the center - the height at the level of the ridge, three meters on pitched roofs - the height is determined at an angle of 10°, between the line of the horizon and the ridge.

Work progress

Before installation, you will need to buy chimney sections, anti-corrosion agent, insulation, brackets and clamps, heat-resistant sealant, moisture-proof fabric, galvanized cladding, profiles for the frame, asbestos sealant, fire-resistant foam.

- Before using the insulation, an anti-corrosion substance is applied to the pipe. A protective film is formed on the surface, which protects the metal from destruction for a long time. Combine and secure the parts of the pipe so that moisture does not enter the joints when draining. The connection should be 5-7 cm long for stability.

- After connecting the segments, the metal pipe is wrapped with insulation. The edges of the insulation are wrapped overlapping and secured with steel clamps or aluminum wire. Externally insulated wire cannot be used. Under the influence of high temperatures, the insulation will melt, the fastening strength will weaken, which will lead to deformation of the winding.

- The soft surface is covered with a vapor barrier fabric, and sheets of galvanized steel are fixed on top of it. The galvanizing is fixed with an overlap, from bottom to top, with an overlap of 7-10 cm, fixed with clamps every 30 cm.

- A hole is cut in the roof, which corresponds in diameter to the insulated chimney.

- Under the roof and on the outside of the ceiling to the rafter structure, a horizontal fastening is installed to stabilize the chimney.

- The gaps between the roof and the structure are sealed with heat-resistant non-combustible materials, blown in with heat-resistant foam, and covered with a metal casing.

How to insulate a chimney pipe

You can make a chimney insulated using different materials. Their cost is not of serious importance, since little insulation itself is required

But the owner must pay special attention to the insulation technology itself. Usually the chimney pipe is insulated from the outside

To ensure decent insulation, it is better to focus on fiber insulation. These include mineral and glass wool. Thermal insulation can be increased using slag concrete, broken bricks and similar materials. The most important thing is that the insulation used has high fire safety, because the heating temperature of the pipe can be very high.

It is better for the home owner to choose thermal insulation materials that he can install on his own. Before performing any procedures, you should read the manufacturer's instructions

Particular attention should be paid when working with glass wool, as it emits dangerous crumbs. You cannot do without protective equipment while working with it.

The technology of pipe insulation is also determined by the material from which this element is made. Most often, brick, steel and asbestos cement are used to create a chimney. Each of these cases has its own characteristics of thermal insulation work.

How and with what to insulate an asbestos chimney pipe

A chimney made of asbestos cement must be insulated with mineral wool. Before the main work, any dust and debris present should be removed from this element. The insulation will be placed in a special casing, which is made of galvanized iron. The diameter of the casing is selected so that it is 6 cm larger than the diameter of the chimney pipe.

The length of this insulation design can be different. But it is made up of parts inserted into each other. Each element has a maximum length of 1.5 meters. When the casing is put on, insulation is laid between it and the pipe. After compacting it tightly, you can put on the next element, thus extending the pipe.

The remaining voids are filled with cement mortar. The last element of the casing should be inclined. Sometimes owners manage to do without a metal casing. If this option is chosen, then the mineral wool needs to be wrapped with clamps. But it is better to use several slabs of mineral wool.

To increase the service life of such a thermal insulation structure, it is necessary to additionally carry out vapor and waterproofing. Otherwise, the mineral wool will deteriorate.

How and with what to insulate a steel chimney pipe

Today it is not difficult to find a steel chimney in a hardware store that has an additional thermal insulation layer. This design is made using two pipes having different diameters. In the space between these elements there is a fire-resistant thermal insulation material. But you can do this kind of insulation yourself.

To do this, two pipes are taken that differ in diameter. The smaller pipe is placed inside the larger one, and the free space is filled with fiber insulation. In this case, you don’t even need to prepare any complex tools. All you need is a tape measure, fasteners, a screwdriver, a stationery knife and a grinder for cutting the material. Scotch tape is also useful, which can be used to fasten individual pieces of insulation.

How and with what to insulate a brick chimney pipe

The most difficult thing for the owner is if he is faced with the task of thermal insulation of a brick pipe. There are two possible options here, each of which is worth dwelling on in detail.

1. Insulation with plaster

The outer side of the brick chimney is covered with reinforced mesh. A plaster solution is applied to it so that its thickness is about 3 cm. You need to prepare the plaster from slag and lime, adding a little cement. Usually 2 layers are applied, the first of which is liquid. When it dries, you can cover the work surface with a thick solution. Having leveled the plaster, you need to rub it well. The chimney is then coated with lime to improve its appearance.

2. Insulation with asbestos cement and mineral wool

A brick chimney is first covered with mineral wool, after which an asbestos-cement lining is formed. In this case, asbestos-cement boards are used. They can later be plastered.

How to properly insulate a chimney pipe

The best decision for the home owner would be to insulate the chimney immediately after the construction of the building is completed. If you miss this moment, the chimney pipe may no longer be saved, as it will begin to collapse. As a result, there will be a need to replace or repair the chimney completely.

Asbestos cement pipe

The most common materials are ursa, isover, basalt fiber

In this case, the optimal thickness of the insulating layer is 100 mm. It is usually secured using a fine mesh. Often, metal boxes made of galvanized iron are used instead. They come in both round and rectangular shapes. All free space of the box is filled with insulation.

Step-by-step insulation technology

Due to the fact that chimneys come in different types and designs, we will describe how to properly insulate a chimney pipe made of brick, asbestos cement and steel.

Chimneys made of asbestos cement

Asbestos cement pipe

To understand how to insulate a chimney from an asbestos pipe, we will analyze the entire procedure step by step, following the recommendations of professional builders:

First, you need to thoroughly clean the work area from dust and dirt; The next step is to make a special folding casing for the insulation (made from galvanized iron)

When determining its parameters, it should be taken into account that at least 6 cm should remain between the pipe and the iron for insulation; Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m; First of all, you should secure the lower part of the casing and carefully fill it with sealant. Then, the second part is put on and the procedure is repeated.

This design must run along the entire length of the asbestos pipe.

Thermal insulation diagram from a home craftsman

This is what an asbestos chimney with a casing looks like

Often, many cottage owners do without a casing. The pipe is simply wrapped in a roll of mineral wool and secured with staples. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we seem to have sorted out the asbestos pipes, now let’s see how to insulate the metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, take a pipe of smaller diameter and insert it into a pipe of larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then we can recommend basalt chimney insulation, which in its structure resembles mineral wool, but is much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than an asbestos pipe, so there should be no problems here.

Brick chimney

Brick chimney

Insulating a brick chimney is perhaps the most complex type of all presented in this article. Now we will present several options, from which everyone will choose for themselves how to insulate a brick chimney:

Plastering method. To do this, you will need to attach a reinforced mesh to the chimney. Then prepare a solution of lime, slag and a small portion of cement. Spread the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which should be at least 3 cm).

When the solution dries, you can add a few more layers and immediately cover up the resulting cracks. To give an attractive appearance, the pipe can be whitewashed or painted in the future.

Thermal insulation diagram of a brick chimney

Insulation with mineral wool. To do this, you will need to take a roll of basalt wool and cut it into pieces that correspond to the dimensions of the chimney area. Then, the insulation is glued to the pipe using tape. The last step of the work is to lay insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

The process of thermal insulation of a chimney with mineral wool

Good luck!

Methods for insulating a metal chimney

Chimneys of different types and designs require different insulation methods. There are types of insulation depending on the purpose of the chimney.

How to wrap stove or fireplace metal chimney pipes?

Steel chimneys can be used for decorative stoves and fireplaces that do not serve as a permanent source of heating. It is enough to insulate such a chimney with a layer of plaster mortar. This method is used mainly for insulating chimneys made of brickwork, but a variation is also possible, designed for metal pipes.

The mixture is prepared from a special mixture and water. Technologically, it would be correct to first pour water into the mixing container, and then add the dry mixture there. After whipping with a construction mixer, you should get a homogeneous dense mass.

To insulate the chimney of a fireplace or decorative stove, you can use special plaster

The solution is applied to the insulated surface in spots using a spatula. Lumps of solution must be distributed evenly over the entire area of the pipe. These areas are needed to attach a reinforcing fiberglass mesh frame to them. Without a frame, a thick layer of plaster can soon crack and become unusable.

A rough layer of plaster is first applied to the reinforcing frame adjacent to the air duct. After applying the main thickness of the plaster, a final finishing layer can be formed.

Helpful advice! The surface of the internal section of the chimney, located in the attic, can be insulated with your own hands using an alternative method. It consists of wrapping the fireplace chimney with mineral wool panels. Flat panels are fixed to the surface of the pipe with masking tape. But this method of insulation is not acceptable for open sections of the chimney, since mineral wool loses its heat-resistant qualities at high humidity.

How to insulate metal chimney pipes of a gas boiler?

Do-it-yourself insulation of functional chimneys can be done using a “sandwich” type structure. This method is the most popular and effective in terms of protecting the structure from condensation and saving energy. The sandwich chimney design consists of two metal pipes and a layer of mineral wool between them. Moreover, a pipe with a larger diameter in this case is a protective sleeve, while a smaller pipe will be a smoke exhaust.

A chimney pipe insulated in this way is not a fire hazard, since the winding layer is protected by stainless steel or galvanized iron.

Mineral wool can be used to insulate both the internal and external parts of the chimney

The formation of a sandwich chimney structure occurs in several stages:

- holes are made in the roof slabs and the roof itself, the diameter of which will be 25 cm larger than the chimney pipe;

- a metal chimney should be insulated with a layer of basalt wool (a more practical type of mineral wool) at least 5 cm thick. The winding overlaps;

- the insulation is fixed using steel wire, which must be wrapped around the pipe several times;

- a casing made of a larger pipe is put on. If the casing was made of thin iron sheet, it is fixed using adhesive tape and tightening straps.

After making sure that the insulation was carried out correctly and there are no unfixed joints, you can put the insulated pipes onto the stove pipe through the hole in the roof. After completing the installation work to connect the chimney to the heating source, it is necessary to fill the sheet of metal surrounding the riser with non-combustible material. Expanded clay, asbestos or clay are used for this.

Today, there are many options for how to insulate a chimney pipe. You can carry out this work yourself; choosing insulation for chimney pipes is also quite simple. The main thing is that the design of the chimney system meets all the necessary requirements. Otherwise, thermal insulation can become a completely pointless waste of money.

Why insulate chimney pipes

To eliminate conditions for the formation of condensation on the walls of the chimney pipe. This is due to the fact that flue gases, coming into contact with the cold walls of the pipe, deposit a wet film on it, which, interacting with soot (unburnt waste), forms harmful chemical compounds that destroy the walls and have an unpleasant odor.

The phenomenon of condensation in nature manifests itself when the moisture content in the air is oversaturated as a result of its cooling, it contracts, increases in density and, having reached the “dew point”, the moisture falls in the form of precipitation (small droplets, fog).

Smoke vapor also has a “dew point”; this point can be located and change its position along the entire length of the pipe. So, for example, when the stove is ignited, it can be located directly in the firebox and, as the pipe channel warms up, it can rise higher and higher until it “flies into the chimney.”

By the way, this expression tells us that the stove must be heated correctly so as not to waste extra firewood: the best option is that the temperature at the beginning of the pipe channel should be in the range of 250-300°C, and at the outlet from 100°C to 150°C WITH.

It is necessary to strive to reduce the time for condensation formation, and this can be achieved by quickly heating the inner surface of the pipe. This is why it is necessary to insulate chimneys. In houses with year-round occupancy, this must be done in order to minimize the amount of condensate formed, since its chemical composition contains dissolved harmful substances, including sulfuric acid, which destroys the pipe channel.

Materials and methods of insulating chimneys.

If the chimney runs from the outside of the building, then it must be insulated along its entire length. Brick pipes can be insulated by plastering using fiberglass mesh and basalt wool insulation. This method has become widespread during the overhaul of Khrushchev-era apartment buildings and is called a thermal fur coat. Materials for thermal fur coats can be purchased at any construction market. The fur coat includes:

- fasteners (dowel and nail with a pressure washer);

- plaster mesh (strong glass fabric, woven in a special way - most known as SSSH - 160)

- insulation (slabs, mats made of mineral wool or expanded polystyrene)

- polymermineral glue (SARMALEP)

- plaster (special finishing composition – SARMALIT)

- paint (special paint for plaster – SOFRAMAL)

The insulation technology is simple: using dowels and nails, the mats are attached to the outer wall of the pipe, the surface of the mat is glued and a mesh is applied, then a layer of plaster and paint are applied to it. This design is very light and does not require additional reinforcement of the walls or emphasis on the foundation.

It happens that you need to install a pipe to additional equipment installed in the utility room or basement. Here you can use a prefabricated system of pipes in the form of a sandwich, which do not require insulation and allow installation through the wall. This is a prefabricated system consisting of heat-resistant stainless pipes (pipe in pipe), the interpipe space of which is filled with non-flammable material with very low thermal conductivity. You can select pipes of the optimal cross-section for your heating system by studying the installation and operating instructions.

Purpose of thermal insulation of air ducts

The installation of ventilation ducts and air ducts is subject to technical rules that dictate the choice of pipes, their placement, connection methods and mandatory thermal insulation if communications pass through unheated areas.

Ventilation pipes run throughout the entire space of the house: they start in the basement, which is often used as a technical or utility room, and end above the roof.

Not all rooms of the house are heated. Often the temperature in the basement and attic is low, which causes problems, the main ones being heat loss and condensation.

Ventilation diagram in a private house. If you are careless about the thermal insulation of the attic and roof, you will have to make more efforts to insulate the air ducts located under the roof

The rules for arranging ventilation are set out in SNiP 41-01-2003. There you can also find information about heating and air conditioning in general.

Thermal insulation of household ventilation air ducts performs 4 functions:

Each of these functions is very important. For example, condensation can cause big problems for home owners. Moisture that forms on the outer walls of pipes causes corrosion of the metal and in a short period of time can lead to the complete replacement of some ventilation sections. Mold forms on the walls of the attic, destroying the wood and creating an unpleasant odor.

Internal condensation is no less dangerous. Moisture seeps through the walls of pipes into living spaces and also causes negative consequences: it increases the overall level of humidity, causes deformation of wooden furniture and decoration, the appearance of fungus and mold, and poor health among residents.

A graph showing the dependence of the thermal conductivity coefficient of modern insulation for ventilation on the air temperature in unheated and residential premises

Both the decrease in temperature in the bedrooms and extraneous noise that disturbs sleep are all the result of cooled ventilation pipes. If you are familiar with the problems listed above, then you can cope with them yourself by insulating the air ducts. First you need to choose the right thermal insulation material.

Do I need to insulate the outside?

As warm exhaust gases pass through the pipe, they are cooled. When cooling, condensation forms on the walls, which can lead to destruction of the chimney pipe.

Also, the draft force in the furnace or boiler depends on how quickly the pipe walls heat up. If the draft is weak, then carbon monoxide will not rise to the top, but will go down, that is, into the house, and this already threatens poisoning.

Any chimney needs to be insulated, whether it is a stove or a boiler, and regardless of what it is made of (brick, metal, asbestos). Carbon dioxide mixes with condensate to form a weak solution of sulfuric acid. Acid destroys metal chimneys, even though chimneys with oxidation protection are available.

Brick pipes are destroyed when condensate gets into cracks, which expand when moisture freezes in them, which can lead not only to the destruction of the pipe, but also the roof itself. The conclusion suggests itself - it is imperative to insulate.

Video: Chimney insulation

This way we protect it from freezing and destruction. So, the sooner we do this, the longer it will serve us.

How to insulate

For insulation you can use materials such as:

- glass wool;

- fiber insulation;

- broken refractory or red brick;

- plaster.

Plastering is not the best way to insulate. A metal mesh is fixed to the pipe and several layers of slag and lime solution are applied. With this option, you will have to grease up the fallen plaster every year. Therefore, you should think twice about the effort-quality ratio before choosing this method of insulation.

Backfill – thermal insulating bulk materials of different sizes are used. One of the simplest and cheapest options. You can use rubble refractory or red brick, expanded clay, slag, etc.

Mineral (stone) wool - made from rocks of basalt origin, some add glass (glass wool). The most popular and reliable method. But there is a drawback: it requires protection from a steel casing. Without additional protection, cotton wool will not last long - wind and moisture will ruin all your efforts.

When choosing insulation, it is better to focus on the quality of the product, since you don’t need very much material. How long the chimney will last depends on the quality of the insulation and the work performed.

Let's sum it up

So, we learned how to insulate a chimney with our own hands. Thermal insulation significantly extends the lifespan. The draft increases, the amount of condensate decreases, which means the amount of soot deposited on the walls decreases.

If you need to extend the chimney (for example, when replacing the roof), trust this only to professionals. Otherwise you may end up with what you can see in the video.

Therefore, be sure to insulate the brick pipe so that there are no problems with heating the house in winter.

At the end, be sure to watch the video in which the famous builder blogger Andrei Terekhov explains the principles and methods of how to insulate a chimney pipe with your own hands.

How to insulate a metal chimney pipe

A separate topic for thought is steel chimneys. A special type of stainless steel is used as a material for modern chimney pipes. The functionality of stainless steel is very high. Firstly, the pipe warms up quickly. Secondly, it does not rust from moisture.

The so-called sandwich chimneys have become widespread. These are structures that consist of two pipes of different diameters. Insulation is laid between them. However, such chimneys have a number of disadvantages, including their price and service life. The advantage is that sandwich chimneys are already insulated. You just need to install them correctly. The quality of chimney insulation is guaranteed by the manufacturer.

Sandwich chimneys help retain up to eighty percent of heat. This means that this type of chimney pipes can be called the most efficient.

However, you can also insulate a steel chimney yourself. To do this, glass wool is selected as insulation, which is wrapped around the pipe, then fixed with wire and foil. In addition, some craftsmen create homemade sandwich chimneys. In addition, they are insulated not only in the space between the pipes, but also outside.

When working with mineral wool you need to be very careful

It is important to ensure that particles of the material do not come into contact with the skin, eyes or respiratory organs. It is recommended to carry out all work wearing gloves

Insulating the chimney will not only preserve its durability, but will also create a beautiful appearance. It is much nicer to look at a plastered brick chimney than at ordinary brickwork. The same can be said about asbestos pipes protruding from the roof.

Insulation of chimneys of any type is done with your own hands - without the involvement of specialists. You just need to do all the work carefully. Insulation materials play an important role in chimney insulation. You need to choose a material that is not susceptible to fire. Fires often occur in the house due to chimneys.

Now that all the work has been completed, you can evaluate the work. First of all, condensation will not form in the chimney. This is not to say that it will not exist at all. However, this is much less than without insulation. In addition, little soot will form in the pipe, which over time can ignite and cause a fire.

Chimney insulation must be approached responsibly. The work requires care and precision. Otherwise, the desired effect will not be achieved. For work you need to use only high-quality and safe materials.

Materials for insulation of smoke exhaust ducts

In order to produce high-quality insulation that will last for many years, you should use only fire-resistant materials with low specific gravity. For this, the following materials are most often used:

- Various lukewarm (mineral).

- Basalt slabs.

- Glass wool.

- Fire bricks (rubble or red).

- Galvanized sheet.

All of them are affordable, easy to use and fireproof. They also have high durability and are absolutely neutral to almost any chemical environment. Due to the fact that all these materials are easy to bend, they can be used to work with objects that have a complex geometric configuration.

Remember, if your choice is glass wool, do not neglect personal protective equipment for your hands, eyes and respiratory tract.

Of all the materials listed above, mineral wool basalt tiles are the most popular for insulating stoves running on gas or coal. It has low thermal conductivity, and as a result it is best suited for chimney insulation. Basalt tiles perfectly maintain the minimum temperature in the outer part of the casing. Among the advantages of this tile the following factors can be noted:

- Basalt tiles are absolutely safe and are made from exclusively environmentally friendly materials.

- To work with this type of insulation you do not need to use many tools. All you need is a hacksaw and a tape measure.

- This material is easy to adjust even to the most complex geometric chimney configurations. Basalt tiles are resistant to fungus and ultraviolet radiation.

- The service life of this insulation is at least 50 years.

Why is chimney insulation necessary?

The main task of thermal insulation of a chimney pipe is to create thermal conditions under which condensation will not form in the pipe cavity. As is known, due to a significant temperature difference between the interior of the operated chimney and the cold outside air, condensate forms in significant quantities on the walls inside the pipe. Insulating the chimney allows you to move the so-called dew point outside the chimney, thereby eliminating the very cause of moisture condensation.

The condensate formed in the chimney contains water and a solution of sulfuric acid, which is obtained as a result of complex processes that occur during fuel combustion. The result of exposure of the pipe to such an “explosive” mixture is its active destruction from the inside.

This applies to the maximum extent to single-layer pipes made of metal. Sandwich, brick and asbestos-cement pipes are somewhat less susceptible to harmful effects.

Condensation stains caused by lack of pipe insulation

Why doesn't insulation solve the condensation problem?

By insulating the chimney, many people expect that they will solve the problem with condensation forever. Imagine their surprise when new spots appear on the walls. To understand why this happens, you need to understand the peculiarities of moisture formation inside the structure. When hot air reaches the dew point, condensation appears on the walls. The colder the chimney walls, the faster moisture forms. If you carry out insulation, the walls will not cool down so quickly. As a result, the dew point will rise, but condensation will continue to settle on the inner surface and then flow down. Only in rare cases, with the help of insulation, is it possible to move the dew point outside the chimney.

Types of gas flues

Depending on the material used, gas chimneys are divided into several types, while brickwork is practically not used for gas removal.

However, brick is often used for piping the exhaust pipeline. This is not a simple facing brick - it has a square shape, and its inner part has a round cross-section.

Stainless steel chimney pipes

Metal chimneys are the most popular. The most commonly used material is stainless steel, which is characterized by high corrosion resistance.

Stainless steel chimney pipes are easy to install and highly corrosion resistant to any aggressive environment

The main advantages of stainless steel structures:

- Resistance to condensed moisture;

- Resistance to precipitation;

- Chemical resistance to soot resulting from gas combustion;

- Resistant to high temperatures;

- The internal smooth surface reduces the coefficient of friction, ensuring the unhindered passage of gases with minimal soot deposition;

- Light weight allows the use of standard fasteners;

- Simple installation eliminates the difficulty of carrying out work with significant destruction of walls;

- Quite affordable price.

It is not recommended to use conventional stainless steel pipes. This is due to the fact that chimney pipes are made from special grades of stainless steel, which, due to the introduction of alloying elements, are highly resistant to acids resulting from the formation of condensation.

Brick chimney installation

Currently, a brick chimney is used much less frequently, because... built mainly for brick kilns, and they are actively being replaced by gas models. In addition, it takes a lot of time to set it up.

Along with this, a brick chimney has the following disadvantages:

- Rough internal surface, promoting the accumulation of soot and reducing traction;

- Instability to corrosion by acid. Due to the hygroscopicity of the material, condensation is absorbed and quickly destroyed;

- Difficulty of construction. Masonry from piece building materials takes much more time than assembling metal or ceramic modules.

The negative qualities of a brick chimney can be eliminated by inserting a sleeve in the form of an asbestos or stainless steel pipe.

Chimney made of asbestos cement pipes

Previously, asbestos-cement pipes were very widely used in the construction of chimneys for gas boilers. Despite the porosity of the material, the roughness of the internal walls and the far from ideal cross-section, the popularity of asbestos-cement pipes is due to their low cost.

A chimney made of asbestos-cement pipes has a low price, but for reliable operation it requires a strictly vertical location

To avoid these disadvantages, a chimney made of asbestos-cement pipes should be as straight as possible with sealed joints. Simple cement mortar is not enough here; dried joints must be treated with sealant or special sealed clamps must be used.

In general, the work is not difficult. If the joints are properly sealed, a chimney made from asbestos-cement pipes will be in no way inferior to its stainless steel counterpart. However, during active use it will serve no more than 3-5 years, after which it requires mandatory replacement.

Smoke channel made of ceramic pipes

Chimneys made from ceramic pipes are reliable, durable, and highly corrosion resistant to aggressive substances and temperature changes.

When installing a high chimney from a ceramic pipe, the construction of a reliable foundation is required, since they are erected according to the “root chimney” scheme

However, along with this, they have their drawbacks - heavy weight, the mandatory construction of a separate foundation and high cost. But all these disadvantages of ceramic chimneys are offset by decades of reliable and stable operation.