Material characteristics

Zinc is a metal with a melting point of 419 C.

The composition of the zinc coating includes an alloy of zinc (99.97%), aluminum, lead and other metals. The layer thickness is standardized by GOST and ranges from 10 to 60 microns.

In air, zinc is covered with a thin film of oxide, which acts as a protection for steel from corrosion.

Galvanized steel is resistant to precipitation and temperature changes.

Convenient to process, easy to bend, roll, stamp and other mechanical loads.

Can galvanized pipes be used for chimneys?

Chimneys with zinc coating are used under certain conditions.

When zinc is heated to 419°, it begins to release substances harmful to humans. Therefore, it is recommended to install outlets made of this material in smoke exhaust systems where the temperature does not exceed 350°C.

The 2009 Ministry of Emergency Situations rules prohibit the use of metal smoke removal agents for coal-fired stoves.

In addition, a single-wall galvanized outlet will burn out after one or two seasons. In practice, it is used as an outer casing in double-walled structures with insulation.

Installation

Do-it-yourself chimney installation is done as follows:

- All necessary measurements are taken.

- A laying diagram is drawn up.

- Surfaces are prepared for installation work.

- The necessary materials are being purchased.

- Brackets are fixed to the wall at intervals of every 40-60 cm.

- The chimney elements are installed in stages.

- In places where floor and roof slabs pass, heat-insulating and non-combustible material is attached.

- Inspection wells for maintenance are installed.

- The build quality and draft are checked, and the heating equipment is started.

Installation rules:

- turns of moves are performed at an angle of 450;

- joints must be sealed with hot glue or clamps;

- It is better to abandon horizontal sections or minimize their number;

- inspection windows must be installed at all corners or turns;

- an umbrella and a net must be installed on the top;

- the height of the galvanized product above the roof should be 2 m higher;

- assembly is carried out using the condensate method (the upper part is inserted inside the lower one) or along the smoke path (the next part is inserted on top of the previous one).

What you need for work

To install galvanized chimney pipes, you will need the following tools:

- metal scissors;

- roulette;

- level;

- marker;

- pliers;

- tools for creating holes in ceilings or walls.

How and with what to insulate a galvanized chimney

A galvanized steel chimney must be insulated with loose or mineral wool roll insulation material. To protect it from moisture (condensation), you need to wrap it with a foil layer. All seams and joints must be taped with a special metallized tape to prevent contact of the insulation with the external environment.

For increased wind loads, it is recommended to additionally tie the insulated layer with wire or clamps at intervals of 40-60 cm.

To insulate, you must do the following:

- Clean the surface of the chimney from dirt, scale and rust.

- Wrap it in mineral wool.

- Secure the layer by tying it with steel wire or mesh.

- Place a steel casing on top or wrap it with a foil layer.

- Paint the casing with special heat-resistant paint.

To insulate mine chimneys, the pipe is first insulated, then it is lowered into a brick structure and connected to an underwater pipe. Broken bricks, expanded clay, and slag are poured into the resulting space. It is recommended that all these actions be performed initially during construction in order to lay the bulk material more densely.

Chimney insulation

Is it possible to paint a galvanized chimney?

Galvanized chimneys lose their aesthetic properties during long-term use, so it becomes necessary to apply a decorative layer. It is necessary to use powder paints for finishing steel roofing sheets.

Conventional enamels are not suitable for these purposes, since with sudden temperature changes they begin to crack and peel off.

Advantages and disadvantages of galvanized pipes

Users include the following advantages of a galvanized chimney pipe:

- long-term immunity to corrosion;

- rapid heating of the chimney and, as a result, ensuring good draft;

- simple assembly method;

- a smooth surface inside the channel, which does not allow soot to linger on the walls;

- Possibility of venting through the wall of the building.

Flaws:

- short service life of a single-wall outlet;

- when cutting a product, the cut lines begin to rust after a short time;

- minor damage leads to the destruction of the protective layer;

- formation of a large amount of condensate.

Safety of the chimney system for human health

When choosing a material treated with zinc, some are concerned about the health safety of using the chimney. It should be noted that pure zinc is not a threat to humans. Moreover, it is present in the body (1.5 -2 g) and contributes to normal metabolism. But when it is heated to a temperature of 419.5 °C and higher, toxic fumes are released, which can indeed lead to poisoning. Thus, using a galvanized pipe at lower exhaust smoke temperatures (no more than 350°C) will not cause any harm to the consumer’s health. And the use of pipes whose design combines stainless steel (for the inner part) and galvanized pipe (outer casing) is absolutely harmless.

What is better galvanized or stainless steel?

It is recommended to make the initial section of the chimney channel from the boiler, where the temperature is especially high, from stainless steel. The inner pipe of the sandwich is made from it, which allows it to be used in any smoke removal system.

Of course, this type of steel is the most durable and rust-resistant. In these parameters it is superior to galvanization. Its main drawback is its high price.

To reduce the cost of sandwiches, galvanization is used to make the casing.

Selection tips and approximate price

Manufacturers offer a large selection of both single-circuit galvanized bends and sandwich pipes with a galvanized shell. There are certain parameters by which you should select elements for the chimney:

- the diameter of the boiler outlet pipe must be equal to or less than the cross-section of the chimney outlet;

- attached chimneys can have no more than three bends along the entire length of the channel.

- Manufacturers indicate the required chimney diameter for boilers in the unit’s passport;

- The wall thickness for the outer casing must be at least 0.5 mm, usually 0.55 mm is used.

The price of single-circuit galvanized steel pipes depends on the diameter and thickness of the sheet metal. A meter bend d=110 mm costs 190 rubles, and d=250 mm costs 390 rubles.

A stainless steel + galvanized sandwich of the same diameter, 0.5 mm thick and 100 cm long will cost 1,230 rubles.

What is a chimney sandwich

A sandwich chimney consists of two pipes of different diameters, one of which is located inside the other. In this case, both pipes are made of galvanized steel, which offers the following advantages:

- The strength of the structure with its fairly light weight;

- Protection from moisture, which develops the corrosion process.

The space between the pipes is often filled with basalt insulation, which:

- Performs an energy-saving function;

- Prevents the formation of condensation and soot accumulation inside the chimney;

- Increases the fire safety of the ventilation system.

The thickness of the metal sheet of both pipes, as well as the thickness of the heat-insulating seal, is selected depending on the operating characteristics of the chimney, its size and the gap between the pipes.

Making galvanized pipes with your own hands

The main feature of a factory-made galvanized pipe is a reliable welding seam.

If you have an argon unit at home and you are a big welder, this makes a difference. Surely what you will get is not a pipe, but a feast for the eyes.

First you need to choose a galvanized sheet for the pipe. Professionals make bends with walls 0.55 mm thick. At the same time, it must be taken into account that the thinner the material, the easier it is to bend.

Required tools and materials

You will need:

- hand scissors for metal;

- mallet with a wooden striking part;

- roulette;

- square;

- metal ruler;

- pencil, preferably a construction pencil;

- pliers.

For the convenience of bending work, a simple workbench is equipped where markings are made. A metal corner (40×40 mm or more) with a length of at least 100 cm, a steel round shape of the required diameter, is attached to the table.

Cutting out the workpiece

Let's look at how to make a pipe with a cross-section of 100 mm.

Calculate the width of the workpiece:

- determine the circumference as the product of the cross section and the value of pi equal to 3.14;

- 15 mm are allocated for the bends for the connecting seam.

In total, for a 100 mm bend, a workpiece with a width of 3.14 × 100 mm + 15 mm ≈ 330 mm is cut out.

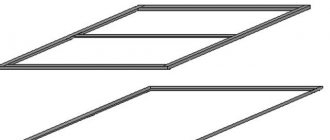

Take into account that the pipes are made slightly cone-shaped for ease of installation using the socket method. Therefore, one side measures 330 mm, the other 340 mm (in the figure).

Formation of a profile

On the cut-out workpiece, mark a fold line for a fold of 5 mm on one side, twice 5 mm each on the other.

The sheet is laid on a workbench, the edge is aligned with the corner. Using a mallet, gradually bend it at a right angle. Then the workpiece is turned over and the fold is placed on the canvas.

In the same way, a 10 mm bend is made on the other edge of the sheet, and another 5 mm wide on it.

Next, the workpiece is manually bent on the forming tube, using a mallet.

Processing the butt seam

After obtaining a round shape of the workpiece, it is placed on a round form or an additional corner, the folds are connected into a lock, tapping them along the edges with a mallet. At the narrow end of the future pipe, the folds are slightly cored. Tap the entire length of the joining seam with a mallet, compacting the folds. The seam becomes almost permanent.

Pros of sandwich chimneys

Sandwich chimneys have a number of undeniable advantages:

- The price of sandwich chimneys remains at an affordable level and is much lower than analogues with similar characteristics;

- Due to the minimal weight of the products, their installation does not require extra effort;

- The installation of the structure is carried out without the need for complex equipment. All necessary fasteners can be purchased in our store;

- Sectional installation does not involve complex operations requiring professional skills;

- The characteristics of the material and the design of the chimney ensure that the opening is protected from condensation, soot accumulation and overheating;

- Thermal insulating material retains heat inside the system, allowing you to save on heating costs;

- Sandwich chimneys can significantly save space when building a ventilation system;

- During operation, round pipes with insulating material make virtually no noise.

You can buy sandwich chimneys in any configuration, as well as connecting parts, by placing an order in the Vent Center online store. We offer quality products at the most affordable prices. You can also place an order for the production of sandwich system elements according to individual measurements. Delivery is carried out to any region of Russia, and is carried out in the shortest possible time. Discounts for regular customers. We look forward to collaborating!

Is it possible to paint a galvanized chimney?

It is possible and even necessary to paint galvanized steel. Over time, rust begins to penetrate through the zinc layer and paint will be a good means of additional protection.

However, a galvanized surface does not have the same adhesion as, for example, black steel. Therefore, ordinary oil and alkyd paints, which oxidize upon contact with zinc, lose adhesion and peel off the painted surface, are not suitable here.

Special compositions have been invented:

- tsikrol, matte acrylic paint with high coverage, light resistance and adhesion;

- Nerzhalux enamel, characterized by high adhesion and wear resistance;

- aluminum enamel Serebrol, which reliably protects against rust and is suitable for outdoor use;

- a number of other compounds that can provide long-term protection from rain, exposure to sunlight, temperature changes, without causing harm to the human body.

It is better to paint no earlier than a year after installing the chimney. During this time, its surface will acquire the desired roughness and create reliable adhesion for coloring compounds.

Features of flue assembly

After preparation, you can proceed directly to designing the system in the following sequence:

- Installation of the chimney pipe starts from the heating unit and works upwards.

- Gradually build up sections, inserting the narrowed part of the segment into the wider one.

- Treat the joints of the modules with a fire-resistant hermetic compound and connect them with clamps.

- Install fastening devices along the entire length of the pipe. The distance between them is determined individually, approximately 1.5 meters.

- Place an umbrella and a lid on top to prevent water from getting on the insulation.

The pipeline, as you can see, is easy to assemble. Although it is better to have this done by professionals in order to avoid various unforeseen situations.

Of course, a galvanized steel chimney requires regular maintenance: cleaning of soot, sealing small cracks that may occur due to high temperatures. You can clean it yourself once a year. You should use a cleaning tool - a pole to which a metal brush is attached. The diameter of the brush bristles should be larger than the diameter of the pipe. Through the windows, cleaning is carried out throughout the entire circuit of the system. When finishing cleaning, you need to treat the inner surface of the chimney with an anti-soot compound that prevents the formation of soot. Finally, the stove should be heated well.

0 0 vote

Article rating

How and with what to insulate a galvanized chimney

Among insulation materials, basalt wool is in first place - a reliable non-flammable product that is successfully used for thermal insulation and insulation of smoke removal systems. Other types of mineral wool are used as a cheap substitute, the main thing being the non-flammability of the material.

The outlet is wrapped with the selected insulation and secured with wire or other reliable and heat-resistant material. Then another pipe, larger in diameter, and usually made of galvanized steel, is placed on the insulated channel. It turns out to be a self-made sandwich. The inner pipe can be a stainless steel product.

Varieties

Galvanized pipes are produced in two types: single-circuit and double-circuit. Both varieties are available in a ready-to-assemble form, with all the necessary connecting and functional elements.

Double-circuit pipe

The easiest to install are double-circuit sandwich pipes, which you just need to buy and assemble like a construction set.

Each section consists of two pipes and a layer of thermal insulation between them. The shaped elements have a similar structure and do not require modification.

We recommend that you read: Use of corrugated stainless steel pipes for heating systems

This design allows you to build a chimney without much effort: the inner pipe acts as a smoke channel, and the outer pipe acts as a protective casing, and to equip a full-fledged working system, it is enough to simply assemble the sections in the right order.

The chimney can be assembled inside the house or outside. In this case, the inside of the sandwich chimney will be absolutely fireproof, since its shell does not heat up much.

A sandwich chimney located outdoors is reliably protected from the vagaries of nature, since the insulating layer prevents heat exchange between the smoke channel and the external environment, and the external galvanized pipe protects from mechanical and chemical influences.

In addition, the assembled double-circuit pipe is a completely aesthetic design that can be successfully used in any design projects.

Single-circuit pipe

For the construction of the internal part of the chimney, for arranging a smoke channel in a combined structure or for a barbecue, single-circuit pipes are used. A single-wall pipe and corresponding shaped elements are cheaper than a double-wall pipe.

However, when choosing, you should evaluate the design features, which in different situations can be both pros and cons:

- when the heating device is operating, the outer surface becomes very hot, which can be a fire hazard, but on the other hand, such a pipe can fully cope with the role of an additional source of heat in the room;

- a single-circuit smoke duct on the street cannot be installed without insulation and a protective shaft or casing, however, such a pipe is ideal for placement inside an existing brick or asbestos-cement chimney;

- the use of a single-wall pipe when constructing a combined chimney or chimney for outbuildings will significantly save effort and money.