To make brick chimney or ventilation ducts, solid ceramic bricks of grade M75 or M50 or special concrete blocks with rectangular or round ducts are used.

The minimum cross-section of channels made of brick is 14 x 14 cm (14 cm is the size of 1/2 brick with seams), and if they are built from circular elements, their diameter should not be less than 15 cm.

The dimensions of the channels in chimneys less than 5 m high for the removal of smoke or combustion products must be increased to 14 x 20 cm or to a diameter of 18 cm.

Chimney ducts must be laid in the walls between heated rooms.

This will protect them from cooling, which can lead to a weakening of the chimney draft. You should try to group the ducts in such a way that there are as many of them as possible in the common chimney leading above the roof. This will reduce the cost of construction and improve the operating conditions of the chimney, because adjacent channels for removing smoke or combustion products, as well as ventilation ducts, heat each other.

A brick chimney is built simultaneously with the construction of the walls of the house. It is constructed according to the same principle, regardless of whether the channels in it will be used as smoke ducts, ventilation ducts, or both.

Under the chimney it is necessary to build a foundation of solid brick or reinforced concrete, and in any case it is necessary to prepare a foundation design. It must be taken into account that the height of the foundation must be no less than 30 cm, and its length and width must be such that on all sides the foundation protrudes beyond the contour of the chimney by at least 15 cm. If the construction of the chimney is planned as a fragment of the outer wall, the bottom its foundation should be at the level of the bottom of the wall foundation so that it is also below the soil freezing zone.

When constructing chimneys, special attention must be paid to their tightness. To build a good chimney, you must adhere to several rules. First of all, the bricks must be laid with dressing, that is, they must be laid in such a way that the vertical seams overlap with the bricks of the previous and next row.

For masonry, you need to use the same mortar as for the load-bearing walls of the house (that is, cement or cement-lime). It is very important that the inner surface of the chimney (chimney channel) is smooth. Therefore, during construction it is worth using special templates.

The vertical seams of each layer of bricks must overlap with the bricks of the previous and next layers. Bricks in the walls, which are partitions between the channels, must be placed at least at one end into the outer walls perpendicular to them.

The thickness of the partitions between the channels for removing combustion products must be at least half a brick, that is, 12 cm.

Between the ventilation ducts they can be twice as narrow. Often the outer walls of the chimney are also made half a brick thick (12 cm). To prevent the combustion products in the chimney from cooling too quickly, it is good to cover the outside of the chimney with a layer of thermal insulation, for example, mineral wool.

- Date: 06-01-2015 Comments: Rating: 34

The chimney for the fireplace must be built in accordance with all rules and regulations.

No mistakes should be made at any stage of its design and construction. For example, incorrect calculation of the height of the chimney pipe will lead to the fact that the fireplace will begin to smoke and fill everything around it with soot and soot. Therefore, if you want your heating system to work without problems and complaints, you need to know the rules for building a chimney for a brick fireplace and do everything in strict accordance with the instructions.

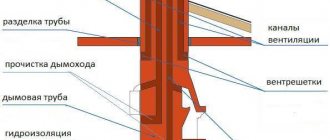

Diagram of a brick chimney.

Determining the size and shape of a brick chimney

The optimal shape for a smoke exhaust pipe is a cylinder.

Corners create additional barriers for smoke, making it difficult to remove. As a result, more soot will accumulate on the walls of the structure. The cylindrical shape is devoid of angles and the mentioned disadvantages.

Chimney structure.

The dimensions of a brick chimney - diameter and height - must be calculated taking into account the power of the equipment, existing obstacles in the path of exhaust smoke, their size, and the width of the inlet. In the process of calculating the height, it is necessary to take into account the height of the house itself, the type of roof, the size of neighboring buildings and construction requirements.

In the process of drawing up the project, it must be taken into account that the length of any horizontal section of the smoke exhaust structure should be no more than 1 m. This is due to the fact that heated air moves in a vertical rather than horizontal direction. And if this requirement is neglected, the draft will decrease significantly, as a result of which soot will be intensively deposited in this area.

Return to contents

Heating scheme using a fireplace.

Quite often, at the stage of connecting the fireplace to the chimney system, an obstacle arises due to different hole diameters. In such situations, you have to use a special reduction adapter.

In this case, the junction of the fireplace with the brick chimney must be treated with sealant. Next, the structure should be assembled so that it expands upward. Thanks to this technique, condensate will not escape onto the outer walls of the chimney.

The assembly of a brick chimney should be carried out in accordance with a previously prepared project. The masonry is laid out in layers. During the construction process, you need to strive to ensure that there are no roughnesses on the inside of the walls of the structure, and be sure to monitor the tightness of the structure.

If your house already has a ready-made old brick chimney that is suitable for your equipment, then a liner must be made before using it. A steel pipe is installed in the old smoke exhaust structure. During installation, you need to ensure that there is a technical gap between the new chimney and the existing brickwork.

Choosing the chimney height.

In the process of building a brick chimney, in most cases it is necessary to use tees. In the design of such tees, it is necessary to provide special inspection doors for more convenient further maintenance and, of course, take into account the outlet angles.

A brick chimney requires mandatory insulation. It will ensure the safety of not only the smoke exhaust system, but also the entire building as a whole.

Properly organized thermal insulation allows you to speed up the heating of the pipe and reduce the accumulation of condensate. In addition, the insulation will protect combustible materials from the effects of a heated brick pipe. In the process of installing a chimney for a fireplace through the ceilings, it is necessary to carry out work in compliance with fire regulations, taking into account the temperature of the ceiling material and the smoke exhaust pipe itself.

For finishing walls and ceilings located in close proximity to the smoke exhaust duct, it is highly recommended to use only non-combustible materials. Otherwise, you will have to additionally install protective metal sheets.

That part of the brick chimney that faces the street must be additionally fixed and protected from the wind. Protection from various debris and precipitation is provided with the help of nets, deflectors and weather vanes.

Return to contents

Fireplace diagram.

When building a brick chimney, no mistakes should be made. Any shortcomings lead to serious consequences - from expensive modifications to the structure to smoke poisoning or fire.

Errors that can lead to extremely adverse consequences include:

- Insufficient thermal insulation of the structure. Because of this, nearby materials may char or catch fire. The use of unifying protection of more than one channel with one fungus. Because of this, the ventilation system is destroyed, as a result of which smoke begins to enter the house. Unauthorized modification or repair of a brick chimney without preliminary recalculations.

It is quite difficult to build a technically safe and maximally correct brick chimney in all respects on your own. Every fireplace, house, etc.

d. has individual characteristics. Therefore, at least at the stage of drafting a smoke exhaust system, it is recommended to consult with specialists.

Return to contents

Drawing of a brick fireplace.

During the design and construction of a brick chimney, at each stage it is necessary to strictly comply with all the requirements for such systems. Violation of technology can provoke extremely unfavorable consequences.

First of all, it is impossible to organize an exhaust ventilation system without arranging compensating supply ventilation. You cannot organize smoke removal through channels that have ventilation grilles. Any obstacles on the path of smoke will delay its removal, and this, as already noted, cannot be allowed.

The fireplace itself must be built next to a partition made of non-combustible material, and it must be internal. The smoke exhaust duct must be installed in an external wall, also necessarily made of non-combustible material.

If necessary, external insulation is performed. It will prevent the formation of condensation from gases discharged by the chimney. If there are no walls suitable for placing smoke exhaust ducts, it will be necessary to use mounted or root pipes.

One fireplace can only be connected to one separate chimney or separate smoke channels.

But there is an exception. Two fireplaces can be connected to one chimney only if they are located on the same floor of the building. The connection of pipes requires a cut with a height of 1 m from the bottom connection and a thickness of 120 mm.

If the fireplace is planned to be used for large-scale heating, you can connect a so-called radiator pipe to it, which allows you to increase the heat transfer area. In the future, the combustion intensity will be controlled by regulating air exchange. Or, as an alternative, you can use a damper.

Tools necessary for work: hammer, trowel, building level, square, jointing.

Smoke removal should be organized in the simplest possible way.

Therefore, the best option is to install a vertical smoke exhaust system with a height of 7 m or more or create a structure with a more complex configuration, having bends with an angle of 45°. If an elbow will be used, then a tee must be installed. Thanks to it, subsequent cleanings will be less difficult.

It is important to consider the location and thermal protection of a brick chimney. The smoke is hot, it will transfer heat to the structure and heat it up, so it is extremely important to provide fire protection for the walls and ceilings. If there is a plastic or wooden structure near the chimney installation site, it must be insulated.

As a rule, basalt wool is used for this. The chimney passage requires additional protection from the cold. A fungus or weather vane is installed at the end of the pipe.

To build a brick chimney yourself, you will need the following materials and tools:

- Container for preparing mortar. Cement mortar (sand and dry cement). A set of chimney pipes with all the required elements. Brick. Sticky aluminum tapes. Square. Lead sheet. Construction level. Trowel. Shovel for mortar. Joining. Stairs. Hammer. Mop.

Return to contents

Brick chimney laying diagram.

When building a chimney yourself, you need to be extremely careful at every stage of the work.

First of all, you need to pay attention to the solution. An ordinary solution consisting of a portion of cement, 3 times more sand and water to a thick sour cream will do. Make sure that no stones or debris get into the solution; check it with your hands.

Each row of masonry must be checked against the order. The structure is erected so that the frame for it does not come into contact with the external walls. As a rule, fireplaces operate in conjunction with an attached pipe that connects to their exhaust vent.

The internal part of the brick chimney structure is laid out on a clay-sand mortar. First, the base of the pipe is laid - at least 3-4 rows. The internal cross-section of the chimney is selected in accordance with the power of the fireplace.

Characteristics of brick.

Make a fluff along the entire length of the ceiling.

It will provide fire protection. The pipe should expand. To do this, you need to shift the brick by 25% of the width to the outer edge.

The base of the extension must coincide with the surface of the ceiling in the room. The thickness of the fluff should be half a meter. If the thickness is insufficient, it will need to be expanded using sheet asbestos or other non-combustible material, laying it around the entire perimeter.

Having completed the preparation of the floor, place the main riser in the gap between the attic floor and the roof sheathing. The dimensions of this element must correspond to the dimensions of the base neck.

Subsequently, the chimney is laid out so that there is another extension on the street side - the so-called otter. Thanks to this expansion, precipitation will not enter the attic. External masonry is carried out using standard cement-sand mortar, the proportions of which were given above.

Return to contents

Stages of laying a chimney.

The chimney pipe must be installed in a strictly vertical position.

Make sure that its inner surface does not have any protrusions and is perfectly flat. The outlet - if it is created - can go to the side no more than 100 cm. There should be no obstacles along the entire path of the smoke exhaust pipe.

A fireplace consumes more air than a stove, so its chimney should be much higher than the stove chimney. It is important to maintain the correct thickness of the chimney walls.

So, the outer cold wall is laid out in brick. In the middle of the room it can be made in half a brick. If the room has walls and partitions made of wood and the pipe has to be laid through them, this can only be done through a sheet of asbestos-cement or metal.

It is better if the pipe has a round cross-section. Square and rectangular shapes are less preferable, i.e.

because soot collects at the corners and interferes with the normal movement of gas. The optimal sections are 1/15, 1/12 or 1/10 of the size of the internal opening of the firebox.

As for pipes, asbestos-cement or ceramic are the most preferable. You can purchase a ready-made kit.

Such kits include standard blocks, collar facing plates, protection for the top of pipes and other important elements. The installation of such systems begins with the installation of the first block on top of the structure. Cement mortar is applied where the smoke collector connects to the pipes.

Make sure that the grooves of this block are facing up. The first block of lining is inserted inside. It is installed with the extended side on top.

The brick cladding is secured using metal anchors. They must be inserted between the external blocks of the chimney pipe.

The brickwork must be brought to the top of the pipe blocks. The solution is placed on the edge of the uppermost block, pressed into it, and then the cuff is inserted into the pipe. Another layer of mortar is applied to the cuff and the bricks are laid.

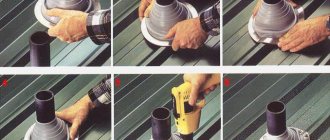

After this, everything is covered with a protective plate. It should be placed on a layer of solution. Where the pipes intersect with the roof, a gap is formed.

Precipitation can penetrate into the house through it. To prevent this from happening, the gap is sealed with a solution. You can also make the casing out of metal.

The metal sheathing is installed using adhesive aluminum tapes and lead sheeting.

The sheathing consists not only of strips, but also of an apron attached to each side. This solution forms a collar design. It will be necessary to seal one edge of such a collar into the masonry seams, and leave the other on the roof surface.

The walls of the head should be one brick thick.

However, if the walls of the smoke exhaust pipe are insulated with asbestos-cement slabs and plastered, then the lining can be half a brick thick.

If you wish, you can buy ready-made pipe heads.

To prevent the draft from tipping over at the mouth of the pipe, it is necessary to install a multi-tiered deflector. A ridge canopy is installed above the head. To ensure that the end part of the head does not collapse under the influence of precipitation, it is necessary to install metal caps and make a edging of roofing steel.

Windproof nozzles are installed on the pipe heads. The head itself must be positioned above the point of exposure to wind pressure. And finally, spark arresters and wire mesh with cells up to 3 mm are installed on the tips.

Thus, you can handle the construction of a brick chimney for a fireplace with your own hands. Happy work!

A fireplace is an installation that has many responsibilities. It should not only warm the room, but also bring coziness, joy, and comfort.

However, in order for the logs to burn and no acrid smoke to enter the room, it is necessary to correctly build a chimney for the fireplace with your own hands - one of the fundamental parts of the entire structure. It must be durable, reliable and safe.

Content:

Chimney placement methods

There are two ways to place a fireplace chimney - internal and external. The first involves installing a pipe to remove smoke and fuel combustion products in the room or in the wall of the room (if it has a shaft provided for during construction).

The second method is to install a pipe outside along the wall of the house, when exhaust gases and smoke are removed from the fireplace through a standard chimney. It is connected by a transition elbow to a horizontal pipe running through the wall. The elbow is connected to a tee onto which a chimney pipe leading upward is installed.

We recommend that you read: Polypropylene couplings for creating various types of connections in pipelines

Both methods of placing a chimney have their advantages and disadvantages. The internal arrangement protects the structure from temperature changes in winter and also reduces heat loss. The disadvantage of placing the pipe indoors is the loss of valuable square meters.

Outdoor placement is more rational in terms of space saving and fire safety, but with this arrangement, condensation often forms in the pipe due to temperature differences.

How is a brick chimney constructed?

Before you start building a brick chimney, you need to understand what main parts such a structure consists of:

- Mounting pipe - a part laid out immediately behind the combustion chamber and into which a draft-regulating valve is installed. Fluff - it follows immediately after the mounting pipe, representing an expansion of the outer part of the chimney up to 25-30 cm. Designed for safer passage through the ceiling Riser - part located in the attic and rising to the roof. It needs high-quality insulation. Otter - is a four-sided extension of up to 15 cm, protecting against precipitation from entering the attic. Neck - part of the chimney located directly above the roof and turning into the final cap

For those who find it difficult to install a brick chimney for a fireplace, there are always simpler, but high-quality options. You can build a structure using ceramic blocks, various pipes, etc.

Types of structures

Chimneys for fireplaces are different. They are usually classified according to installation method, location and production raw materials. Taking these parameters into account, chimneys are distinguished:

- Built-in. They are a vertical shaft for removing combustion products. Such devices are distinguished by their efficiency.

- Hanging. Suitable for island-type models and used exclusively in manufactured homes. Ceilings and load-bearing roof structures serve as fastenings for the pipe. The ideal solution in this case could be a metal chimney. This choice is explained by the ease of the device.

- Based on the hearth. Due to the considerable weight of the device, it is installed directly on its own foundation.

Chimneys are classified into several types.

During construction, various materials can be used: brick, stainless steel, pipes made of asbestos cement or ceramics. The cost of installation work depends on the materials used for the work.

Preparing for work

The fundamental stage is preparation for the work. It is necessary to familiarize yourself with the various drawings and choose the most suitable one. It would be a good idea to indicate on the diagram all the characteristics of the pipe being constructed and save it.

Watch the video preparing the solution:

Chimneys for brick fireplaces have their own characteristics, depending on the type of stove being installed:

- For wood-burning models, it is enough to make brickwork. For gas models, you need to place a metal pipe inside the masonry.

Before laying the chimney, a rectangular foundation is erected. It is made 30-40 cm high and 15-20 cm wide in one of two options:

- Formwork is installed and concrete is poured. Lay out of refractory solid bricks

To build a brick chimney for a fireplace, you need to prepare the following tools and materials:

- Fireproof brick (grade M200 and higher) Mortar consisting of cement, fine sand, water and clay Hand tools (trowel, level, plumb line, etc.) Thermal insulation materials Steel sheets Electric tools (grinder, drill)

Choosing material for constructing a chimney

Currently, most chimneys are built on the basis of a metal pipe made of stainless or galvanized steel. Occasionally, structures based on brickwork are found, mainly in old houses.

In new residential buildings, brick chimneys are just an imitation of masonry: they are based on the same metal pipe, simply lined with brick on the outside.

If owners want to get an authentic brick chimney, they need to choose a special type of material.

It is important! For contact with hot air, smoke and exhaust gases, you need a special refractory brick that can withstand temperatures up to 700 degrees.

In addition to metal, ceramic and glass chimneys are also used. Ceramics have a long service life - from 30 years and above, but the cost of such a design is several times higher. Glass chimneys are also an expensive option, usually found in designer fireplaces.

We recommend that you read: Production and regional sales of pipe products

Most home or cottage owners prefer a stainless steel metal pipe when installing a fireplace. This material is more affordable, is resistant to corrosion and high temperatures, is lightweight and easy to install.

Laying of the mounted pipe

It is necessary to decide what the cross-section of the chimney will be for a fireplace built from brick.

The smoke, rising upward, moves in a spiral. Therefore, it is customary to give preference to a round-shaped channel, but it is extremely difficult to lay it out of stone. You have to make a section in the form of a square, the size of which depends on the fireplace portal:

- Closed portal - approximately 15x25 cm Open portal - approximately 25x25 cm

It is necessary to start laying from the top, arranging the nozzle pipe.

It is very important to monitor the ligation of seams between rows, vertically and horizontally. The thickness of the seams should be 1-1.5 cm. One value should be maintained throughout the entire construction.

We make a fireplace from start to finish: stages of work in order:

It is necessary to continue laying the mounted pipe until 5-6 rows remain from the ceiling. To ensure that the smoke does not have any obstacles, it is recommended to plaster the inner surface with the mortar used for joints. It is better to lay the layer not thick, so as not to greatly reduce the diameter of the chimney for a brick fireplace.

If the mounted pipe is laid directly against the wall, it must be secured. To do this, pins are installed every 25-30 cm, one end of which is driven into the masonry, the other into the wall.

Having laid the last row of the chimney pipe, it is necessary to check the vertical and horizontal, it is time to begin the most important and difficult stage of construction - the construction of the fluff, the otter and the riser located between them.

Diameter

In order to calculate all the parameters, it is now necessary to decide on the material that will be used in the construction process. It is most convenient to carry out the calculation on paper, creating a sketch of the future structure; it is necessary to take into account some nuances:

- The diameter of the chimney for a fireplace must have a certain relationship with the firebox. Calculating this value has its own subtleties. For example, when calculating the diameter of a pipe that connects to an open firebox structure, a proportion of 1:10 is used. This method is only correct for a cylindrical type of chimney.

- The calculation of the cross-section for a square type device contains proportions of 1:15. But the diameter should be smaller than the size of the blower. If the resulting heat transfer is less than 300 cal/hour, the cross-section should not be less than 140 x 140.

- In order to determine the optimal diameter of the fireplace chimney, you can take as a basis state standards, which stipulate the permissible cross-section under certain conditions.

- In addition, the height and diameter are calculated in accordance with the area of the room.

Standard dimensions of internal diameters and cross-sectional area of brick chimneys

It would be useful to show your calculation to specialists and analyze it together. In addition, a suitable calculation scheme can be posted on the Internet.

It must be remembered that the calculation of these parameters must be done correctly; the efficiency of the heating device depends on this.

Fireplace through attic and roof

In order to pass a chimney for a fireplace built by yourself through the ceiling as safely as possible, you need to lay out the fluff. The thickness of its walls should be equal to at least one brick placed in length. In this case, the expansion is done in stages, moving by ¼ with each row.

Sometimes, instead of the classic tub of the thickened part, a concrete box is used, filled with pebbles, sand or expanded clay and installed around the chimney pipe. This option is easier to implement:

- First, the wooden formwork is arranged so that it rises 7-10 cm above the ceiling; it must be secured more securely and make sure there are no cracks. The inside of the boards is covered with a solution of sand and clay so that the formwork can be easily dismantled after the concrete mixture has hardened. Next, reinforcement is done by rigidly connecting the rods and brick masonry with each other A solution consisting of a high grade of cement, sand and the selected filler is prepared, thoroughly mixed and poured, completely hiding the reinforcing rods. After drying, the formwork is dismantled. The surfaces must be smooth so that it is possible to cover the fluff with masonry without any problems.

In order to maximally protect the structure of the ceiling, which should not touch the chimneys for stoves and fireplaces, it is necessary to make a steel edging around the perimeter of the hole, and put glass wool impregnated with clay mortar into the resulting gap. It is also recommended to lay the insulation to the sides, removing up to 20-30 cm.

Watch the video, the chimney through the roof slab:

After the formation of the fluff, the installation of the riser continues.

In this part, the size of the chimney for the fireplace is made similar to the mounted pipe, only plastering with clay mortar is carried out simultaneously from the inside and outside. During the heating season, the attic temperature is set to low. To eliminate the big difference inside and outside the chimney, it is recommended to wrap the riser with non-flammable insulation.

The most difficult stage of the instructions on how to build a chimney for a fireplace has been completed.

Having reached the roof, it is necessary to proceed to the next stage - arranging the otter. The pipe is expanded, as when laying fluff, but only slightly. In this case, it is necessary to install a galvanized metal casing around the perimeter with a small protrusion on the roof, which is covered with soft waterproofing and roofing.

Brick chimney

Inexpensive designs include brick chimneys; they fit perfectly into the architectural structure of any building.

A brick chimney must be built in such a way that it can be easily maintained.

To install a fireplace chimney, it is necessary to comply with the relevant building codes and regulations when constructing vertical structures.

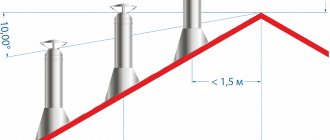

- The chimney flue of the fireplace stove must ensure sufficient removal of combustion products. The design, 5-6 meters high, improves traction. The best option is when the chimney is 50 centimeters above the level of the roof ridge.

It should be remembered that too wide the internal volume of the pipe reduces the performance of the heating device, and too narrow one makes it difficult to remove combustion products.

If the chimney is located next to a high wall, then it is built up with stainless steel materials, asbestos or ceramic pipes.

- It is important to place the chimney duct vertically, possible deviation angle: 300, in a segment no longer than 2 meters.

- The channel for connecting the heating boiler to the chimney should be short, with few bends.

- For better traction, the channels must have the same diameter.

- The chimney should be laid carefully and the seams between the bricks must be completely filled.

Strict adherence to the rules improves the tightness of the structure and creates good traction.

Finishing the fireplace

Having finished building the otter, you need to start arranging the final part - the neck of the chimney for the fireplace with your own hands.

Let's watch the video, the first firebox:

It is made similarly to a riser and rises to the selected height, which depends on the distance from the ridge:

- Up to 1.5 m - 0.5 m above the highest point Up to 3 m - at the level of the top point More than 3 m - a straight line drawn between the top point and the pipe being erected should deviate from the horizontal no more than 10 degrees

All that remains is to complete the head for the future chimney. Its construction is carried out similarly to fluff. Upon completion of the work, it is recommended to install the cap and weather vane.

Materials for constructing the device

When building a fireplace, you can use ceramic or steel sandwich pipes to remove smoke. Ceramic pipes are compact in size and can be installed not only inside the structure, but also outside. The average service life is about 30 years, but with proper care it can be extended by 15 years.

When installing ceramic pipes, pouring the foundation is not required. The lightweight structure is installed on a monolithic base of a concrete pipe. To use solid fuel raw materials for heating a room, you should purchase a model with a layer of thermal insulation. Such products can withstand temperatures up to 400 degrees.

Steel sandwich pipes are made in the form of two steel cylinders. During the installation process they are inserted into each other. Between them there is a thermal insulation layer. Their service life is somewhat shorter - about 20 years. Component parts are selected taking into account the diameter of the inlet pipe after calculating the required chimney height for a normal draft device.

When installing a chimney with your own hands, you should familiarize yourself with all the construction parameters in advance. The choice of materials depends on the client’s income level, the condition of the building and personal preferences. To avoid carbon monoxide poisoning or fire, you should trust the work to professionals. In this case, you can get not only a high-quality design, but also warranty and service.

Popular mistakes and tips

The most common mistake is made at the calculation stage. If the fireplace is placed incorrectly, the chimney pipe may rest against one of the beams. The problem can be eliminated by installing additional elements of the rafter system.

Watch the video, installation of connections to the pipe:

Many people, in order to save money and time, combine more than one channel with one fungus. This is one of the biggest mistakes. The ventilation system ceases to fully perform its functions, as a result of which mold and condensation appear.

There is nothing difficult about how to make a brick fireplace for a chimney with your own hands. However, you cannot begin repairs or make any structural changes without permission. It is necessary to contact a specialist and carry out additional preliminary calculations.

Watch the video and recommendations from experts:

Each fireplace or duct must exit into one chimney. If this is necessary, the common part is expanded and a cut is made in the center with a thickness of 12-15 cm to a height of one meter.

There should not be many changes in the direction of the chimney, since smoke removal should be carried out in the simplest and fastest way. The construction of complex structures with slopes of no more than 45 degrees is permitted only with a minimum chimney length of 6-7 m.

Traction criteria

The main purpose of the chimney is to remove combustion products through draft. By draft we mean the pressure difference of the room-atmosphere type. The pressure properties, speed of movement of gases and air in the fireplace structure depend on the operating mode used.

Usually only air moves through the smoke duct. The draft is formed naturally when the fireplace is not in use. When backdraft is formed, all the smoke goes back into the room.

If the draft is weak, the fireplace may smoke heavily during operation. With strong pressure, the amount of products burned increases. In this case, the heat leaves along with the smoke. If there is no draft in the chimney, it is prohibited to use the fireplace.

In this video you will learn how to install a chimney with your own hands:

Design features of the chimney

The purpose of the fireplace chimney, as well as the main function of the chimneys of stoves or boilers, is to discharge fuel combustion products out into the atmosphere. Gases along with soot flow from the furnace into the chimney under the influence of draft.

The correct formation of a chimney consists in choosing and constructing a structure in which a minimum of soot remains on the walls of the pipe, and the draft prevents the flow of gases into the room.

Chimneys made of different materials have their own characteristics and may differ in design. For example, a traditional brick chimney consists of the following parts.

Modern chimneys made of steel or ceramics do not have such fragments as otter or fluff, but for the normal removal of smoke in brick pipes and to protect the ceilings from heating, they are simply necessary

When choosing a material, it is necessary to take into account the temperature of the gases: in the furnace it is higher, at the outlet it is lower, but even at the highest point it can reach +100 ° C. The creation of draft is based on the temperature difference - hot air is replaced by cold air.

Also important are indicators such as the height and internal diameter of the chimney - they are calculated when drawing up the project.

A variant of a fireplace design with a chimney made of a steel pipe. Features: floor and wall cladding with non-combustible materials, finishing of floors, possibility of creating non-vertical sections using half-bends

No matter how hard you try, it is impossible to build a chimney that does not need cleaning. Even in a properly assembled ceramic chimney, soot accumulates over time, making it difficult for gases to escape. Therefore, chimney cleaning must be carried out regularly. This is usually done during the period when the fireplace is idle.

In addition, it is necessary to monitor the integrity of the connections and the internal surface: cracks, potholes or protrusions that may appear over time prevent the normal circulation of hot air.

Block chimneys made of ceramics

*

The blocks for constructing the pipe are made of lightweight concrete.

- They are connected thanks to vertical reinforcement.

- A ceramic pipe is placed into the inside of the block structure and wrapped in fire-resistant thermal insulation.

Advantages and disadvantages of ceramic chimneys

The advantages include the following characteristics:

- feature of quick installation - ease of assembly;

- provides high efficiency;

- long service life;

- there is a variety of blocks for constructing the desired structure and already provided openings for the chimney;

- The smoke exhaust pipe can be easily cleaned thanks to the existing hole;

- There is a hole at the bottom of the pipe for condensate to escape.

Block structures have disadvantages, such as:

- high price;

- long delivery from abroad.