We recommend that you read

- Stainless steel chimneys

- Boiler chimney

- Steel chimneys

- Chimney height

- Chimney sandwich

- Metal chimneys

- Chimney cable stays

- Chimney masts

- Chimneys for boiler rooms

- How to calculate a chimney

- Typical designs and drawings of chimneys

- Industrial chimneys

- Chimney calculation

- Design of industrial chimneys

Causes of malfunctions and ways to solve them

Let us highlight the common reasons for decreased performance of the smoke exhaust duct that require immediate solutions:

1. Blockages and improper installation. During operation, the draft in the chimneys deteriorates with the subsequent accumulation of combustion products in them.

Industrial waste may enter directly into the structure. The draft in the chimney ducts is affected by the rough surfaces inside the structure, its diameter and the serviceability of the head. In some cases, a collapse inward may occur, followed by clogging of the smoke exhaust duct. The latter is relevant for brick types of construction. Solution: Check for blockage by lowering a weight.

If there is blockage, the structure is dismantled in this place. Soot formed over 3 mm is removed with a brush or weight. Please note that chemicals of powder or liquid type have been created, which during combustion form gas to clean the internal surface of the smoke exhaust duct from soot. You can find out more from our consultants. 2. Presence of condensation. One of the common problems that require repair of industrial chimneys .

Condensation reduces the performance of the heating unit. The problem arises in the absence of normal insulation of the smoke exhaust duct, the presence of through holes and cracks. Solution: plastering the chimney or the room in a metal case.

The space must be filled with thermal insulation materials that meet the requirements of SNiPs and GOSTs. 3. Blowing out the chimney .

Occurs when the deflector is damaged or missing, or there are tall trees and buildings near the structure that impair performance. Solution: install or repair the deflector.

When the pipeline is located in the area of wind pressure, it is necessary to build up the smoke channel by 0.5-1 m in height in order to increase draft.

Types of defects

Chimney defects can be divided into several types. Depending on their type, the progress of repair work changes. Defects can occur when performing a number of actions:

- roof replacement;

- pipeline construction;

- dismantling furnace equipment;

- changing the location of the tubes due to redevelopment.

Blockage

Causes:

- accumulation of soot that has not been cleaned out for a long time;

- collapse of part of the brickwork;

- ingress of leaves, dust, and debris into the channel.

To ensure that less soot accumulates inside the pipeline, you need to heat the stove with aspen wood once a month.

Aspen firewood (Photo: Instagram / farmstead.rancher)

Condensation Formation

If gross mistakes were made during the construction of the chimney, condensation will accumulate inside. This negatively affects the condition of metal surfaces. They are constantly exposed to the destructive effects of moisture; in winter, the metal is covered with an ice crust.

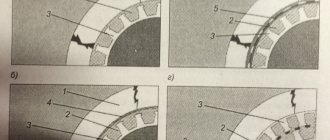

Cracks

They can form both in brickwork in rows and on metal surfaces. The main reason is constant temperature changes. They lead to complete destruction of the channel, smoke in the premises, and increased fire danger.

Blowing out

Poor draft occurs when the integrity of the smoke exhaust channel is violated, the use of too weak or high-power stove equipment, or the presence of cracks in the pipe.

Types of work during repairs

Repair of chimneys of boiler houses in industry includes the following types of work:

- Restoration of coverage.

- Use of marking paint.

- Application of anti-corrosion protection to the pipeline trunk.

- Correction of roll when the maximum permissible value is exceeded.

- Repair or replacement of tension elements if the structure is made of metal.

- Restoration of pipe duct brickwork.

- Repairing the lining of a brick chimney.

- Work to strengthen the head.

- Installation and dismantling of smoke exhaust pipes.

- Installation of protection or its replacement.

- Repair of blind areas.

- Resumption of concrete casting.

or brick

chimneys The type of work is determined by the volume and type of breakdowns. Major repairs are carried out only by specialized companies whose employees have been properly trained, received a certificate and have the appropriate qualifications. A permit to carry out work at height is required here. Repair work begins only after an examination has been carried out and a conclusion has been received from the results of the inspection of the condition of the pipeline. This includes strengthening/complete replacement of unsuitable elements or structure. Major repairs are carried out as usual, with the exception of restoration work on the head. This requires shutting down technological units.

Chimney inspection

Maintenance of a metal flue in a boiler room begins with an external inspection performed twice during the calendar year (in spring and autumn). To ensure the effectiveness of internal and external inspection, specialists from organizations with appropriate permission are involved in the work. 365 days after the product is put into operation, the first mandatory inspection is provided. The frequency of further internal inspections depends on the serviceability of the structures. Inspections are carried out as necessary, at least once every five years. Specialized organizations conduct an examination of the risk of chimney failure. Maintenance of the metal flue of the boiler room is carried out after the heat-generating boilers are turned off. If the equipment cannot be turned off, the test is carried out using a device operating in the infrared region of the electromagnetic spectrum - a thermal imager.

Carrying out a chimney inspection

The examination is carried out on the basis of assessment and inspection of structures. It is regulated by law and includes:

- Assessing the condition of the surface of the structure outside and inside.

- Identification of roll and its permissible values.

- Identification and assessment of the load-bearing capacity of the chimney.

During the examination, destructive and non-destructive devices are used. If breakdowns and the nature of damage in the structure are detected, the technical condition is classified:

- Emergency: unsuitable for further use.

- Limited working condition with repair needed.

- Operable with minor faults resolved.

- Good condition of the structure.

Upon completion of the examination, an estimate for chimney repairs . The development of the document is based on the type of structure, types of damage or defects and methods for eliminating them. Additionally, foundation repairs may be required.

Mandatory internal inspection of the gas duct

Each planned shutdown of serviced equipment must be accompanied by an internal inspection of the gas ducts. This is especially true for equipment put into operation less than 1.7 years ago. Determining the current state of the protective layer of metal, walls and floor slabs is the main task of the survey. Maintenance of a metal flue in a boiler room determines a number of additional parameters:

- Thickness and density of deposits from mineral impurities of the fuel;

- Humidity of deposits from mineral impurities of fuel;

- Time period of accumulation and areas of maximum accumulation of sediments.

The degree of sediment load on the structures ensuring the stability of the object is indicated schematically. Actual and calculated deposits are taken into account, often within the range of 300 kgf/m2. The complete results of the inspection of the chimney and flues are recorded in the inspection report and are also recorded in the inspection log. When a pipe tilt is detected, the slope value is calculated. The table of Construction Norms and Rules SNIP 11.15-74 indicates the permissible tilt range. If the calculations at the facility practically correspond to the permissible value, monitoring of the change in the slope in the base of the gas exhaust channel in the range of +0.5-4-1 m is organized. Observation is organized once a calendar year and more often.

Ready-made drawings and projects of chimneys

Mast

watch Mast chimneys are designed for removing flue gases from boiler houses operating on liquid,…

Self-supporting

watch The self-supporting chimney is designed to remove combustion products and provide natural draft into the fuel...

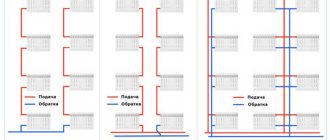

Facade and flue ducts

see The façade (wall) chimney consists of separate insulated sectional chimneys and roof elements…

On guy ropes

look Chimneys on guy wires are a single-barrel vertical steel structure, fixed with a steel...

Truss

watch Truss chimneys are a steel lattice tower of SRB and thermally insulated gas suspended on it...

Columned

watch The column chimney is a structure consisting of a metal supporting outer shell and a gas outlet…

Each type of structure has a separate type of chimney repair work. Brick smoke ducts often require replacement of masonry in places of destruction. Reinforced concrete structures used in industry require dismantling of the corroded area. If its thickness exceeds 3 cm, the sealing is carried out over a metal mesh in several layers. Metal structures may require degreasing, surface preparation and painting. If it is necessary to clean the surface 100%, strong acid solutions are used.

- Reviews

- Add a review

Chimney repair Reviews

Reviews: 2, Rating: 5.00

Andrey — 2019-10-19:

Rating: 5

Which pipe repair is easiest to carry out - one made of steel or brick and it is also interesting to know if there is some kind of scheduled inspection, if there is somewhere to find out the frequency. And how often is the chimney cleaned of soot or is it never cleaned at all?

Alexey Safonov - 2019-10-18:

Rating: 5

thanks for the article

Add a review

Services

Estimate documentation

The local estimate for the chimney is drawn up according to the “Methodology for determining the cost of construction products on the territory of the Russian Federation” - MDS 81 - 35.2004, put into effect on 03/09/2004...

more detailsChimney demolition

Before the start of demolition and dismantling of the chimney, a set of preparatory measures is carried out in accordance with paragraph 6.9 of SP 48.13330.2011.

The preparation of the territory and workplaces, warehousing, temporary tran… read moreOOS development

The purpose of developing the environmental protection section is to determine the impact of an existing or newly built boiler house, as well as after technical re-equipment, on environmental pollution, as well as to develop measures for ...

moreChimney installation

We provide quick and high-quality installation of boiler room chimneys of any type and height.

All work is carried out under the control of engineering and technical personnel, the work project and is accompanied by a warranty for a period... moreManufacturing

Chimneys are manufactured and installed according to individual projects, which include measures to ensure safe and durable operation.

We manufacture chimneys of various types: one... more detailsLight barrier

The light barrier is designed to warn aircraft of danger at night or in poor visibility.

Signal lights are installed on pipes on one or several tiers in height depending on the height of the building... moreAerodynamic calculation

Aerodynamic calculation determines the throughput of the structure at a minimum value.

The throughput must have such an indicator that will allow hot gases and other substances to freely pass through the chimney and escape into the atmosphere... moreStrength calculation

Optimal stability and strength are calculated taking into account several factors.

divided into two categories: -external (seismic activity, soil stability, amount and intensity of precipitation, wind rose); -operational (weight of the structure, number… more detailsDevelopment of QOL

KZh - working documentation for the manufacture of monolithic reinforced concrete structures at the construction site.

In the KZH section, all reinforcement components of reinforced concrete structures are studied in detail, dimensional drawings of the formwork, specifications of materials are provided... moreThermal insulation of chimney

Poor quality insulation or its complete absence leads to premature destruction of the gas outlet trunk.

There are several reasons that have a particularly strong impact on the integrity and functionality of the chimney. more detailsKM development

The company's experienced specialists are ready to develop design documentation for the CM stage (metal structures) in the shortest possible time.

We can develop both stage P (project), necessary for passing the examination, and stage P (working). more detailsKMD development

KMD design is carried out on the basis of KM calculations and represents the development of detail drawings of the designed metal structures.

This set of construction documentation is necessary for the manufacture of metal structures, t... more details

Manufactured by TsEEVT JSC

TsEEVT JSC has been successfully producing its own industrial gas ducts for boilers for more than 25 years. Heat exchange products are manufactured according to individual orders, in compliance with the working environment, technical requirements and customer wishes. Manufactured chimneys are installed at industrial facilities in Moscow, the Moscow region, the Far East, the Ural region, and the Siberian region.

Kunstkamera

Zhukovsky's blow in the chimneys

The boiler reached operating mode, that is, hot gases flowed through the pipe at the calculated flow rate, then the burner suddenly went out - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone.

The boiler was started in violation of the operating schedule, without pre-heating... more detailsPoor quality chimneys

Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg/m3 instead of 120 kg/m3 according to the project.

Photo 2. Absence of a condensate trap at the bottom of the vertical gas outlet of the boiler. Photo 3. Foreign objects on the diaphragm of the explosive... more detailsSmoke Leaning Tower of Pisa

Comments on the project The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated version of SNiP 2.09.03-85.” The use of this design solution (rigid struts in the form of a system of volumetric trusses) is… more details30 meters, Du-500, Du-400, ...

1. The adopted design solutions of the “KM” section do not comply with the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated edition of SNiP 2.09.03-85”: – the shape of the load-bearing exhaust lattice tower does not meet the requirements of paragraphs. 9.4.8, 9.4.11; ... more detailsDestruction of load-bearing belts...

The only reason that can cause tensile stresses in the wall located along the generatrix of the cylindrical surface is water.

When water turns into ice, it increases its volume by 9.05%. Ruptures of seamless pipes, as they look in the photo, are typical for damage caused by ... more details