Time does not stand still; instead of steel and cast iron, modern materials, especially plastic, are becoming increasingly popular. HDPE pipe is now most often used. The abbreviation HDPE stands for “low-density polyethylene”. Pipes made from this material are a durable and flexible plastic structure. The main advantages are lightness, durability, and the absence of the risk of corrosion and salt buildup.

Properties of HDPE

What is PND? This material is high-density polyethylene. It has an affordable price and is distributed everywhere. The international abbreviation looks like HDPE - stands for high density polyethylene (translated: high density polyethylene). The conditions for manufacturing the material are contained in its name - “low pressure”.

Polyethylene granules - raw materials for the production of HDPE pipes

The characteristics of PDN include its resistance to solvents at room temperature and chemical inertness. When placed in an alkaline or acidic solution, this polyethylene remains intact (with the exception of 50% nitric acid, chlorine and fluorine). The polymer density is 0.94-0.96 g/cm³. The color of the unpainted material is white, thin sheets are transparent.

Advantages:

- It can be used in the food industry for storing food and water. This material is absolutely harmless to people and animals.

- Low temperature resistance – can withstand -60°C and below.

- Plastic and durable.

- Chemically inert.

- Quite inexpensive to produce.

Disadvantages of polymer:

- Does not tolerate high temperatures well: at 70-80°C it loses strength.

- Not tolerant of ultraviolet radiation.

Features of the material, its advantages and disadvantages

The physical and chemical properties of HDPE material determine a number of its operational features that distinguish it favorably from most types of plastic, including, it would seem, from the related LDPE:

- The density of the molecular crystal lattice provides the material with high strength, elasticity and gas impermeability. It is resistant to external and internal pressure, stretching and temperature changes. These qualities make it possible to lay HDPE pipes underground without worrying about soil movements, which is why they are widely used in seismically active regions.

- The elasticity of the polymer allows it to be easily bent and, if necessary, to be installed without fittings, saving a considerable part of the budget for the purchase of connecting elements.

- The microporous structure makes the HDPE material lightweight, facilitating the delivery and installation of reinforcement. In addition, micropores absorb vibration noise created by water flow.

- Inert to most salts, acids and alkalis of both organic and inorganic origin and other chemicals. Interaction with water and oxygen does not provoke the oxidation process and does not trigger corrosive processes.

- Production technologies make it possible to achieve absolute smoothness of the surface, which improves the hydraulic capabilities of the line, and deposits do not accumulate inside and build-ups do not form.

- HDPE material is not susceptible to biological contamination; bacteria and fungi do not multiply in its structure and on the surface.

- Polyethylene belongs to the class of dielectrics, which means it is not capable of conducting electric current.

- The organic nature and absence of toxic substances in the material make it environmentally friendly and safe.

To make the picture complete, we cannot neglect the disadvantages of HDPE materials:

- The higher the density, the greater the load the material can withstand. However, at the same time, the crystal lattice becomes more fragile and susceptible to shock loads and extremely low temperatures.

- Ultraviolet rays also have a detrimental effect on the structure of the polymer, which dries out and cracks over time.

- Under the influence of high temperatures, HDPE plastic tends to soften, so the temperature regime of the carrier is usually limited to 40°C.

- Polyethylene is flammable and when burned, initially safe substances are transformed into toxic ones.

- If you install a HDPE pipeline taking into account all the shortcomings, the water supply network can last about 60-80 years trouble-free.

Application area

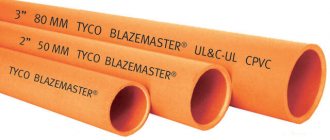

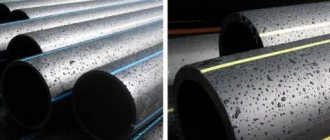

The gas pipe is marked with a yellow stripe.

Eighty years have passed since ethylene was first polymerized. This discovery has been widely used in various fields. Cheap and practical material with high density is used for industrial and domestic needs. It is made from:

- Containers and containers. These are containers for storing food products, plastic bottles, canisters, barrels, containers for transporting bulk materials. Large tanks for water storage and treatment facilities are also made from HDPE.

- Films for greenhouses, vapor and waterproofing, bubble; dense for packaging and thin for food products; tape and bags.

- Household and household items: buckets, boxes, pots, dishes, toys. Decorative details: accessories for furniture and tailoring. Interior elements - chairs, chests of drawers, tables, etc.

- Equipment for children's playgrounds.

- Boats, as well as cabinet products for small equipment, household appliances and equipment.

- Pipes and their connecting parts - for gas and water supply, drainage, sewerage, alkalis and acids, casing for drilling wells. They also produce pipes for aggressive environments in production. But low-density polyethylene is incompatible with solvents.

- Anti-corrosion coating for steel pipes. In particular, HDPE is used to make the outer lining of large-diameter oil pipelines (intended for transporting gas and oil products).

- Insulating material for wiring and equipment.

- Insulating material – foamed polyethylene foam (including foil).

- Adhesive (hot-melt adhesive).

Low pressure polyethylene pipe

Let's look at its pros and cons.

- Long service life. The only condition is the absence of ultraviolet radiation and extremely high pressure. The first introduced products have already been in use for fifty years.

- Durability . Pipes are capable of recovery after deformation and withstand hydraulic shocks.

- Plastic. The pipeline may have slight bends. When heated, the HDPE pipe can be bent up to 90 degrees. If water freezes inside, the pipe endures pressure, and after thawing it returns to its original shape.

- Easier to transport and install . The material is light in weight. The weight of the PDN pipe is 8 times less than its metal counterpart.

- Easy to assemble and install , mounted using connecting elements, butt or electrodiffusion welding, easy to cut or bend.

- Corrosion resistance . Plastic does not require constant processing and painting.

- Low level of surface adhesion - due to the smooth wall from the inside, magnesium and calcium salts are not deposited during use, which means the pipeline does not become clogged.

- Chemically inert material . The water in such pipes is not saturated with foreign tastes or odors, and their resistance to aggressive environments allows them to be used in production and in the petrochemical industry.

- Safety for consumers and environmental friendliness , because they can be recycled.

- It does not tolerate ultraviolet radiation well , so pipes made of low-density polyethylene are laid exclusively indoors or in the ground, but not in open areas.

- The need to maintain temperature conditions . The recommended limit for operating pipes without additives is from 0°C to +40°C. For a short period of time it can withstand heating up to +80°C. With intense overheating, long sections of the pipeline may “lead.”

- The need to withstand limited pressure , as a result of which the use of HDPE pipes is impossible in some areas of production. The permissible value is 2.0 MPa.

- Aesthetics : Color (bright blue or black stripes) is often inappropriate in indoor spaces.

Technical characteristics GOST 18599 2001

Weight

Estimated weight of 1 meter of PE32 pipe in kg

| Outer diameter (nominal), mm | ||||

| SDR 6.0 | SDR 9.0 | SDR 13.60 | SDR 21.0 | |

| Wall thickness Sst., mm | ||||

| 2,50 | 4,0 | 6,30 | 10,0 | |

| 160 | 8,13 | 5,61 | 3,77 | |

| 140 | 6,24 | 4,29 | 2,89 | |

| 125 | 6,90 | 4,96 | 3,42 | 2,29 |

| 110 | 5,34 | 3,84 | 2,66 | 1,78 |

| 90 | 3,58 | 2,59 | 1,80 | 1,19 |

| 75 | 2,48 | 1,79 | 1,25 | 0,831 |

| 63 | 1,75 | 1,27 | 0,885 | 0,582 |

| 50 | 1,10 | 0,798 | 0,552 | 0,376 |

| 40 | 0,713 | 0,511 | 0,358 | 0,249 |

| 32 | 0,459 | 0,329 | 0,233 | 0,197 |

| 25 | 0,280 | 0,201 | 0,151 | |

| 20 | 0,182 | 0,134 | ||

| 16 | 0,116 | 0,92 | ||

| 12 | 0,065 | |||

| 10 | 0,052 | |||

Estimated weight of 1 meter of PE80, PE63, PE100 pipe in kg

| Outer diameter (nominal), mm | |||||||

| SDR6 | SDR7.4 | SDR13.6 | SDR17.6 | SDR21 | SDR 33.0 | SDR41 | |

| Wall thickness Sst., mm | |||||||

| 2,50 | 3,20 | 6,30 | 8,30 | 10,0 | 16,0 | 20,0 | |

| 1600 | 239 | 193 | |||||

| 1400 | 280 | 183 | 148 | ||||

| 1200 | 242 | 206 | 134 | 108 | |||

| 1000 | 214 | 168 | 143 | 93,5 | 75,4 | ||

| 900 | 173 | 136 | 116 | 75,9 | 60,9 | ||

| 800 | 137 | 108 | 91,4 | 59,9 | 48,3 | ||

| 710 | 108 | 84,7 | 72,1 | 47,3 | 38,1 | ||

| 630 | 84,8 | 66,6 | 56,6 | 37,1 | 29,9 | ||

| 560 | 67,1 | 52,6 | 44,8 | 29,4 | 23,6 | ||

| 500 | 92,1 | 53,5 | 42,0 | 35,8 | 23,5 | 19 | |

| 450 | 46,6 | 43,3 | 34,0 | 29,0 | 19,0 | 15,2 | |

| 400 | 69,0 | 59,0 | 34,2 | 26,9 | 22,9 | 15,1 | 12,1 |

| 355 | 54,4 | 46,4 | 27,0 | 21,2 | 18,0 | 11,8 | 9,53 |

| 315 | 42,8 | 36,6 | 21,3 | 16,7 | 14,2 | 9,35 | 7,49 |

| 280 | 33,9 | 28,9 | 16,8 | 13,2 | 11,3 | 7,38 | 5,96 |

| 250 | 27,0 | 23,1 | 13,4 | 10,6 | 8,91 | 5,9 | 4,81 |

| 225 | 21,9 | 18,7 | 10,9 | 8,55 | 7,29 | 4,76 | 3,84 |

| 200 | 17,3 | 14,8 | 8,56 | 6,78 | 5,77 | 3,82 | 3,3 |

| 180 | 14,0 | 12,0 | 6,98 | 5,71 | 5,47 | 3,78 | 2,47 |

| 160 | 11,1 | 9,46 | 5,5 | 4,35 | 3,71 | 2,41 | 1,98 |

| 140 | 8,49 | 7,27 | 4,22 | 3,35 | 2,83 | 1,87 | 1,53 |

| 125 | 6,77 | 5,78 | 3,37 | 2,66 | 2,26 | 1,5 | 1,25 |

| 110 | 5,25 | 4,49 | 2,61 | 2,07 | 1,77 | 1,16 | 0,93 |

| 90 | 3,52 | 3,00 | 1,76 | 1,40 | 1,18 | 0,782 | 0,63 |

| 75 | 2,45 | 2,09 | 1,23 | 0,97 | 0,821 | 0,543 | 0,469 |

| 63 | 1,73 | 1,47 | 0,869 | 0,682 | 0,573 | 0,392 | |

| 50 | 1,47 | 0,935 | 0,545 | 0,436 | 0.369 | ||

| 40 | 0,701 | 0,60 | 0,353 | 0,281 | 0,244 | ||

| 32 | 0,453 | 0,385 | 0,229 | ||||

| 25 | 0,277 | 0,24 | 0,148 | ||||

| 20 | 0,180 | 0,162 | |||||

| 16 | 0,115 | 0,102 | |||||

| 12 | 0,064 | ||||||

| 10 | 0,051 | ||||||

size table

| SDR 26 | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | ||||||

| PE 80 | PN 5 | PN 6.3 | PN 8 | PN 10 | PN 12.5 | |||||

| PE 100 | PN 6.3 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||

| Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg | Wall thickness, mm | Weight 1 m, kg | Wall thickness, mm | Weight 1 m, kg | Wall thickness, mm | Weight 1 m, kg | Wall thickness, mm | Weight 1 m, kg |

| 20 | 2,0 | 0,116 | ||||||||

| 25 | 2,0 | 0,148 | 2,3 | 0,169 | ||||||

| 32 | 2,0 | 0,193 | 2,4 | 0,229 | 3,0 | 0,277 | ||||

| 40 | 2,0 | 0,244 | 2,4 | 0,292 | 3,0 | 0,353 | 3,7 | 0,427 | ||

| 50 | 2,0 | 0,308 | 2,4 | 0,369 | 3,0 | 0,449 | 3,7 | 0,545 | 4,6 | 0,663 |

| 63 | 2,5 | 0,488 | 3,0 | 0,573 | 3,8 | 0,715 | 4,7 | 0,869 | 5,8 | 1,05 |

| 75 | 2,9 | 0,668 | 3,6 | 0,821 | 4,5 | 1,01 | 5,6 | 1,23 | 6,8 | 1,46 |

| 90 | 3,5 | 0,969 | 4,3 | 1,180 | 5,4 | 1,45 | 6,7 | 1,76 | 8,2 | 2,12 |

| 110 | 4,2 | 1,420 | 5,3 | 1,770 | 6,6 | 2,16 | 8,1 | 2,61 | 10,0 | 3,14 |

| 125 | 4,8 | 1,830 | 6,0 | 2,260 | 7,4 | 2,75 | 9,2 | 3,37 | 11,4 | 4,08 |

| 140 | 5,4 | 2,310 | 6,7 | 2,830 | 8,3 | 3,46 | 10,3 | 4,22 | 12,7 | 5,08 |

| 160 | 6,2 | 3,030 | 7,7 | 3,710 | 9,5 | 4,51 | 11,8 | 5,50 | 14,6 | 6,67 |

| 180 | 6,9 | 3,780 | 8,6 | 4,660 | 10,7 | 5,71 | 13,3 | 6,98 | 16,4 | 8,43 |

| 200 | 7,7 | 4,680 | 9,6 | 5,770 | 11,9 | 7,04 | 14,7 | 8,56 | 18,2 | 10,4 |

| 225 | 8,6 | 5,880 | 10,8 | 7,290 | 13,4 | 8,94 | 16,6 | 10,9 | 20,5 | 13,2 |

| 250 | 9,6 | 7,290 | 11,9 | 8,920 | 14,8 | 11,0 | 18,4 | 13,4 | 22,7 | 16,2 |

| 280 | 10,7 | 9,090 | 13,4 | 11,300 | 16,6 | 13,8 | 20,6 | 16,8 | 25,4 | 20,3 |

| 315 | 12,1 | 11,600 | 15,0 | 14,200 | 18,7 | 17,4 | 23,2 | 21,3 | 28,6 | 25,7 |

| 355 | 13,6 | 14,600 | 16,9 | 18,000 | 21,1 | 22,2 | 26,1 | 27,0 | 32,2 | 32,6 |

| 400 | 15,3 | 18,600 | 19,1 | 22,900 | 23,7 | 28,0 | 29,4 | 34,2 | 36,3 | 41,4 |

| 450 | 17,2 | 23,500 | 21,5 | 29,000 | 26,7 | 35,5 | 33,1 | 43,3 | 40,9 | 52,4 |

| 500 | 19,1 | 29,000 | 23,9 | 35,800 | 29,7 | 43,9 | 36,8 | 53,5 | 45,4 | 64,7 |

| 560 | 21,4 | 36,300 | 26,7 | 44,800 | 33,2 | 55,0 | 41,2 | 67,1 | 50,8 | 81,0 |

| 630 | 24,1 | 46,000 | 30,0 | 56,500 | 37,4 | 69,6 | 46,3 | 84,8 | 57,2 | 103,00 |

| 710 | 27,2 | 58,500 | 33,9 | 72,100 | 42,1 | 88,4 | 52,2 | 108,00 | 64,5 | 131,00 |

| 800 | 30,6 | 74,100 | 38,1 | 91,400 | 47,4 | 112,0 | 58,8 | 137,0 | 72,6 | 166,00 |

| 900 | 34,4 | 93,800 | 42,9 | 116,000 | 53,3 | 142,0 | 66,1 | 173,00 | ||

| 1000 | 38,2 | 116,000 | 47,7 | 143,000 | 59,3 | 175,0 | 73,5 | 214,00 | ||

| 1200 | 45,9 | 167,000 | 57,2 | 206,000 | 71,1 | 252,0 | ||||

The file with the complete document of the interstate standard is here >>>

HDPE pipes ∅ up to 110 mm are supplied in coils and in sections of 12 meters.

Pipes with a diameter of more than 110 mm are supplied only in 12-meter lengths.

Coil diameter table

| HDPE pipe diameter, mm | Coil length, m | Overall dimensions, m |

| 32 | 100 | 1,2 |

| 40 | 100 | 1,4 |

| 50 | 100 | 1,5 |

| 63 | 100 | 2 |

| 75 | 100 | 2,2 |

| 75 | 50 | 1,9 |

| 90 | 100 | 2,7 |

| 90 | 50 | 2,5 |

| 110 | 100 | 3 |

| 110 | 50 | 2,8 |

What does SDR mean?

If we look at the dry decoding, the abbreviation SDR comes from the English Standard Dimension Ratio , which means standard dimensional ratio. Its essence comes down to the ratio of the diameter to the pipe wall. This value is determined not only by the thickness of the polymer layer, but also by the ability of the product to withstand internal and external loads.

SDR by inverse proportions: the higher the index, the thinner the wall. Therefore, products of the same size group, but with different SDR , have different intended uses. For example:

- SDR 13.6 – have high strength and are therefore suitable for capital water supply systems.

- SDR 17 - pipes with an average rating, which are used in low-rise construction.

- SDR 21 – not suitable for pressure systems and underground communications.

Note: in all three cases, we are talking about PE 80 .

| SDR 41 | SDR 33 | SDR 26 | SDR 21 | SDR 17,6 | SDR 17 | SDR 13,6 | SDR 11 | SDR 9 | SDR 7,4 | SDR 6 |

| 4 atm. | 4 atm. | 5 atm. | 6 atm. | 7 atm. | 8 atm. | 10 atm. | 12 atm. | 16 atm. | 20 atm. | 25 atm. |

Marking

Pipes must be marked. In this case, the maximum permissible interval of inscriptions is 1 meter. Identification labels contain the following information:

- manufacturer's name;

- designation of manufacturing standard;

- international name of the product brand (for example, PE-63, PE-100, PE-80);

- dimensions: external diameter, as well as wall thickness (in mm);

- pressure recommended for work;

- date of manufacture;

- batch number.

HDPE pipe marking. Blue stripe - water pipe

Marking with colored stripes

In order to easily recognize the purpose of pipes, they are usually painted in certain colors, namely:

- products intended for gas supply are usually black with a yellow stripe, sometimes just yellow;

- for technical purposes – black (without stripes);

- for drinking water - blue or black with a blue stripe;

- for drainage - green;

- for sewerage - gray, white or black;

- intended for installation of external sewage systems are usually bright red in color;

- casings of electrical cables (corrugated products) are red.

Types and varieties of low-density polyethylene pipes

By purpose:

- As a cold water supply . For this, blue pipes are used in basements (wiring) or underground. Mostly smooth structures are used. If the diameter is large, the elements are connected by welding, if small - fittings. However, these products are not used indoors.

- for installing drainage systems .

- When constructing pressure sewer systems, black pipes for technical purposes are used, which are installed using connecting elements or welding. If free-flow sewerage is assumed, socket-shaped products are used. Each subsequent element in such a design is inserted into the socket of the previous one. The sealant is a rubber seal. When the depth is sufficiently large, a two-layer corrugation with sockets is used.

- For electrical cables , Internet and communication lines, as well as sewer systems, corrugated or smooth red and black pipes are used.

- In order to protect the well from soil shedding, pipes made of low-density polyethylene are installed. At the same time, the depth of the aquifer can reach 50 m. A pump is placed in the well to draw water. There are restrictions for HDPE products: seismic hazard or threat of landslides.

- Industrial technological networks use corrugated or smooth black pipes for technical purposes.

When laying pipelines, the following grades of material are used: PE-100 with a maximum permissible pressure of 1.25 MPa, PE-80 with an indicator of 1.6 MPa, PE-63 - maximum pressure of 1.0 MPa.

Pipe Strength Ratio (SDR)

SDR is an abbreviation for Standard Dimension Ratio, translated as standard dimensional ratio. It is a method for assessing pipe strength as a function of pressure. It is defined as the ratio between the outer diameter and wall thickness (according to GOST 18599-2001). This indicator is a standard value.

Kinds

non-pressure and pressure pipes . Non-pressure ones are used in gravity sewer and drainage systems, as well as to protect cables when laid underground and under water.

The polyethylene grades PE63, PE80 and PE100 differ in the structure of their macromolecules. PE63 has low resistance to cracking, PE80 is more resistant, PE100 has high resistance to crack propagation. The use of PE80 and PE100 contributes to a significant reduction in wall thickness compared to PE63 and significantly reduces the cost of feedstock. Pressure pipes PE100 and PE80 can withstand high pressure and are used for the construction of pressure sewer systems and product pipelines for transporting technical liquids with which polyethylene does not interact.

How to choose the right HDPE pipe

In order for the choice to meet your goals, you need to decide in which area the products will be used, and also consider operating parameters: depth in the ground, temperature conditions, aggressiveness of the environment.

For example, if you plan to install a water supply system, only HDPE pipes with a blue stripe are suitable. The fact is that they are made from virgin polyethylene and are completely harmless to both animals and humans. The use of black technical pipes not marked with colored stripes for these purposes is strictly prohibited, since they are made from recycled materials, which means that harmful substances can be released into the water.

When sewerage is carried out, socket elements are used, drainage - perforated structures. In this case, it is worth considering the load on the product. It depends on the depth or thickness of the concrete screed above them. If the load level is high (for example, when the layer of earth above the communication exceeds one and a half meters, there is a massive screed or rocky soil), it is advisable to use two-layer corrugated pipes.

Smooth structures are suitable for casing structures, electrical cables, information communications, and pipelines.

It is recommended to use pipes of a color that corresponds to the intended purpose in any work. Then, in case of repair, it will be easy to determine the necessary communication, and when buried in the ground, the bright color of the structure will be easy to detect.

What does the abbreviation mean?

These letters indicate the type of material from which the pipes are made. HDPE pipes can also be deciphered by technical variety. There are two positions that differ from each other in color:

- Longitudinal yellow (along the entire pipe) indicates that the material is intended for the construction of a gas pipeline.

- The blue stripe indicates that the pipes can be used in plumbing installations.

GOST products 18599-2001. If such marking is present on the pipe, this indicates that the product is manufactured in accordance with the requirements of the technology, will serve the specified period, and meets all its inherent characteristics.

How to connect

Electric welded HDPE fittings have built-in heating elements for welding with pipes

The appropriate connection method is determined by the diameter of the products and the location.

- If the diameter does not exceed 315 mm, polyethylene compression fittings are used.

- Bell-shaped casing and drainage pipes are inserted into each other.

- If the wall is thicker than 5 mm, welding is possible.

- If it is necessary to install a large-diameter pipeline, the most suitable option is welding thermistor couplings. This connection method is the most expensive, but also the most reliable.

A short video lesson on connecting HDPE pipes

DIY installation features

Comparing the costs of installing a steel and HDPE pipeline, the latter allows you to save up to 40% of the family budget, primarily due to the ability to do the work yourself and without the use of expensive equipment.

The use of polyethylene pipes is also relevant in cases where it is necessary to replace an old water supply system. The flexibility of the products makes it possible to simply stretch them inside the failed pipeline, which will also provide additional protection for the new pipeline.

Rules for installing polyethylene water supply

By adhering to a few simple rules, you can easily arrange a water supply circuit from HDPE pipes yourself:

- Before starting work, it is necessary to create a design diagram of the future water main. It will help you determine the required quantity and size of pipe material and fittings.

- When laying a pipeline in the ground, a trench should be prepared in advance:

- It is advisable to place the depth of the ditch below the soil freezing level, otherwise thorough insulation of the main along its entire length will be required.

- The width of the trench should be 4 cm greater than the diameter of the pipe: 2 cm on each side.

- At the bottom of the ditch, a drainage “cushion” of sand or a mixture of sand and gravel is installed and compacted with a layer of 10-20 cm.

- The soil in direct contact with the pipeline must be cleared of objects that pose a potential risk of damage.

- To reduce the load exerted by the thickness of the earth on the highway, it is advisable to use a protective box that will combine the functions of protection and insulation.

- When laying a polyethylene pipeline on the surface, it should be protected from harmful ultraviolet radiation. Insulation will also extend its service life.

- If it is necessary to bend a rigid pipe, the latter must be preheated using a hair dryer.