We recommend that you read

- Chimney repair

- Stainless steel chimneys

- Boiler chimney

- Steel chimneys

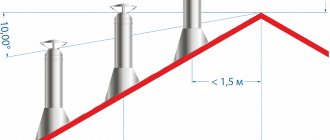

- Chimney height

- Chimney sandwich

- Metal chimneys

- Chimney cable stays

- Chimney masts

- Chimneys for boiler rooms

- How to calculate a chimney

- Typical designs and drawings of chimneys

- Industrial chimneys

- Chimney calculation

- Design of industrial chimneys

To ensure efficient combustion of fuel during the operation of the boiler room, it is important to ensure the supply of fresh air flows into the boiler firebox, as well as the removal of flue gases and their release into the atmosphere. If existing requirements and established standards are violated, the efficiency of an operating boiler room can be significantly reduced, fuel consumption increased, thereby reducing the efficiency of the heating system as a whole.

The importance of correct calculation

A chimney is a device that is necessarily included in the boiler equipment set. With its help, not only the efficient operation of the chimney is ensured, but also the protection of the surrounding atmosphere from harmful emissions. Correctly selected chimney height allows minimizing the harmful effects of emissions on the human body during boiler room operation.

Aerodynamic calculation of the chimney is performed by specialists of our company. You can also make all the necessary calculations and get ready-made measurement results using an online calculator.

Features of aerodynamic calculations

We will calculate aerodynamics quickly and with perfect accuracy. For this purpose, the company has selected experienced, highly qualified engineers with extensive practical experience. During the calculation process, the following main nuances will be taken into account:

- The characteristics of the boiler are taken into account (power, productivity, dimensions, etc.).

- Calculations are made of the required strength and durability of the chimney.

- The optimal (minimum) height of the smoke exhaust pipe is determined, taking into account the volume of fuel burned, as well as the type of draft used (natural or forced) of smoke.

- Calculations of turbulator parameters.

- Determination of the permissible operating load on the boiler room.

- At the last stage, a drawing of the chimney is created with optimization of the sections.

Aerodynamic calculations are necessary to determine the height of the pipe in the case of using natural draft. Then you should also calculate the rate of spread of emissions, which depends on the topography of the territory, the temperature of the gas flow, and air speed.

Aerodynamic calculation of the gas path

The purpose of the aerodynamic calculation of the gas path of a boiler installation is to select the necessary smoke exhausters based on determining the performance of the traction system and the total pressure drop in the gas path. Determine design data for the design of gas ducts.

Construct gas ducts in the section of the gas path, from the exit from the boiler to the exit from the chimney:

— Calculation of the aerodynamic resistance of the gas path section within the boiler;

— Selection of an ash collector and assessment of its aerodynamic resistance;

— Layout of the gas path from the boiler outlet to the ash catcher and calculation of its aerodynamic resistance;

— Preliminary selection of a smoke exhauster;

— Layout of the gas path from the exit from the ash catcher to the entrance to the smoke exhauster and calculation of its aerodynamic resistance;

— Layout of the gas path from the outlet of the smoke exhauster to the outlet of the chimney and calculation of the height of the chimney;

— Calculation of gas path gravity;

— Calculation of the total pressure drop along the gas path. The final choice of smoke exhauster;

— Checking the absence of pressure behind the smoke exhauster;

— Determination of the efficiency of the smoke exhauster. Calculation of the power of the smoke exhauster drive motor; The purpose of the aerodynamic calculation of a boiler installation (calculation of draft and blast) is to select the necessary draft machines based on determining the performance of the draft and blast system and the total pressure difference in the gas and air paths. In addition, during the calculation, the elements and sections of the gas-air path are optimized, ensuring minimal estimated costs, and calculation data for the design of gas-air pipelines are determined.

Preliminary selection of smoke exhauster (DS)

The smoke exhauster is selected according to the performance of the smoke exhauster and the resistance of the three sections. We multiply the performance by the safety factor and pre-select a smoke exhauster. We determine the vacuum at the outlet of the furnace, necessary to prevent the knocking out of gases, the reduced gravity in the lower convective shaft at one meter in height, and the gravity in the area of the lower convective shaft. Total gravity of the tract Hck= , mm water. Art. If the value is minus, then this indicates the direction of flow is downward, i.e. gravity is negative, if positive, then the direction of flow is upward, i.e. gravity is positive. Afterwards, the total pressure along the gas path is determined taking into account the safety factor. According to the summary graph of the characteristics of centrifugal smoke exhausters with double suction, we select a smoke exhauster. Layout of the gas path from the outlet of the smoke exhauster to the outlet of the chimney and calculation of the height of the chimney.

Calculation of gravity gas path

The static pressure in the discharge path must be negative (i.e. there must be a vacuum). The vacuum value is at least 2 mm water. Art. If this condition is not met, the gas pipeline must be constructed taking into account the pressure in it, i.e. in gas-tight design (made of steel). Calculation of the power of the smoke exhauster drive motor. For this you need: efficiency of the smoke exhauster, gas compressibility coefficient, power consumed by the smoke exhauster, power reserve factor, design engine power.

Necessary data for aerodynamic calculation of a chimney

- Information about the location of the boiler room:

- free-standing (in a building, in a container);

- attached;

- built-in

- roof

- Chimney height (if environmental calculations have been carried out).

- Characteristics of the design of the chimney (single-barrel load-bearing pipe - with or without guys, single-barrel or multi-barrel with a support mast or external load-bearing pipe, stainless steel chimney, other options).

- Characteristics of the design of the “trunk” of the chimney:

- internal diameter of the “trunk”;

- thickness and material of the “trunk” wall;

- thickness and material of thermal insulation of the “trunk”

- Number of boilers.

- Boiler data:

- manufacturer;

- name and type;

- type of fuel (indicating the dew point temperature, °C);

- rated capacity, kW;

- thermal power of the firebox, kW;

- CO2% content;

- mass (or volumetric) flow of exhaust gas, g/sec;

- exhaust gas temperature, °C;

- diameter (internal) of the boiler pipe (and wall thickness of the pipe) of the boiler, mm.

- Connection diagram of the connecting sections (from the branch pipe of each boiler) to the chimney (indicate the thickness of the walls and ceilings at the places where the connecting sections and the chimney trunk pass.

- Geometric parameters of the connecting sections (from the pipe of each boiler to the chimney):

- internal diameter of each connecting section, mm;

- total extended length of each connecting section, m;

- “extended” length of the street part of each connecting section, m.

- Availability (indication of the manufacturer and characteristics) of explosion valves, noise suppressors, draft regulators, dampers, adapters, nozzles at the “mouth” of the chimney (trunk).

- Location of the boiler room and its geodetic height, m.

- The greatest height (exceeding the height of the pipe) and width of nearby (within a radius of 50 meters) buildings.

- Reviews

- Add a review

No reviews.

Add a review

Calculation of chimney height (DT)

The height of the chimney is calculated according to the maximum permissible emission concentration (MPC), depending on the fuel used.

Checking for excess static pressure in the chimney:

If R>1, then the pipe is under excess pressure.

In order for the pipe to be under vacuum, it is necessary to change its design in two ways. The first is to install a diffuser at the outlet of the chimney. The second is an increase in the outlet diameter of the pipe, which leads to a decrease in the speed of flue gases at the outlet of the pipe and a decrease in the dynamic resistance of the pipe.

Services

Estimate documentation

The local estimate for the chimney is drawn up according to the “Methodology for determining the cost of construction products on the territory of the Russian Federation” - MDS 81 - 35.2004, put into effect on 03/09/2004...

more detailsChimney demolition

Before the start of demolition and dismantling of the chimney, a set of preparatory measures is carried out in accordance with paragraph 6.9 of SP 48.13330.2011.

The preparation of the territory and workplaces, warehousing, temporary tran… read moreOOS development

The purpose of developing the environmental protection section is to determine the impact of an existing or newly built boiler house, as well as after technical re-equipment, on environmental pollution, as well as to develop measures for ...

moreChimney installation

We provide quick and high-quality installation of boiler room chimneys of any type and height.

All work is carried out under the control of engineering and technical personnel, the work project and is accompanied by a warranty for a period... moreManufacturing

Chimneys are manufactured and installed according to individual projects, which include measures to ensure safe and durable operation.

We manufacture chimneys of various types: one... more detailsLight barrier

The light barrier is designed to warn aircraft of danger at night or in poor visibility.

Signal lights are installed on pipes on one or several tiers in height depending on the height of the building... moreAerodynamic calculation

Aerodynamic calculation determines the throughput of the structure at a minimum value.

The throughput must have such an indicator that will allow hot gases and other substances to freely pass through the chimney and escape into the atmosphere... moreStrength calculation

Optimal stability and strength are calculated taking into account several factors.

divided into two categories: -external (seismic activity, soil stability, amount and intensity of precipitation, wind rose); -operational (weight of the structure, number… more detailsDevelopment of QOL

KZh - working documentation for the manufacture of monolithic reinforced concrete structures at the construction site.

In the KZH section, all reinforcement components of reinforced concrete structures are studied in detail, dimensional drawings of the formwork, specifications of materials are provided... moreThermal insulation of chimney

Poor quality insulation or its complete absence leads to premature destruction of the gas outlet trunk.

There are several reasons that have a particularly strong impact on the integrity and functionality of the chimney. more detailsKM development

The company's experienced specialists are ready to develop design documentation for the CM stage (metal structures) in the shortest possible time.

We can develop both stage P (project), necessary for passing the examination, and stage P (working). more detailsKMD development

KMD design is carried out on the basis of KM calculations and represents the development of detail drawings of the designed metal structures.

This set of construction documentation is necessary for the manufacture of metal structures, t... more details

Kunstkamera

Zhukovsky's blow in the chimneys

The boiler reached operating mode, that is, hot gases flowed through the pipe at the calculated flow rate, then the burner suddenly went out - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone.

The boiler was started in violation of the operating schedule, without pre-heating... more detailsPoor quality chimneys

Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg/m3 instead of 120 kg/m3 according to the project.

Photo 2. Absence of a condensate trap at the bottom of the vertical gas outlet of the boiler. Photo 3. Foreign objects on the diaphragm of the explosive... more detailsSmoke Leaning Tower of Pisa

Comments on the project The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated version of SNiP 2.09.03-85.” The use of this design solution (rigid struts in the form of a system of volumetric trusses) is… more details30 meters, Du-500, Du-400, ...

1. The adopted design solutions of the “KM” section do not comply with the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated edition of SNiP 2.09.03-85”: – the shape of the load-bearing exhaust lattice tower does not meet the requirements of paragraphs. 9.4.8, 9.4.11; ... more detailsDestruction of load-bearing belts...

The only reason that can cause tensile stresses in the wall located along the generatrix of the cylindrical surface is water.

When water turns into ice, it increases its volume by 9.05%. Ruptures of seamless pipes, as they look in the photo, are typical for damage caused by ... more details

Why is a chimney calculation required?

Calculation of a chimney for a stove, boiler, fireplace or other heating equipment is necessary for:

- ensuring proper draft, with the help of which all substances harmful to human health formed as a result of combustion are removed outside the living space. If unacceptable substances enter the house, a person may receive severe poisoning that can be fatal;

Backdraft in the chimney, which can cause harm to health

- optimizing the heat received in relation to the fuel consumed. If most of the heated air goes out into the chimney, then more firewood will be required to warm the room. With the correct ratio of fuel and heat received, the heated air will maximally heat the walls of the stove and the chimney duct, which will reduce the resources expended;

- chimney calculations are also required to ensure maximum fire safety. Highly heated air coming out of the smoke duct or low draft can cause sparks to hit flammable surfaces, which will inevitably lead to a fire.

Heating device with a correctly designed and installed chimney

Carrying out calculations of pipe parameters will not only save on fuel resources, but also ensure a comfortable and safe stay for people in a residential area.