Thanks to the zinc coating, galvanized pipes have increased durability and resistance to corrosion compared to ferrous metal products. The range of products made of ferrous metals and with a zinc layer is identical. Galvanized steel is widely used in water supply, heat supply, gas supply, construction, installation of outdoor advertising, and traffic signs.

Galvanized pipes are highly resistant to corrosion and are used on a wide variety of construction sites

Welding technologies for galvanized products

Technologists offer several ways to solve the problem of welding galvanized pipes:

- preliminary removal of the protective coating and its subsequent restoration;

- reduction of welding temperature;

- reduction of welding time;

- preventing zinc evaporation by using flux.

Cleaning of the work area is carried out either mechanically or chemically. In the first case, use a grinder with a metal brush or an abrasive wheel. Here it is difficult to control the locality of protection removal. Chemical removal of galvanization is carried out by treating the joint with a solution of hydrochloric acid. It is applied carefully, in small portions, without damaging the base metal.

Standard service life of steel pipes according to GOST

One of the important characteristics of the product is, among other things, the period of operation. Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of different grades is used in production, but it is not corrosion resistant. Such rolled metal products require additional protection - painting, for example;

- galvanized steel pipes - products are coated with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. Obviously, the service life according to SNiP and GOST for such a model is much longer;

- stainless steel – alloys with the addition of nickel and chromium. Depending on the size of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows use in sea water, for example, and also does not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rare, but used in domestic conditions. They are distinguished not only by their resistance to corrosion, but also by their disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will vary.

Alas, this option is not particularly durable. Even with the most careful painting and care, they will rust over time. The fact is that after the construction of communications, individual fragments turn out to be inaccessible, and it turns out to be impossible to update the paint, for example.

In addition, black steel loses its smoothness quite quickly. And this leads to the fact that the water-gas or heating pipe “overgrows” quite quickly: first very small debris and salt deposits are retained on the unsmooth surface, and then increasingly larger particles of rust, fibers, and lime deposits. The rate of sediment accumulation is directly proportional to water hardness.

Standard operating times are:

- the service life of steel water pipes - riser or liner - is 15 years;

- the heating system assembled from gas steel pipes is suitable for use for 10 years;

- heated towel rails in the bathroom can “work” for 15 years;

- According to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

In fact, destructive factors of various kinds significantly reduce the operating time. For example, a pipeline with cold water wears out much faster than with hot water, since it rusts faster: condensation appears in the warm season. And the pipeline overgrows faster, since hot water contains special additives that prevent this.

Cink Steel

This material is much more resistant to corrosion, which significantly extends the standard time. The most significant destructive factor here is only the welded connection, if for some unknown reason the installation is carried out by welding. The photo shows water and gas steel pipes.

In fact, this installation method is prohibited: the zinc completely burns out during welding, and accordingly, the seams remain completely defenseless against rust.

Galvanized steel products overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, there is much less “garbage” itself - particles of rust, scale, sand. But if the taps in the plumbing system are not fully opened and there is not a sufficiently dense flow of water, scale and sand can accumulate.

The service life of the product according to GOST is as follows:

- risers and connections in cold water supply systems are in use for 30 years;

- the service life of steel heating pipes in a house with a closed system is 20 years;

- an open heating system will last 30 years.

It is allowed to construct a gas pipeline from galvanized pipes. But there is still a nuance: unlike plumbing systems, the gas pipeline must be one-piece, which requires welding. And the connection destroys zinc at the junction. On the other hand, gas pipelines, like water pipelines, are coated with polymer paint, which prevents corrosion.

In fact, galvanized steel pipes for both water supply and heating last 50–70 years.

Types of pipes and their scope

Classification of profile pipes with a protective zinc coating can be made according to the following criteria:

- manufacturing method;

- section shape;

- overall dimensions;

- wall thickness.

Manufacturing methods and their advantages

Depending on the manufacturing method, profile galvanized pipes are manufactured:

welded. Pipes made by welding have a reduced wall thickness, but at the same time a smaller margin of safety. They are mainly used for the manufacture of decorative partitions, benches, and small greenhouses;

Profile pipes made by welding

seamless. They are characterized by higher strength, since there is no weak point - the weld. The scope of application starts from the construction of building frames and ends with the manufacture of small items.

Durable profile pipes with protective coating

In turn, seamless pipes are divided into the following subgroups:

- cold-formed. Profile pipes produced by this method are distinguished by the accuracy of the stated dimensions, the ability to withstand water hammer, negative temperatures, temperature changes, and the ability to bend independently;

- hot-deformed. They are distinguished by their strength, including resistance to earth vibrations, resistance to mechanical damage, water hammer, pressure drops, etc., as well as increased wall thickness. This method of production does not allow strictly observing the dimensions of the products, so they may differ by 3 - 5 mm from the declared ones in a larger direction.

Scope of application of cold-deformed pipes:

- production of furniture frames;

- construction of lamps;

- construction of various pipelines;

- organization of operation of boiler installations;

- mechanical engineering;

- oil and gas industry.

Garden furniture made of profile pipes

Hot-formed pipes are used:

- in construction. From them you can build the frame of a building, gazebo, garage and other premises;

- during the construction of heating mains and domestic heating;

- in the gas, chemical and oil industries.

Frame of a residential building made of profile hot-deformed pipes

Varieties of wall thickness

Various manufacturing methods allow you to obtain:

- thick-walled profile pipes;

- thin-walled pipes.

The greater the thickness of the pipe wall, the greater the load the product can withstand.

Thanks to this pattern, the scope of application of pipes with different wall thicknesses is determined:

- thin-walled ones are widely used in the construction of gazebos, fences, furniture, the construction of a roof, a frame for a greenhouse and so on, that is, where there are no significant loads;

- from thick-walled ones you can build a garage, a house, and so on, that is, those structures that will bear a large load.

Types of section

For the construction of various structures, profile pipes of different sections are produced:

- rectangular;

- oval;

- square;

- round.

Fences, frames, gates, and so on are made from pipes with corners (square, rectangular). Oval and round pipes are mainly used in mechanical engineering, as well as for laying pipelines.

Range of pipes of different sections

Pipe sizes are determined according to the following GOST standards:

- square pipes (GOST 8639-62) are produced with an outer diameter from 10 mm to 180 mm, while the thickness of the pipe wall can vary from 0.8 mm to 14 mm. The most popular sizes used in private construction are 20x20 pipes (for additional elements) and 40x40 pipes (for the manufacture of main load-bearing structural elements). The length can be measured (set by the manufacturer) or unmeasured, determined by the consumer’s order;

Shape and most popular sizes of square pipes

- rectangular pipes (GOST 8645-68) are also available in standard sizes, measured or unmeasured lengths;

Sample shape and range of rectangular pipes

- oval pipes are also produced in accordance with GOST under the number 8642-68. Diameters can vary from 3x6 mm to 90x32 mm, while the wall thickness of the oval pipe can be 0.5 - 2.5 mm.

Shape and dimensions of oval pipes

You can watch the video about the production and use of profile pipes.

All the main parameters of profile pipes with a protective coating are indicated on the marking, which is applied directly to the product (if it is large in diameter) or is available in the accompanying documentation. From the markings you can find out the size and shape, details of the document in accordance with which the pipe was made and the manufacturing method, which is quite enough for independent selection.

Installation

The standards provide for high requirements for the tightness of structures to prevent losses of transported compounds.

Recommended methods for installing galvanized steel pipes using:

- couplings;

- threaded connections;

- welding machine.

Fastening elements using couplings does not require the use of special equipment (soldering iron, welding). The method is based on a locking connection of elements; the inner surface of the coupling is fixed to the pipe. For reliability, the coupling is combined with a threaded connection. The method allows for prompt repairs and reconstruction. Disassembly is carried out using a wrench. In fire pipelines operating under high pressure, only a coupling connection is allowed.

The thread is applied to the outer surface of the pipeline by machining or using a die. A coupling with a thread of 2-3 turns is secured on top of the pipe. The threaded connection is technically complex and has a high price.

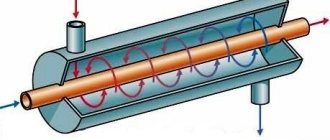

A common method for installing galvanized elements is electric welding. Work is carried out in ventilated areas. The joints must be degreased. Under the influence of the elevated temperature of the arc, zinc is converted into a gaseous state, ensuring a tight joining of the elements. After welding, the heat-affected area is cleared of zinc to prevent the formation of cracks during cooling.

When welding thin-walled products (up to 5 mm), copper overlay rings are used. The attachments are removed after work, maintaining the integrity of the zinc layer.

Disadvantages of steel pipes

Unfortunately, despite all the advantages, steel pipes have many disadvantages. Firstly, they have significant weight and large dimensions, which makes them difficult to operate. Secondly, gas welding used to connect them significantly increases the cost of installation.

The main disadvantage of steel pipes lies in their corrosion instability and susceptibility to various damages. These pipes quickly become overgrown with rust and various deposits, which causes the release of harmful substances into the water and deterioration in the functioning of the shut-off elements. Due to rusting, the internal diameter of the pipes decreases, impeding the circulation of the coolant, which is the reason why the pipes hum. The optimal method of protecting steel pipes is galvanizing them. But, after this process, the use of antifreeze becomes impossible.

It is believed that galvanized pipes cannot be connected by welding. This is due to the combustion of the zinc coating on the seams. To connect them, couplings, tees and bends are used, which is an additional cost. Due to their low throughput properties, steel pipes are inferior to pipes of similar parameters made of copper and plastic. When transporting cold water, steel pipes have negative thermal conductivity due to their sweating and rusting, which can destroy adjacent building structures.

Types of galvanized pipe products

Pipes with a protective zinc layer are used for pipelines for various purposes:

| View | Application | Dimensions |

| Water and gas pipeline | for internal highways located indoors | length - 4-12 m |

| Pipe for electric welding | agricultural engineering and construction | diameter - 110-480 mm |

| Profile with square or rectangular cross-section | industrial and domestic construction | section size - 10 -150 mm |

| Seamless pipe made of carbon or alloy steel | mechanical engineering | wide size range |

The diameter of pipe products with a galvanized surface is from 17 to 150 mm. The nominal diameter is 10-155 mm.

By weight they are distinguished:

| Pipe type | Wall size (thickness) in mm |

| light galvanized | 2 — 4 |

| galvanized regular | 2.2 — 4.4 |

| galvanized reinforced | 4.5 — 5.0 |

Where is hot dip galvanizing used?

Hot-dip galvanizing of pipes is labor-intensive and far from harmless, but it is distinguished by its versatility of use. Parts that have undergone this anti-corrosion treatment can be used:

- in energy;

- communications;

- road improvement,

- industrial, commercial and civil construction;

- housing and communal services;

- extraction and transportation of minerals, in particular oil;

- in mechanical engineering.

Elements of turbine halls of hydro and nuclear power plants, structures for sports, as well as embedded parts for the installation of pipelines are subject to mandatory galvanization according to the ISO-9000 standard.

Advantages of zinc-coated profile pipes

Profile pipes are manufactured in full accordance with GOST 13663-86. High-alloy steel is used for production, mainly of the following grades:

- St2sp;

- St2kp;

- St2ps;

- St4sp;

- St4kp;

- St4ps and so on.

The properties of different types of pipes are presented in the following table:

Mechanical properties of pipes depending on steel

The properties of pipes also determine the advantages of this type of product, which include:

- enhanced mechanical strength, which allows you to expand the scope of use of pipes to enormous sizes;

- corrosion resistance. The main disadvantage of steel pipes is their susceptibility to rust. This disadvantage was minimized by using zinc as a protective layer. The profile galvanized pipe does not rust even under the most unfavorable conditions;

- light weight;

- ease of installation. To connect pipes, you can use various methods: welding, coupling, connection with fittings, and so on.

Due to the additional zinc coating, the service life of profile pipes increases by 10 – 15 years compared to conventional steel pipes.

Is it possible to paint galvanized steel?

Not only is it possible, but it is necessary! Painting gives products a presentable appearance and extends their service life by an average of 10-30 years. However, there are several nuances in the matter of painting galvanized steel:

- The zinc coating must age. Those. Before painting, galvanizing is aged for about 1-2 years under natural conditions. During this time, oxidation products disappear, a durable zinc patina (“white rust”) and some roughness are formed, due to which the adhesion to the paint will be stronger.

- For painting galvanized steel, only special paint compositions that are characterized by a high level of adhesion, hardness and elasticity are suitable. These include:

- Polymer powder paints based on resins and hardeners. When heated, the composition polymerizes, thereby providing strong adhesion to the zinc coating.

- Alkyd, plastisol, polyester and aluminum enamels, characterized by resistance to ultraviolet radiation, moisture, temperature changes and seasonal changes.

High-quality coloring is difficult to do on your own without the appropriate skills. Therefore, painting of galvanized steel is most often done in factories or specialized workshops.

Standard service life of steel pipes according to GOST

One of the important characteristics of the product is, among other things, the period of operation. Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of different grades is used in production, but it is not corrosion resistant. Such rolled metal products require additional protection - painting, for example;

- galvanized steel pipes - products are coated with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. Obviously, the service life according to SNiP and GOST for such a model is much longer;

- stainless steel – alloys with the addition of nickel and chromium. Depending on the size of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows use in sea water, for example, and also does not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rare, but used in domestic conditions. They are distinguished not only by their resistance to corrosion, but also by their disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will vary.

Alas, this option is not particularly durable. Even with the most careful painting and care, they will rust over time. The fact is that after the construction of communications, individual fragments turn out to be inaccessible, and it turns out to be impossible to update the paint, for example.

In addition, black steel loses its smoothness quite quickly. And this leads to the fact that the water-gas or heating pipe “overgrows” quite quickly: first very small debris and salt deposits are retained on the unsmooth surface, and then increasingly larger particles of rust, fibers, and lime deposits. The rate of sediment accumulation is directly proportional to water hardness.

Constant contact with moisture - in the bathroom, for example, in the toilet, leads to faster destruction of the material, which is reflected in SNiP standards. Here the weak link is often the seams: the first fistulas appear precisely on the welds and threads, where the wall thickness decreases.

Standard operating times are:

- the service life of steel water pipes - riser or liner - is 15 years;

- the heating system assembled from gas steel pipes is suitable for use for 10 years;

- heated towel rails in the bathroom can “work” for 15 years;

- According to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

In fact, destructive factors of various kinds significantly reduce the operating time. For example, a pipeline with cold water wears out much faster than with hot water, since it rusts faster: condensation appears in the warm season. And the pipeline overgrows faster, since hot water contains special additives that prevent this.

Rules of service

For efficient operation, galvanized pipes are cleaned of deposits (soot, soot) and debris at least once a year or as an emergency when a blockage occurs in the pipeline. Products used in chimneys require removal of condensate.

Regular testing of the strength and tightness of connections is necessary. Cracks and chips are removed using putty and sealant. Galvanized elements in heating and hot water supply systems require seasonal inspections and repair of damage.

Connection methods

The most common methods of connecting steel pipes are threading and welding. But modern technologies do not stand still, but are constantly being improved. Today it is already possible to connect steel pipes without welding or threading. However, there is one limitation here: in this way, pipeline elements whose diameter does not exceed 60 cm can be hermetically joined.

Small diameter pipes can be connected without welding using special fittings

Most often, a special coupling is used to connect steel pipes without welding. Its design includes:

- frame;

- four washers and two nuts;

- two rubber gaskets.

To connect, you need to thread the ends of the pipes through gaskets, washers and nuts and join them inside the housing. When the nuts are tightened, the gaskets are compressed, ensuring a tight seal. If its level is insufficient, an additional spacer ring should be added.

The success of this operation depends on the correct selection of the coupling diameter. And if everything is clear regarding too small a value of this parameter - the pipes simply will not fit into its body, then a coupling with a cross-section that is too large will not create a tight connection.

The flange method is another alternative type of threadless connection for steel pipes. It should be understood that there are no threads on the surface of the pipes and are only present on the fittings.

Connecting pipes using flanges is considered one of the most reliable, but only if it is done correctly

This method of docking involves taking into account the following points:

- Misalignment of the nuts is not allowed. That is, they need to be tightened not in a circle, but diametrically against each other;

- the gasket must be made of asbestos cardboard;

- bolts should not protrude more than halfway from the nuts;

- the outer diameter of the gasket should not touch the bolts, and the internal size should be slightly larger than the cross-section of the pipe;

- In order not to reduce the tightness and trouble-free operation of the pipeline, several gaskets should not be used for one flange.

If the technical characteristics correspond to the expected operating conditions, the flange connection will be the most reliable.

In conclusion, it should be noted that the installation of a heating system can only be entrusted to an experienced technician. This way you will eliminate the possibility of everyday problems arising for you and your neighbors.

Acceptance rules

Galvanized VGP pipes are accepted in batches. Each includes bends of the same alloy and standard size. A document of product characteristics is issued to the group.

VGP steel bends are sold by weight. No more than 60 tons of products are allowed in one batch.

Each released product is checked for:

- Dimensions.

- Weight.

- Curvature.

- Strength.

- Surface and weld quality.

In addition, a selective method is used to control the remains of burrs, burrs, bending parameters, chamfers and some other characteristics determined by GOST.

Galvanized products that do not pass inspection are rejected.

Test methods

All inspections of VGP structures are carried out according to the methodology defined by regulatory documents:

- Inspection of the surface of VGP outlets is carried out visually.

- Strength is checked by hydraulic tests.

- The weld seam of VGP products is checked by X-ray, ultrasonic and visual methods.

- The thickness of the galvanized coating is controlled by special devices.

- Micrometers are used to control the external section and thickness of the galvanized layer.

Labeling, packaging, transportation and storage

The marking for VGP bends with a cross-section of up to 159 mm is placed on the label. It includes the standard sizes of the VGP product, alloy grade, and manufacturer’s trademark. The label is attached to the product packaging.

During transportation, products are securely secured with various devices to prevent their arbitrary movement.

Store galvanized pipes on racks and platforms in the open air. They are laid in groups according to standardization and steel grades to eliminate the possibility of mixing.

Classification of steel pipes

For the manufacture of pipes intended for water heating, preference is given to mild carbon steel. Its use is explained by the significant strength and plastic properties of the raw material. Thanks to this, steel pipes are processed by bending, cutting, welding, riveting and other manipulations.

Steel pipes have significant heat-conducting properties, which is important when moving heated water. An important factor influencing the laying of pipes in concrete is the correspondence of their temperature coefficient of linear expansion to the coefficient of concrete expansion

For water heating systems, preference is given to:

- “Seam” water and gas black welded pipes, obtained by bending a sheet of steel with subsequent seam welding, and electric-welded galvanized pipes with a straight seam. Such pipes are a low-cost option with a limited service life of up to 4 years. At the junction of the steel layers, a weld seam is formed, processed from the outside, which prevents the appearance of bumps and nicks on the surface of the pipe. The inside of the weld cannot be processed, and its quality control is difficult. Due to a small shell flaw, the metal in this place becomes thinner. This leads to leakage, followed by forced dismantling of steel pipes.

- Seamless, seamless pipes, which are more reliable in operation, used in places that are difficult to access for repairs. They are made by pressing, forging and rolling. However, the cost of such products is an order of magnitude higher than the suture version.

Manufacturers produce pipes with diameters from 8 to 150 millimeters. The thickness of steel pipes can be light, ordinary or reinforced. The most common and cost-effective option is steel pipes with a thickness of 2.7 millimeters and a diameter of 25 millimeters. Such parameters ensure pipe protection from rupture.

Permissible maximum deviations

For walls, GOST generally allows deviations of up to 15%, and for diameters in the range of 17-48 mm - 0.4-0.5 mm, for diameters from 60 to 159 - 0.8-1%.

The weight of the pipe directly depends on its size and density.

It ranges from 1 kg of a meter product to 35. Weight is commonly used for structural design. But pipes are purchased by the meter.

It should also be noted that galvanized pipe does not have a specific standard. Therefore, they are produced according to the standards of conventional steel pipes. Even though this is not entirely correct, GOST is taken alone, for the year 91.