A shut-off valve

(also

valve

) is a shut-off and control valve, structurally designed in the form of a valve, that is, its locking element moves parallel to the axis of the flow of the working medium [1].

Like other types of shut-off valves, shut-off valves are used to completely block their flow area, and therefore the flow of the working medium; that is, the locking element, which in a shut-off valve is most often a spool

, during operation is in the extreme positions “open” or “closed”. To regulate the flow of the medium by changing the flow area, control valves are successfully used; there are also shut-off and control valves that combine these functions.

It should be noted that until 1982[2], valves in which the valve is moved using a threaded pair of spindle-running nut were called valves

, however, this name was abolished [3] and now a valve is called both a valve with a threaded spindle (transmitting torque from the drive) and a smooth stem (transmitting translational force from the drive).

Valve-type valves are operated manually or electrically, while smooth-stem valves are operated by hydraulic, pneumatic or electromagnetic actuators, as well as mechanically actuated by other devices. Shut-off valves with high-speed piston pneumatic actuators are part of the protective valves and are called shut-off valves

.

Valves are widely used as shut-off valves, which is explained by the ability to provide good sealing in the shut-off body with a comparative simplicity of design. The valves are used for liquid and gaseous media with a wide range of operating parameters: pressure - from vacuum 5·10−3 mm Hg. Art. up to 250 MPa, temperatures - from -200 to +600. Valves are usually used on pipelines of relatively small diameters, since in the case of larger sizes it is necessary to deal with a significant increase in the effort to operate the valve and the complexity of the design to ensure correct seating of the valve

onto

seat

[4][5].

Advantages and disadvantages

In addition to the above advantages, valves also have others, for example:

- possibility of use in conditions of high temperatures and pressures, vacuum, corrosive and aggressive environments;

- comparative ease of maintenance and repair under operating conditions.

The design of valves is in many ways similar to the design of gate valves, but its fundamental difference is that the movement of the gate coincides with the axis of movement of the medium flow, and not perpendicular to it, giving valves a number of advantages over gate valves, including:

- small stroke of the valve for full opening (usually no more than 0.25 of the nominal diameter, while for gate valves - no less than the diameter) and, accordingly, low construction height and weight;

- in valves it is much easier than in gate valves to ensure the required tightness of the valve (by using o-rings made of various non-metallic materials);

- when closing and opening the valve, unlike a gate valve, friction between the valve

and

the seat

, which significantly reduces wear of the sealing surfaces; - the possibility of using a bellows as a seal for fittings in relation to the external environment.

The disadvantages of valves include:

- high (compared to ball valves and gate valves) hydraulic resistance, which, with large passage diameters and high fluid velocities, creates large energy losses and necessitates a corresponding increase in the initial pressure in the system;

- limitation of application limits by diameter, which was mentioned above;

- the presence in most structures of stagnant zones in which mechanical impurities from the working environment and sludge accumulate, which leads to the intensification of corrosion processes in the valve body [4] [5].

Principles of selection and prices

Prices for parts vary depending on their size, the material from which they are made, the presence of an electric drive, weight, type of sealing elements, type of fastening to pipes. Average price depending on the material:

- Cast iron - 250 rubles.

- Steel - 550 rubles.

- Brass - 750 rubles.

When choosing a device, you need to consider some features:

- Brass - resistant to rust, can withstand frequent temperature changes and high pressure. The disadvantage is the high price.

- Steel is a popular material for the manufacture of locking mechanisms. Withstands heavy loads and sudden temperature changes. During manufacturing, the alloy is saturated with alloying additives that change its characteristics.

- Cast iron - low price, prevalence, good casting qualities made models made from this material attractive to buyers. The main disadvantages are low resistance to rust formation and low strength.

The packages with the parts indicate what working environments they are intended for and what pressure they can withstand. This is what you need to take into account when choosing a straight-through valve.

Features of choice

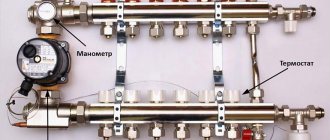

Device and principle of operation

The body (yellow in the explanatory figure) has two pipes with ends for connection to the pipeline; it can be in any known way: flange, coupling, fitting, pin, welding. There is a seat inside the body, which in the “closed” position is closed by a shutter (spool (3)

).

The spindle (1)

passes through the gland seal in the cover.

In the design shown in the explanatory figure, the running gear of the shut-off body is moved outside the working environment area using a yoke assembly (2)

. The seal can also be a bellows seal; in this case, removal of the running unit is not required.

Spindle (1)

transmits torque from a hand wheel or mechanical drive through a fixed running nut to the spool, converting it into forward movement of the spool; in the lowest position, the spool sits in the seat and the flow of the medium is blocked. The force transmitted from the drive can also be translational; in this case, there is no running nut, and a smooth rod is used instead of a spindle.

Scope of application

Shut-off valves are used to regulate the working flow. They are installed on systems to ensure good sealing of connections. Areas of application:

- Chemical, gas, oil industries.

- House construction, production of heating systems, water supply, gas.

With their help, you can control not only the liquid, but also the gas environment.

Application of shut-off valve

Differences in Designs

Seal designs

According to the method of sealing the movable connection between the spindle (stem) and the cover, valves are divided into stuffing box

,

bellows

and

membrane

(diaphragm).

Gland fittings

In stuffing box fittings, the tightness of the connection between the cover and the moving part of the valve is ensured by a stuffing box device. The essence of the stuffing box device is that on the outside of the cover or body, in the place where the rod or spindle passes through it, a stuffing box is created into which sealing material is placed - stuffing box packing. Using special devices, the packing is pressed along the axis of the spindle (rod), resting against the walls of the stuffing box and compacted. This creates a tight seal and the working environment does not penetrate outside the housing. In fittings of small diameters, the packing is compressed with a union nut, in larger diameters - with a special part - an oil seal using two folding or anchor bolts with nuts.

The gland seal has many advantages that make it preferable in most cases. Among them:

- the ability to manufacture stuffing box packings from various materials to ensure good sealing over a wide range of operating pressures and temperatures;

- simplicity of design;

- possibility of re-stuffing the oil seal or changing the packing during operation.

Oil seals simplify the design as much as possible and reduce the cost of the fittings, however, for a nominal pressure of 2.5 MPa and a nominal diameter of more than 50 (these limits are very approximate), the running unit is removed from the working environment area and is located above the stuffing box, and the running nut is placed in the yoke unit, located above the valve cover, that is, the design becomes significantly more complicated to eliminate the influence of the working environment on the spindle-nut connection and increase its durability and reliability.

Bellows fittings

In bellows fittings, the seal of moving elements relative to the external environment is ensured by a bellows assembly. Its main element is a bellows - a corrugated tube. The metal bellows is connected by welding or soldering to the upper or lower rings (or other shaped parts), forming a so-called bellows assembly. The bellows assembly, with its upper part, is motionlessly and hermetically connected to the body parts of the valve, and the lower part is connected to the valve stem or spool, thus blocking the possibility of the working medium escaping to the outside. The forward movement of the rod to control the spool occurs inside the bellows, which can change its length due to the deformation of the corrugations.

Bellows valves are used to operate in environments where leakage into the environment is unacceptable. The advantage of such valves over stuffing box valves is the elimination of leakage of the working medium into the atmosphere within the service life of the bellows assembly. But this advantage is achieved by significantly complicating the design and, accordingly, increasing the cost of the valve. In addition, repairing a valve bellows due to fatigue failure is a complex operation to replace the bellows assembly, so in such cases the valve must be replaced with a new one.

Membrane fittings

Diaphragm valves are fundamentally different from valves of other designs.

In membrane fittings, external sealing is provided by a membrane made in the form of an elastic disk made of elastic materials (rubber, fluoroplastic). The profile of the membrane allows in its central part to carry out a reciprocating movement sufficient to close or open the shut-off or control valve of the valve. The membrane is installed and clamped along the outer diameter between the body and the cover, this ensures the tightness of the connection of the body parts and at the same time completely isolates the internal cavity of the valve from the external environment[6].

The peculiarity of these valves is that the diaphragm can simultaneously act as a shutter, blocking the passage of the working medium through the body under the action of the spindle.

This design allows, without the use of stainless steel, to have cast iron valves suitable for various aggressive environments. This is achieved by coating (lining) the internal surfaces of the housing with various corrosion-resistant materials (fluoroplastic, rubber, polyethylene, enamels).

The disadvantages of such valves are the short service life of the membrane and the limits of their use limited by low pressures and temperatures [4].

Flow direction

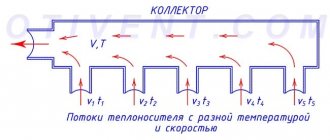

According to the design of the housing and location on the pipeline, related to the direction of flow of the working medium, shut-off valves differ:

- pass-through

- in them the direction of the medium flow at the inlet and outlet is the same, but sometimes the axis of the outlet pipe is shifted parallel to the inlet. In such a valve, the flow of medium in the body makes at least two turns by 90, which leads to high hydraulic resistance and the appearance of stagnant zones in the body; - angular

- in them the flow turns 90°, but only once, which reduces hydraulic resistance. A significant disadvantage of such valves is that their scope of application is limited to rotary sections of pipelines; - direct-flow

- in them, as in pass-throughs, the flow direction is maintained, but the spindle axis is not perpendicular, but oblique to the passage axis. This design makes it possible to significantly straighten the flow and reduce hydraulic resistance, however, this increases the valve stroke, construction length and weight of the product.[5]

Working body design

Gates in valves can be poppet (spool) or conical.

The sealing surfaces of a poppet valve can be flat or conical; in the latter case, the seat in the body is made in the form of a chamfer. Flat seals can be manufactured from a variety of metals, alloys and non-metallic materials; they work well in liquid and gaseous media that do not contain suspended particles. Cone seals, metal to metal, are used for high pressure valves with suspended particles in the working fluid.

The conical valve is used in valves with a nominal diameter of no more than 25, for nominal pressures of 16 MPa and above. These valves are called needle valves

[4].

Flow direction:

Based on the design of the body, shut-off valves are divided into straight-through, corner and direct-flow. Globe valves

are designed in such a way that the flow of the working medium at the inlet and outlet has the same direction, but inside the valve itself it makes 2 turns by 90°.

Such valves can be used to shut off working media with high temperatures and pressures, withstand significant overloads and maintain tightness. However, such a design leads to high hydraulic resistance and the appearance of stagnant zones in the housing. Angle valves

rotate the flow of the working medium by 90° and are used on rotating sections of the pipeline.

Compared to straight valves, angle valves have less hydraulic resistance. Direct flow valves

are somewhat similar to straight-through valves. In them, the direction of flow is maintained, but the spindle axis is not perpendicular, but inclined to the axis of the passage. The design of a direct-flow valve makes it possible to significantly straighten the flow and reduce hydraulic resistance, however, this increases the stroke of the shut-off element, the overall length and weight of the valve.

Notes

- GOST R 52720-2007. Pipeline fittings. Terms and Definitions.

- In 1982, GOST 24856-81 came into force, establishing new terms and definitions in the field of pipeline fittings.

- Currently, the use of this term is not allowed by standards and is excluded from technical documentation, but is still widely used as a colloquial term.

- ↑ 1234

Let's talk about fittings. R. F. Usvatov-Usyskin - M.: Vitex, 2005. - ↑ 123

Industrial fittings for general and special purposes. Directory. A. I. Goshko - M.: Melgo, 2007. - Pipeline accessories. Reference manual. D. F. Gurevich - Leningrad: Mechanical Engineering, 1981.

Purpose

Shut-off valve (valve) - serves to shut off the flow of the working medium in the pipeline moving in one direction. Direction of movement of the working medium according to the arrow on the body. The locking element moves parallel to the flow axis.

Shut-off valves are used most often on steam and water pipelines, since they create high flow resistance, higher than gate valves. During flow, the flow bends, changes its direction, narrows, and then expands to its original size. In this case, intense vortex formation occurs.

Therefore, they are used when the movement of the medium occurs only in one direction and does not cause large hydraulic resistance. Special valves are used for manual throttling of pressure (for example, a pressure reducing valve in thermal cracking units).

It should be noted that until 1982, valves in which the valve is moved using a threaded pair of spindle and running nut were called valves. Currently, valves are also called valves with a threaded spindle and a smooth stem.

Shut-off valves must comply with the requirements of GOST 5761 (regarding gland and bellows valves, steel and non-ferrous metals), TU and KD.

Nominal pressures from PN1.6 MPa (PN16) to PN25MPa (PN250) inclusive.

Excerpt describing the Shut-Off Valve

- He killed her to death - he beat the owner!.. He beat her like that, she dragged her like that!.. - For what? – asked Alpatych. - I asked to go. It's a woman's business! Take me away, he says, don’t destroy me and my little children; the people, he says, have all left, what, he says, are we? How he started beating. He hit me like that, he dragged me like that! Alpatych seemed to nod his head approvingly at these words and, not wanting to know anything more, went to the opposite door - the master's door of the room in which his purchases remained. “You are a villain, a destroyer,” shouted at that time a thin, pale woman with a child in her arms and a scarf torn from her head, bursting out of the door and running down the stairs to the courtyard. Ferapontov followed her and, seeing Alpatych, straightened his vest and hair, yawned and entered the room behind Alpatych. - Do you really want to go? - he asked. Without answering the question and without looking back at the owner, looking through his purchases, Alpatych asked how long the owner was supposed to stay. - We'll count! Well, did the governor have one? – Ferapontov asked. – What was the solution? Alpatych replied that the governor did not tell him anything decisive. - Are we going to leave on our business? - said Ferapontov. - Give me seven rubles per cart to Dorogobuzh. And I say: there is no cross on them! - he said. “Selivanov, he got in on Thursday and sold flour to the army for nine rubles a sack.” Well, will you drink tea? - he added. While the horses were being pawned, Alpatych and Ferapontov drank tea and talked about the price of grain, the harvest and favorable weather for harvesting. “However, it began to calm down,” said Ferapontov, drinking three cups of tea and getting up, “ours must have taken over.” They said they won't let me in. This means strength... And after all, they said, Matvey Ivanovich Platov drove them into the Marina River, drowned eighteen thousand, or something, in one day. Alpatych collected his purchases, handed them over to the coachman who came in, and settled accounts with the owner. At the gate there was the sound of wheels, hooves and bells of a car leaving. It was already well after noon; half the street was in the shade, the other was brightly lit by the sun. Alpatych looked out the window and went to the door. Suddenly a strange sound of a distant whistle and blow was heard, and after that there was a merging roar of cannon fire, which made the windows tremble. Alpatych went out into the street; two people ran down the street towards the bridge. From different sides we heard whistles, impacts of cannonballs and the bursting of grenades falling in the city. But these sounds were almost inaudible and did not attract the attention of residents in comparison with the sounds of gunfire heard outside the city. It was a bombardment, which at five o'clock Napoleon ordered to open on the city, from one hundred and thirty guns. At first the people did not understand the significance of this bombing. The sounds of falling grenades and cannonballs aroused at first only curiosity. Ferapontov’s wife, who had never stopped howling under the barn, fell silent and, with the child in her arms, went out to the gate, silently looking at the people and listening to the sounds. The cook and the shopkeeper came out to the gate. Everyone with cheerful curiosity tried to see the shells flying over their heads. Several people came out from around the corner, talking animatedly. - That’s power! - said one. “Both the lid and the ceiling were smashed into splinters.” “It tore up the earth like a pig,” said another. - That’s so important, that’s how I encouraged you! – he said laughing. “Thank you, I jumped back, otherwise she would have smeared you.” The people turned to these people. They paused and told how they got into the house near their core. Meanwhile, other shells, now with a quick, gloomy whistle - cannonballs, now with a pleasant whistling - grenades, did not stop flying over the heads of the people; but not a single shell fell close, everything was carried over. Alpatych sat down in the tent. The owner stood at the gate. - What haven’t you seen! - he shouted at the cook, who, with her sleeves rolled up, in a red skirt, swaying with her bare elbows, came to the corner to listen to what was being said. “What a miracle,” she said, but, hearing the owner’s voice, she returned, tugging at her tucked skirt. Again, but very close this time, something whistled, like a bird flying from top to bottom, a fire flashed in the middle of the street, something fired and covered the street with smoke. - Villain, why are you doing this? – the owner shouted, running up to the cook. At the same moment, women howled pitifully from different sides, a child began to cry in fear, and people with pale faces silently crowded around the cook. From this crowd, the most audible were the moans and sentences of the cook: “Oh, oh, my darlings!” My little darlings are white! Don't let me die! My white darlings!.. Five minutes later there was no one left on the street. The cook, with her thigh broken by a grenade fragment, was carried into the kitchen. Alpatych, his coachman, Ferapontov’s wife and children, and the janitor sat in the basement, listening. The roar of guns, the whistle of shells and the pitiful moan of the cook, which dominated all sounds, did not cease for a moment. The hostess either rocked and coaxed the child, or in a pitiful whisper asked everyone who entered the basement where her owner, who remained on the street, was. The shopkeeper who entered the basement told her that the owner had gone with the people to the cathedral, where they were raising the Smolensk miraculous icon. By dusk the cannonade began to subside. Alpatych came out of the basement and stopped at the door. The previously clear evening sky was completely covered with smoke. And through this smoke the young, high-standing crescent of the month strangely shone. After the previous terrible roar of guns had ceased, there seemed silence over the city, interrupted only by the rustling of footsteps, groans, distant screams and the crackle of fires that seemed to be widespread throughout the city. The cook's moans had now died down. Black clouds of smoke from the fires rose and dispersed from both sides. On the street, not in rows, but like ants from a ruined hummock, in different uniforms and in different directions, soldiers passed and ran. In Alpatych’s eyes, several of them ran into Ferapontov’s yard. Alpatych went to the gate. Some regiment, crowded and in a hurry, blocked the street, walking back. “They are surrendering the city, leave, leave,” the officer who noticed his figure told him and immediately shouted to the soldiers: “I’ll let you run around the courtyards!” - he shouted. Alpatych returned to the hut and, calling the coachman, ordered him to leave. Following Alpatych and the coachman, all of Ferapontov’s household came out. Seeing the smoke and even the fires of the fires, now visible in the beginning twilight, the women, who had been silent until then, suddenly began to cry out, looking at the fires. As if echoing them, the same cries were heard at other ends of the street. Alpatych and his coachman, with shaking hands, straightened the tangled reins and lines of the horses under the canopy. When Alpatych was leaving the gate, he saw about ten soldiers in Ferapontov’s open shop, talking loudly, filling bags and backpacks with wheat flour and sunflowers. At the same time, Ferapontov entered the shop, returning from the street. Seeing the soldiers, he wanted to shout something, but suddenly stopped and, clutching his hair, laughed a sobbing laugh. - Get everything, guys! Don't let the devils get you! - he shouted, grabbing the bags himself and throwing them into the street. Some soldiers, frightened, ran out, some continued to pour in. Seeing Alpatych, Ferapontov turned to him. – I’ve made up my mind! Race! - he shouted. - Alpatych! I've decided! I'll light it myself. I decided... - Ferapontov ran into the yard. Soldiers were constantly walking along the street, blocking it all, so that Alpatych could not pass and had to wait. The owner Ferapontova and her children were also sitting on the cart, waiting to be able to leave. It was already quite night. There were stars in the sky and the young moon, occasionally obscured by smoke, shone. On the descent to the Dnieper, Alpatych's carts and their mistresses, moving slowly in the ranks of soldiers and other crews, had to stop. Not far from the intersection where the carts stopped, in an alley, a house and shops were burning. The fire had already burned out. The flame either died down and was lost in the black smoke, then suddenly flared up brightly, strangely clearly illuminating the faces of the crowded people standing at the crossroads. Black figures of people flashed in front of the fire, and from behind the incessant crackling of the fire, talking and screams were heard. Alpatych, who got off the cart, seeing that the cart would not let him through soon, turned into the alley to look at the fire. The soldiers were constantly snooping back and forth past the fire, and Alpatych saw how two soldiers and with them some man in a frieze overcoat were dragging burning logs from the fire across the street into the neighboring yard; others carried armfuls of hay. Alpatych approached a large crowd of people standing in front of a tall barn that was burning with full fire. The walls were all on fire, the back one had collapsed, the plank roof had collapsed, the beams were on fire. Obviously, the crowd was waiting for the moment when the roof would collapse. Alpatych expected this too. - Alpatych! – suddenly a familiar voice called out to the old man. “Father, your Excellency,” answered Alpatych, instantly recognizing the voice of his young prince. Prince Andrei, in a cloak, riding a black horse, stood behind the crowd and looked at Alpatych. - How are you here? - he asked. “Your... your Excellency,” said Alpatych and began to sob... “Yours, yours... or are we already lost?” Father... - How are you here? – repeated Prince Andrei. The flame flared up brightly at that moment and illuminated for Alpatych the pale and exhausted face of his young master. Alpatych told how he was sent and how he could forcefully leave. - What, your Excellency, or are we lost? – he asked again. Prince Andrei, without answering, took out a notebook and, raising his knee, began to write with a pencil on a torn sheet. He wrote to his sister: “Smolensk is being surrendered,” he wrote, “Bald Mountains will be occupied by the enemy in a week. Leave now for Moscow. Answer me immediately when you leave, sending a messenger to Usvyazh.” Having written and given the piece of paper to Alpatych, he verbally told him how to manage the departure of the prince, princess and son with the teacher and how and where to answer him immediately. Before he had time to finish these orders, the chief of staff on horseback, accompanied by his retinue, galloped up to him. -Are you a colonel? - shouted the chief of staff, with a German accent, in a voice familiar to Prince Andrei. - They light houses in your presence, and you stand? What does this mean? “You will answer,” shouted Berg, who was now the assistant chief of staff of the left flank of the infantry forces of the First Army, “the place is very pleasant and in plain sight, as Berg said.” Prince Andrei looked at him and, without answering, continued, turning to Alpatych: “So tell me that I’m waiting for an answer until the tenth, and if on the tenth I don’t receive news that everyone has left, I myself will have to leave everything and go to Bald Mountains.” “I, Prince, say this only because,” said Berg, recognizing Prince Andrei, “that I must carry out orders, because I always carry out them exactly... Please forgive me,” Berg made some excuses. Something crackled in the fire. The fire died down for a moment; black clouds of smoke poured out from under the roof. Something on fire also crackled terribly, and something huge fell down. - Urruru! – Echoing the collapsed ceiling of the barn, from which the smell of cakes from burnt bread emanated, the crowd roared. The flame flared up and illuminated the animatedly joyful and exhausted faces of the people standing around the fire. A man in a frieze overcoat, raising his hand, shouted: “Important!” I went to fight! Guys, it’s important!.. “It’s the owner himself,” voices were heard. “Well, well,” said Prince Andrei, turning to Alpatych, “tell me everything, as I told you.” - And, without answering a word to Berg, who fell silent next to him, he touched his horse and rode into the alley. The troops continued to retreat from Smolensk. The enemy followed them. On August 10, the regiment, commanded by Prince Andrei, passed along the high road, past the avenue leading to Bald Mountains. The heat and drought lasted for more than three weeks. Every day, curly clouds walked across the sky, occasionally blocking the sun; but in the evening it cleared again, and the sun set in a brownish-red haze. Only heavy dew at night refreshed the earth. The bread that remained on the root burned and spilled out. The swamps are dry. The cattle roared from hunger, not finding food in the sun-burnt meadows. Only at night and in the forests there was still dew and there was coolness. But along the road, along the high road along which the troops marched, even at night, even through the forests, there was no such coolness. The dew was not noticeable on the sandy dust of the road, which had been pushed up more than a quarter of an arshin. As soon as dawn broke, the movement began. The convoys and artillery walked silently along the hub, and the infantry were ankle-deep in soft, stuffy, hot dust that had not cooled down overnight. One part of this sand dust was kneaded by feet and wheels, the other rose and stood as a cloud above the army, sticking into the eyes, hair, ears, nostrils and, most importantly, into the lungs of people and animals moving along this road. The higher the sun rose, the higher the cloud of dust rose, and through this thin, hot dust one could look at the sun, not covered by clouds, with a simple eye. The sun appeared as a large crimson ball. There was no wind, and people were suffocating in this still atmosphere. People walked with scarves tied around their noses and mouths. Arriving at the village, everyone rushed to the wells. They fought for water and drank it until they were dirty. Prince Andrei commanded the regiment, and the structure of the regiment, the welfare of its people, the need to receive and give orders occupied him. The fire of Smolensk and its abandonment were an era for Prince Andrei. A new feeling of bitterness against the enemy made him forget his grief. He was entirely devoted to the affairs of his regiment, he was caring for his people and officers and affectionate with them. In the regiment they called him our prince, they were proud of him and loved him. But he was kind and meek only with his regimental soldiers, with Timokhin, etc., with completely new people and in a foreign environment, with people who could not know and understand his past; but as soon as he came across one of his former ones, from the staff, he immediately bristled again; he became angry, mocking and contemptuous. Everything that connected his memory with the past repulsed him, and therefore he tried in the relations of this former world only not to be unfair and to fulfill his duty.