Electrified gate valves are a modern type of shut-off pipeline valves, which are successfully used for installation on main and technological lines that drain waste and waste water, hot/cold water supply to objects for various purposes, as well as in structures pumping oil and oil, in heat supply systems, air conditioning, gas supply, energy facilities.

Important! The electric valve must not be used to regulate the pressure and speed of movement of the pipeline contents. Such actions can cause a sharp increase in pressure and water hammer, which will lead to failure of the unit.

Structural similarities and differences between different modifications of locking equipment

The body of all devices of this type, equipped with an electric drive, consists of a body and a cover, forming a hollow structure, in the cavity of which the operating mechanism unit and part of the moving medium under pressure are located.

For connection to the process there are two outlets for welding or with threads for screwing on a coupling or flange.

The working mechanism consists of two saddles, parallel to each other or mounted at an angle.

In the “closed” position, their entire plane is pressed against the valve with sealing material on the surface, provided to increase the degree of sealing. The gate inside the electric valve body is connected to one end of the spindle (rod) and with its help moves at right angles to the direction of flow of the working medium passing through it. The second end of the spindle comes out through the cover, sealing gaskets and is connected to the electric drive.

The use of electrified valves is directly related to their technical characteristics and the specific structure of the structure.

Shut-off valves of this type are manufactured in several modifications, differing:

- direction of flow of the working substance - one-way, two-way;

- design of the locking mechanism: wedge (have a rigid wedge, double-disc wedge or elastic wedge), parallel (with one disk, two disks or a gate);

- spindle type - retractable and non-retractable spindle;

- manufacturing materials - steel, cast iron, aluminum, bronze, brass, titanium electric valves;

- by production method - cast, welded, stamped or combining casting and welding, stamping and welding;

- design features of the flow body part - full bore, with a narrowed hole;

- the initial location of the locking part of the electric valve is normally open; normally closed;

- method of sealing the body/cover connection - an oil seal without self-sealing, an oil seal with a self-sealing property, with a valve, with a water seal or a combination of a water seal and a valve;

- type of force transmission from the electric drive to the locking element - rotational or translational type drive.

The electric drive of all types of devices includes two main components - a motor and a gearbox that converts the speed of the motor crankshaft.

Electric valves are mainly powered by an AC motor, but can be connected to a motor powered by an independent source - a network supplying DC current.

To equip the electric drive, indicators and position sensors of the working body are used, which are necessary for remote control of the degree of opening of the unit at any time, as well as limiters that prevent its overload.

Data from sensors and power supply is received through special cables; a flange or coupling connection is used for attachment to the electrified valve.

Important! To automatically monitor the operation of the locking device, as well as to avoid the negative impact of unauthorized voltage surges in the network, the electric drive is connected to the control cabinet.

Advantages of using an electric drive

An electric drive is an element that allows you to automate shut-off valves. The use of this product is very popular and electric drives are often installed even in private homes.

Advantages of using an electric drive:

- Possibility of automatic control of the sewer gate. There is no need to go down to the basement or look for the required area in a large enterprise. It is enough to use the dispatcher console.

- The product is light weight, which means there is no additional load on the pipeline. It also greatly simplifies transportation and installation.

- Easy to use. Does not require specific skills or knowledge.

- Does not require frequent maintenance. Repairs do not take much time and money.

Electric sewer valves are in great demand. This product is especially considered indispensable in large enterprises and industries.

Positive and negative aspects of their work

Electric gate valves have a number of advantages:

- minimum degree of hydraulic resistance when the passage opening is fully opened;

- the flow of the substance contents inside the product moves in a straight line, without turns;

- can block the flow of a viscous medium;

- possibility of installation in limited space, as they have a short construction length;

- can supply media flows in any direction;

- ease of installation, repair, and maintenance;

- low consumption of related building materials during installation.

The disadvantages of electric valves include:

- low response speed;

- the need for an electrical cabinet for connection;

- impossibility of use for systems transporting media with crystallizing inclusions;

- restriction on tolerance for pressure level surges on the shut-off valve, for use in explosive objects.

Maintenance and repair

This electric drive product does not require frequent maintenance; it is enough to carry out periodic inspections of the device and check its performance.

During maintenance, the quality of operation of the valve, the speed of operation of the electric drive, and the serviceability of the manual mechanism are checked. The tightness of the product body deserves special attention. If necessary, tighten the bolts. The valve must be in the correct position at different wastewater pressures.

Repair of a shutter with an electric drive can be carried out either independently or in a factory setting. If the mechanical part is damaged, the failed element is replaced with a new one. If the problem is in the electric drive, then the involvement of a specialist is required, since the electronic circuit of the device can be quite complex.

Shut-off devices in external heat and water supply networks

On lines that supply cold and hot water to facilities, electrified wedge valves are mainly installed, having a valve whose sealing surfaces form an angle with each other, and the locking part is wedge-shaped.

Important! Such valves must withstand high intra-system pressure and have an additional safety margin in case of its increase.

For cold water mains, cast iron products with a diameter of 15 - 2000 mm are used, designed for an internal system pressure of no more than 25 MPa. On pipes carrying hot water, it is recommended to install steel electric valves or stainless steel valves that are more resistant to temperature changes, as well as models coated with special compounds that have anti-corrosion properties. Their construction and connection dimensions, weight and other technical characteristics depend on the specific modification.

Technical characteristics of the most popular cast iron shut-off devices with electric drive

| Brand | 30h906br | 30h39r | 31h917br |

| Nominal pressure, MPa (kgf cm²) | 1 (10) | 1,6 (16) | 1,0 (10) |

| Nominal diameter | 50 — 500 | 50-300 | 50-300 |

| Temperature range of the substance contents in the pipeline | +225ºС | From -30ºС to +130ºС | +225ºС |

| Ambient temperature range | From -30ºС to +40ºС | From -30ºС to +45ºС | +80ºС |

| Compliance with tightness classes established by GOST 9544-93 | WITH; D | A | IN; WITH; D |

| Type of process connection | flanged | flanged | flanged |

| Service life, years | 5 | 5 | 5 |

| Average resource, hour | 40000 | 40000 | 40000 |

| MTBF, hour | 9000 | 9000 | 9000 |

Technical characteristics of the most popular electric steel locking devices

| Brand | 30s915nzh s | 30s927nzh with not | 30s941nzh (ZKLPE 2-16) | 30s942nzh |

| Nominal pressure, MPa (kgf cm²) | 4 (40) | 2,5 (25) | 1,6 (16) | 1,0 (10) |

| Nominal diameter | 50 — 400 | 300-1000 | 50 — 1200 | 150 — 300 |

| Temperature range of the substance contents in the pipeline | From -40ºС to +450ºС | From -40ºС to +450ºС | From -40ºС to +450ºС | From -70ºС to +300ºС |

| Ambient temperature range | From -40ºС to +50ºС | From -30ºС to +45ºС | From -30ºС to +40ºС | From -40ºС to +40ºС |

| Compliance with tightness classes established by GOST 9544-93 | A | A | WITH; D | IN; WITH; D |

| Type of process connection | flanged | flanged | flanged | flanged |

| Type of climatic modification according to GOST 15150-84 | U1 | U1; T1 | U1; T1 | U; T |

| Service life, years | 10 | 10 | 10 | 10 |

| Average resource, cycle | 2500 | 2500 | 2500 | 2500 |

| MTBF, cycle | 500 | 500 | 500 | 500 |

Summing up

An electrically operated sewer valve is an important component of shut-off valves. This device significantly reduces contamination in the pipeline. The product does not require special maintenance; it is enough to inspect and test the device for functionality.

An electric shutter is used both in large enterprises and in private homes. It does not require special installation conditions, is lightweight and has an affordable price policy.

Main sewer shut-off devices

Gate-type shut-off valves are installed on main structures made of pipes that discharge sewage, sludge and pulp.

Electric gate valves have parallel sealing surfaces of the valve mechanism elements and a gate made in the form of a knife plate (gate).

The main parts of the devices are formed from:

- cast iron or its alloys with graphite;

- steel (stainless, carbon, low-carbon);

- non-ferrous metal alloys;

- thermoplastic polymer vinyl chloride (PVC).

To increase the service life, a polyester or epoxy coating is applied to all planes of the metal plates.

Operating principle of a sewer valve

The sewer valve uses the return movement of the main valve. The valve has a simple design, requires minimal effort during installation, and also has a long service life.

In the normal position, without applying force, the shutter flap is constantly closed. But under the influence of sewage, it opens and allows wastewater to flow further into the system. After the pressure has ended, the damper returns to its original position.

The valve body has a special hatch that allows cleaning and maintenance of the device. This element also allows you to get to the place where the pipeline is clogged.

The design of the device is quite simple, it consists of a valve and a damper. If they break down, these elements can be quickly replaced; it is enough to have new ones available.

Device and principle of operation

The principle of operation of electrified gate valves on MCC networks is to transfer force through a rod to a knife plate made of durable steel, which, when moved longitudinally, opens and closes the passage opening.

Tightness when connecting the body to the cover is ensured by an oil seal consisting of graphite, synthetic or cotton fiber.

Limit switches are used to set the extreme positions; to increase the level of tightness, elastomer seals are installed in the housing cavity, to which the gate is pressed under the influence of the pressure of the working medium.

The product is connected to the main pipeline by flanges or by welding.

Important! An electrified gate valve must be placed on a fixed temporary platform to avoid excessive load on the inlet pipes.

Main parameters and technical characteristics of gate valves:

- Nominal pressure, MPa (kgf/cm²) - 1.6 - 12.5 (16 - 125);

- Nominal diameter, mm - from 100 mm to 1200 mm;

- Temperature range of the working environment (depending on the type of seal) - from -15ºС to +200ºС;

- Ambient temperature range - from -40ºС to +120ºС;

- The seal tightness class according to GOST 54808 is A;

- Type of climatic modification according to GOST 15150-84 - U1; HL1;

- Average service life - 30 years;

- The frequency of repairs and maintenance is once every 5 years.

Fire shut-off valve (valve)

The fire valve (valve) is included in the fire hydrant kit, which is installed on the fire pipeline. The fire damper must be equipped with a fire connection head and a hose with a manual barrel (clause 3.1 of GOST R 53278-2009).

The figure shows a fire valve as part of a fire hydrant.

Fire shut-off valves are classified according to the following criteria:

- Installation type: wall or duct;

- Housing design - direct-flow, through-flow, or angular (with a deflection angle of 90° or 125°);

- Body material: brass or cast iron;

- Diameter DN - 40, 50 or 65 mm;

- The type of connection is coupling/coupling or coupling/socket.

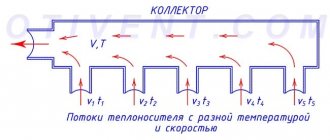

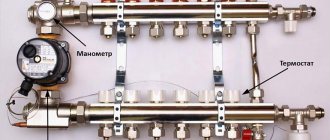

Locking devices in internal heat and water supply networks

Shut-off valves for the internal heat supply and water supply systems of an apartment building are installed on each input section of the network, at the base and top of risers with a vertical loop and on the ring line in the network distribution to allow it to be disconnected from the process for repairs.

The diameter and cross-sectional size of electric valves must correspond to the parameters of the pipes. Shut-off valves used in pipelines for household purposes usually have a small diameter of 20 - 100 mm.

The price of such products is low and depends not only on the size, but also on the material used for manufacturing. So, for example, you can buy a product with a diameter of 20 mm from cast iron 30ch906br for 30 dollars, and a product with a diameter of 20 mm from steel 30S941NZh for 50 dollars.

You can also buy high-quality full-bore electric valves produced by the Spanish company at a very affordable price. They can be used in both cold and hot water supply systems with a maximum medium temperature of up to +115ºС and a working medium pressure of no higher than 1.6 MPa.

Their body is made of GGG-40 cast iron, coated with epoxy resin to protect against the negative effects of corrosive processes on the outside and inside. The product is equipped with a non-retractable rod; a rubberized wedge is used to enhance the tightness; a flange connection is provided for connection to the process.

Main types and types of sewer valves

These sewerage products are very popular and in demand, and are also divided into certain types. The following types of sewer protection are defined:

- Local. Requires the use of a one-way valve, as it is installed to protect a specific device. The main condition should be the location of the device below the well outlet level. It has compact dimensions and installation is quick.

- General. The difference lies in the location of the shutter. For general protection, it is installed on the exhaust line. It is necessary to use products of large dimensions, since such systems are characterized by large dimensions.

Main structural types of mechanical valves:

- Single chamber valve. It is based on the natural circulation of wastewater and has no manual control. It is quite easy to maintain, but regular cleaning is required for long-term use.

- Single-chamber valve with manual locking. The direction of the damper is adjusted using a lever located on the outside of the device.

- Double chamber valve with manual control of one chamber. It has a more complex design, but allows you to regulate various wastewater flows. Requires frequent maintenance and cleaning. This valve is designed for use in sewer environments containing excess fecal waste.

- For wells. It has significant dimensions and is easy to maintain.

- For vertical installation. It has the same internal structure as horizontal models. Able to function for a long period of time.

Modern valves are made from hard plastics that are designed for use in aggressive environments. Additional elements include a rubber cuff, and the damper itself is located in a subframe made of the same material as the device body.

Installation of shut-off valves on fire-fighting water pipelines

The overwhelming number of industrial buildings, a number of multi-storey residential buildings, and administrative and residential complexes are required to be equipped with a fire extinguishing system.

The fire water pipeline is usually equipped with an electric valve with a diameter of 100 mm or 150 mm. It is connected to the bypass line of the water meter mounted on the inlet section of the cold water supply system and should open automatically from buttons that start fire pumps or when fire automatic sensors are triggered.

Watch the video:

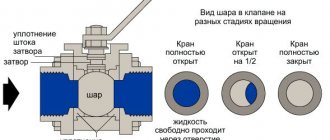

What is a motorized valve?

This is a type of shut-off or control valves, which can be controlled remotely or automatically based on alarm signals or blockages. To do this, an electric drive unit is installed on it, consisting of:

- engine;

- gearbox;

- couplings;

- end position sensors.

The explosion-proof design of the electric drive for valves involves the installation of reversible magnetic starters in the block. This improves the commutation and performance properties of the motor.

The torque from the actuator to the valve stem is transmitted through the load nut. To increase it, a gearbox is installed. In cases where the limit switches do not operate, a torque-limiting clutch is used to prevent destruction of the valve. When the response set point is reached, a signal is given to stop the engine.

The valve's electric drive allows it to be controlled from a local station. A push-button remote control is provided for this. In the event of a power failure or motor failure, the valve can be operated manually. The transition is carried out by moving the lever to the appropriate position. The steering wheel is used as a manual drive (understudy).