Sewer wells are a mandatory attribute of external sewerage; without them, its installation is impossible. They must run along the entire length of the pipeline. Their design and quantity may vary slightly, depending on the type and purpose of the structure, complexity and length of the system.

The process of constructing such a device is not complicated, the main thing is to understand the difference in types of structures, because a homemade septic tank or cesspool is also a well, and to comply with the rules and requirements. After this, it will be easier to make an efficient and trouble-free sewage system for your home.

Types of sewer wells

A structure of this kind has its own purpose and method of construction. Sewage tanks differ in a number of ways.

By functional purpose

There are several types of wells:

- Cumulative. This is a more modern and environmentally friendly option for a waste pit. It carries out fractionation of wastewater and sewage. Liquid and light particles are directed into the filtering septic tank, and heavy particles fall to the bottom of the storage tank. The volume of the structure is 2-50 thousand liters and depends on the amount of water used. It must be installed at the lowest point of the site, which ensures the correct angle of inclination of the sewer pipes.

- Filtering. The structure is designed to discharge wastewater into the soil. The well design has no bottom. The installation of filter collectors is allowed only on sandy and sandy-clayey soils. As a rule, wells are made of reinforced concrete rings. Sand, crushed stone and special materials can serve as a filter.

- Lookout. Used for periodic inspection and convenient cleaning of the drainage system in small areas where the direction, slope or diameter of pipes changes, in connection areas. Unlike other types of treatment facilities, presented in the form of a pipe or collection tank, the inspection tank is an open container. It is mounted in a straight line in increments of 15 meters, while the initial well is placed at a distance from the house no closer than 3 meters and no further than 12 meters.

- Turning. The structure is intended for areas with a branched drainage pipeline, as well as in cases where the angle of rotation on the pipeline exceeds 90 degrees. This is due to the lack of possibility of constructing a continuous straight section from a residential building to a storage septic tank. Rotary collectors must be erected at each bend of the laid pipe. This design can be used as an inspection septic tank, which makes it quite easy to clean a certain section of the pipeline through it.

- Perepadny. Used in areas with large elevation differences. In this case, the inlet pipe is placed much higher than the outlet pipe. The design of the septic tank has a drop, which is a vertical pipe going into the well, which is connected to the inlet. The lowering is attached to the tank wall using clamps. The length of this element depends on the difference in the area. On the reverse side of the lowering, a 45 degree bend is installed.

By materials used

Collectors are made from various materials:

- Reinforced concrete. The structures are durable, resistant to the negative effects of chemical compounds, and fairly easy to install. In addition, they have a large weight and different ring diameters. The products are used for constructing septic tanks of filtering, storage and inspection types. Suitable for installation in any type of soil.

- Brick. For the construction of the collector, clay waterproof bricks are often used. Brick can be used to build structures of square, rectangular or round shape.

- Plastic. Structures made of polyethylene are characterized by high strength, tightness, wear resistance, as well as ease of installation and relatively low cost. They are used for installing rotary, differential and inspection septic tanks.

Reinforced concrete structures are durable, resistant to the negative effects of chemical compounds, and fairly easy to install

Types of concrete rings

The production of all rings is the same, but they differ in purpose. Main types:

- Wall. These are through products that are installed on a solution. Used for the construction of septic tank chambers.

- Perforated. With holes in the walls. Used in filter wells, the liquid is absorbed into the soil faster.

- Auxiliary. Among them there are additional ones, which are needed to slightly increase the height of the concrete well for sewerage. The support ones are installed on the finished well so that the hatch with the cover is at the required height.

Rules and requirements

The process of planning and construction of sewer systems is carried out by Special Rules and Regulations (SNiP), regulating certain requirements, the main of which are:

- Structures should be located away from sources of drinking water and plumbing systems.

- Collectors should be installed at a distance from residential buildings and nearby areas.

- The volumes of the tanks must correspond to the number of people living in the house and the average volume of wastewater over a certain time period.

- The depth of the pit for the tank should not exceed 2.5 meters , and its diameter should be half a meter larger than the diameter of the structure.

- The need for waterproofing at high groundwater levels.

- The bottom of the pit must be covered with a sand cushion 10 cm high.

- A gap of 60 cm must be provided between the bottom of the tank and the bottom of the pipe

Collectors should be installed at a distance from residential buildings and nearby areas

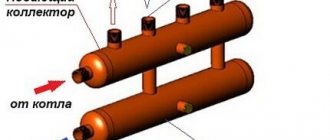

Volumes of septic tanks, dimensions of concrete rings, bottoms and ceilings

According to standards, 1 person on average consumes 200 liters of water per day. The well (drainage is not taken into account) must take a three-day norm - 600 liters. To calculate the sewer volume, this number is multiplied by the number of family members to obtain the tank capacity. If there are 2 chambers, the first should receive ⅔ of the waste, the second - ⅓.

Rings are selected according to the calculated volume of the wells. Pay attention to the markings. The letters indicate the type of reinforced concrete, and the numbers indicate the dimensions in inches: first the diameter, then the height. The latter figure is predominantly 0.9 m, but with a diameter over 1.5 m it can be 60 cm to reduce weight. The diameter of the rings for a septic tank is from 0.7 to 2 m.

Decoding the markings of the reinforced concrete ring

The volume of 1 ring is calculated based on the dimensions. For example, KS10-9 has a diameter of 1 m, a height of 0.9 m, and its volume is 0.24 m³. For a two-chamber treatment plant you will need 3 elements for 1 person. If there are up to 3 people in a family, 2-3 such containers are required. The volume is increased due to the diameter, and not the number of rings - it is not recommended to install more than 3 on top of each other, since the stability of the structure is weakened.

The diameter of the bottoms is available in sizes 150, 200 and 250 cm. Installation is simplified and tightness increases if, instead of a separate element, you choose a monolithic product with a bottom. There are overlaps for all types of rings, except KS7. They have an off-center hole with a standard diameter of 0.7 m.

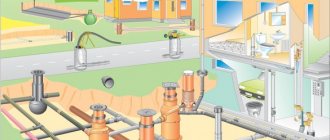

Construction of a sewer well

Preparatory work

Preparation for the construction of sewer septic tanks consists of several stages:

- drawing up a drawing of a sewerage diagram with marking of the installation location of the collector, layout of the site;

- cleaning the construction site;

- organization of a temporary road for equipment at the construction site;

- digging a pit and trench;

- cleaning and leveling the bottom of the pit.

Sewage well design diagram

Installation of a concrete well

Sewage wells made of concrete and brick practically do not differ in the stages and progress of installation work. In any case, installation proceeds as follows:

- A pit of the required size is dug.

- The foundation is being laid - pouring the foundation or a finished slab.

- Construction of walls - pouring or installing rings.

- Waterproofing walls and seams.

- Backfilling and compaction.

- Cover device.

In order to lower the finished rings into the pit, you will need to use special equipment.

Construction of a stone well

The construction of a septic tank from reinforced concrete rings is carried out as follows:

- After installing the first ring, holes are made in its walls for pipes, which should be inserted into the ring no more than 10 cm

Soil is excavated from the internal contour to level the structure horizontally. To eliminate errors in operation, this process should be controlled using a level.

- After installing the first ring, holes are made in its walls for pipes , which should be inserted into the ring no more than 10 cm. The hole is sealed around the circumference of the pipes with a solution.

- At the bottom of the tank there is a concrete trench located from the pipe inlet to the outlet. The cross-section of the gutter must be equal to the diameter of the pipes. To make it, you can take part of a sewer pipe.

- After installing the first ring, install the next one. At this stage, it is necessary to ensure that the locks on the inside of the rings are located at the same level.

- Upon completion of the installation of the last ring, the bottom of the collector is filled with concrete mortar , and the junctions of the rings are sealed with a sand-cement mixture. When constructing a filtering septic tank, its bottom is not concreted, but covered with 0.5 m thick crushed stone or crushed brick.

- Next, the structure is covered with a concrete slab with a hatch. You can also install a frame with a hole and fill it with concrete.

- After installing the well, they begin laying the pipeline at a depth of 60-70 cm with a slope of 2 cm through each meter of the pipeline.

- The next step is to test the design for 24 hours. To do this, the collector is filled with water, and the ends of the pipes are closed with plugs.

- After testing, the outer walls of the tank are covered with earth and thoroughly compacted.

- The final stage is to make a concrete blind area around the neck 1.5 meters wide.

Let's consider the technology of building a brick collector:

- A pit is dug, at the bottom of which formwork is installed and filled with a solution of cement, sand and crushed stone 20 cm high.

- Allow the solution to harden for 7 days , while periodically sprinkling with water.

- After the mortar has hardened, they begin laying brick walls using a cement mixture.

- The erected walls are plastered with sand-cement mortar.

- Without waiting for the solution to completely harden , iron the surface by rubbing a thin layer of dry cement into the plaster.

- The bottom of the collector is formed depending on its purpose.

- Waterproofing of the plastered layer is carried out.

- Cover the internal walls of the septic tank with mastic or bitumen.

- Form holes for pipes.

- The pipes are installed, and the resulting gaps are sealed with sealant.

- Fill the space between the pit and the walls of the well with soil and compact it thoroughly.

- Cover the collector with a hatch.

The construction of a well from natural stone is carried out according to a similar scheme. Difficulties in the process of its construction arise due to the unequal size and shape of the stones. Therefore, arranging the collector requires much more time and solution consumption.

Construction of an inspection drainage well

Types of drainage wells

According to its purpose, the drainage shaft can be:

- Lookout.

- Collector.

- Absorbent.

The inspection well for drainage has several other working names. It may be called audit or inspection. Designed to monitor the technical condition of the drainage system, its timely cleaning, maintenance and repair.

An inspection well is installed for drainage in places where pipes turn or change their direction. On straight pipes, installation of shafts is carried out every 30 meters with a pipeline diameter of 15 cm or every 50 meters with a pipeline diameter of 20 cm. Additionally, you can install an inspection well for drainage at the intersection points of the drains.

If it is planned that there will be a descent for maintenance, then the plastic inspection well shaft must have a diameter of at least 1.0 meters. If the shaft is cleaned with water pressure from an external hose, then the optimal diameter for the shaft will be 35-45 cm.

Plastic stormwater collection wells are typical for private country houses. If the site has a slope, then the installation of the shaft is carried out at the lowest point of the site.

If the site is flat, then the installation of drainage pipes is carried out at a slight slope of the sewer system, and storm wells are installed slightly below the level of the pipes. This will ensure a random outflow of water from the pipes into the mine.

The liquid can accumulate or drain naturally into the central drainage channel, the nearest body of water. If there is no outlet, then the water is pumped out using a pump, which often comes with the tank.

The collector storage tank can serve as an element of the sewer system. The drainage well for sewage is equipped with a system for removing solid elements. After passing through several levels of purification through the septic tank, liquid accumulates in the shaft, which is subsequently pumped out. The dimensions of the drive are not adjustable, it all depends on the wishes of the owner.

An absorption or filter tank is designed to drain a certain small area of the area where it is impossible or there is no need to install a general drainage structure. For drainage, soil is selected in which the volume of liquid passing through the well is no more than 1 cubic meter. m.

A characteristic difference between a well is the absence of a bottom, its shape and method of installation. It has the shape of a truncated cone, which is installed with a smaller diameter upwards. If desired, you can install a shaft of a different shape.

For installation, a pit with a depth of about 2.0 meters will be equipped. A cushion of crushed stone, 2-3 cm thick, is placed at the bottom of the pit. But the cushion is installed in a cone wrapped in geotextile. Inside the shaft, a lining is made of small stone, crushed stone or slag, which is covered with geotextile. When the mine is flooded, the liquid is pumped out and the geotextiles are replaced.

By type, wells are divided into:

- Turning.

- Tee.

- Cross.

- Passage.

- Dead end.

- No holes.

A rotary plastic drainage well is installed at the places where the pipes turn. Often these are the external and internal corners of buildings. These areas are most vulnerable to clogging. The pipes at the rotary well are located at an angle of 90°.

A cross-well and a tee-well can be located in the place of rotary shafts, to which additional drainage lines are connected. The cross and tee can be used as inspection points in certain areas where several drainage lines are connected to one point.

The pipes in such shafts are located at an angle of 90° relative to each other. The dead-end type of shaft is applicable to a collector well and has one inlet pipe. A storage tank without holes is used as an absorption shaft.

Features of well construction

When building a septic tank, it is important to take into account the installation features of each, depending on their purpose and material of manufacture.

The peculiarity of a filter well is that its main task is to clean wastewater from harmful impurities. To accomplish this task, the bottom of the collector is covered with crushed stone about 1 meter high. In this case, the bottom is not completely filled with concrete solution, but only along the perimeter. This prevents the destruction of the base and the release of water through the center of the circle in which drainage and cleaning occur.

For the construction of an inspection well, it is customary to use a pipe with a diameter of 46 cm. This pipe size makes it possible, if necessary, to clean the structure with water using a hose. If you need to go down into the tank, the diameter of the pipe must exceed 92.5 cm.

When constructing an inspection collector on an area without a road surface, an additional blind area is required, which facilitates the drainage of wastewater. If the road surface is of high quality, installation is carried out 7 cm above the ground surface.

Storage tanks are installed in the lowlands of the site to ensure water flows into the well. The structure is placed at a depth of 3-6.5 meters, no more than 7 rings are used during construction. At the bottom, special depressions are made, which are filled with sand or crushed stone. Water from the reservoir can be used for domestic needs.

Features and advantages of concrete rings

The advantages of reinforced concrete circles for the construction of treatment facilities appear when compared with other materials used for these purposes:

- Tanks made of red brick require waterproofing of internal and external walls. Even with careful work, they are short-lived and are destroyed by aggressive substances present in wastewater.

- The metal is susceptible to corrosion, especially in aerobic septic tanks under the influence of oxygen. The service life of containers made of black steel is short, and stainless steel is expensive.

- The main disadvantage of plastic is its light weight. Even when filled with water, it can be squeezed out when the soil heaves. Requires anchoring to a reinforced concrete slab. Eurocubes and plastic barrels have thin walls and require protection with a metal frame to prevent them from being crushed by the soil.

- The construction of a reinforced concrete monolith is a labor-intensive and long-term process.

The construction of sewerage from concrete rings occurs quickly; when using technology, the work is completed in 1 day. The structure is strong, moving soils will not be able to destroy it. Concrete in factory products has low moisture absorption. Additional waterproofing guarantees complete tightness. Durability is confirmed by the fact that city sewerage treatment plants are made of reinforced concrete.

Blitz tips

- It is not recommended to make the trench depth too large , because you will need to add soil, which will subside over time. As a result, the highway may change the correct slope.

- To avoid damage to the pipeline, it is prohibited to place solid objects under the pipes during their installation .

- When choosing a site for the construction of a filtration or storage collector, it is necessary to provide for the possibility of equipment access to clean the structure.

- Despite the fact that a sewer septic tank is a wet type of well, its tightness must be ensured. This is necessary in order to minimize the penetration of wastewater into the environment. To waterproof the ring joint areas, special waterproof compounds are used.

- During the period of providing a waterproofing layer for 3 days, it is necessary to exclude the impact of mechanical loads and low temperatures on the surface. During this time, the treated areas should be regularly moistened using a regular sprayer. You can also cover the surface with a film, which helps reduce moisture evaporation.

What types of concrete rings are there?

It must be said that the rings are made at factories from fine-grained concrete, which, of course, gives them strength. In addition, reinforcement is often used for even greater reliability. Therefore, there is no doubt that the sewer well will last for many years.

When choosing concrete rings, pay special attention to the diameter. It can be different. And the volume of the future well will depend on which one you choose. In general, experts advise calculating all the necessary data at the design stage. To correctly determine the volume of a well, take as a basis the fact that about 200 liters of waste water per person per day.

If the sewer wells are small in volume, they will have to be emptied very often. And this, as they say, is money down the drain. Therefore, it is worth taking the design of the structure very seriously.

Having found out the required volume of the well, calculate the number of concrete rings that will be required for construction (read also: “Installing sewer rings - what to do and in what order”).

Concrete rings are produced in two types:

- Concrete rings of normal permeability

. Suitable for use in non-aggressive, soft soils. And in aggressive, clayey soils they are used only for closed pipelines. When planning a septic tank in clay soil, you need to study the features of such a device. - Concrete rings of low permeability

. Can be used in soils of any composition. They are also ideal for collectors, septic tanks and inspection wells.

Septic tank with filter well

Engineering communications of a private house

This option is already an engineering structure where the wastewater undergoes real treatment and is then drained into the soil. The level of wastewater purification (clarification) is up to 80% .

The principle of operation of this design is as follows: wastewater from the home enters the septic tank - a sealed sewer well. Here, solid particles settle to the bottom, and clarified water flows into a drainage well, where it is further purified and released into the ground.

In order to improve the quality of cleaning, you can use 2-3 drainage wells (sewage well series).

Septic tank and 2 drainage wells

You build a septic tank with your own hands according to the principle of a sealed drainage pit (see above). A drainage well is built according to the same principle, only without a bottom and not sealed. Moreover, the lower edge of the walls of the drainage well is made with perforation for better drainage of water into the ground.

Example of a septic tank with a drainage well

We dig a hole under the drainage well with a depth reserve of 40 cm. We put 20 cm of sand on the bottom, and 20 cm of gravel on it. This is an additional filter structure. We make the walls of the well perforated about a meter from the bottom. We also sprinkle the outer wall of the perforated well with 20 cm of gravel to prevent the holes from clogging with soil.

SNIP regulates such sewer wells in the same way as drainage pits. All distances are the same.

Sealed cesspool

Sealed sewer well

It is possible to fully meet the requirements for sewer wells only by constructing a sealed sewer well . This method does not harm the environment; the volume of wastewater can be increased.

This method is recommended in areas with moderate wastewater output. For example, a family of 4 can produce about 600 liters of sewage per day, assuming 150 liters per person. Therefore, it is better to build a cesspool with a reserve in volume. It is worth remembering that its depth should not be more than 3 meters, otherwise the sewerage machine’s pipe will not reach the bottom.

The requirements and distances between objects according to SNIP for a sealed well are similar to the above requirements for a pit without a bottom.

The accumulated sewage is collected by a sewage disposal truck 1-2 times a month.

The construction of sealed sewer wells is possible using various materials.

The most popular today are:

- Reinforced concrete rings.

- Brick.

- Polymer tanks.

Advice: there are now many offers on the market from manufacturers of turnkey autonomous sewer systems. These are energy-dependent structures (with a pump) that save you time and site space. In addition, they will do all the work themselves. The downside is the high cost.