Electromagnetic valves for water are devices with which you can remotely shut off or open the flow of water, gas and any other medium located in the pipeline. These devices are called electromagnetic because they use an electromagnetic coil (solenoid) to operate. There are several types of such devices and each has its own characteristics and differences in operating principles.

An electromagnetic valve is a type of shut-off valve installed on various pipelines, including domestic ones

Basic elements of the solenoid valve and principle of operation

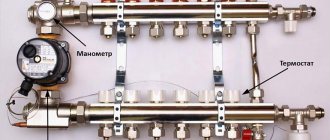

The electromagnetic valve for water and other media includes the following components:

- frame;

- lid;

- membrane and seal;

- plunger;

- stock;

- electric coil.

The body of the devices is usually made of brass, stainless steel (to improve anti-corrosion qualities) and cast iron. Plastic solenoid valves for water are extremely popular.

For the manufacture of plungers and rods, materials that have magnetic properties are used. Electromagnetic coils are produced in a special protective housing, which has high leak-tightness. The winding for the coils consists mainly of copper wire or enameled wire. The operation of such devices is carried out by applying voltage to the coil.

Product membranes are made from polymer materials that have high elasticity.

Such materials include:

- membranes EPDM, NBR, FKM.

- PTFE or TEFLON seals.

Valves are made of different materials; the body can be plastic, brass or cast iron

The thermal properties of membranes and seals are summarized in Table No. 1. Table 1

| Name | Material | Temperature (min), °С | Temperature (max), °С |

| EPDM | Ethylene-propylene rubbers | –40 | +140 |

| NBR | Nitrile-butadiene rubbers | –30 | +100 |

| FKM | Fluorine rubber | –30 | +150 |

| PTFE | Polytetrafluoroethylene | –50 | +200 |

| TEFLON | Polytetrafluoroethylene | –50 | +250 |

Working principle of water solenoid valve

If there is a need to shut off the supply of the transported medium, then a pulse is sent from the control device to the electromagnetic coil. As a result of this signal, the middle of the device lowers or rises (this depends on the type of product) and shuts off the water. After the tension disappears, the center returns and the movement of the medium resumes.

Important! Valves are used in different environments, which have individual pressure and temperature indicators. The choice of model must match the characteristics of the environment, otherwise the device will not last long.

Valve check

The carburetor valve should be checked in the following modes:

- Idling. After starting, increase the speed to 2100 and listen to the carburetor. A sharp characteristic sound should be heard indicating the shutter is closing. Next, smoothly reduce the speed to 1900; an opening click should be heard.

- Engine braking. You need to let off the gas without changing gear. In this case, a working valve will not work, even if the speed has dropped to 1900. If a click is heard, the device is faulty.

- After stopping the engine. If, when the ignition is turned off, spontaneous outbreaks of the detonating working mixture continue in the cylinders, the engine jerks and vibrates - this means that the valve does not shut off the fuel supply to the chambers and further to the cylinders.

- If you pull the solenoid valve power wire out of the connector while the engine is running, the engine should stall. If it continues to work, it means the valve is faulty.

In addition to ways to check the solenoid valve “on the go,” you can unscrew the valve from the carburetor body and try to apply voltage to it from the battery. One wire from the battery is connected to the contact block, the other to the body of the device. When voltage is applied, the valve should click and pull the needle inward. After the circuit opens, another click is heard and the return spring retracts the needle. At the same time, you can check whether the parts of the device are contaminated with resinous deposits. They need to be soaked in gasoline and removed with a soft cloth.

It is also necessary to check whether control voltage is supplied to the contacts. Its normal value is 10.5-14.4 volts. If there is voltage on the control unit, but not on the contact, it means the wire is faulty. It needs to be repaired or replaced.

If there is no voltage at the control unit connector, then most likely the unit itself is faulty. It is checked by connecting the valve to the battery with another temporary wire. A voltmeter or test light is connected to the terminal of the control unit that controls the valve. Next, you should start the engine. When the speed reaches 900 rpm, the light should flash, and at 2100 rpm it should go out. If you reduce the defense to 1900 rpm, it will flare up again. This behavior of the light bulb means the control unit is working properly. If the light does not light up or go out at all, and also turns on and off at different speeds, the control unit is subject to in-depth testing and, possibly, replacement.

Application area

The solenoid valve is a fairly useful device and is used in various fields. Basically, the scope of application is determined based on the material from which the valve is made. Such products are used in washing machines, sewer systems, irrigation structures, for controlling hydraulic systems, heating systems, etc.

The solenoid valve can be installed on the water supply or heating mains in your home

In addition, solenoid models are used to control and regulate the transportation of various aggressive media in production. Manufacturing devices can have enormous diameters. It is strictly forbidden to use brass products in aggressive environments, such as acid, diesel fuel.

Where is it used?

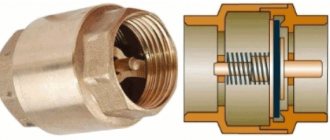

A non-return valve is very useful in the water supply of a private home.

If for some reason the pump stops, it prevents water from flowing back into the well or borehole. In the event of a power outage or pump shutdown, there is no need to refill the system with water.

On water pipes.

The supply of hot and cold water in private and apartment buildings is carried out through different pipes. Sometimes different water pressure causes hot water to fill cold water pipes. The valve allows you to bring the pressure back to normal.

In front of the cold and hot water meter.

Helps protect against damage in the event of a water hammer.

At the inlet to the water heater.

The boiler is filled under pressure. When warming up and pressure increases, the displaced coolant will be directed back into the cold pipe. Prevents churn

Advantages of solenoid valves for water

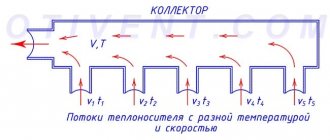

The main advantage of a solenoid valve for water is that its use allows for quick regulation of the transported medium in a water supply system or any other. For the product to perform its function, 2-3 seconds are enough. Thanks to this, the solenoid model is an indispensable device in water supply systems of apartments and private houses. It will allow you to control the temperature in the system by regulating the water supply.

The electromagnetic product allows you to evenly distribute the temperature in the system and this prevents its contamination. This affects the extension of the service life of the entire heating structure. Thanks to these characteristics, solenoid models occupy a leading position in the shut-off valves market.

Due to the absence of mechanical parts in the design that quickly wear out and fail, the solenoid device is considered more reliable. It can be installed in systems with different pressures, because this parameter does not affect its operation.

The solenoid valve can operate stably in systems with different pressures

Advantages and disadvantages

Check valves have strengths and weaknesses. Advantages:

- In case of breakdowns, you can replace any part of the structure.

- Reliable pipeline shut-off, high tightness.

- The device opens slowly, and the system does not experience shocks from the working mixture, overloads, or pressure surges.

- When working with a part, you do not need to exert much effort.

- Models equipped with an electric drive allow you to set the algorithm for opening and closing the damper based on time or depending on changes in pressure.

Flaws:

- Complex shape of the flow part.

- High price.

- If the structure has seals, additional maintenance of the equipment is necessary.

- If the flow part has defects, stagnation occurs that can destroy the structure.

Taking into account the disadvantages, many problems can be avoided when operating locking mechanisms.

Types and characteristics of solenoid valves

The solenoid valve (its types) can be divided into two main categories, which differ in the principle of operation of the on and off mechanism:

- direct action.

- pilot action.

In addition, they are divided into several main types that have functional characteristics. Devices can be:

- normally closed (open). If there is no voltage supply to the coil, it will always be in the closed position. When voltage arrives, it opens the device. A normally open valve acts in the opposite way - without tension it does not interfere with the movement of the medium;

- bistable. When voltage is supplied, the operating positions are switched.

Based on the type of coils, devices are divided into:

- DC - the coil of such devices has a low electromagnetic field strength.

- alternating current - the strength of the electromagnetic field of such a coil is quite large.

Helpful information! There is a special type of device called a shut-off device. Shut-off models perform the function of instantly shutting off a pipeline or blocking one of the pipes in an emergency.

In addition, the unit, depending on the nature of its functioning, is divided into:

- one-way;

- two-way;

- three-way.

A two-way valve has two pipes - inlet and outlet

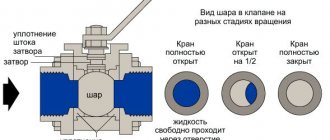

Single-pass ones have one pipe and do not combine different fluid flows. Two-way valves have two pipes (inlet and outlet). The operating principle of one-way and two-way devices is based on the functioning of a cone or ball used for closing.

Three-way solenoid valves for water - have three pipes and operate by mixing liquid flows. Also, three-way solenoid valves can control and regulate temperatures by mixing water flows. In addition, there are explosion-proof models that are used in explosive environments. These valves are made from durable, fire-resistant materials. There are also vacuum valves.

Electromagnetic coils

An electromagnetic or induction coil converts electricity into forward motion. The most common coils are those with a copper winding on a cylinder. The cylinder includes a magnetic plunger. When a pulse is applied to the coil, a magnetic field is generated. As a result of the action of the magnetic field, the core is drawn into the coil.

What is it and what is it for?

A valve, or valve, is a type of shut-off pipeline fitting. The name “valve” has been abolished since 1982, but it is still used.

A valve is a fitting in which the locking element moves parallel to the axis of movement of the liquid or gas in the pipe and completely covers its working section. The valve has two operating positions: “open” and “closed”.

Some tips for choosing the right device

There are several important parameters to consider when choosing a solenoid valve. One of the main indicators is the size of the inlet and outlet openings. The range of electromagnetic products is very wide. They may have distinctive design features. But, as a rule, this does not affect performance. One-inch solenoid devices, which have a flow rate of up to 40 l/min, are very popular.

The size of the valve outlet plays an important role; the throughput of the device depends on it

Important! Before purchasing a valve, it is recommended to pay attention to the mechanical regulator that is built into the device. It may have a different number of modes. The more there are, the more accurately the control in the system will be carried out.

If you need a valve with the highest possible throughput, you can purchase a device from the SVR series. The normally closed valve of this series has a fluid flow rate of up to 100 l/min. Prices for different valves differ and are determined by their quality characteristics.

DIY water solenoid valve installation

According to the type of connection to the pipeline there are:

- flanged valves;

- threaded valves.

When installing and using solenoid valves, you need to remember the following important points:

- Before you begin installing a solenoid device for water with your own hands, it is recommended to carry out preparatory work. This includes pipe cleaning and marking.

- The location for installing the valve must be in a visible place so that it can be easily accessed. The compact size of solenoid valves simplifies this task.

- It is strictly forbidden to install the device if the electromagnetic coil functions as a lever.

- Installation and dismantling of the device is carried out in a de-energized state.

- It is advisable that the water supply system be equipped with a dirt filter. This will prevent the product from clogging with foreign particles.

- The solenoid valve must not be subject to stress from the weight of the pipes.

- There are special arrows on the surface of the valve that indicate the direction of movement of the medium. Installation is carried out according to them.

- If installation is carried out in an open area, the device should be protected with special insulating materials.

- It is recommended to use FUM tape to seal the connection between the valve and the pipe.

- The device is connected to the electrical network using a cable. It must be flexible and have a core cross-section of at least 1 mm.

Shut-off and control valves should be selected and installed according to calculations made in advance. It is necessary to use one or another type of valve depending on the type of pipeline and the medium transported through it.

Smart electric drive for water or gas ball valve with Wi-Fi ecosystem Tuya

After installing the water leakage sensor from the previous review, the idea came up to automatically close the cold water ball valve. An automatic electric drive (servomotor) for Smart Valve Tuya ball valves is ideal for this purpose. The smart valve will connect to the smart home via the WiFi protocol, which saves you from purchasing a gateway. But there is also a version with the ZigBee protocol. Paired with a leakage sensor or with a separate gas analysis sensor (if you install this automatic smart electric drive on a gas tap). In the event of a signal of flooding or excess gas, the ball valve will AUTOMATICALLY close.

Smart WiFi faucet - CHECK THE PRICE

WiFi flood sensor - CHECK THE PRICE

WiFi gas sensor - CHECK THE PRICE

Content

- Appearance

- Internals of the device

- Installation

- Software and Automation

- Automation

- Video review

- conclusions

Appearance

The faucet is delivered in a regular cardboard box, without any identification marks. Inside is everything you need to connect.

There is no particular need for instructions; what is useful is how to attach the faucet and see the characteristics of the device.

The faucet requires 12V power to operate. For this purpose, the kit includes a 12V - 1A power supply. with European plug. The total length of the wires is about 5 meters, but if necessary, it can be increased.

At the top of the faucet there is an on/off button (used to open or close the faucet without using a mobile application) and an LED indicating WiFi connection.

You can close or open the faucet even if there is no electric power at home; to do this, you need to use the ring, pull the locking mechanism towards you and turn the faucet lever 90 degrees to close or open.

In fact, this device can be used wherever you need to turn something 90 degrees; some are even used for opening small windows in a greenhouse.

The width of the “hook” can be adjusted, the maximum value is 23 millimeters.

The dimensions of the device are 68*79*103 millimeters.

Internals of the device

The rather popular TYWE3S module is responsible for the smartness of the device. TYWE3S is a low power consumption built-in Wi-Fi module developed by Tuya. “It consists of a highly integrated wireless RF chip (ESP8266), several peripherals, an integrated Wi-Fi network protocol stack, and various library functions.” Google Translate"

The control button and operation indication LED are located on a separate board.

I thought there would be a regular gearbox with plastic gears inside. But I was very pleasantly surprised when I found out that the gears were metal. A big + to the service life of this device.

To limit the opening/closing angle, limit switches are installed in the form of small buttons.

Installation

I have 1 cold water root tap, and I will mount this device on it.

We attach a metal bracket from the kit to the automation for installation on a pipe.

Next, we fix the automation on the pipe, not forgetting to tighten the “hooks” to the width of the ball valve handle.

We connect the power and use the open/close button to check the operation of the mechanism. If necessary, you can further adjust the position of the lever using “hooks” on the arm of the automation.

In normal mode, the power is 0.4W, and during operation 1.6W.

Full opening or closing occurs in just 8 seconds.

Software and Automation

Download and install the Smart Life or Tuya Smart application on your smartphone. We put the automation into pairing mode by holding the open/close button for 7-10 seconds until the indication LED starts flashing quickly. Go to the add devices menu and select any WiFi device (socket, switch, extension cord). Next, select your WiFi network as standard and enter its password. The software will automatically detect what we have added, after which you can rename it to your taste.

In the main menu, you can immediately see the status of the device (closed or open) and by “pressing” the virtual button, we can control the tap.

You can set operation timers to open or close. This function will be convenient, for example, for organizing automatic watering of the lawn.

After creating various opening/closing timers, they can be controlled from the additional menu.

In addition to the timer, it is possible to set a countdown to change the status from closed to open, and vice versa. In this case, under the virtual button there will be a notification that after N time the device status will be changed.

In addition, you can view the device status, view timers and other counters from the main screen of the Smart Life application.

I recommend turning on status notification, then if there is no WiFi connection to the device, a reminder will be sent to your smartphone. At the time of writing the review, the firmware was 1.1.2, you can set the update mode to automatic, or you can update “manually”.

Automation

If there is a leakage sensor or a gas leakage sensor, it is necessary to turn off the water/gas. To do this, go to the automation menu and select the condition that if the leakage sensor is triggered, close the tap.

You can trigger an open/close action or even a close+open action (Reverse Switch). Or first the countdown timer, then changing the status of the device. By the way, I recommend setting one task per month for closing + opening, in order to prevent the tap from “souring.”

Another automation can be added after a leak or gas leak is fixed. Namely, to open the tap. But in the case of gas, I would not do this without visual control.

In my case, automation looks like this. The script has not yet been added - close and open the tap once a month.

In case of operation, a notification is sent to the curtain about the operation and the status of the faucet. On average, from the moment of “flooding” to the start of closing the tap is 3-7 seconds - shown in detail in the video review.

Video review

conclusions

As I already said, there is a WiFi version and there is Zigbee. In the case of WiFi, there is no need to buy any additional gateways, but if you already have a ZigBee gateway at home, then I think it would be preferable to use the ZigBee version. But with WiFi it turns out to be more autonomous. I will use this automation in conjunction with the WiFi leak sensor from the previous review. In fact, for a fairly small amount you can protect your home from big problems. The response time after flooding is 3 seconds, and the complete closing of the tap is only 7 seconds. And this is all completely automated + notification to a smartphone or other smart home system. If you went on vacation and forgot to turn off the water or gas - that’s also not a problem, go to the Smart Life application and with one click turn off the water with a smart tap, from anywhere in the world. Since the leakage sensor and automatic faucet work via WiFi, they can be used as a separate set in the house, without the need to additionally purchase and configure gateways.