Currently, polymer pipes are widely used for laying water supply, sewer and heating communications; depending on the type of materials, they are connected by soldering, threading, flanges and fittings. Relatively recently, a technology for laying pipelines has appeared on the domestic market, which uses adhesive PVC pipes.

It should be noted that the installation method using adhesive joints of polyvinyl chloride (PVC) pipes is especially relevant in some areas of civil engineering and industry, where there are no equivalent alternatives. In domestic use, the laying of communications from adhesive PVC pipelines has not yet received widespread development due to a number of negative factors.

Rice. 1 PVC pipe for gluing

Technical and operational characteristics

The name PVC in relation to pipes refers to unplasticized polyvinyl chloride (PVC-U) or vinyl plastic - a hard, durable material, and not soft plasticized polyvinyl chloride.

Due to its remarkable technical qualities, polyvinyl chloride is one of the most popular plastic materials for pipes.

PVC characteristics:

- Durability. The first pipelines stood for more than 60 years, others worked for more than 50 years. Potentially, PVC can last up to 100 years (in good conditions - underground, in a building).

- Tightness, very low permeability to gases, including oxygen.

- Complete anti-corrosion.

- High resistance to ignition (for CPVC - 482 ° C), self-extinguishing ability.

- High mechanical strength, resistance to hydraulic shocks. These indicators are the best among plumbing plastics.

- Chemical inertness, durability - does not dissolve in gasoline and kerosene, oils; resistance to alkalis and acids.

- Biological stability.

- Smooth walls provide low hydraulic resistance and prevent the deposition of calcium and magnesium salts on the walls.

- UV resistance.

- Frost resistance (up to -15 °C).

- Easy installation, good technological qualities - PVC is easy to cut, bend, weld, and glue.

- Low price - the lowest compared to the most popular polymers for pipes (PVC, polypropylene, polyethylene);

- Recyclable.

- Non-toxic to humans.

- Dielectric properties.

- Safety during destruction in industrial conditions. However, you should not burn PVC at home - incomplete combustion produces toxic substances.

- Environmentally friendly. During production, 43% of oil (by weight) is wasted.

Negative properties of PVC pipes:

- Insufficient heat resistance of the material - up to 66 ° C; chlorinated PVC can withstand temperatures of 100 °C.

- Limitation of working pressure – up to 1.6 MPa.

What does it consist of and how is it produced?

Polyvinyl chloride is a hard and durable thermoplastic. It is obtained from vinyl chloride by polymerization. In the hydrocarbon chain, every fourth hydrogen atom is replaced by chlorine.

PVC production technology is complex, but not very expensive. In mixers, different components are combined, the suspension or emulsion is polymerized. They receive either a semi-finished product - sheets, granules - or immediately finished products, for example pipes, corrugated sheets.

A small amount of lubricating additives is added to the composition to facilitate processing, and stabilizers to improve strength properties. Sometimes modifiers, dyes, and fillers are added. Fillers reduce cost, modifiers and fillers improve mechanical properties. Dyes add color and make the plastic opaque - this is necessary for protection from ultraviolet rays.

After painting, ultraviolet light penetrates to a shallow depth; only the ultra-thin top layer of material (0.05 mm) is subjected to photodestruction. The bulk of the plastic does not degrade, which is why polyvinyl chloride is called UV-resistant, without going into the intricacies of creating resistance to sunlight.

Regular PVC has little resistance to elevated temperatures, so it is chlorinated to create chlorinated PVC.

Scope of application

The connection of polyvinyl chloride pipes forms engineering networks: pressure water supply systems, sewerage systems, pipelines for transporting aggressive liquids and gases. The material is used to make containers for liquids, air ducts, laboratory glassware and equipment.

PVC pipelines, due to their ability to self-extinguish and high resistance to fire, began to be used for fire water supply systems. Chlorinated PVC is used for hot water and heating pipes.

Conclusion

The main advantages of adhesive pipes are low cost and ease of installation. Even a non-specialist in this field can perform the connection of pipe structures described above. Therefore, the products are an excellent material for installing household pipelines.

You can get more information on this topic from the video in this article.

Previous entry Pipe ram: description and principle of operation

Next entry Polypropylene sewer pipes: characteristics, classification and installation methods

Advantages and disadvantages of PVC pipes

Compared to steel and cast iron pipes, the great advantage of PVC products is corrosion resistance and durability, chemical resistance, low adhesion - pipelines do not become overgrown with salts.

Main advantages compared to polyethylene and polypropylene:

- UV resistance.

- Lower price.

- Strength.

- Higher fire resistance.

The main disadvantages of polyvinyl chloride pipes are insufficient strength compared to steel, limited operating pressure to 1.6 MPa, and insufficient resistance to elevated temperatures.

Physical characteristics of PVC

| Parameter | Test Method | Unit | Meaning |

| Density | ISO 1183 ASTM D792 | g/cm3 g/cm3 | 1,38 1,38 |

| Modulus of elasticity | ISO 527 | MPa=N/mm2 | 3000 |

| Notched IZOD impact strength at 23°C | ASTM D256 | J/m | 50 |

| Elongation at break | ISO 527 | % | 50 |

| Rockwell hardness | ISO 868 | Shore D | 80 |

| Ultimate tensile strength | SO 527 | MPa=N/mm2 | 50 |

| Heat resistance according to VICAT (B/50) | ISO 306 | °C | 76 |

| Deformation temperature when heated (0.46 N/mm2) | ASTM D648 | °C | 86 |

| Thermal conductivity at 23°C | DIN 52612-1 ASTM C177 | W/(m°C) W/(m°C) | 0,15 0,15 |

| Coefficient of thermal expansion | DIN 53752 ASTM D696 | m/(m°C) m/(m°C) | 8 x 10-5 8 x 10-5 |

| Coefficient of thermal expansion | DIN 53752 ASTM D696 | % % | 45 45 |

is the official distributor of the FIP plant (Italy). We supply a full range of PVC pipes, fittings and shut-off valves for adhesive joints. Products are always available in a warehouse in Moscow.

Methods for connecting PVC pipes

Ways to connect segments:

- Bell-shaped Used for non-pressure sewer systems.

- Using flanges attached to the pipe without glue. This type of connection is more often used for large diameters, at the entrance to the building for fastening a crane or valve.

- Adhesive connections using simple, dismountable couplings; fittings transitional to metal parts of the pipeline or shut-off valves.

Cold welding

Cold welding is the joining of polyvinyl chloride systems using glue. It forms a very reliable, durable, tight connection. Installing engineering systems using glue is easy and quick; you don’t need a soldering iron or expensive tools.

Advantages of adhesive bonding

Advantages of “cold welding”:

- The adhesive connection is very reliable, reducing the risk of leaks.

- Gluing work is very simple, even an inexperienced home craftsman can handle it.

- This work will require a minimum of labor costs.

- There is no need to purchase a soldering iron or other complex equipment.

- The method is inexpensive.

- The adhesive connection is suitable for pipelines of any diameter, laying utility lines for any purpose.

Purpose of fittings

Butt bonding is less reliable than bonding using fittings. The area of the bonded surface when using a fitting is larger, and the adhesive connection is more reliable, airtight and durable than a butt connection. Butt welding is undesirable, but is allowed with a wall thickness of at least 5 mm.

Types of Adhesive Fittings

Adhesive fittings are divided into two groups: collapsible and non-separable. Collapsible ones are more expensive. The coupling halves are glued to the pipe, the connection can be disassembled in a matter of seconds. Due to the price, it should be used only when absolutely necessary.

Permanent couplings are divided into straight and angular, simple connecting and transition with threads (for screwing on metal transition fittings).

PVC product range

| PVC pipes for adhesive joints | PVC fittings for FIP adhesive joints, Italy | PVC shut-off valves FIP, Italy | PVC shut-off valves with electric drive |

| PVC shut-off valves with pneumatic drive |

| PVC fittings for adhesive joints China |

How to choose

It is better to buy in large stores or construction supermarkets. Keep the receipt - if something happens, you can return the product.

Criteria for choosing pipes, type of glue and fittings

Adhesives come in one- and two-component types, in large or small packages. The principle of operation of any adhesive composition is approximately the same, but the likelihood of error is higher when working with two-component glue. It is better not to use large packages - the glue quickly thickens and hardens, and if it has deteriorated it will give a less reliable connection.

When choosing, be guided by the characteristics of the product and the reliability of the seller.

When purchasing, pipes and fittings must be inspected to see if there are any bends, cracks, chips, or delaminations. The presence of defects is already a reason to look for another seller, since polyvinyl chloride products are now sold everywhere.

Review of popular manufacturers of PVC pipes and glue

The most popular brands of glue manufacturers for polyvinyl chloride: German company Tangit, American Genova, Griffon (Netherlands), Gebsoplast (France). Domestic “Phoenix”, “Mars”, “Vinilit” are quite popular, but most consumers prefer to play it safe and buy imported compounds.

Manufacturers of PVC products are found in every region. The best quality is for the brands REHAU, NIBCO, GF, METRIX, Wavin, and Polyplastic.

Adhesive installation of PVC pipes

For gluing, the performer does not need special skills, but attention and accuracy are required.

Installation methods

There are two methods for gluing pipes: butt gluing and using fittings. Butt gluing is used on pipes with a larger diameter than the usual ½”, ¾” pipes, so the technology for gluing pipes using fittings is described below.

Bonding technology

First you need to draw a pipeline laying diagram and carefully measure all distances. Then the blanks are marked and cut. A pipe cutter will come in handy - the cut should be neat, strictly perpendicular to the axis.

The edges are cleaned with a fine file or sandpaper, and burrs are carefully removed. Remove dust and dirt with a rag, be sure to degrease the surfaces to be glued, and this also applies to fittings.

Apply glue with a glue gun or brush. Make sure that the entire end of the workpiece is covered with glue.

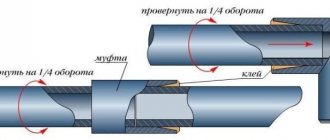

Vigorously insert the workpiece into the fitting and turn it a little (about a quarter turn) so that the glue gets onto the entire surface of the fitting. Then, with little force, press both parts for about 20-30 seconds. You need to quickly remove the exposed glue with a damp rag: it will be more difficult to do this later. The node must be postponed for a day. Complete polymerization of the adhesive joint will end after 24 hours.

Only then do they check the system by filling it with water.

All the subtleties of adhesive joining of segments into a single whole can be seen in our video:

Installation methods

Soldering of adhesive PVC products is carried out in two ways:

- Hot bonding - suitable for straight pipes and those with a socket.

- Cold welding - used only for connecting socket products.

Note! Before applying the adhesive, the surfaces to be glued must be cleaned of dust and debris, degreased and dried. Foreign particles or grease left on the surface will lead to the formation of cavities between the pipes, making the unit unreliable.

The hot gluing process is similar to welding metal products:

- the surfaces to be joined are evenly lubricated with an adhesive composition for hot welding;

- heated until softened (up to 260ºС) using a special soldering iron, inserting its nozzles into the ends of the pipes, or blowing the pipes with a construction hairdryer;

- insert the end of one pipe with a chamfer into the socket of the other;

- hold the knot motionless for half an hour so that the glue has time to “set” and dry, this takes about half an hour;

- after 2.5 hours the plastic will finally cool down, and after a day the polymerization process will be completed - the polyvinyl chloride molecules of the mating surfaces form strong bonds.

We recommend that you read: Fittings for connecting corrugated stainless steel pipes

The cold welding process is more reminiscent of the usual gluing of two elements:

- evenly coat the surfaces with glue,

- insert the lubricated areas into each other,

- hold the unit motionless for about 1-4 minutes for the glue to set;

- The polymerization process during cold welding also takes about a day.

Note! After mating the pipes, you need to remove excess glue that has protruded beyond the boundaries of the unit being formed. This must be done before the adhesive dries, since then removing it will require a solvent, which can harm the pipes.