When there is a need to repair or replace hot or cold water pipelines in a country house (apartment), the home owner faces a difficult question: how to choose a ball valve among the huge variety of shut-off equipment? The device is important - the efficiency and safety of utilities, including the water supply system, depends on the quality of the ball valve.

Therefore, this part of the pipeline system is the first to be located at the point of water entry into the building. In the event of an accident or a pipe leak, it is the quality of the tap that determines whether the home will flood and whether large material costs will be avoided. In our article we will look at how to choose a ball valve for water and what you need to pay attention to first.

What is a ball valve and why is it needed?

This is a separate type of pipeline fittings, the main element of which resembles a sphere. The equipment is used to shut off or resume the flow of water, without the possibility of regulating it. Its versatility allows it to be used both for private homes and for industry, for example, transportation of energy resources (oil, gas, etc.).

This equipment has replaced wedge-shaped valves, which have shown to be ineffective. Before purchasing a unit, you need to know which ball valve to choose for your water supply. The main advantage of the mechanism is its simple and reliable design. It is very important during the manufacturing process to obtain a perfectly smooth surface of the shutter, for which manufacturers resort to diamond polishing and chrome plating. After high-quality processing of the ball valve, the likelihood of foreign particles sticking and jamming of device elements is prevented, which generally increases the reliability and service life of the equipment.

Passage types

According to the passage characteristics, cranes are divided into two types:

- Full bore. This is the name for mechanisms in which the declared value of the nominal bore is equal to the diameter of the actual bore. For example, if the declared diameter is 80 mm, then the actual diameter in the channel is 80 mm.

- Standard pass. A device in which the stated opening size is larger than the actual opening. For example, if the declared diameter is 80 mm, the actual passage may be 60 mm. Compared to full bore valves, such valves are much cheaper.

In recent years, the second option has become most widespread. The design of such mechanisms provides minimal resistance to passing gases and liquids, therefore in some cases their throughput capacity is even greater than that of full-bore ones, although the actual diameter is smaller.

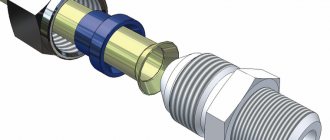

Design features of ball valves

In the center of the body, between the PTFE seals (seat), there is a spherical valve mounted on a rotating spindle to allow force transmission from the handle. The wear-resistant and sealed design of the device, quick closing/opening of the passage by turning the shutter by 90° ensures durable and effective use of the locking element.

The principle of operation of the mechanism is as follows: in the initial position, the hole is located at a right angle to the axis of the tap, thereby cutting off the water supply in the water pipeline. When the valve is opened, the inlet hole is in the same axis with the pipe, ensuring free passage of liquid through the shut-off device.

The demand for ball valves in the plumbing equipment market has led to the emergence of a huge range of products, and for most users there is a dilemma: which ball valve is better to choose? In fact, choosing the right product is not easy, due to the variety of taps of low quality and dubious origin. Therefore, it is important to study the technical and physical parameters that determine the functionality, performance of equipment and the piping system as a whole.

Housings

Based on the type of housing, locking devices can be divided into:

- All-welded. Steel non-demountable devices, which have a more attractive price compared to collapsible mechanisms. They have a long service life - about 20 years, so the need to use dismountable devices almost never arises.

- Collapsible. Devices that can be disassembled when maintenance is required. This will require specialized equipment, otherwise after disassembly/assembly, the device will lose its original tightness parameters.

Criteria or how to choose a ball valve for hot water

How to choose a ball valve for an apartment? In this case, coupling devices with a threaded connection type are suitable. For one apartment you have to buy on average 5-6 products for piping pumps, collector boilers and other utilities. High demand for products gives rise to the appearance of a large number of taps of dubious quality, which will last a maximum of one or two seasons. Which exit?

To confirm the country of origin and equipment manufacturer, ask the seller to provide a quality certificate and warranty card. Official dealers of famous brands, whom customers trust, can document the originality of the product and dispel all doubts about its quality.

Basic criteria for reliable ball valves for apartments

Housing material

This is one of the main selection criteria.

Ideally, high-quality taps are made from CW617N brass, the high price of which affects the final cost of the finished product. The main component of brass is copper. To reduce costs, some manufacturers use silumin alloys and aluminum-zinc compounds in the technological chain. Ball valves made of silumin are characterized by increased fragility compared to brass products, therefore, answering the question “which valves are better for hot water supply”, silumin is definitely not! They will quickly fail at high temperatures and pressures in the system. Products made from silumin are most often used in the automotive industry, as well as in the serial production of heating and air conditioning equipment.

When the water temperature in the pipe is up to 150 °C and the system pressure is up to 40 bar, brass taps can be used. If water flows in the pipeline at a temperature of 200 °C, and the pressure reaches up to 160 bar, a steel product can be installed. The most optimal solution for installing central heating and cold water supply are cast iron taps.

Product weight and color

The weight of a brass faucet significantly exceeds the similar characteristics of aluminum devices. The weight of the device must correspond to the characteristics stated in the passport and should not differ radically from analogues in weight. In simple terms, choose the one that is heavier among devices with the same markings. Although many manufacturers use a trick, equipping the device with a massive handle, which ultimately affects the overall weight of the mechanism.

Silumin ball valves have a pronounced silver tint, which does not change during oxidation. You can recognize a faucet made of brass in a simple, proven way - remove the top layer of nickel with a sharp object, after which you can observe the characteristic yellowness of the surface.

Ball valve

It is very important that the ball valve has a perfect mirror finish. Branded reliable valves are made of brass, the coating is polished and chrome-plated. Unlike nickel, chromium is not afraid of mechanical stress and boiling of the main parts.

A poor quality mechanism can be easily recognized by its characteristic matte finish with a cloudy tint. You can also take a magnet and check the attraction of the faucet; if it occurs, then the device is made of electrical steel, which is not suitable in terms of performance characteristics for use in water supply systems - the valve will quickly rust and fail when in contact with hot water. Brass is not attracted to a magnet.

What materials are they made from?

There are many materials for the manufacture of ball structures:

- Carbon steel. The most commonly used steels are 20 and 09G2S (this steel can be used at temperatures down to -60°C). Steel products are inexpensive, strong, durable, but susceptible to corrosion - they are coated with chromium or nickel to protect them.

- Stainless steel, most often grade 12Х18Н10Т. Stainless steel products can be used in systems with aggressive environments, at low temperatures, they are strong and durable, but quite expensive.

- Brass is an alloy of copper and zinc. Brass is strong and ductile, does not rust, is durable, but loses strength already at 200°C. But in residential buildings such temperatures do not exist, and at the moment this is the most popular material for small-diameter taps in housing.

- Bronze is an alloy of copper and tin (varieties of bronze are alloys with aluminum, silicon, beryllium, lead). The quality of the products is similar to brass, the price is higher. They don't occur very often.

- Titanium. Lightweight, durable, expensive, not used in everyday life.

- Plastic. They are used for plastic pipelines, made of the same material (some are made of unplasticized PVC, polyethylene, polypropylene). Such taps have sufficient strength, are not prone to corrosion, and are chemically inert. Less reliable than metal products. In everyday life, they are used on water supply and heating systems, but not at the entrance to an apartment or house.

- Ceramics. New strong, durable material. Durable, non-corrosive, chemically inert. They are quite expensive and, despite their strength and wear resistance, they are fragile and resistant to shocks and falls.

- Cast iron. Archaism. Found in some old plumbing systems (not in households).

- Silumin. Aluminum alloy with silicon. In practice, we can assume that silumin fittings are fake. They don’t last long, they crack, the threads are cut off, and they start leaking at the most inopportune moment. In general - transfer of money.

Type of connection or how to choose a ball valve based on pipe diameter

The type of connection is an important criterion for choosing the desired device model, which determines the features of operation and installation of pipelines. If you choose the wrong faucet according to the type of connection, you will not be able to install it in any other way.

Connection methods:

- Welded. A high-quality ball valve will have high tightness. Due to the complexity of repair or replacement, equipment is usually installed on lines with little wear on the fittings and minimal adjustment of the flow of the transported liquid.

- Flanged. Easy to install and quickly replaced if it fails. This type is used on cranes with DN 15-800 mm. Tightness is achieved by installing a rubber or paronite gasket between the flanges, as well as tight pressing with a bolted connection. The disadvantage of a flange connection is that leaks more often occur due to loosening of the bolt fastening.

- Threaded. Ball valves with a threaded connection type are usually installed on pipelines with low pressure and low temperature of the transported working fluid. Can be used in water supply systems or gas pipelines with a diameter of 8-100 mm in residential premises.

Ball valves are classified by bore diameter:

- Full bore (throughput 90-99%) - the hole in the valve is almost identical in size to the diameter of the pipe. Mounted on pipelines serving intra-house communications.

- Standard bore (throughput 70-90%) - the diameter of the hole in the valve is slightly smaller than the size of the pipe. Installed on utility networks where flow pressure losses are allowed.

- Partial bore (throughput 40-70%) - the diameter of the gate passage is significantly smaller than the diametrical size of the pipeline. Installed to specifically limit the flow of energy resources.

Tips for installation and operation

Before installing the tap, wipe the threads with a rag and clean them from dust, shavings, and dirt; the old thread should be driven out with a die - this will clean the thread from rust and deposited calcium and magnesium salts. First, the faucet is tried on - screwed on without FUM tape and the number of turns is remembered. The direction of winding the tape must coincide with the direction of winding the reinforcement. Screw the tap on the same number of turns as during fitting. The minimum number of turns is 4. Then the bend is screwed in in the same way or the nut is screwed on the other side.

The system is filled with water and tested; if there is a leak, the connection will have to be unscrewed, a sealant (FUM) added, tightened and tested again.

During operation, it is necessary to close and open the tap at least once a month - this will remove salt deposits from the ball. The shutter cannot be kept partially open - this will lead to premature wear of the shutter. The handle position must be either open or closed.

Which taps are best installed on cold water and hot water risers?

Previously, in our article it was already described which valve is better, ball or valve. With the help of the latter, you can not only block, but also regulate the direction of energy flow on the risers. Naturally, it is better to install reliable taps on residential hot water and hot water risers! It’s better to spend money on quality devices than to make repairs for yourself and your neighbors.

|

Types of seals

More than 90% of all faucets on the market have a fluoroplastic seal. This is a special polymer characterized by resistance to temperature fluctuations. This compaction makes it possible to use devices in different networks. The minimum and maximum temperatures that the material can withstand are -40 and +200 degrees, respectively.

However, there are also valves with a metal seal. The main advantage of this design is its ability to withstand extremely high temperatures. However, there is also a minus - relatively low tightness.

Specifications

The technical characteristics of ball valves are determined by:

- thread diameter;

- node dimensions;

- purpose;

- withstandable temperature;

- maximum pressure.

The main selection criterion for installation in a specific pipeline system is the size of the internal diameter of the ball valves. It is specified in inches , but can also be specified in mm.

The materials from which the body and ball are made determine the temperature up to which the unit will operate normally, and the maximum pressure that it will withstand.

Ball fittings are smaller in size than their screw counterparts. They are installed using union nuts, flanges, and welding.

Device Description

Why is the valve called a “ball valve”? The answer is simple - there is a metal sphere inside the device. When the valve is turned, it allows or prevents the passage of water or gas through the pipes. This type of locking device is especially popular in private houses or apartments.

Depending on the manufacturer, as well as on the purpose of use, the dimensions of ball valves may vary, so this must be taken into account when purchasing. But nevertheless, if we compare the sizes of modern products with those that were produced 10 years ago, then the current ones will be much more compact, more reliable and more functional than their predecessors.

Each device contains the following parts:

Comments

Submit Comment

Popular posts from this blog

Review of pumping and mixing units for “warm floors”

First of all, we associate “warm floors” with pipes, substrate and collectors. Pumping and mixing units are not always remembered. Some due to a lack of understanding of how to set it up, where to put it, and most importantly, why? Some because of the high cost. But this unit is the basis of panel heating. Let's look at the options for nodes that are on the Ukrainian market.

Functionality

Underfloor heating is a type of low temperature system. For a number of reasons, the coolant must be supplied to the pipelines at a temperature below 55°C. In our country, “warm floors” are often combined with radiator heating. The latter works with high-temperature coolant (above 55°C). This is where the pumping and mixing unit (PMU) finds its application. It reduces the coolant temperature to the calculated value for underfloor heating. By mixing two flows - hot (from the main line of the heating system) and cooled (usually from the return line after passing through the “warm floor” loops...

Where can I buy?

After determining all the characteristics that the locking mechanism you need must meet, all that remains is to buy it. You can choose the store yourself, it could be the plumbing store closest to you or an online store, however, you should only buy certified devices that come with a guarantee.

In addition, it is important to look at the novelty of the product. You should not buy hardware that is 7 or 10 years old. It is recommended to choose devices manufactured no later than 5 years ago. Over many years, materials (especially polymers) may lose some of their properties and the faucet will not be able to serve for a truly long time.

It is also necessary to take into account the seller's reviews. That is, it is recommended to first study reviews about the company or store where you plan to purchase a locking device. An abundance of negative reviews may indicate the sale of low-quality products.

In addition, if you have friends who understand the functioning of engineering systems and the equipment used to build them, it is recommended that you first seek their advice. They can advise you on which product is best suited for your application.