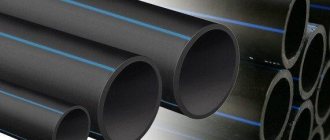

Anyone who chooses polyethylene pipes for the first time has a question: in what temperature ranges can they be used. After all, it is known that at low temperatures polymers become brittle, and at high temperatures they soften. Some sources increase concerns by indicating the operating range of HDPE pipes from 0° to + 40° C.

However, below zero, polyethylene pipes do not lose strength, and extensive operating experience, including in Russian frosts, shows that HDPE pipes are quite suitable for winter. In some aspects they are even preferable to steel ones. But the flexibility of polyethylene is still reduced, so the installation and operation of water supply has its own characteristics.

What to do to prevent pipes from freezing?

We are going to select pipes for internal piping in a country house, which will freeze from time to time. Which pipes to choose in this case and what to do to prevent the pipes from freezing and bursting? The final radical way is to drain the water from the water supply. You can also use Ensto heating cable to heat the pipeline in critical places.

Our reasoning is as follows: we definitely will not use steel or metal-plastic pipes, because when these pipes freeze, the ice breaks them. Copper pipes are not afraid of freezing - copper is ductile. But copper pipes are very expensive. Therefore, we will choose polypropylene pipes that are installed by welding. Our views are drawn to polypropylene water pipes in three categories of price and quality: Russian polypropylene pipes Proaqua in white, Czech polypropylene pipes Ekoplastik in gray and German polypropylene pipes Banninger in green.

According to rumors, white pipes are the worst able to withstand freezing of water in them and burst. We'll check if this is true?

| We take pipe sections for freezing testing. White - Proaqua, gray - Ekoplastik, green - Banninger. | For the test we use polypropylene pipes with a diameter of 20 mm and 25 mm. |

| We produce plugs for pipes from wooden plugs sealed with fum tape. | Close one end of the polypropylene pipe tightly. |

| We collect water into a polypropylene pipe. Close tightly with a wooden stopper on the other side. | and place the pipe with water in the freezer at minus 18 degrees. |

| Let's leave the polypropylene pipes in the freezer overnight. | Let's look at the results after 10 hours of freezing polypropylene pipes with water: White Proaqua pipe - did not burst, the plug was squeezed out by ice, gray Ekoplastik pipe - did not burst, the plug was squeezed out by ice, green Banninger pipe - did not burst, the plug was not squeezed out by ice. |

| What our polypropylene pipe freeze test results show: green Banninger pipes are more resilient than white and gray polypropylene pipes. The walls of the green pipe simply stretched as the ice expanded. This is confirmed by manual testing of the elasticity of the pipes: the green pipe is more pliable when frozen, while the gray and white pipes become “woody”. | If, when using white or gray pipes, there was no room for the ice to expand (for example, all the valves are closed), then the ice would most likely tear off or rupture the iron fittings in the pipeline. When using more elastic green polypropylene pipes, the likelihood of a pipeline accident when pipes freeze is reduced. |

What can be done to ensure that pipes freeze, or that losses when pipes freeze are minimal? Here are our recommendations:

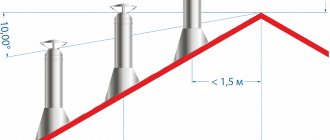

1. Use plastic polypropylene water pipes (for example, German Banninger or Belgian Green Life-Green Pipe (tested twice on frozen water pipes)). Price of 20 mm pipes per 1 m: Proaqua - 26 rubles, Ekoplastik - 33 rubles, Banninger - 48 rubles. 2. When designing the pipeline, provide taps at the lowest points of the pipelines to drain residual water when leaving home. 3. When designing a pipeline, provide for external insulation of the pipeline and laying of a heating cable. 4. Lay the pipeline openly - do not hide them in boxes and walls - this will help warm up the pipes faster when they freeze. 5. When leaving a freezing house, turn off the water supply, drain the water from the pipelines, flush the toilet and pour salt into the remaining water in the toilet and throw a wooden block into the water - this will protect the toilet from destruction. Alternatively, pump out the water at expected low temperatures. Leave all faucets and taps open. 6. It is possible to provide pipes with nipples for connecting a car compressor for purging pipelines.

Corrugated stainless steel pipe fittings

Does not shine and can withstand freezing. You can’t think of anything better; by the way, large companies use stainless steel heat exchangers in their boilers and buffer tanks. We recently did one project, where the customer asked us to make him a heat exchanger in the font. Children swim in this font, and the water is cold. We did it very simply, we left the heating system, like a radiator. Several meters of this corrugated stainless steel pipe were laid on the bottom of the font and everything worked great. But connecting it with a pipe will not work either conveniently or functionally. Not afraid of the sun or precipitation.

All about corrugated stainless steel pipes

And most importantly, I would advise using a corrugated stainless steel pipe for electrical installation. If we need to install wiring in wooden houses, then congratulations on the partition and ceiling. But this is inconvenient where you need to weld corners, turns here. This is how we do it and lay out the wiring, but there are small nuances. We cannot bring these pipes into junction boxes, but there is a much greater violation of the installation. Despite the fact that their wall thickness is 0.3 mm, this is not standardized for wiring with a cross-section of up to two and a half square millimeters. This pipe is suitable everywhere, although it is expensive, but for safety in wooden houses it is the best way. Well, that’s all about the ways in which this corrugated stainless steel pipe can be used. If you have any thoughts on this matter, other than those that I listed, I would be happy to read them in your comments.

Parameters of polypropylene pipes: frost resistance, service life, roughness

Over the past ten years, polypropylene pipes have become popular both among professional builders and those people who are furnishing their apartment or country house. When going shopping, many are faced with the problem of choosing a product, since there are a lot of polypropylene pipes on the market. But, first of all, the parameters of polypropylene pipes must correspond to the parameters of your engineering system.

Life time

1. The service life of polypropylene pipes is 50 years in a cold water supply system. In the heating system, as well as in the hot water supply system, they will last 25 years, while maintaining all their original characteristics.

2. You need to know that the maximum service life of polypropylene pipes depends on the correct combination of two important factors: pressure and temperature. At high temperature and low pressure, or vice versa, pipes can last a long time. This is even indicated in special tables. But if both the pressure and temperature are high, then the pipes will not last long.

3. What can be done to make the pipes last as long as possible? In order for the service life to be maximum, that is, 50 years, the temperature should be no more than 60-75 degrees or the pressure should be no more than 4-6 atmospheres. In general, a polypropylene pipe will last as long as it can withstand without destruction, taking into account the reliability factor of the influence of constant temperature and pressure on it. And if you comply with all operational parameters specified in building codes, polypropylene pipes will last a long time.

Polypropylene pipes and frost

Polypropylene pipes can be used at temperatures up to 40 degrees below zero. They have high frost resistance. They will not crack in frost and will not defrost in winter even at shallow burial depths. Even if the water in the pipes freezes, they do not collapse, but only increase slightly in size; when they thaw, they return to their previous size. The only thing you need to be wary of is putting too much external pressure on the pipe, which could cause it to burst. Despite temperature standards, the temperature of hot water in the heating system may exceed the specified 95 degrees in some regions. First of all, this applies to regions with a sharply continental climate: Yakutia, the Far East and Siberia. If the temperature is 52 degrees below zero, then to heat buildings at such a high temperature, the water in the heating mains must be heated much above the boiling point. And at the same time, polypropylene pipes may suffer. Therefore, there is only one conclusion: polypropylene pipes can be safely used in heating and water supply systems everywhere except in the coldest regions.

Additional thermal insulation and insulation of water pipes

The most popular protection against freezing of pipes is the preliminary adoption of measures for additional thermal insulation of the water supply system and water pipes. The materials used can be very different.

Mineral wool. This type of insulation is used quite often. It is in great demand in construction. Its advantages include resistance to temperature changes, ease of installation work, and the ability to perform its immediate functions for a very long time.

Foamed polyethylene. It is distinguished by its availability and high thermal insulation properties. The top layer of insulation based on foamed polyethylene is made of foil, which allows heat to be reflected inward, which further reduces heat loss.

Polystyrene foam (expanded polystyrene). Foam insulation for pipes is presented in the form of a kind of cover (box), consisting of two halves in a longitudinal section. To insulate the connecting nodes, a special foam shell of various shapes is used. The individual elements are fastened manually.

These articles may also be of interest to you:

- Types of water pipes and fittings

- Soldering copper pipes. Soldering restoration

- Cold welding - eliminating pipe leaks without welding

- Electric heated floors. What are they?

Will summer water pipes made of reinforced polypropylene break?

Hello. Please tell me. Do reinforced polypropylene pipes tear in winter? I want to install a new summer water supply for the area, the pipe will be 20.

It’s still not possible to drain the water - frosts come unexpectedly