Icer

5096 0 0

Icer July 22, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Over time, plaque begins to accumulate in all pipelines, and if flushing of sewer pipes is carried out more often, little attention is paid to plumbing and heating. Meanwhile, all systems need to be flushed, because over the years the internal diameter decreases due to plaque, in the waste system this is fraught with blockages, in the water supply - a decrease in pressure, in heating - a decrease in efficiency several times.

Therefore, it is necessary to clean communications at least once every 5 years, and in this review I will talk about the main methods and features of their implementation.

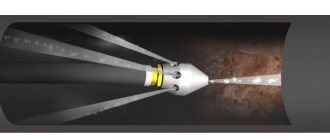

In the photo: this is what can happen inside a heating pipe

Flushing water supply pipelines after installation

APPENDIX 5 (Recommended)

PROCEDURE FOR WASHING AND DISINFECTION OF PIPELINES AND DOMESTIC WATER SUPPLY STRUCTURES

1. For the disinfection of pipelines and drinking water supply structures, it is allowed to use the following chlorine-containing reagents approved by the USSR Ministry of Health

dry reagents - bleach according to GOST 1692-85, calcium hypochlorite (neutral) according to GOST 25263-82 grade A;

liquid reagents - sodium hypochlorite (sodium hypochlorite) according to GOST 11086-76 grades A and B; electrolytic sodium hypochlorite and liquid chlorine according to GOST 6718-86.

2. Cleaning the cavity and flushing the pipeline to remove remaining contaminants and random objects should be performed, as a rule, before conducting a hydraulic test by water-air (hydropneumatic) flushing or hydromechanically using elastic cleaning pistons (foam rubber and others) or only with water

3. The speed of movement of the elastic piston during hydromechanical flushing should be taken within the range of 0.3 - 1.0 m/s at an internal pressure in the pipeline of about 0.1 MPa (1 kgf/cm2)

Cleaning foam pistons should be used with a diameter within 1.2 - 1.3 of the pipeline diameter, length - 1.5-2.0 of the pipeline diameter only on straight sections of the pipeline with smooth turns not exceeding 15°, in the absence of ends protruding into the pipeline pipelines or other parts connected to it, as well as when valves on the pipeline are fully open. The diameter of the outlet pipeline should be taken one gauge less than the diameter of the flushed pipeline

4. Hydropneumatic flushing should be carried out by supplying compressed air through the pipeline together with water in an amount of at least 50% of the water flow. Air should be introduced into the pipeline at a pressure exceeding the internal pressure in the pipeline by 0.05 -0.15 MPa (0.5 - 1 .5 kgf/cm 2) The speed of movement of the water-air mixture is assumed to be in the range from 2.0 to 3.0 m/s

5. The length of the flushed sections of pipelines, as well as the places where water and piston are introduced into the pipeline and the order of work must be determined in the work project, including a working diagram, route plan, profile and detailing of wells.

The length of the pipeline section for chlorination should, as a rule, be no more than 1-2 km.

6. After cleaning and washing, the pipeline must be disinfected by chlorination at a concentration of active chlorine of 75 - 100 mg/l (g/m3) with a contact time of chlorine water in the pipeline of 5 - 6 hours or at a concentration of 40 - 50 mg/l (g/m3 ) with a contact time of at least 24 hours. The concentration of active chlorine is assigned depending on the degree of contamination of the pipeline

7. Before chlorination, the following preparatory work should be carried out

carry out the installation of the necessary communications for the introduction of a solution of bleach (chlorine) and water, air release, risers for sampling (with their removal above ground level), installation of pipelines for the discharge and disposal of chlorine water (with the provision of safety measures); prepare a working chlorination scheme (route plan, profile and detailing of the pipeline with the application of the listed communications), as well as a work schedule;

determine and prepare the required amount of bleach (chlorine), taking into account the percentage of active chlorine in the commercial product, the volume of the chlorinated section of the pipeline with the accepted concentration (dose) of active chlorine in the solution according to the formula:

where T is the required mass of the commercial product of the chlorine-containing reagent, taking into account 5% for losses, kg;

D and l are the diameter and length of the pipeline, respectively, m;

K is the accepted concentration (dose) of active chlorine, g/m3 (mg/l);

A is the percentage of active chlorine in the commercial product, %

Example. For chlorination with a dose of 40 g/m of a pipeline section with a diameter of 400 mm, a length of 1000 m using bleach containing 18% active chlorine, a commercial mass of bleach will be required in the amount of 29.2 kg

8. To monitor the content of active chlorine along the length of the pipeline during its filling with chlorine water, temporary sampling risers with shut-off valves should be installed every 500 m, installed above the ground surface, which are also used to release air as the pipeline is filled. Their diameter is taken by calculation, but not less than 100 mm.

9. The introduction of a chlorine solution into the pipeline should continue until water with an active (residual) chlorine content of at least 50% of the specified value begins to flow out at points farthest from the point of supply of bleach. From this point on, further supply of chlorine solution must be stopped, leaving the pipeline filled with chlorine solution during the estimated contact time specified in paragraph 6 of this appendix.

10. After the end of contact, chlorine water should be discharged to the places specified in the project, and the pipeline should be flushed with clean water until the residual chlorine content in the wash water decreases to 0.3 - 0.5 mg/l. To chlorinate subsequent sections of the pipeline, chlorine water can be reused. After disinfection is completed, the chlorine water discharged from the pipeline must be diluted with water to an active chlorine concentration of 2-3 mg/l or dechlorinated by introducing sodium hyposulfite in an amount of 3.5 mg per 1 mg of active residual chlorine in the solution.

The places and conditions for the discharge of chlorine water and the procedure for monitoring its discharge must be agreed with the local sanitary and epidemiological service authorities.

11. At the points of connection (insertions) of a newly constructed pipeline to the existing network, local disinfection of fittings and fittings should be carried out with a solution of bleach.

12. Disinfection of water wells before putting them into operation is carried out in cases where, after washing them, the water quality according to bacteriological indicators does not meet the requirements of GOST 2874-82.

Disinfection is carried out in two stages, first of the above-water part of the well, then of the underwater part. To disinfect the surface part of a well above the roof of the aquifer, it is necessary to install a pneumatic plug, above which the well is filled with a solution of bleach or other chlorine-containing reagent with a concentration of active chlorine of 50-100 mg/l, depending on the degree of expected contamination. After 3-6 hours of contact, the plug should be removed and, using a special mixer, a chlorine solution should be introduced into the underwater part of the well, so that the concentration of active chlorine after mixing with water is at least 50 mg/l. After 3-6 hours of contact, pump out until the noticeable smell of chlorine disappears in the water, and then take water samples for control bacteriological analysis.

Note: The calculated volume of chlorine solution is taken to be greater than the volume of wells (in height and diameter) when disinfecting the above-water part - 1.2-1.5 times, underwater part - 2-3 times

13. Disinfection of tank structures should be carried out by irrigation with a solution of bleach or other chlorine-containing reagents with an active chlorine concentration of 200 - 250 mg/l. Such a solution must be prepared at the rate of 0.3-0.5 liters per 1 m 2 of the internal surface of the tank and, by irrigation from a hose or hydraulic remote control, cover the walls and bottom of the tank with it. After 1-2 hours, rinse the disinfected surfaces with clean tap water, removing the spent solution through the dirt outlets. work must be carried out in special clothing, rubber boots and gas masks; Before entering the tank, you should install a tank with a bleach solution for washing boots.

- Characteristics of HDPE pipes for water supply

- Cold welding for plastic water supply pipes

- Repair clamp for water supply pipes

14. Disinfection of filters after loading them, settling tanks, mixers and small-capacity pressure tanks should be carried out using the volumetric method, filling them with a solution with a concentration of 75-100 mg/l of active chlorine.

Note! How to attach a water supply collector to a wall?

15. When chlorinating pipelines and water supply structures, the requirements of SNiP III-4-80* and departmental safety regulations must be observed.

DEPARTMENT 1.4 FGU VNIIPO EMERCOM OF RUSSIA

microdistrict VNIIPO, 12, Balashikha, Moscow region, 143903 Tel., 521-83-70 tel./fax E-mail

The collection materials can be used only with the permission of the Federal State Institution VNIIPO EMERCOM OF RUSSIA © FGU VNIIPO EMERCOM OF RUSSIA, 2009 All rights reserved

Conclusion

By flushing your heating, water supply or sewerage system, you restore its functionality. Experts recommend not to take matters to extreme measures, but to use preventive methods so as not to spend money on expensive repairs. The video in this article will help you find additional information on this topic.

Previous post How to soundproof sewer pipes: overview of options and useful recommendations

Next entry Soda and vinegar for cleaning pipes: application features

Chlorination and disinfection of pipelines

Washing and disinfection of water supply pipelines should be carried out regularly, including new ones, before they are launched.

The procedure for washing and disinfecting pipelines and drinking water supply structures.

For the disinfection of pipelines and drinking water supply structures, it is allowed to use the following chlorine-containing reagents approved by the USSR Ministry of Health:

dry reagents - bleach according to GOST 1692-85, calcium hypochlorite (neutral) according to GOST 25263-82 grade A;

liquid reagents - sodium hypochlorite (sodium hypochlorite) according to GOST 11086-76 grades A and B; electrolytic sodium hypochlorite and liquid chlorine according to GOST 6718-86.

- Circulation pump for cold water supply

- Water circulation in a hot water supply system

- Coat for water supply pipes

Cleaning the cavity and flushing the pipeline to remove remaining contaminants and random objects should be performed, as a rule, before conducting a hydraulic test by water-air (hydropneumatic) flushing or hydromechanically using elastic cleaning pistons (foam rubber and others) or only with water.

Hydropneumatic flushing should be carried out by supplying compressed air through a pipeline together with water in an amount of at least 50% of the water flow.

Air should be introduced into the pipeline at a pressure greater than the internal pressure in the pipeline.

The length of the pipeline sections to be washed, as well as the places where water and the piston are introduced into the pipeline and the procedure for carrying out the work must be determined in the work project, including the working diagram, route plan, profile and detailing of the wells.

Washing and disinfection are carried out until the pipes are free of rust and the water in the water supply pipeline is completely free of dirt, turbidity and other contaminants.

After cleaning and washing, the pipeline must be disinfected by chlorination at a concentration of active chlorine of 75 - 100 mg/l (g/cubic meter) with a contact time of chlorine water in the pipeline of 5 - 6 hours or at a concentration of 40 - 50 mg/l (g/cubic meter). m) with a contact time of at least 24 hours. The concentration of active chlorine is prescribed depending on the degree of contamination of the pipeline.

The quality of the tested water must fully comply with the provisions of the standards and the requirements of sanitary and hygienic standards. If, after analyzing water taken sequentially after some time, the results completely coincide and comply with established standards, washing and disinfection can be considered successfully completed .

Washing and disinfection of water supply pipelines is carried out by the efforts and funds of the installation organization and with the obligatory presence of an employee of the State Sanitary and Epidemiological Supervision service and the operation service, who take water samples for laboratory analysis.

- Causes of noise in water supply pipes

- Soundproofing of water supply pipes in an apartment

- Installation of a water supply station in a private house

After the washing and disinfection of water supply pipelines is completed, and hydraulic tests are carried out, a report is drawn up , which indicates the test date and duration.

To control disinfection after completion of work, the residual content of the disinfectant reagent, turbidity, iron, odor, and microbiological indicators of water are determined.

When chlorinating pipelines and water supply structures, the requirements established by the standards for the chlorine-containing reagents used, SNiP III-4-80 and departmental safety regulations must be observed.

Get advice on protecting your property from pests.

Types of equipment and attachments

Household appliances are portable, electric, single-phase, designed to operate from a 220 V network. More powerful industrial equipment is connected to a three-phase network or installed on a car chassis and powered by its engine.

There are also models that run on propane gas. Electrical equipment is used to flush internal sewerage. Gasoline and propane machines are suitable for washing external communications where there is no possibility of connecting to the electrical network.

Nozzles are divided into the following types:

- Punchy type. For breaking through tight traffic jams.

- Bottom. They are used when it is necessary to remove significant deposits of silt, sand and mud.

- Chain carousels. Remove debris, plant roots and other objects.

- Rotary type. Used to remove fat deposits.

- Universal nozzles. For regular flushing of the sewer system from other types of blockages.

Tips for choosing

A hydraulic cleaning machine must be selected according to the following indicators:

- Water pump performance. For hydroflushing small-diameter pipes (up to 110 mm) of sewerage in private houses, storm canals, and sewer lines in an apartment, a device with a water flow rate of 10–12 liters per minute is suitable.

- Maximum operating pressure injected into the pipe.

- Engine's type. The choice of motor depends on the availability of the energy source. If it is possible to connect to the electrical network, then it is better to buy a device with an electric motor, otherwise - with a gasoline or propane motor.

- Hose length. To wash long routes, you need professional installations with a hose length of 30 m or more. For household mini-washes, the hose length is 15 meters.

- Engine power. The larger it is, the more powerful the pump on the installation will be. Such equipment can flush larger diameter pipes.

Main stages and requirements for washing and disinfection

1. In what cases and for what purpose is it necessary to wash?

Pipelines and domestic water supply systems regularly need to be flushed and disinfected. This type of pipe maintenance must be carried out not only for preventive purposes before testing the pipeline under pressure for strength and integrity, but also for sanitary treatment before commissioning and after repair work of heating and water supply networks. For the purpose of prevention, washing and disinfection are performed to remove scale, rust, plaque, grease and silt deposits formed on the inner walls of pipes.

2. Preliminary cleaning of the pipeline.

Before starting, the pipeline must be cleared of any contamination and random foreign objects formed during the installation process. Cleaning is carried out using bypass pipelines, which are connected to the existing one. The flow rate of water, provided that the pipeline is completely filled, must be at least 1 m/sec.

3. Conditions and rules for performing washing and disinfection.

Rinsing and cleaning of pipes must be carried out until the rust on them is completely removed and the water is cleared of impurities and sediment. For pipelines with a diameter of 900 mm or more, an internal inspection is carried out to determine the presence of foreign objects.

If the length of the pipeline is very large, then its flushing is carried out sequentially in each section of no more than 3 km in length through permanent water outlets. In the absence of water outlets, washing and disinfection may be carried out through temporary water outlets equipped specifically for these purposes, or fire hydrants.

4. Disinfection of water supply by chlorination.

Disinfection is carried out with a chlorine-containing solution with a Cl concentration of 40 mg/l. The pipeline is filled with chlorine solution and kept there for 24 hours. Then the chlorine water is drained and the pipeline is flushed again with clean water using flushing compressors or pumps. All work must be carried out strictly observing all safety regulations: wear specialized protective clothing and shoes, and a gas mask.

5. Analysis of drinking water samples.

At the end of the work, sanitary control authorities, in the presence of representatives of the installation, construction and operating companies, take water samples, and then measure the residual chlorine content in the water in laboratory conditions: normally it should not exceed 1 mg/l. Water is sampled for analysis from one point in the pipeline several times in succession. The results of both analyzes must absolutely comply with the requirements of sanitary and hygienic standards, only in this case the washing / disinfection is considered successful. Otherwise, the pipeline must be flushed and re-treated until a positive result is achieved.

6. Safe discharge of chlorine water.

An important step in the disinfection process is the disposal of waste water. It is allowed to be discharged into the domestic sewage system. Otherwise, in order to avoid the harmful effects of chlorine-containing water on the environment, it is diluted at the point of release with clean running water until the chlorine content in the water reaches 1.5-2 mg/l, and dechlorinated using sodium hyposulfite. The procedure and place for the discharge of contaminated water must be agreed upon with the sanitary and epidemiological supervision authorities. Chlorine-containing water should not get into open water bodies and not pose a threat to the surrounding flora and fauna and to the population.

Note! DIY water supply comb installation

7. Preparation of necessary documents.

After carrying out all the manipulations for flushing water supply systems and checking them for integrity and strength, authorized persons draw up an Act on the flushing and disinfection of domestic and drinking water supply pipeline networks. The Report indicates basic information about the work being carried out: date, name of the object and its technical parameters, reagents used, duration.

The main causes of clogged pipes

There may be several reasons why problems with the normal functioning of the sewage system periodically arise. However, in any case, the main condition for its normal operation is the timely and correct implementation of preventive measures.

Reason #1 – fat deposits

The first reason is those fatty deposits or organic plugs, which were discussed above and which inevitably arise during the operation of the sewage system, mainly when washing dishes.

An effective way to combat fat deposits can be a grease trap mounted under the kitchen sink. The main function of this device is to separate grease from wastewater.

The design of such a device is quite simple, and if desired and with the right approach, it can be made independently from available materials.

Through the inlet pipe, contaminated wastewater enters the grease trap chamber. The chamber has at least two vertical separator partitions. The first with a gap at the bottom, the second at the top

Fatty formations, lighter than water, remain on the surface of the first compartment, and fat-free wastewater, passing through the upper gap of the second partition, enters the sewer.

A general preventative measure to prevent the accumulation of grease and small pieces of food waste in pipes is to periodically, preferably at least once or twice a week, flush the sewer system with hot water at the maximum possible pressure. This procedure must be carried out from 5 to 15 minutes.

Reason #2 – hair plugs

Hair causes a lot of trouble, especially in drains from showers and bathrooms. To prevent the formation of hair plugs, it is necessary to create a barrier for hair to enter the sewer.

In large quantities and in various variations, you can find protective grilles on sale that cover the drain hole or are attached to the bottom of the sanitary appliance using suction cups.

An original modern plumbing fixture is the hair catcher. It is a decorative element placed on the drain hole, with a chain with silicone stops attached to it.

The chain is lowered into the drain and hair, as well as other debris, is retained on the restrictors and does not fall further into the sewer system. All that is necessary is to periodically remove the chain and clean it.

This item, in addition to being useful, also performs a decorative function.

Reason No. 3 – deposits in siphons

A common cause of blockage is deposits that have accumulated in the bends of the exhaust siphon. These devices have a useful purpose - they provide a water seal.

Due to the design features, there is always waste water at the bottom of the siphon, which, by creating pressure in the system, prevents sewer odors from penetrating into the room.

It is in the siphon and sump that household waste accumulates in large quantities, therefore, for normal operation of the sewerage system, this plumbing equipment requires periodic maintenance, which consists of manual cleaning and rinsing

Disassembling and cleaning the siphon will not be difficult, but the benefits of this work are undoubted. Removal of not only large debris, but also high-quality flushing of all parts of the siphon from grease and small waste is a guarantee of stable operation of the sewage system.

Reason #4 – installation errors

Structural or technical blockage is the result of violations committed during the construction of the sewer system or complications that arose during its operation.

The main reasons for this may be:

- insufficient diameter of sewer pipes;

- improperly installed drainage system;

- subsidence or break of a sewer pipe;

- failure to comply with the minimum pipe slope.

In case of such malfunctions, any preventive measures and work to flush the system will only give a temporary result.

According to SNiP, the slope angle of apartment sewer pipes should be 3 cm per meter for 50 mm pipes and 2 cm for pipes from 85 to 100 mm

Therefore, in order to save yourself from constant problems with the sewerage system, it may be better to immediately resort to “surgical measures” - to repair or replace the sewerage system or its faulty part.

Reason No. 5 – overgrowing of sewer drains

Cast iron and steel pipes that have been in use for a long time are often susceptible to this problem. The roughness formed on their inner surface causes snags of hair, threads and other small debris, which over time become overgrown and become the center of the plug. And grease from kitchen sinks and dishwashers makes the situation worse.

For preventive cleaning of a sewer system made of cast iron and steel, the flushing methods described above are quite acceptable. But an effective solution, albeit somewhat drastic, would be to replace such pipes with metal-plastic ones.

In the absence of preventive cleaning, the clearance in cast iron pipes narrows, reducing their throughput. Failure to take timely measures can lead to a complete stop of the sewer system and the need for its repair.

BREXIT solutions for flushing and cleaning heating and water supply systems

Compressor for flushing Brexit systems B-PULSE 1000

The compressor is a microprocessor-controlled combined device for flushing water pipes, floor heating systems, and water heaters. Washing and disinfection of water supply pipelines is carried out using a reducer and an injector.

Has a wide range of applications - used for flushing:

- Corroded hot and cold water supply systems;

- Floor heating systems from silt and bottom sediments;

- Heating systems after installation and repair;

- Drinking water supply pipelines (both flushing and disinfection);

- Solar panels for heating water from silt and bottom sediments;

- Can be used as a conventional compressor to produce compressed air;

Brexit descaling pumps B-Decal 17 and B-Decal 27

Used for cleaning/rinsing various closed liquid circuits from scale, various organic deposits, and rust.

These flushing pumps are used for easy and quick flushing of:

- heat exchangers;

- molds;

- chiller circuits;

- cooling towers;

- thermostats;

- boilers;

- any hydraulic circuits;

For more detailed information and a profitable purchase of washing equipment, we invite you to our store at the address: Moscow, Onezhskaya street, building 15. You can also place an order through our website.

Types of water pipes

Before you begin chemical flushing of water pipes, you need to become familiar with their types.

Product materials and their features are presented in the table:

| Advantages | Flaws |

| |

| |

Methods for flushing water supply pipelines

The main reason why people think about flushing their water supply pipeline is low water pressure. If the premises are supplied from the main network, and the problem is identified throughout the riser, then the problem is in the centralized system.

In cases where everything is fine with neighbors or at other connection points, the blockage is local in nature. There are several ways to clean a pipeline; I want to describe in detail not only the most effective methods, but also introduce you to the technological features of the process.

- 1 Causes of clogged pipes

- 2 Consequences of pipeline blockages

- 3 Methods for flushing the pipeline 3.1 Mechanical cleaning

- 3.2 Cleaning with hydrochloric and citric acid

- 3.3 Hydrodynamic flushing

- 3.4 Hydrochemical flushing

- 3.5 Hydropulse washing

- 3.6 Punching under water pressure

- 3.7 Cleaning a water pipe using a cable

- 3.8 Using a plunger

- 3.9 Ultrasonic cleaning

Pros and cons of the method

The list of advantages of the sewer flushing method using hydrodynamic equipment includes:

- Possibility of complete cleaning of the walls.

- Ensuring flushing of pipelines along the entire length.

- No risk of damaging pipes. Washing with water under pressure, unlike cleaning with a metal cable or chemicals, does not have a destructive effect on the internal surfaces of communications.

- High processing speed. Flushing a sewer in a private house will take approximately 5–6 hours; in an apartment it can be done in 1 hour.

- Possibility of flushing hard-to-reach and remote areas, regardless of the configuration of the sewer system.

- Possibility of washing external sections of pipelines between wells at sub-zero temperatures.

The disadvantages include the somewhat high cost of the procedure. To carry out hydrotreating, the installation must be connected to a water supply system, and a lot of water will be required for flushing.

Causes of clogged pipes

The throughput often decreases due to build-up in the inner part of the wiring surface; I would like to include the following factors as common reasons:

- Limestone deposits, this element is introduced into the liquid as an antiseptic for disinfection at the DFS.

- The formation of corrosion, rust can spread so much that the permeability of the pipe is reduced to “0”.

- Natural components, salt is a natural impurity in liquids, often abundant formations can be seen after the use of wells or wells.

- Failure of the filter station, solid particles in this situation directly enter the water supply system and settle on the walls.

In most situations, you can eliminate the decrease in pressure yourself; this does not require special skills or a lot of time.

Types of blockages

All blockages in the sewer system are divided into the following types:

- Mechanical. Formed by large objects that do not dissolve in water.

- Operational. Consist of small particles of organic or inorganic origin.

- Technological. They arise due to violations of technical requirements during sewer assembly or excessive wear of pipes.

Pipeline flushing methods

To solve a problem that requires cleaning in the bathroom, sink, kitchen sink, toilet, or to avoid unpleasant leaks on the surface of the pipe in the bathroom, it is worth taking some measures in advance.

In apartment buildings, manipulation will be somewhat more difficult, but still possible. There are several proven and effective methods; I would like to introduce you in more detail to the question of how to clean plastic drain pipes.

Mechanical cleaning

The advantages include the minimum of preparatory measures for this process and an environmentally friendly environment during the work; the cost of the manipulation will not seem too high, even when it comes to fire wiring. To implement the plan, specially designed metal cables and brushes are introduced into the internal cavity.

It is possible to use nozzles gently to clean the communication from limestone deposits; in this case, they are rubber. To bring the device into the most productive state, winches are used; all deposits are quite simply removed.

Cleaning with hydrochloric and citric acid

The method will require special care in relation to the process; the chemical compositions are quite concentrated and can harm the mucous membrane of the eye, respiratory tract and human skin with their vapors.

Clearing clogged water supply pipes occurs blindly, so I do not consider this operation to be the most effective. There is also a myth that the composition can corrode cast iron pipes; although the danger is dubious, I believe some gaskets can be damaged.

Hydrodynamic flushing

This type of mechanical solution to the problem has a fairly powerful effect, but will require special equipment for networks. After all, to achieve a good result you will need a high pressure of 200 atmospheres. A water jet is created, it washes away all deposits in the inside of the pipe and removes the blockage; flushing the pipeline is quite painstaking work, which involves a number of specific actions.

Hydrochemical flushing

The principle of manipulating the disinfectant effect is somewhat similar to the previous method, but before starting the process, specialists calculate the degree of contamination, conduct hydraulic tests and select a chemical reagent.

After which the product is applied under pressure to the problem area, the most complex excesses in the system are quite easily solved in this way, but the operation cannot be called environmentally friendly, since all substances have a strong effect and can easily leave a mark on the skin after one touch.

Hydropulse washing

I would like to immediately draw your attention to the fact that this method can be used in multi-apartment buildings where the pipeline diameter is at least 30 mm. The cleaning method is quite common; using it, you can easily get rid of blockages such as:

- Fat deposits.

- Soleil.

- Rust.

- Scale.

The principle of operation is to create pulses that are not critical for connections between pipes together with the water supply; a jet under pressure acts on deposits and eliminates them, simultaneously washing them out of the system. The building codes prescribed in SNiP do not prohibit the use of this method.

Breaking through under water pressure

A column of liquid under pressure is capable of washing out a lot of deposits known to people, even in fire-fighting units; to organize the process, you will need special equipment capable of creating the necessary flow of water.

The application cannot be called gentle, so I do not recommend using such manipulations to clean the water supply prefabricated plastic sewage system or sewage systems. The pipe can easily be damaged; it is often held in place by rubber gaskets and hung on clamps, so it is better to use the method for metal or soldered systems.

Cleaning a water pipe using a cable

A special device in the form of a thin soft steel rod is equipped with a special handle at the end to give it rotational movements. At the end of such a cable, according to the rules, various attachments are attached. The method is suitable for a pipeline with a small pipe diameter, but to implement the plan, I would advise choosing a device of maximum length, which will be convenient to work with and will reach the extreme point of the system with a blockage.

Using a plunger

Every owner has a plunger in his house; the principle of eliminating the problem is to use a special device at a minimum cost. As soon as you remove the rubber tip after pumping water to the highest point, it will flow back and bring the entire mass down onto the resulting plug.

Note! Selecting a pump for water supply

The method is quite simple and effective; it can be used at home for minor stains. To achieve maximum effect, before starting the process it is worth adding a special chemical that will soften the deposits that have formed.

Ultrasonic cleaning

For such cleaning of internal contaminants, ultrasonic vibrations are used using one of the available methods. These auxiliary actions are sent along with the liquid to the point of blockage of the fire water supply or other communication. The quality of work using this technique improves significantly.

Cleaning methods

There are many ways to remove blockages in the sewer:

- Based on direct mechanical action.

- Hydrodynamic method.

- Flushing of sewerage using chemicals.

The choice of method depends on the degree of blockage of the sewer and the location of the blockage.

Mechanical

The mechanical method involves using a plunger or a special plumbing cable to remove plugs and blockages in sewer pipes. A plunger consists of a handle and a rubber valve that covers the drain hole of a plumbing fixture. By alternately pulling the handle and pressing the valve, you can create a vacuum in the pipeline, which helps pump dirty water and small debris out.

To remove more complex contaminants in the sewer, a plumbing cable is already used. The tool is available in different designs and materials. At one end it must be equipped with a handle, at the other it may have a sleeve - a tip for attaching removable attachments of different shapes:

- Punchy. For removing old clogs in the sewer.

- Bottom. For construction waste.

- Hook-shaped. For removing rags and hair.

- Loop-shaped. Remove water seals.

- Ruff. For cleaning interior walls.

There are several types of cables:

- Cable. Diameter 6 mm, length 5 m. Made of galvanized steel in the form of a tightly twisted rope with crimped ends. The product is characterized by high elasticity and flexibility, so it easily passes through pipeline bends and connecting parts. When broken, the end section turns into a brush, with which you can remove a clump of hair or a wad of thread from the drainage system. It is used for cleaning sewers in private houses and apartments.

- Flexible plumbing cable. It is a flexible steel shaft tightly wrapped with wire. For ease of drain cleaning, it is equipped with a handle. The diameter of the product can reach up to 28 mm, the length varies from 5 to 60 meters.

- Metal tape. Such a device has a nozzle in the shape of a quadrangular peak at the working end and a handle at the opposite end. Tapes are available in widths up to 25 mm and lengths up to 30 meters.

- Spring cable. Consists of a twisted steel spring and handle. The length of the product can reach up to 25 m, diameter - up to 13.5 mm.

- Tension cable. The product has a rigid design, can be all-metal or with a vinyl braid, and is equipped with a mount for attachments. It is a professional tool and is used to remove complex clogs in the sewer.

- Electric cable. They are an electrical installation consisting of a long cable with a nozzle wound on a drum, a drill and a pistol-type handle. By placing the end of the cable with the nozzle into the sewer pipe and adjusting the speed of the drill, you can remove any blockage.

Chemical

The chemical method involves flushing the sewer using special preparations that corrode the grease and dirt inside the pipes. They can be purchased at any hardware store. These products are available in different forms:

- Powder or granules. It is poured into the drain hole and filled with a small amount of water. After a few hours, the sewage system is flushed with hot water. The most popular of them are “Pothan”, “Floop” and “Anti-clog”.

- Gel or liquid. It is poured into the sewer in the required volume and acts much faster than bulk preparations. The most common of them are “Mole”, active gel “Mr. Muscle” and “Tiret”.

Depending on the main active ingredient, chemical preparations are:

- Alkaline. Used to remove fat deposits.

- Acidic. Dissolves clogs of organic origin - hair, animal fur, etc.

Hydrodynamic

The hydrodynamic method involves cleaning the lumen of sewer pipes with jets of water entering them through a nozzle under high pressure from 150 to 300 atm. The working nozzle has a unique design. It can independently move through the pipeline, simultaneously breaking through plugs and cleaning the walls from plaque and deposits to the base.

Which way is better

The most effective and at the same time gentle on the pipes themselves is the hydrodynamic method. Flushing sewer pipelines with high-pressure water removes even old plugs, regardless of their density, while the pipe walls are completely cleaned.

Using a plumbing cable, you can only remove the plug itself, providing a temporary result. You will not be able to remove all limescale and fat deposits completely from the internal surfaces without scratching them.

Chemical reagents cover only a small sector of the pipeline and can negatively affect the plastic from which sewer lines are mainly collected. Even if the external integrity of the pipes is maintained, the deformed internal surface will contribute to the accelerated deposition of contaminants.

Flushing the water supply and removing blockages: goals and means

Why and how are water mains flushed? Are there any instructions for doing this? Is it possible to somehow clean the water supply if its permeability after several years of operation has catastrophically decreased? Let's figure it out.

The operation of a new water supply line begins... with its flushing.

Let's immediately separate the flies from the cutlets, so to speak.

- Testing and flushing of the yard water supply network is carried out as part of the transfer of the facility from the construction to the operating organization . The pipeline is pressure tested, checked for leaks, cleaned of debris and foreign objects and disinfected.

Important: cold water supply is positioned as drinking water, which implies strict requirements for the composition of the water.

- If the throughput of the water supply system is significantly lower than the norm for a pipe of a given diameter, it needs mechanical cleaning or chemical washing with reagents that dissolve lime deposits and rust . The use of hydropneumatic flushing in this case, as a rule, does not bring any results.

Water supply pipes become overgrown with lime and rust.

Design and principle of operation of hydrodynamic equipment

The hydrodynamic sewer cleaning machine consists of:

- Water compressor.

- Electric or internal combustion engine drive.

- High pressure hose wound on a drum.

- Tip on the hose for attaching the nozzle.

- Nozzles with holes.

The principle of operation of hydrodynamic equipment is to immerse a hose in the sewer and supply water under high pressure through nozzles with holes directed forward and backward.

Water jets directed forward break up plugs and deposits on the pipe walls. The flow of water coming out through the holes directed towards the rear creates a jet draft in the pipeline. Due to this, the nozzle with the hose moves along the pipe, simultaneously washing away all the dirt.

How expensive is this technology?

Prices for hydrodynamic machines start from 110–130 thousand rubles; there is no point in buying one for flushing sewers in a private house or apartment. If necessary, you can rent it or order such a service from a specialized organization. The cost of sewer flushing work is approximately from 220 to 260 rubles. per linear meter of pipeline.

Testing, washing, disinfection: regulatory requirements

Tests

The procedure for hydraulic tests is comprehensively set out in SNiP 3.05.04-85, which regulates, in particular, the construction of external water supply networks.

According to SNiP, the test must be carried out hydraulically or, if it is impossible to fill the water supply before it is put into operation, by air. The pressure during testing should be:

| Pipeline type | Test pressure |

| Welded steel, pressure up to 7.5 kgf/cm2 | Operating x factor 2 |

| Steel welded pressure from 7.5 to 25 kgf/cm2 | Operating x coefficient 1.5 |

| Cast iron with hammered sockets | Working + 5 kgf/cm2, but not less than 10 and not more than 15 |

| Cast iron with sockets on rubber seals | Operating x coefficient 1.5, but not less than 15 kgf/cm2 |

| Reinforced concrete | Working with a coefficient of 1.3 |

| Asbestos-cement | Same |

| Plastic | Same |

Disinfection and washing

Guidelines for disinfecting water supply can be found in the same SNiP.

According to the document, you can use:

- Bleach solution.

Bleach is the most common disinfectant.

- Sodium hypochlorite solution.

- Liquid chlorine.

Flushing (cleaning) of the pipeline can be performed:

- Elastic piston. As a rule, this role is played by a foam rubber cylinder with a diameter 1.3 times larger than the internal diameter of the water supply and a length of 1.5 - 2 diameters.

The photo shows foam rubber pistons for cleaning water supply pipes.

- Water distilled through a section of a water pipeline for discharge.

- Pulp (water-air mixture). Hydropneumatic flushing is organized by supplying air with a compressor; The optimal ratio of water and air in the pulp is 1:1.

SNiP contains several additional recommendations for specialists performing cleaning and disinfection.

The foam piston can be used in areas with smooth turns at an angle of no more than 15 degrees with the valves fully open and in the absence of structures protruding inward. The speed of the piston at a pipeline pressure of 1 kgf/cm2 should be in the range of 0.3 - 1 m/s. In this case, the diameter of the discharge through which contaminants leave the water supply system can be only one step smaller than the diameter of the pipe being flushed.

When hydropneumatic flushing, air should be supplied into the pipeline under pressure 0.5-1.5 atmospheres higher than water pressure. The speed of pulp movement should be within 2 – 3 m/s.

Disinfection of pipelines is carried out in sections no longer than 1-2 km at a time. In this case, temporary control valves are installed every 500 meters to take samples for chlorine concentration.

Based on the results of the work, a certificate of flushing the internal water supply systems and its disinfection is drawn up.

Its text should indicate:

- Composition of the commission (SES, construction and installation organization and operators).

- Description of the object (type, length, diameter, volume).

- Type of reagent and concentration of active chlorine.

- Duration of processing.

- Results of biological and physicochemical analyzes of water after treatment.

A certificate for flushing the water supply and its disinfection upon transfer to the operating organization.

Equipment for hydrodynamic cleaning of sewer pipes - types and characteristics

The design of the equipment for flushing sewerage using a hydrodynamic method, used in industry and everyday life, is quite similar. As a rule, the main difference lies in the nozzles used and the pressure power. The cleaning device includes the following elements:

- water compressor;

- hose;

- tip where the nozzle is attached;

- motor or electric drive.

Hydrodynamic equipment is in most cases classified according to the type of fuel used. There are electric and petrol devices.

Electrical devices are often used in household cleaning of pipelines using a hydrodynamic method - in houses and apartments. Such equipment works with pipes with a diameter of up to 200 mm and a length of up to 40 meters.

The device operates with a range of 500-1500 rpm. and electric drive of alternating or 3-phase current. In most cases, an electrical device has a sealed housing that absorbs internal vibrations.

Gasoline devices have a powerful engine (pressure ranges from 200 to 500 atmospheres) and do not depend on external power sources, thereby achieving increased productivity.

They are often used at large industrial facilities and are used to clean drainage systems. Such devices have a pressure gauge, a safety valve, an engine ignition switch, and a water filter.

If you plan to flush a sewer with a diameter greater than 350 mm using a hydrodynamic method, the device is loaded onto a vehicle base on wheels and thus becomes mobile.

Removing blockages

Dealing with clogged pipes in a cold water supply system is very different from flushing a heating system or cleaning a sewer. The key difference is that the blockage cannot be destroyed by a stream of water or weak mechanical action: the pipes are overgrown with durable lime deposits and rust.

However: sometimes the initial cause of a blockage is sand or a piece of scale. If it is not removed immediately, after some time the blockage becomes cemented and can be destroyed with great difficulty.

Is it possible to do something with your own hands if the water pressure in a house with an old steel water supply has dropped catastrophically?

- Try plugging the faucet with your finger and simultaneously fully open the cold and hot water taps. DHW pressure is noticeably higher most of the year; the counterflow can destroy a fresh blockage, after which its fragments will be carried out by water into the sewer.

- If this does not help, repeat the operation by resetting the cold water riser. The pressure difference between the hot water supply and the empty riser will be significantly greater.

- Is the water still not flowing at normal pressure? Open the valve (with the riser down, of course). Debris deposits under the valve seat are a common problem with cast iron and, to a lesser extent, brass screw valves.

Please note that ball valves do not suffer from blockages. There are simply no pockets in their body where debris accumulates.

- Finally, if all else fails, try disassembling all available threaded connections and cleaning the pipe with a steel wire from the curtain rod, bending a hook the size of a pinhead at its end. On the second side of the string a handle is formed, resembling a well gate. The string is fed into the pipe with continuous rotation; after it passes the blockage, its remains are washed with water.

Tip: lime deposits dissolve well with acid solutions. It is enough to plug the pipe near the valve and fill it with the reagent for a couple of hours. As an active substance, you can use imported Cillit or, which is much better, a solution of dry oxalic acid: its price is several times lower with much greater chemical activity.

Oxalic acid solution perfectly dissolves lime and rust.

Options for flushing sewer pipes

There are many methods for clearing blockages in the sewer system.

In order to correctly determine the most optimal one in a particular situation, you must first find out:

- the degree of blockage and, accordingly, the complexity of work to remove it;

- design features of the sewerage system and its length.

Each of the ways to solve a problem associated with a violation of drainage from an apartment or home requires the availability of appropriate tools, equipment or special means.

Let us consider in detail the basic techniques used to flush the pipes of the sewerage system in an apartment or home.

Option No. 1 - spilling with water

Minor disturbances in the capacity of sewer pipes, as a rule, occur due to fat deposits in them. Added to these accumulations are small fractions of household waste that fall into the sink drain, for example, from the kitchen when washing dishes. Therefore, a blockage situation often occurs in a section of the pipeline that is slightly removed from the kitchen sink.

If you do not delay solving the problem with fatty deposits, you can try to resort to the simplest and least expensive method of troubleshooting, if you do not take into account the consumption of hot water - flushing the sewage system with hot water

To begin with, plugs are installed (can be made from a wet rag, if there is no standard one) on the holes for water overflow, after which hot water, approximately 60 °C, is supplied to the sewerage system under the maximum possible pressure from all water points.

Under the influence of excess pressure and water temperature, small plugs or fatty deposits will be washed away.

It must be remembered that this procedure is carried out under constant supervision to avoid water overflowing through the sink.

Cool boiling water will work well when flushing pipes. A volume of 1-2 liters is often enough to wash away fatty deposits.

But some peculiarities of using boiling water should be taken into account. It will not harm good modern plastic pipes, especially cast iron pipes. However, the main thermal shock will fall on the siphon, the material of which, like the rubber seals used for sealing, is much less resistant to the effects of hot water than pipes.

Option No. 2 - using a plunger

Additional assistance when flushing the sewer system can be provided by a plunger, which is advisable to have in your arsenal to combat clogged pipes in every home.

Depending on the intended use (sink, bath or toilet), plungers may differ in the volume of the bowl and the angle of its attachment to the handle.

A regular plunger is a simple device, the main elements of which are a plastic or wooden handle and a rubber bowl-shaped nozzle

The method of using a plunger is quite simple. The step-by-step instructions are as follows:

- The sink or bathtub is filled with a small amount of hot water, with a level of a few centimeters at the drain hole, but not exceeding the height of the valve.

- Plug the overflow hole.

- The bowl of the plunger, like a suction cup, closes the drain hole.

- Several intense pumping motions are performed, after which the device is abruptly removed.

When the plunger works effectively, elements of contaminants come out of the hole along with wastewater, some of which can be removed before they return to the system. The drain is filled with water again, and the pumping procedure is repeated several times until the cause of the blockage is completely eliminated.

In addition to conventional plungers, the modern sanitary equipment market offers a large assortment of their pneumatic counterparts, which successfully cope with clogs in apartment sewers.

Some products can be classified as professional equipment, with an appropriate price. But there are also quite decent quality and affordable devices - from 500 to 1000 rubles.

This device operates on the principle of a pump, which looks like a large syringe with a suction cup attachment. The mechanics of the piston creates a vacuum discharge of the air in the cylinder, due to which the dirt plug is gradually loosened and pushed out.

The undoubted advantage of these devices over a traditional plunger is the greater power of the hydraulic shock. The cylinder volume, depending on the model, is usually from one to two liters. The device is usually equipped with two adapters: one for sinks, bathtubs and the second for the toilet.

The work of cleaning the sewer is completed using plungers of any type by flushing the pipes with hot water.

Option No. 3 - use of special means

The use of household chemicals is another method of flushing drains and sewage systems from blockages that allows you to get the desired result.

The following types of means used are distinguished:

- liquid;

- gels;

- granules (powders).

We will tell you how to flush drains, siphons and sewer pipes using preparations of each specified type using the example of the most popular modern means.

Synergetic to remove blockages. This is a concentrated liquid. Contains A-tensides of plant origin, soda and water. According to the manufacturer, it is completely natural.

The product is supplied in a liter bottle or 5 liter canister. From 250 ml to 1 liter of liquid is poured into one drain hole for half an hour. The procedure ends with a generous flush of water, preferably hot water.

Advantages of Synergetic:

- does not cause allergies;

- contains substances capable of complete biodegradation in water into harmless components - water and carbon dioxide;

- fights bacteria;

- harmless to the microflora of septic tanks.

The liquid works effectively in drains of plumbing fixtures, eliminates grease deposits and unpleasant odors, but it will not cope with severe blockages and plugs with hair inclusions.

Sanfor is a thick gel. 250 ml of product is poured into the drain hole. For small blockages, it is enough to wait from 5 to 15 minutes, for severe ones - a little more, and after that, flush the system for a minute under strong water pressure.

Sanfor dissolves well not only fat, food residues, but also hair, and the chlorine it contains perfectly disinfects communications and removes germs

Based on the majority of real user reviews, we can conclude that the gel, for its price of 110 rubles, is really effective and better than many expensive chemicals in combating blockages and sewer odors.

A 750-gram bottle is just enough for a one-time cleaning procedure for three drains (kitchen, bath and toilet).

The only advice from housewives is, if possible, leave the gel poured into the pipes, without spilling, for a longer period than indicated in the instructions. Moreover, the product is safe for all types of communications.

Bagi granules for blockages Pothan . The product is supplied in a 250 gram container.

For a one-time procedure, it is recommended to pour 50-70 g of Pothan powder into the drain, then pour half a glass of hot water into the product

After 3 minutes, thoroughly rinse the pipe under the maximum possible water pressure.

During the reaction, an unpleasant odor and foam may be released. Therefore, it is necessary to work with the drug very carefully and wear skin and respiratory protection.

Despite the apparent aggressiveness of the product, users confirm that it does not cause any harm to the coating of plumbing fixtures. The powder has a good rating and a large number of offers on online resources.

Reviews confirm the effectiveness of Bagi Pothan and the strong chemical reaction visually observed during its use, accompanied by hissing, as well as the release of foam and steam.

Option No. 4 - traditional methods

There are methods that allow you to flush pipes without using specially purchased ready-made products. Knowledge of the main components that make up the drugs and the chemical processes that occur when they interact with other substances helps in this.

Caustic soda is caustic soda. This is an alkali with a fairly wide range of applications - from cooking and cosmetics, to industrial washing and fuel production on a large scale.

Caustic, which has the property of decomposing organic substances, is part of many household products, including those intended to clear sewer blockages.

In a dry substance, caustic soda can be granular and flake.

To flush the sewer, it is better to use granulated caustic soda. In one drain it is enough to pour 3-5 tablespoons of the substance and pour 300-400 ml of hot water

Spilling the sewer with running water after the procedure using caustic is carried out no earlier than 2 hours later.

Baking soda and vinegar . For one drain you need to prepare up to 250 g (half a pack) of soda and 100-150 g of vinegar. Soda is poured into the drain in dry form; it cannot be mixed with water. Before pouring the prepared vinegar into the drain hole, it is advisable to warm it up a little in the microwave or a container of hot water.

Immediately after pouring vinegar, the hole should be plugged as tightly as possible with a rag so that the action of the chemical reaction is directed inside the pipe. After half an hour, boiling water is poured into the drain (you can use a whole kettle), and the system is drained from the water supply.

The option of flushing the drain with soda and vinegar will be useful for minor blockages caused by fatty deposits. It is unlikely to help with traffic jams and hair congestion.

But this method can be effective if it is possible to properly seal the entire waste system, including drains and overflow holes.

The argument is that the reaction is accompanied by the release of a large amount of carbon dioxide, the force of which, in the absence of leaks, may be sufficient to simply push the resulting plug further into the sewer and get rid of it by subsequent drainage of the system.

Option No. 5 – hydrodynamic flushing

The use of chemicals and other special means can bring the expected effect if the blockage is organic. But even organic matter, in large quantities or pressed, can resist these methods of cleaning pipes. And there is no talk at all about dissolving plugs formed from construction waste or other large inorganic waste that has entered the sewer system.

Therefore, to flush pipes with large blockages, you should resort to the modern hydrodynamic method. To implement this method, you need special equipment that can be used both in everyday life and in production.

The permissible diameter of pipelines served by the hydrodynamic method is from 50 to 300 mm.

The hydrodynamic kit consists of a hose that can withstand high water pressure and a nozzle with nozzles. For residential sewage systems, as a rule, triangular (punching) nozzles are used. A good turner is quite capable of making a punch attachment on his own.

The forward movement of the hose, deep into the pipe, while simultaneously breaking up the blockage, occurs due to the strong pressure of water jets ejected from the nozzle nozzles

Step-by-step sewer flushing using hydrodynamics is as follows:

- determining the nature and degree of complexity of the blockage and, based on this, selecting a nozzle;

- immersing a hose with a nozzle into the sewerage system and connecting a pump;

- using reciprocating movements, moving the hose with the tip towards the blockage;

- increasing, if necessary, the power of water pressure until the result is achieved.

This method effectively destroys and flushes even the most stubborn, hard-to-reach clogs. Most often it is used to eliminate blockages in the sewer system of a private home and in industrial networks.

If it is not possible to resort to hydrodynamic flushing, you should use a plumbing cable. It also copes quite effectively with blockages in sewer pipes.