What will happen to the screed if you turn on the heated floor before it completely hardens?

The question of how serious a mistake it was to turn on a heated floor interested me even at the pouring stage. I, like any other person who is far from this area, wanted to continue the renovation as soon as possible. And, to be honest, thoughts were spinning in my head that with the help of heating this process could be accelerated. And it’s good that I didn’t do this and decided to consult with specialists. Otherwise, trouble would have been inevitable! Forced drying would have a detrimental effect on the quality of the screed.

Why can’t you turn on the heated floor until the screed has completely hardened? There are enough reasons for this:

- the screed will crack. It is best if it hardens in natural conditions and at the correct temperature and moisture. Regardless of the type, the solution may crack;

- the appearance of voids near the heating element. The uncured screed dries out from the action of heat and cavities appear around the pipes or electrical mats. This leads to the fact that the base does not heat up evenly, and the heat flows to the surface much worse. During the cold season this can become a real problem;

- the service life of the underfloor heating system will be reduced. This reason comes from the first two. Such conditions negatively affect heated floors, which can lead to faster failure. And, you understand, this will lead to additional expenses.

Water heating

The first switching on of the water-heated floor is carried out only after pressure testing of the system. This is testing for the tightness of pipes and connections.

Pressure testing is carried out as follows:

- if the floor line is made of steel or copper pipes, then cold water is run into it; the pressure gauge should read 6 bar; leave the system for a day; check the indicator on the pressure gauge; if it remains unchanged or drops by no more than 1.5 bar, then the system is ready for operation;

- when crimping a pipeline made of cross-linked or heat-resistant polyethylene, water is pumped under a certain voltage; operating pressure is 4 bar; it is increased by 2 times; the line is left for 24 hours;

- crimping can be carried out using air; a compressor is used for this; a plug is installed at one end of the pipe; air is pumped through the other end using a compressor; the line is left for 12 hours; the pressure reading on the pressure gauge should not change.

We recommend: How does the underfloor heating calculator work?

Some craftsmen use high-temperature coolant, up to 85 0C, into the water circuit as a pressure test. If no leaks are detected at the base within half an hour, then the system is sealed and ready for connection.

The main line is closed with a screed when the water in the pipes has cooled. There is no need to drain it. On forums they often discuss when to turn on the “warm floor”. The first switching is carried out immediately after crimping.

- It is necessary to bleed air from the system. To do this, open all the valves in the circuit, the air tube, and the cover in the three-way valve.

- Turn on the circulation pump; it works for 3-4 minutes; the system is filled with water;

- Alternately close the valves on the collectors for a few minutes and open them again; achieve a certain pressure in the pipes.

- If the system does not have a circulation pump, the system is closed, then the air is removed using liquid. It is pumped into the main line from below. The pipeline and heat exchanger are filled until the pressure gauge reads 4 bar. Next, the valves on the manifold are closed. The pressure should drop. This means that air is leaving the system. Add more coolant, bringing its pressure to normal. The steps are repeated until the pressure is established. Liquid is visible at the outlets of the falling and return manifold.

After the air has left the system, close the air pipe, install a thermal head on the three-way valve, close the end valves, and keep the valves on the manifold open. Perform a screed. After 28 days, when the concrete coating has dried, the floor covering is finished. Next they turn on the “warm floor”.

- The temperature on the thermal head is set to 20 0C.

- The same mode is set on the thermostat, which is located on the boiler.

- The floor temperature is increased gradually. Otherwise, the concrete coating may deform or crack due to sudden temperature changes.

- Within 2 days the temperature is brought to normal, to 45 0C.

- On the supply manifold, it is necessary to set the filling level of the water main. The flow meter is set to 1.5.

- Subsequently, the microclimate in individual rooms is monitored. Perhaps the highway's capacity should be increased.

We recommend: How to connect a heated floor from a stove?

Pressure testing of the pipeline is carried out every time before the start of the heating season. Otherwise, there will be areas with air in the line. When heating water, the air will not allow all the thermal energy to be transferred to the floor. The water circuit will undergo heavy loads.

What kind of heated floor requires a screed?

Warm screed is used both under water and electric heated floors. Of course, each of these cases has its own technology features that should be taken into account. However, regardless of the choice of system, the best option would be to use a semi-dry screed.

The question of when exactly electric heating elements should be installed leads to a lot of controversy. In practice, it turns out that its installation is possible both under the screed and into it, and even from above. The installation option depends on the characteristics of the heated floor, as well as the finishing coating. For example, laying a heated floor over a screed is preferable when laying tiles. The main thing is to choose the right specialist who will do all the work. Otherwise, the tiles may crack.

The screed is poured onto the water floor after the pipes are laid directly. That is, the pipes must literally “sink” in the solution. This will allow the heat to be evenly distributed when heated, as well as protect the pipes from external influences. That is, filling the screed in this way allows you to increase the service life of the entire system.

Tiling

A good heat conductor is tile. That is why it is used as a finish for heated floors.

Craftsmen take into account the fact that porcelain tiles have high thermal conductivity, while ceramic chips have a thermal insulating effect.

Without a screed, it will not be possible to make a flat floor under the cladding. When installing a heated floor, it becomes a support for the finishing material with weight and protection for the heating structure. By observing the standards for installing heated floors under tiles, the thickness of the concrete layer is maintained - from 40 mm. It dries completely after 28 days. In addition, it takes 7 days for the adhesive layer to dry under the tile.

Advice: according to the regulations, after laying the facing material, the heated floor can be put into operation at least after 35 days.

How long should the screed dry before turning on the heated floor?

The most important question that interests the majority. So, the time it takes for the screed to completely harden, after which you can turn on the heated floor, depends on several factors:

- layer thickness;

- the presence of plasticizers in the solution;

- type of waterproofing;

- room temperature and humidity.

The approximate time for the screed to completely harden is approximately 3 weeks. Of course, after just a day you can assume that the solution has set well. However, there is still enough moisture inside that should dry out naturally. The first switching on of the heated floor should be at a temperature of 25 degrees.

In conclusion, despite the long drying time, the wait time is definitely worth it. It’s better to wait a bit than to think later about how to fix all possible problems in order to minimize their occurrence and mentally prepare for repairs.

Installation of the structure

Is it safe to use asbestos chimney pipe?

In most cases, concrete systems of water heated floors are performed. The total thickness of the cake reaches 80-140 mm. The total load on the floor reaches 300 kg/sq.m. The subfloor should be as level as possible.

The standard floor heating scheme looks like this:

- base;

- waterproofing/thermal insulation layer;

- multifoil;

- reinforcing layer;

- warm floor;

- screed

When checking the flatness of the floor with a two-meter strip, the clearance cannot exceed 7 mm.

Thermal insulation

Function – reduction of heat loss downwards. The work is carried out using rigid mineral fiber boards or polystyrene foam mats of 35 kg/cub.m. by density. Laying thickness is 30-90 mm, which depends on the thermal conditions and heat loss of the room. For basement floors it is 90 mm, for others – 30 mm.

Multifoil

The material functions as a waterproofing agent. If the thermal insulation is already equipped with a foil layer, or a layer of polyethylene film is placed, multifoil is not required.

Reinforcement mesh

They work with typical reinforcing mesh 100*100*4 or 150*150*4. The material is necessary to strengthen the screed layer and can be used as a base for attaching heated floor contours (instead of special mats). The reinforcing layer is laid on the thermal insulation. With double reinforcement, the mesh can also be mounted on top of the system pipes.

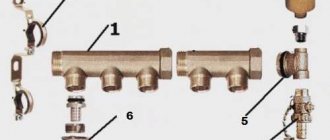

Pipes

The distribution box is mounted in the manifold. The system is connected to the central heating system. If desired, fasteners (tires or mats) are then installed, or installation is carried out on a reinforcing mesh. Laying the line begins with connecting the comb to the nozzles.

The pipe is laid in increments of 100-300 mm, using the chosen method (spiral, double coil, coil). If there is a reinforcing mesh below, fastening is carried out using clamps. Where the seams will be located, the pipe is protected with corrugation. Each loop ends and begins at the distribution manifold. There should be no kinks at turning points.

Damper tape

A heated floor screed at 40 degrees has a linear expansion coefficient of 0.5 mm/m. This forces the slab to be isolated from all vertical structures, which will eliminate all unwanted stress.

The material is laid around the perimeter before working with concrete and has the following functionality:

- compensation for thermal expansion of the screed;

- thermal insulation, reducing heat loss through walls.

The thickness of the tape cannot be less than 5 mm. It is optimal to use polyurethane foam combined with polyethylene film. The height of the damper must be equal to the height of the concrete casting. The performance of the system is checked, the presence of defects and leaks is monitored.

Fill

Work begins after the installation of the heated floor circuits has been completed and hydraulic tests have been completed. The system is filled with a layer of cement mortar 30 mm thick above the pipes - this is the thickness that can ensure optimal heat transfer. Otherwise, a zebra effect may occur, that is, uneven heat distribution.

The brand of solution should not be lower than M300 (class B22.5). When mixing, crushed stone of a fraction of 5-20 mm is used. Underfloor heating systems allow the use of plasticizers.

The introduction of plastic fiber into the formulation significantly improves the grade strength of concrete

Composition and proportions of M300 solution:

- Portland cement M400 – 1 hour;

- sand – 1.9 hours;

- crushed stone – 3.7 hours.

In some cases, with large loads on the heating plate, the grade of concrete and the thickness of the structure may change, which is calculated by the designers. It is mandatory to carry out calculations for the heating panel. The greater the thickness of the fill, the more time it will take to bring it into stable heating mode, and the inertia of the system increases.

After filling the screed, you can start the system in gentle mode. The coolant temperature should be 25-27 degrees. The structure is brought into operating mode 28-30 days after installation.

If expansion joints are cut over a large area of work (every 15 m), the pipes crossing the seam are protected with a special corrugation, extending 300 mm on each side of the seam. Let us remind you that it is optimal to place the entire circuits within one compensation zone. This way, only the return and pressure pipelines of the circuit will pass through the seams.

Thermal insulation

To prevent heat loss through the ceilings, thermal insulation is used. When choosing it, take into account the heat-shielding properties, on which the overall thickness of the screed depends. On the ground floor, slabs 5 cm thick are used as thermal insulation; if there is an apartment below with heating, insulating layers no more than 2-3 cm can be used.

The heat insulator is taken with a metallized coating. Aluminum foil does not withstand prolonged contact with the screed and is destroyed. It is necessary to use metallized coatings in the form of spraying with lavsan, etc.

The slabs are laid without gaps. The resulting cracks are filled with polyurethane foam, all joints are sealed with adhesive tape.

Frequently asked questions about underfloor heating

Answers to questions are based on the experience of Raychem specialists.

Question: Can I heat my entire house with just an underfloor heating system?

Answer: Of course! Electric underfloor heating systems are installed in thousands of homes. In addition, installing an electric heating system costs much less than installing a hot water heating system. Article about underfloor heating.

Question: Do I need professional help when installing a floor heating system?

Answer: HandyHeat systems can be installed by anyone with their own hands. If laying tiles or any other type of flooring is not a problem for you, then you just need to follow our installation instructions. But it is better to use the help of an electrician when connecting the system to the electrical wiring. All of our products come with wiring diagrams, installation instructions and warranty information.

Question: Will the floor get too hot?

Answer: Raychem thermostats perfectly regulate and control the temperature you select.

Question: Is it expensive to use underfloor heating?

Answer: For a bathroom with an area of 8 square meters, the usable area is approximately 7 square meters. for floor heating. When using the comfortable heat mode, the required power is 120-150 W/m2. The cost per kilowatt varies in different countries. The operating time of a floor heating system averages 82 hours per week for one year. An article about the electricity consumption of underfloor heating

Question: I don't want to have large electricity costs; Is it necessary to keep the underfloor heating system on all the time?

Answer: A smart thermostat with a programming function can be used for a floor heating system. There is no need to have the heating system on when you are not at home. This thermostat uses a mode to lower the temperature to the desired level. Thermostats are here...Constantly (without a regulator) the heat turned on will not damage the tiles and porcelain tiles, but will consume the maximum amount of electricity.

Question: What if the floor surface is not square and the mat does not fit in size?

Answer: The heating mat can be cut along its entire length, so that the mat, when bent, takes on an “L”- or “U”-shape. The main thing is not to damage the cable when cutting the mat. The heating cable must under no circumstances be cut or shortened. Installation of a thin heating mat under the tiles...

Question: Will heat damage the tiles and adhesive?

Answer: The Raychem heating system provides a temperature of 25-29° C on the floor surface, and below the surface the temperature is several degrees higher. But this temperature does not affect the tiles and adhesive in any way. This has been proven by most tile manufacturers.

Question: Can a wood floor heating system cause a fire?

Answer: All Raychem heating systems, installed in accordance with the instructions, are absolutely safe, since the heating cables are manufactured according to international fire safety standards - IEC 335 / EN 60335 standards. Raychem offers the T2Red smart cable specifically for wooden floors. However, only a professional electrician should connect the heating system to the electrical wiring

Question: What happens if the floors are flooded?

Answer: All Raychem heating cables and heating mats have waterproof connecting cables. There is also a grounding shield under the very surface of the heating cable for additional protection

Question: What happens if you drive nails or screws into a heated floor?

Answer: It is strictly forbidden to drive nails or screw screws into floors with a heating system. But if this happens, each heating cable is grounded in the form of shielding, which prevents a short circuit

Question: What is the service life of a floor heating system?

Answer: If the heating system is installed correctly in accordance with all installation instructions, the heating cable will last as long as all other ordinary wires in the room or building itself.

Question: Do I need a thermostat?

Answer: Yes. The thermostat is a very important part of the floor heating system. It helps maintain the desired temperature in the room/premises. Floor heating uses a thermostat with a floor sensor to maintain the desired temperature. When heating the entire room, a thermostat with a floor and air sensor is used, when the floor heating system is the main source of heating.

Question: How is the system controlled?

Answer: The system is controlled by an electronic thermostat mounted in the wall and having a floor temperature sensor. This prevents large heating of the floor surface. The most acceptable floor surface temperature is 25-28° C, but it is also possible to select a different temperature according to individual desire. The temperature is adjusted using a switch or wheel on the thermostat itself

Question: How dangerous is it to have electric floor heating in a bathroom?

Answer: All electrical cables in the bathroom and kitchen must be installed together with a differential circuit breaker according to European standards to prevent short circuits and current leakage in the event of a system malfunction.

Question: It is very cold on my veranda in the spring and autumn, since it is an extension. What can be done?

Answer: Heating systems can be installed under all types of floors, providing heating for both the floor and the room itself. In this case, the power of the system depends on the quality of the thermal insulation of the veranda. Typically this is a power of 200 W/m2. These can be heating cables or zonal heated floors.

Question: How can I install a Raychem underfloor heating system?

Answer: All installation instructions have a detailed description and are a detailed installation guide. In any case, it is always best to read the installation instructions carefully again before you begin. This way you can get an overall picture of the work ahead.

Question: Is it possible to cut off the end of a mat or cable that does not fit?

Answer: In no case, because... mats or cables are made of conductors with a certain resistivity and when it is shortened, the current value will increase significantly. Rapid burnout and even fire are possible.