In winter, due to a sharp decrease in air temperature and freezing of the soil, ice plugs may form in the external branches of the water supply system. To prevent this from happening, it is necessary to organize heating of the water supply using one or more effective technologies.

The article we presented describes all the methods to prevent the formation of ice in water supply pipes. We will tell you how to properly maintain the functionality of communications in cold weather and prevent equipment breakdown. Do-it-yourselfers will find instructions on how to install thermal insulation and heating systems.

Heating of industrial pipelines

Heating of industrial pipelines is used in petrochemical, chemical, gas, food, metallurgical and other industries.

The heating cable is subject to special safety requirements for operation at such facilities. The heating cable and all components of the heating system must be certified for use in hazardous areas. In addition, a fairly large number of pipelines in the petrochemical and chemical industries are subjected to heat treatment to clean the inner wall of resin and paraffin deposits (superheated steam cleaning). In this regard, the heating cable installed on these pipelines is additionally required to meet the maximum external temperature.

The diameter, length and material of the industrial pipeline can be any, and for each specific case a different heating cable is used. In order to correctly select the specific power and temperature class of the heating cable, it is necessary to have complete information about the object.

Free project estimate

More about the project

Heating cable manufacturers

The need for heating homes and infrastructure is in demand for residents of the northern regions, so this technology and materials came to us from there.

There are many companies on the world market that produce thermal cables. The most popular ones that produce high-quality products are presented below in more detail:

- Ensto (EFPO10, TASH0.05) - the country of origin is Finland. Produces a self-heating cable that meets the latest innovation requirements. The products are easy to install and have an improved design.

- Nelson - the line of models produced by the American company is quite large (CLT; LT; LLT; HLT; SLT-2; QLT; HLT; NC). The products have a long service life and have constant, improved performance characteristics during operation.

- Lavita is a South Korean company. Three main models produced by it:

- HPI 13-2 CT - long, uninterrupted operation;

- GWS 10-2 - energy efficient performance;

- VMS 50-2 CX (CT) is a model with increased resistance to external loads.

- DEVI is a Danish company. Large range of models (DEVIflex, DEVIsnow, DEVIiceguard, DEVIpipeguard, DEVIhotwatt), all types with a 20-year warranty - replacement and reinstallation of cables that have become faulty. In addition, the products are famous for their high performance and speed. It is successfully used for both external and internal heating systems.

- FreezStop is a Russian manufacturer; this product also cannot be ignored. All models (FreezStop, Freezstop Inside, Freezstop Simple, FreezStop-Lite) are of high quality and are suitable for different systems.

It should be noted that the Swedish heater SVK 20 with a power of 1645 W is intended for both underfloor heating and heating water pipes.

As you can see, the range of self-regulating cables for heating pipes is huge, and it’s up to you to decide which model to choose. The main thing is that the product matches the performance characteristics of your system.

Heating of long-distance pipelines

For long-distance pipelines, the task of minimizing the number of power connection points comes to the fore, because

For this type of facility, the cost of the distribution network increases significantly. The heating cable is required to ensure its maximum possible length. In this regard, the use of self-regulating and resistive cable is limited to a pipeline length of up to 1 km. This is due to the increase in the number of junction boxes and power cables for supplying power to these boxes. For pipelines with a length of more than 1 km, heating is used based on a three-wire heating cable of constant power or the SKIN effect. Free project estimate

More about the project

Water supply heating installation services

LLC DESIGN PRESTIGE 8(495)744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

Heating from DESIGN PRESTIGE LLC Type: water here > /otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

Heating cost calculation

The cost of repairing heating systems

Cost of installation of water supply

Similar services:

- Heating of sewer pipes and its options Contents: [hide] Film heating option Fastening of heating cables Heating of sewer pipes is a necessary measure if it is not possible to lay pipes under…

- Baseboard heating Skirting heating Skirting heaters ELECTRIC BASED HEATING (SKINTER HEATING) Baseboard heating Many people have come across ordinary, fairly high electric convectors, which are placed under the window opening....

- A septic tank for a dacha, as the most important element of the cycle. A septic tank for a dacha. In any dacha project, the system plays the most important role......

- How to choose the right cable? Different types of cable are used for different purposes. There is a large supply of this product on the modern market. To successfully buy a cable, it’s worth...

- Pump power in the assembly Element -2 Services for installation of heating water supply LLC DESIGN PRESTIGE In addition to fast and high-quality repair of heating pipes, we provide professional installation of systems…

- Thermostat "Uni LH" 7-28 C, 0 * liquid. feelings. element, white Services for installation of heating water supply LLC DESIGN PRESTIGE 8(495)744-67-74 In addition to fast and high-quality repair of heating pipes, we provide professional installation of systems…

- Heating a home Today, many Russian citizens prefer to live in their own real estate and install heating communications and water supply for a comfortable stay. Naturally,…

- Automatic blinds as an element of comfort Automatic blinds today are the optimal solution for giving windows an original and sophisticated appearance. In addition, such designs are as simple as possible...

- Maintenance of gas boiler houses as an element of their uninterrupted operation Maintenance of gas boiler houses as an element of their uninterrupted operation Trouble-free operation of an automated gas boiler house involves regular preventive maintenance of equipment that…

- A new solution for repairing and replacing old pipelines Undoubtedly, installing heating with plastic pipes is much cheaper than copper, therefore, most people install plastic pipelines without thinking about the fact that...

- Pipeline repair - cost Repair of external water supply is carried out by the operating organization or by contractors specializing in this area of work. Increasingly, their implementation can be done without...

- Insulation of water supply pipes When installing water supply in your yard from a well or borehole to the house, do not forget about winter. In order for the outside…

- Why you should entrust the installation of a polyethylene pipeline to specialists Installation of heating pipes made of cross-linked polyethylene requires high qualifications. Given the cost of production, mistakes can be quite costly. Most often homemade...

- Installation of a heating heating cable for pipes In winter, the operation of the water supply, sewerage or heating route is subject to freezing of pipes with further breakthrough. In this regard, the regions...

- Stove heating Not all dachas are provided with electricity and gas mains. In such a situation, all that remains is to choose the only heating system for the dacha - the stove...

- Installation of electrical wiring Time from 1 day Warranty 6 months Contract Official transparent contract Crew with 15 years of experience Price: from 150 rub. form…

- Pipeline inspection Heating maintenance Any communication system requires constant attention. Regardless of the cost of equipment and......

- Heating a private home Living outside the city, people invariably face the need to equip an optimal heating system, which guarantees comfort and coziness in a private home...

- Mechanical methods of pipeline repair These methods are quite numerous, since craftsmen successfully use various available materials. Medical bandage and cement This is the simplest option...

- Replacement of the water supply pipeline Despite the efforts of design specialists and installation teams, any pipe communications fail over time. Often, restoring the functionality of the plumbing...

Heating of pipelines of small diameter and length

This type of pipeline usually has a diameter of 15-50mm and a length of up to 40-50m.

The pumped liquid is water. The heating cable is used to protect against freezing in the autumn-winter period. Low-temperature cable is used both for external installation on a pipe and for installation inside a pipe. The specific power of the cable is usually 10-30 W/m and depends on the operating conditions of the pipeline and the type of thermal insulation used. Free project estimate

Instructions on how to insulate pipes yourself

Step-by-step instructions:

- it is necessary to make calculations and purchase thermal insulating materials;

- wrap the pipes with foil tape or foil. In this case, the foil plays the role of a heat reflector;

- installation of insulation around the pipe. The rigid sectional casing and soft insulation simply need to be placed on the pipe. Regarding other soft materials, they must be cut into pieces equal to the width of the pipe diameter. Then wrap it around the pipe and secure it with clamps, tape or wire. With rigid insulation the situation is more complicated. It is necessary to create a kind of box around the pipe from it (or use pipe shells of the required diameter);

- inspect the pipe for the presence of “cold bridges” and eliminate them;

- secure the thermal insulation to the pipe using metallized or plumbing tape;

- if necessary, cover the thermal insulation with protective material (film), and seal the joints with tape.

The money spent on the purchase and insulation of pipes quickly pays off thanks to savings on payments for heating the home.

Heating of water pipes

To heat water pipes with a diameter of 50 to 200 mm, which serve to transport water in transit and supply it to the distribution network for consumers, a low- and medium-temperature heating cable with a power of 30-60 W/m is used.

The purpose of heating is to protect against freezing during the cold season. The cable is installed outside the pipeline; the cable can be laid parallel to the pipe in one or several threads, depending on the heat losses of the pipe, or wound in a spiral with a certain laying pitch. Free project estimate

Main types

Depending on the characteristics of their functioning, such heating elements are divided into resistive and self-regulating. They are internal and external. The first category includes heating elements that are mounted inside the pipe, and the second - those that are outside.

Resistive

The design of a resistive cable is similar to an elongated boiler. The wire located inside ensures uniform and intense heating of the product along its entire length. It is often sold in lengths, so you can buy a heating element of the desired length. You cannot do the shortening yourself. Resistive cables are available in single- or double-core types.

In everyday life, for heating sewer risers and water pipes with a diameter of up to 400 mm, located in basements and other unheated rooms, two-core products are more often used.

In this case, one core acts as a current conductor, and the other heats up. They need to be connected to the mains on one side only. This simplifies installation as much as possible.

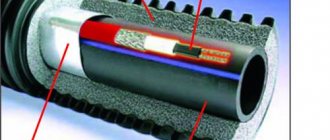

Structure of a resistive cable.

Single-core cables are used to heat long-distance pipelines. They require connection to the electrical network on 2 sides. Often resistive elements are used to create heated floors. Such cables are laid without tension. They must be covered on top with thermal insulation material.

Their main advantage is their low price.

Resistive elements have many disadvantages:

- Their length cannot be adjusted.

- During installation, it is unacceptable to cross them, because this will lead to burnout.

- Heating should be carried out evenly. Thus, raising the temperature at a single point is impossible.

- To control the operation of the cable, you need to install a number of auxiliary devices.

Self-regulating

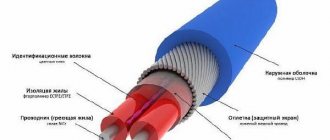

Such cables are a more modern analogue of resistive ones. They ensure that pipes are heated only in the area where it is needed, significantly reducing energy costs. The element includes 2 cores, combined with each other by a special thermostatic matrix made of a material capable of passing current and regulating its intensity.

Structure of a self-regulating cable.

The devices respond to ambient temperature. It is recommended to install such cables in dachas and in houses where people do not live all year round, but the heating, sewage and water supply systems must be protected from freezing.

The only obvious disadvantage of self-regulating devices is their high cost.

The benefits outweigh:

- Such systems are easy to install yourself.

- If necessary, you can adjust their length.

- Crossing the cable and installing it in 2 layers will not lead to its burnout.

- Thanks to automatic heating control, even after the first heat has arrived, the system will not be disconnected from the power supply, which will not lead to damage.

- There is no need to install auxiliary equipment during installation.

Heating of hot water pipelines

This type of heating is used in the event of a stop in the movement of water through a pipe, which arises out of necessity, during repair work or emergency situations on the pipeline.

In this case, cable heating is used to protect the pipeline from freezing when water pumping is stopped. The heating cable is subject to requirements for a maximum external temperature in the off state of up to +90..+99C, which hot water can reach. The specific power of the cable depends on the diameter of the pipeline and operating conditions and is determined by thermal engineering calculations. Another way to use a heating cable is to maintain the required water temperature in hot water supply systems. For these purposes, a medium-temperature (or high-temperature) heating cable is used, having a maximum operating temperature of +110C and above.

Free project estimate

Why do you need insulation?

Pipes are covered with thermal insulation, mainly in order to reduce heat loss in heating systems, which inevitably occurs after cold weather sets in. Thermally insulated lines significantly reduce heat loss.

Thermal insulation for heating pipelines is necessary not only to maintain the required temperature of the coolant in the lines, but also to prevent the accumulation of condensate on the walls of the pipes and insulation, freezing of the coolant during stagnation, and in addition to slow down the process of corrosion of iron elements. Because of this, the service life of the entire system increases significantly.

Thermal insulation of heating pipes makes it possible to:

- reduce heat loss where pipes pass along the ground, are installed by the so-called ground (air) method, or are located in an unheated room;

- prevent freezing of the coolant (its freezing can cause a pipe to burst);

- in the case of metal pipelines, the likelihood of corrosion on the surface is reduced;

- prevent condensation formation;

- opportunity to save money on heating your home.

Based on this, we can conclude that the better the heating system is insulated, the higher the efficiency and the less money you will have to spend on energy resources (gas, electricity).

Due to the fact that the coolant circulates through the heating system, the main task of insulating pipes is to reduce heat loss and prevent rupture of system lines in the event of freezing.

The most common solution in this case is the use of thermal insulation materials. It is perhaps the simplest and most cost-effective solution in terms of independent implementation.

Heating of sewer pipelines

The purpose of the sewer heating system is to protect against freezing for the unhindered passage of wastewater.

The peculiarity of heating this type of pipeline is the presence of an aggressive environment, therefore the heating cable has increased requirements for its outer sheath; it must be resistant to chemically active substances. In this segment, heating cables with a fluoropolymer sheath are often used. Installation of the heating cable is carried out both outside and inside the pipeline, but it is more preferable, if possible, to install the cable externally. The specific power of the cable is usually 25-40 W/m. Free project estimate

Blitz advice

At the moment, the market for heating self-regulating cables has grown significantly, and finding products that are suitable specifically for a given customer is not difficult. There are ready-made kits of a certain length, in which the electrical plug is already mounted and the end is sealed with a special end coupling.

If you cannot find a finished product of the required length, you can buy a self-regulating cable of any desired length and make the connection yourself. Special connection kits are sold for this purpose. A set of spare parts for installing it inside the pipeline is also sold.

Purpose

The main purpose of pipeline heating is to maintain the required temperature of the transported product. Thermal insulation prevents some of the heat loss from the surface of the pipeline, but does not protect the product from freezing in the cold season, and even more so does not solve the problem of maintaining the required process temperature. Heating of pipelines is currently carried out mainly by a heating cable (resistive, self-regulating, mineral-insulated cable), which has replaced steam heating.

Heating of industrial pipelines is carried out in conditions of exposure to chemically aggressive environments or potentially explosive areas. Therefore, increased requirements are placed on the heating cable: acid-resistant sheath, mandatory grounding, and the ability to work in explosive areas.

Do I need to use thermal insulation?

Simple insulation with heat-insulating material can maintain the working condition of the pipeline system in slightly cold conditions. Thermal insulation material is selected according to the characteristics for the climatic zone and has important qualities:

- Strength and wear resistance

- Resistance to aggressive environments

- Low thermal conductivity

Mineral wool, polyurethane foam, and foam rubber can withstand slight frosts. This method of protecting pipeline systems is best used in basements and ground floors. For pipelines located in the ground, such a system is not effective.

A much better heating effect for pipelines is provided by a system of heating cables installed inside or on the surface of the pipes. This is a modern and effective choice that allows you to solve the issue of maintaining the working condition of pipes in winter for decades. At low temperatures, different types of cables are used. They all have their own important distinctive features. We'll tell you more about them below.

Heating tasks

- Maintaining process temperature – heating an object to the temperature required in the technological process and further maintaining this temperature.

- Freeze protection – the heat generated by the heating cable ensures that the pipeline wall maintains a positive temperature and thereby prevents the liquid inside the pipeline from freezing.

- Starting heating is heating the process fluid to a temperature at which it can be pumped without changing viscosity.

- Heat loss compensation – the use of a heating cable prevents the liquid temperature from dropping to unacceptable values when the ambient temperature drops.

Free calculation of pipeline heating within 2 hours

- Let's calculate the required power

- We will select the cable and fasteners suitable for your facility

- We recommend a convenient control system

Thank you, our manager will contact you shortly

Fill in required fields

By submitting the form, you consent to the processing of personal data.

Calculations will be sent to your e-mail, please check the data carefully when sending.

Heating cable for pipeline

Choose

Self-regulating cable SAMREG 24-2

- Linear power: 24 W/m.p.

- Purpose: pipeline

- Country of origin: South Korea

- Screen: no screen

- Type: self-regulating

- Type: low temperature

Self-regulating cable ALPHATRACE ATMI-CP17

- Linear power: 17 W/m.p.

- Purpose: pipeline/tank

- Type: self-regulating

- Type: low temperature

- Application: explosion-proof

- Max. temperature (operating): 65 °C

Heating cable Heat Trace 11FSM2-CT

- Linear power: 11 W/m.p.

- Purpose: roof / pipeline / tank

- Country of origin: UK

- Type: self-regulating

- Type: low temperature

- Application: explosion-proof

To section

Warming up pipelines

There are 2 options for the task of heating pipelines: heating a cooled pipeline to the required temperature and heating the product while moving through the pipeline from one point to another. For both options, a heating cable with a high specific power of 60-90 W/m and an operating temperature of up to 200 C is used.

In the first case, the power of the heating system depends on how quickly it is necessary to heat up the cooled pipeline, as well as on the difference between the initial and final temperatures during heating.

In the second case, heating of pipelines using a heating cable is very limited due to the relatively small specific power of the cable itself. As a rule, for this type of pipeline heating it is necessary to apply more power per 1 m of pipe, therefore for such systems a high-temperature resistive or self-regulating cable, as well as a mineral insulated cable, is used. The power of the heating system depends on the diameter and length of the pipeline, as well as the speed of movement of the product through the pipeline. The cables are laid in a spiral around the pipe or in parallel in several threads.

System composition

The pipeline heating system consists of the following parts:

- The heating part is an element of the heating system that performs direct heating. For pipelines, this element is a resistive, self-regulating heating cable or mineral insulated cable. For self-regulating cable, coupling kits are used together with it at the installation site or a fully assembled section is supplied at the manufacturer.

- The cable fastening system and auxiliary elements are special elements that ensure fastening of the heating cable to the pipeline. It ensures good contact of the heating cable with the surface of the pipeline to improve its heat removal. The fastening consists of mounting and fastening tapes made of fiberglass or aluminum. In addition, metal clamps are also used to secure power supply and control system devices.

- Power supply and control system - specialized connecting power boxes of the appropriate design, in which the heating and power parts are connected, and control boxes, in which the control cable and temperature sensors are connected. For pipelines, it is very important to install these boxes directly on the pipeline itself.

- The distribution network is the power and control cable lines that supply electrical energy to the junction boxes, as well as the elements for laying these cable lines.

- Heating control system - designed to collect information about the parameters of the heating process and generate control signals for stable and safe operation of the heating system. Includes a thermostat or thermostat, temperature sensors, power, control and start-protection equipment.

The temperature sensor can be installed either directly on the pipeline wall to monitor its surface temperature, or measure the air temperature to turn on the heating system at low ambient temperatures.

The regulator controls the temperature of the heated pipeline and, based on the information received, controls the operation of the heating cable sections. The temperature controller is usually installed in the electrical heating control cabinet.

The thermostat is installed mainly on the surface of the pipeline and locally controls the operation of the heating system. Thermostats are used to control the operation of small heating systems, because... the load power connected to it is limited.

The electric heating control cabinet provides power supply to the heating sections, protection of the power and heating parts in the event of an emergency, overheating or short circuit, signaling the operating status of the heating system, reducing the peak load on the power supply network, transmitting information about heated objects to the process control system and other tasks. The electrical heating control cabinet is developed individually for each facility based on the technical specifications for the electrical heating system. It is used for heating systems of medium and long pipelines. The use of a control system as part of a heating system can significantly save energy and protect the heated product from overheating, which is especially important for pipelines.

Thermostats

The installation of a thermostat is primarily due to the task of saving energy. The secondary goal is to prevent the object from overheating.

When choosing a thermostat and relay, pay attention to the load current - use the safety factor 1,6

for self-regulating cables, and

1.35

for resistive and zonal.

If the calculated current exceeds the thermostat relay rating (usually 16A), then it is necessary to assemble an electric heating control panel. It's not that difficult. We will definitely tell you how to do this if you intend to buy a heating cable from us.

Thermostats

- Electronic temperature regulator RT-300 2704 rub.

- Thermostat for heating pipes ETI-1551 6060 RUR

- Universal thermostat OJ electronics ETN4 1999 RUB 9,200

- Pipe temperature sensor OJ electronics ETF-622 2500 RUR

- TCON-CSD/20 Electronic thermostat for DIN rail RUB 26,763.64

- Electronic temperature controller RTM-2000 RUR 10,175

- Thermostat exTHERM-AT, type 60/00588595 RUR 31,788

Principles of calculation

- To determine the brand and length of the heating cable, a thermal engineering calculation of the pipeline is carried out based on the initial data about the object:

- technical characteristics of the pipeline,

- technical characteristics of thermal insulation,

- climatic and operational conditions in which the facility is located,

- the required task that the electrical heating system must perform, etc.

- Thermal engineering calculations determine:

- heat loss from the surface of the pipeline,

- safety factor of the electric heating system,

- brand of heating cable, taking into account the maximum permissible exposure temperature, hazard class of the zone in which the object is located and the presence of chemically active substances,

- number of heating sections,

- total power of the electric heating system.

- Based on the results of the thermal engineering calculation and selection of the heating cable, kits for terminating the heating cable, connecting power and control boxes are determined.

- Next, the type and number of elements of the fastening system are determined

- Automation is selected to control the heating system.

- The parameters of the heating system are calculated: operating and starting power, operating and starting current of the system. This information is important in the initial assessment of the cost of supplying power to the heating system.

Installation of a heating cable on a pipe

The sequence of installation of a pipeline heating system depends on the composition of the system, the presence of previously installed elements of the heating system, and other factors.

Installation sequence

- Preparatory work;

- manufacturing and installation of heating sections;

- installation of junction boxes;

- protection of heated objects with thermal insulation;

- installation of control cabinets;

- installation of power supply and control systems;

- test activation of the system.

Depending on the parameters of the pipeline, several methods of installing the heating cable are used:

- Laying along the pipe

When installing a self-regulating cable along a pipe, it is recommended to place it in the lower sector of the pipe. This will prevent damage to the cable when various objects fall onto the pipe.

- Laying the cable in a spiral

When installing a self-regulating cable in a spiral, the amount of cable per linear meter of pipe increases and depends on the cable laying coefficient:

Required cable length = Pipe length * Cable laying factor

The laying pitch of the self-regulating cable in mm is calculated based on the diameter of the pipe.

Cable laying pitch depending on pipe diameter

| Diam. pipes, mm | Cable laying coefficient (meters of cable per meter of pipe) | ||||

| 1,1 | 1,2 | 1,3 | 1,4 | 1,5 | |

| 34 | – | – | – | – | – |

| 48 | – | – | – | – | – |

| 60 | 430 | – | – | – | – |

| 76 | 510 | 360 | – | – | – |

| 89 | 610 | 430 | 330 | – | – |

| 102 | 710 | 480 | 380 | 330 | – |

| 114 | 790 | 530 | 430 | 360 | – |

| 125 | 890 | 610 | 480 | 410 | 360 |

| 140 | 990 | 660 | 530 | 460 | 380 |

| 168 | 1170 | 790 | 640 | 530 | 460 |

| 219 | 1500 | 1040 | 840 | 710 | 610 |

Cable handling

- Use the spool holders to unwind the cable.

- The cable must be positioned freely on the heated object, without excessive tension and installation on sharp edges and surfaces.

- Allow an extra 300-450mm of heating cable per mains connection, T-connection, termination to make these connections easier.

- Do not make loops in the cable or hit it. Also avoid walking on it.

- In a typical installation, the self-regulating cable may be secured to the pipe or tank with aluminum adhesive tape (LAMS) or fiberglass tape. Plastic clamps can also be used on the pipeline if the permissible temperature for using the clamp is similar to or higher than the operating and maximum possible temperatures of the cable and pipeline.

- To avoid possible damage to the cable, do not secure the cable with metal strips, wire, vinyl tape, or regular adhesive tape.

- If the cable is left for a long time, protect it from mechanical damage and all cable ends from moisture penetration.

- The heating cable should be installed in such a way as to facilitate the removal of valves and other small components without excessive removal of insulation and the need to cut the heating cable. This is achieved by creating a loop in the cable. The amount of additional cable required to form a loop on latches, supports, hangers, etc. different for pipes of different diameters and types of pipe elements.

Heating sections are manufactured directly on site according to the actual dimensions of the heated objects, using a standard set for the end seals of heating tapes. After fixing the heating sections, it is necessary to glue them along their entire length with aluminum tape to ensure better contact of the heating cable with the heated surface.

Junction boxes are installed on the surface of the pipeline using a device for inserting the heating cable under the thermal insulation, included in the box, which is secured with tape clamps.

The temperature sensor is installed on the heated surface in accordance with the installation drawing and secured with self-adhesive aluminum tape.

Control cabinets are usually installed in a dedicated dry heated room (+5...+40*C) in accordance with the requirements of the PUE. The installation location of the control cabinet is agreed with the Customer.

Features of installation of heating elements

The easiest way to install a self-regulating cable is by surface method. It can be fixed with aluminum tape. In relatively warm regions, the cable is attached directly to the bottom of the pipe. If the temperature in winter drops to critical levels, it is recommended to lay the heating element in waves.

In northern regions, it is recommended to wrap pipes in increments of no more than 5 cm. After installation, the cable is wrapped in foil film to protect it from rodents and mechanical damage, avoiding tension on the cable. Then mineral wool or foam insulation is laid on top.

Design

Our company is engaged in the design of heating systems for pipelines of any length, branching, complexity and application conditions and is ready to develop a project for a specific facility in the shortest possible time. During the design process, we take into account the customer’s wishes, offer our solutions and coordinate them with the customer. When designing pipeline heating systems, we are guided by the requirements of regulatory documents (PUE, SNiP 23-01-99, GOST R 50.57125-2001, GOST R IEC 62086-2—2005), technical data, instructions and recommendations of equipment and materials manufacturers.