The very first thing visitors see from the owner’s property is the gate. Therefore, owners of private houses strive to give all elements of the fencing structure of their plots a noble appearance. After all, this is how passers-by make assumptions about what is inside, and guests evaluate their desires to visit a well-kept (or not so well-kept) house. Attractive elements of the fence can arouse the intention to enter or vice versa: do not provoke any interest. When searching for materials for manufacturing, they are based on their properties in relation to price. A gate made of corrugated sheets will be the optimal solution due to its good appearance, resistance to moisture, durability, reliability, and low cost.

Advantages of corrugated sheets

Fences in which a profile sheet acts as upholstery are increasingly being used. This is due to a large set of advantages, and the presence of only a few disadvantages.

Advantages:

- The surface of the material is covered with a protective film that protects it from corrosive destruction. In addition, intense sunlight and temperature changes have virtually no effect on the strength of the material.

- Light weight and easy to install. If desired, the gate can be installed in one day, provided that the support pillars are dug in in advance. During installation, you only need to seriously monitor the dimensions of the workpiece.

- Variety of colors and textures.

- Wear resistance and long service life. If the surface is treated with protective materials, the material will last more than 60 years.

- Low price.

- Possibility to choose any desired width and height of the sheet.

- Easy to use.

Flaws:

- Lack of sound insulation.

- The material is easily deformed.

- The appearance of even small damage on the surface violates the integrity of the protective surface, which leads to the appearance of rust.

The ratio of strengths and weaknesses pushes many to make not only wickets, but also swing gates from corrugated sheets.

Standard design diagrams

Regardless of the materials used, the structure of the wicket - like the gate - consists of a frame and decking. If we are talking about a metal gate, then the frame is metal, and the filling of the plane can be metal or from other building materials.

Mandatory elements of a gate made of a pipe or other type of metal profile:

- base for installation - supports fixed in the ground, to which the structure is attached using the canopy method. The base can be the masonry of the boundary wall, existing fence supports, or gates;

- rectangular or shaped (with a complex configuration) frame with additional reinforcing elements - braces;

- filling gaps in the frame. It can be composite or integral. For a metal frame, the filling is usually made from a solid metal panel (corrugated sheet, flat sheet) or wooden boards.

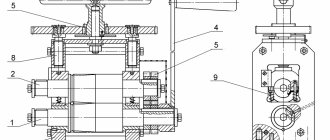

The standard design also includes locking elements. For metal gates, a metal box is usually used, inside which the lock and/or latch mechanism is hidden. If you do not want to install relatively complex mechanisms, installing a conventional deadbolt is acceptable. For its fastening, reinforcement of the frame is provided at the fastening point and at the place where the locking bracket fits.

Below are typical drawings of a pipe gate.

With one support and incomplete covering of the opening. The support pillar is buried in the ground and concreted

With two supports and a rigid frame with braces. The opening is covered by 95%, the supports are fixed on a prepared base (concrete, stone)

Built into swing gates, the frame is partially integrated with the gate frame. The supports are concreted in the ground

With straight frame elements, complementing the basic design of swing gates

Considering the above diagrams, the basic designs can be divided into two groups:

- separately located gates can rest on supporting fence posts, be located next to the gate or at a distance from it;

- combined with the gate structure. In this case, the gate may have common supports with the gate or be part of one of the gate leaves.

Based on appearance, design and partial construction, models with solid and lattice (partial) filling of the frame are distinguished. Any sufficiently durable and practical materials are suitable for complete filling: wood, metal, polymers (including polycarbonate), and less often glass. Lattice structures are divided into products with a rectangular or shaped frame. The simplest option is a chain-link mesh or similar attached to a frame. The appearance of forged and welded artistic products is limited only by the imagination of the master.

Lattice products can be supplemented with transparent or opaque sheet filling of the frame.

Choosing corrugated sheeting: tips for professionals

When choosing a material, you should give preference to galvanized profiled sheet. This will eliminate the need for additional processing.

You can also choose an option with polymer protection for the painted side. This will protect the drawing from fading and washing out.

Lit marking:

- N – carrier. Durable sheets with deep stiffening ribs, often used as roofing material.

- C – wall. Plays the role of a protective screen that is installed on a house or fence.

- NS are universal. Has the strengths of both options.

Numbers can also be placed after the markings. They show the profile height. The gate does not require heavily corrugated surfaces, so models C and CH are suitable.

Of course, the absence of ribs will not have a beneficial effect on the strength of the structure, so the maximum step should not be more than 20 cm.

Covering and decor

Before covering and decorating the gate, the frame and posts must be sanded, treated with an anti-corrosion primer and painted with two layers of paint. It is advisable to remove the gate structure from its hinges and assemble it on a flat surface (see the paragraph on welding the frame).

There are many options for decorative design of the gate:

Net

The easiest way to finish a gate is by covering it with mesh. Wicker or woven mesh is cut to size, welded to the frame and painted.

Polycarbonate

Polycarbonate is secured using self-tapping screws. The polycarbonate is cut out, the ends are covered with an end profile and special adhesive tapes. The combination of polycarbonate and forged pattern looks beautiful.

Profiled sheet or other metal

Covering gates with corrugated sheets is very popular. Installation of corrugated sheets is carried out in the following sequence: the sheet is cut using a grinder, screwed using colored roofing screws with rubber washers into the lower part of the wave. The edge of the sheet is processed with a file, coated with an anti-corrosion compound and paint.

The gate is also sheathed with sheet metal. Installation of the sheet can be welded or threaded - with self-tapping screws. More often the sheet is attached to the frame by welding.

Tree

You can cover the gate with wooden boards and even bamboo. The boards are sanded, primed with antifungal primer and painted. The bamboo is cut, coated with primer and varnish. Fastened with self-tapping screws.

Forging

The most beautiful designs are made from forged parts. Forging work is complex, but you can buy ready-made forged parts and weld them onto the gate frame. The main thing is to think ahead and draw a picture, and then carefully carry out the welding work. Separate parts of the picture can be decorated with gold paint, or the entire picture can be covered with bronze or copper paint.

Locks

A lock or latch is installed on the gate. A mortise lock is preferable - when opening the gate outwards it is more difficult to break it. At the place where the lock is inserted, a slot is made in the gate frame pipe (with a grinder with a small disk). A casing is welded from the sheet and welded to the pipe. The casing protects the lock from breaking and from precipitation. A lock is installed in the slot in the pipe, attachment points for screws and the cylinder mechanism are marked, and holes are drilled for them in the casing. The lock is installed. The lock strike plate is attached after the final installation of the gate - its location is marked, holes are drilled, and the bar is screwed in with self-tapping screws.

At the very end of the work, the handle is attached. The installation can be welded or threaded.

Making a gate from corrugated sheets with your own hands

Before you make a gate from corrugated sheets, you need to provide it with reliable support. Existing fence supports are ideal for this, but if the entire structure is being built from scratch, you will have to install them yourself.

The first thing to do is dig a hole 1.5 meters deep. A cushion of sand and gravel is poured onto its bottom. The support pile must be made of a steel pipe with a diameter of at least 10 cm. It is installed vertically in the hole, which is then filled with concrete. It is worth continuing work only after 7 days.

Before installation

We determine the dimensions of the future gate. Experts consider a meter wide opening to be optimal. A smaller size will create problems when bringing large items into the site. Large width increases the load on hinges and supports, thereby reducing their service life.

The passage and the fence should be the same in height - this will visually give integrity to the entire fence.

Installation

The progress of installation of swing gates is practically no different from the design of the gate.

Among the features, we note that an excessive number of crossbars (used to impart rigidity) makes the structure heavier and causes the sashes to sag.

When installing such gates, padlocks are used rather than mortise ones.