Preparing to Carve by Hand

Threading pipes at home can be done using available tools. The basic rules of preparation are as follows:

- At the place where the coils are cut, dirt, rust and other contaminants are removed. This recommendation is due to the fact that foreign elements can degrade the quality of the turns.

- If there is a chamfer on the pipe, it is carefully removed using a file. In some cases, this process is carried out with a grinder, but the quality of the resulting chamfer may be low. Therefore, if there is no need to rush, then it is best to carry out the work with a file.

- At the time of work, the surface should be well lubricated with oil. Only in this case can the smooth running of the mechanism used be ensured.

Cutting process

If you do not follow the above recommendations regarding the preparatory stage, the working part can quickly wear out, and the process itself becomes more complicated. In some cases, strong impact can lead to pipe failure.

Introduction

We cut the thread ourselves

We will cut the thread using a special tool - a die. This is a die (die) for forming a thread, equipped with a seat for a pipe (jacket, shank, etc.). The cost of this tool is 300-500 rubles, depending on the diameter.

If you are connecting to a central water supply system, then using this method is strictly not recommended - high pressure. This requires the experience and skill of a specialist.

The carving may be different. It differs in tooth shape, pitch, and purpose. Klupp cuts conical threads; it is not recommended for pipe connections, but is acceptable.

Step No. 1 – preparation for work

Lubricate the pipe

1 First of all, you need to trim the pipe. You can do this using a grinder or a hand hacksaw.

2 If there is a thick layer of paint on the pipe, it must be removed. But there is no need to remove the chamfer on the pipe, otherwise the clamp will not catch on to it.

3 To facilitate work, the pipes should be treated with lubricant: litol, grease, etc. Some plumbers use lard.

Lubricate the clamp

4 The die also needs to be treated.

Stage No. 2 - cutting the thread

If the pipe is “flimsy”, then we use two keys

1 We put the clamp on the pipe as shown in the figure. If the pipe is old and there is a suspicion that it is rotten, then it is better to use two gas keys. One will hold the pipe in a static position, and the other will turn the clamp.

2 Special ratchet wrenches are sold for pipe dies and clamps, but for one-time work a regular gas wrench will do.

Two or three turns clockwise

3 Turn the clamp clockwise. After making two or three turns clockwise, you need to remove the resulting chips.

Turn counterclockwise - cut off the chips

4 Turn the gas key over and make one turn in the opposite direction.

Turn clockwise - cut the thread

5 Repeat the cycle until at least 7 threads have been cut.

Counterclockwise - cut off the chips

Step-by-step instructions for cutting threads using a die

The most common is a die of various types. It is one of the necessary tools for thread cutting. Among its features, we note the following points:

- The die looks like a nut made of hardened steel. On the end sides there are holes made in the shape of a flower. To ensure mechanical processing, the faces are represented by sharp cutting edges. The petal shape ensures removal of chips from the cutting zone.

- The body has holes for installing the handle. They are located on the sides, thereby ensuring uniform impact.

The die has become widespread due to the fact that it is quite easy to use. Recommendations for its use are as follows:

- At the time of processing, the pipe must be vertical. At the same time, it is fixed using a vice.

- It is recommended to clean the surface and create a chamfer.

- Oil should be applied to the pipe, which will simplify the movement of the die along the pipe.

- It is worth considering that the die must be positioned strictly vertically. Even a deviation of only 10 degrees will lead to a decrease in the quality of the resulting turns.

- The handle should be rotated clockwise.

- In order to improve the quality of the resulting surface, after two turns, one should be made in reverse, thereby ensuring the removal of metal residues from the cutting part.

Thread cutting with a die

During work, you should periodically lubricate the working part and the pipe with oil. Lubricants make the cutting process easier and smoother.

Required Tools

To complete the work you will need threading tools:

- A die or blade is a device in the form of a nut made of hardened metal, which has pointed cutting edges (cutters). They are round, square and hexagonal in shape. Types of dies: solid, sliding, split. Holes are provided to remove chips.

- Klupp is a tool based on a sliding die. The two-part body allows you to adjust the cutting diameter. A handle is provided for ease of use. Some models are equipped with a ratchet that allows you to perform rotational movements with one hand. The professional tool is equipped with an electric drive.

- A tap is a hardened steel screw with cutting edges. Consists of a working part and a shank. The set includes devices for roughing and finishing work.

Additionally prepare auxiliary devices:

- tape measure and pencil - for measurements and marks;

- caliper - determines the diameter of pipes and fixtures.

The tools used must be of high quality, the metal of the cutters must be sharp and durable. When working with dies and taps, you will need a vice.

Preparing for work

The area where you will have to work with a thread-cutting device for water pipes is cleaned of rust, dirt, and paint residues. Sandpaper is used. The surface should be cleaned to a metallic shine. The end surface is chamfered. It is necessary to prepare a lubricant for processing the pipe and cutting tool. You will need a rag to clean the shavings.

Threading set for pipes and rules for its use

You can significantly simplify the task of cutting threads by purchasing a special set for pipes. It is ideal for use at home. An example is a clamp - a slightly modified die, which is used together with a ratchet and a guide. The set may include various accessories:

- Monolithic ones are represented by a cylindrical body with an internal hole. For work, the kit also includes a special die holder.

- Sliding ones consist of incisors, the distance between which can be adjusted if necessary. It is used for cutting a threaded surface in several passes, thereby increasing quality.

The hole is selected depending on the diameter of the pipe and the direction of the thread. The cutting process is characterized by the following features:

- A special tool called a clamp is installed in the ratchet.

- Oil is also applied to the cutting part, which simplifies the movement of the working part.

- A guide is installed on the edge of the pipe being processed.

- The ratchet rotates around an axis, due to which threads are formed.

- During machining, oil is added from time to time.

Pipe threading set

It is worth considering the fact that the device may become dull after prolonged use. That is why you need to monitor the condition of the cutting edge.

How to cut threads on a pipe yourself. Photo and video

How to correctly cut external and internal threads on a pipe using clamps and dies. Threaded connections of metal pipes are durable and airtight, and can withstand significant pressure. However, independent thread cutting requires knowledge of certain rules.

To work you will need tools and materials:

- Vernier calipers - for accurately measuring the diameter of the pipe.

- Vise - when using solid dies or a tap.

- Machine oil or any lubricant.

- A rag or sponge.

- Protective equipment - glasses, gloves.

And also, a device for cutting threads, depending on the specific task (solid or sliding dies, electric dies, ratchet dies or taps).

Preparing for work

First, you need to select and, if necessary, cut a suitable piece of pipe with a grinder or a hacksaw. When cutting, you need to make sure that the cut is strictly perpendicular to the planes of its walls.

Immediately before cutting the thread, you should clean the surface of the pipe from rust or old paint, and other foreign deposits using sandpaper and a file. In addition, you need to chamfer the end of the pipe with a file in order to make the thread easier. Now let's move on to preparing for thread cutting.

Basic mistakes when cutting threads

- the pipe diameter does not match the thread diameter;

- using incorrectly aligned, rusty or dull tools;

- working without lubrication of the tool and pipe leads to cracks or breakage of threads;

- excessive physical effort as a consequence of a complete lack of work skills leads to thread failure.

Cutting external threads with a solid die

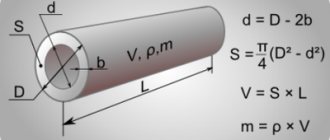

Solid dies are often used for cutting external threads on pipes. They are a hardened nut with internal cutting edges. This tool is suitable for cutting threads with a diameter of up to 52 millimeters.

It is inexpensive, characterized by good rigidity and precision, but does not last long because it wears out quickly. Working with dies requires some experience, so in order not to damage the tool and pipe, it is advisable to practice on a section of pipe.

Threading a pipe near a wall

The most problems arise with cutting threads on a pipe that is located near the wall. This is due to the location of the workpiece and insufficient free space. That is why a common question is how to cut threads on a pipe.

In such a case, processing is carried out using similar tools. However, threading a pipe near a wall is often only possible by partially removing the wall. Among other features of the procedure, we note the following points:

- If you need to cut a thread on one of the sections of the pipeline, it is recommended to first dismantle it. In some cases this is possible.

- Cutting pipe threads also requires a fairly large amount of oil, which facilitates the movement of the device. However, when the pipe is positioned horizontally, it begins to drain quickly, which creates significant problems with carrying out the process in question.

- The carving is made in several passes, which ensures a high quality surface.

It is quite difficult to cut a thread on a water pipe when it is in a horizontal position. This is due to the fact that it is quite difficult to control the strict position of the mechanism used parallel to the axis, as well as to apply the required load.

Tapping internal threads

Using a tap, cut the internal thread in the pre-drilled hole. The hole should be smaller by approximately the thread size (the thread size is indicated on the tap). Approximately as in the table:

Hole diameter for internal thread with tap

It is worth remembering that the drill will not give an absolutely accurate diameter; it will be larger by a few fractions of a mm. This is especially noticeable on diameters up to 3 mm. This should be taken into account and take a drill less than a tenth of a mm.

Just like with dies, there is a tap holder.

There are rough and finishing taps. Sometimes they cut first with a rough tap, then with a finishing tap, but mostly they use finishing taps straight away.

Manual cutting of internal threads with a tap (video)

The process is almost identical to thread cutting with a die. The tap is attached to the holder and installed perpendicular to the hole. The part with the hole must be securely fastened.

The tap and hole are lubricated and this is done periodically, after several turns. Just like with a die, you need to make 1-2 turns and 0.5 turns back to remove chips.

To check the accuracy of thread cutting, use a square, checking the verticality of the tap after several turns.

How to cut internal threads?

In some cases, an internal thread is required, which can also be cut using hand tools. Often, for such work, a tap is selected, which consists of three main parts:

- Fence.

- Calibrating.

- Tail.

The intake is applied directly at the time of cutting, the calibrating guide guides the tool and ensures its vertical position. The tail part is required in order to secure the die in a special holder.

An internal thread can be formed as follows:

- The pipe is fixed in a vertical position.

- The tap and the workpiece being processed are lubricated.

- The device is placed strictly vertically, after which several rotations are made clockwise and one counterclockwise.

Internal thread tap

During operation, oil should be added from time to time. This ensures smooth running of the tool.

Development of slicing

The sequence of thread cutting on a pipe consists of the following steps:

- Clean the desired section of the pipe from rust, other irregularities and paint stains on the outer diameter of the pipe.

- Liberally lubricate the required section of the pipe with machine oil or sulforesol, due to which the load on the handle when cutting will be much less. The same can be done with respect to the die/dies.

- Securely secure the pipe in a vice. Along with this, the end of the pipe protruding for threading should not be more than 5–8 of its diameters; otherwise, cutting accuracy is not guaranteed. Dies with a guide bushing or die do not require such restrictions.

- The pipe is prepared for cutting by using a file to obtain a lead-in cone at the end with a height of at least half the height of the die. At this point, a running section of thread is formed; if this is critical, then it can then be removed with a hacksaw.

- A die or die is inserted, and by vigorously rotating the knob, the desired threaded section is obtained. Don’t forget that the length of the cut section of the thread should be a couple of turns more than required. To be sure, you can run the die over the cut area a couple of times.

So, if you follow the recommendations and instructions proposed in the article, you will be able to quickly and properly cut threads on a pipe. Do you have any questions on the topic? Then ask questions by writing a comment on the article.

Gutter cutting machine

Special machines are often used in production. In terms of design features, they are in many ways reminiscent of vertically oriented machines. Among the features we note:

- The diameter and thread pitch are adjustable.

- If necessary, you can carefully adjust the number and speed of rotation of the cutting element.

- Almost all models are characterized by the ability to process external and internal surfaces.

Modern machines can be used even when cutting thin-walled products. Difficulties can only arise if the workpiece cannot be removed and installed vertically.

Basic cutting methods

There are two main ways to cut coils on the surface being treated: manually or using automatic equipment. In home workshops, hand tools are often used, as they are cheap and easy to use. The most commonly used die is the following ones on sale:

- Kluppovye.

- Whole.

- Split.

The main part of the device can be made in the form of a square and hexagons. The most widespread are disk versions, which are used for thread cutting.

Set of taps and dies

Split or spring-loaded versions are characterized by high wear resistance. However, the peculiarities of their design determine that it is practically impossible to achieve high accuracy and cleanliness of the cut turns.

You can also use sliding dies, which often consist of two working parts. This ensures versatility in application.

Thread cutting technique

As previously noted, the die is represented by a modernized die, which has adjustable cutters. In addition, the cutting part can be replaced if necessary and extend the service life of the tool.

On sale you can find a manual version, as well as an electric one. Hand tools are more common; they are easy to use and inexpensive.

Electric ones are characterized by high performance. The clamp is installed in different positions, but most often in a vertical position.

Cutting with a hand clamp

In a home workshop, it is recommended to carry out the cutting using a hand clamp. Among the features of this process, the following points can be noted:

- The working part is installed in a special holder made in the form of a ratchet. It greatly simplifies the process of cutting coils on the pipe surface.

- You can start by cleaning the pipe. It is worth considering that when cutting turns, it is possible only in the absence of strong defects.

- The surface is cleaned down to the metal until it begins to shine.

- The outer edge is processed to obtain a chamfer. This ensures that the tool enters.

- The surface is treated with technical Vaseline. It reduces the degree of friction and makes the tool move smoother.

- The pipe is secured in a vice; you can also hold it with a gas wrench. It is important to eliminate the possibility of the pipe tilting or moving when a high load is placed on it.

Using a manual clamp

The work involves making several turns clockwise, and then in the opposite direction. This is done in order to remove chips from the cutting zone.

Cutting with an electric clamp

In addition to hand tools, electric tools have also become widespread. The advantage of this design option is high performance. The work when using it has the following features:

- The part to be processed is carefully prepared.

- Ensures reliable fastening of the workpiece.

- The mechanism is attached at the starting point.

- The free movement of the guides and the direction of rotation of the cutting part are checked.

- The first turns are cut in the jog mode.

On the tool you can set basic parameters, for example, the length of the cut. Application features depend on its functionality and other performance characteristics.

The procedure for cutting external threads on a water pipe

There are water pipes in almost every residential and commercial premises. The sequence of actions when cutting threads is as follows:

- Preparation. At the preparatory stage, the main thing is to remove all dirt and possible rust, as well as remove all defects. Otherwise, difficulties may arise in carrying out the work.

- Installation of the workpiece. The pipe must be positioned strictly vertically, otherwise the die may move to the side.

- Cutting. At this stage, you need to ensure that the mechanism used is strictly vertical, since even a slight displacement can lead to significant problems.

- Quality checking. This stage involves screwing on the nut, due to which the cleanliness of the turns and the accuracy of their location are checked.

Thread restoration

When using a lathe, it is possible to create turns in one longitudinal pass. However, screw-cutting lathes are not the best suited for the task at hand.

On a stainless pipe

Stainless steel is often used in the manufacture of pipes. It is characterized by high strength and resistance to corrosion. However, the presence of a large number of alloying elements leads to a decrease in the degree of machinability. That is why quite a lot of difficulties can arise with thread cutting.

The cutting process can be simplified by liberally using a lubricant. In addition, you need to choose a die or tap made of wear-resistant material that will not become dull during processing.

In conclusion, we note that it is not necessary to have any skills or special tools to obtain threads on the surface of pipes. It is important to use the selected thread cutting mechanism correctly, as well as monitor the presence of lubricant. It is worth considering that an insufficient amount of lubricant can lead to jamming of the die or tap.

Main reasons for marriage

The cause of defects in work is the inattention of the worker or the use of low-quality tools. Common pipe cutting defects when working with a tap or die:

- Torn threads - a problem occurs when using a dull die, untimely removal of chips, or insufficient lubrication.

- Incomplete thread - the diameter of the thread hole exceeds the recommended one.

- Skewed helical grooves – incorrect installation of the die or tap.

- Thread failure is caused by clogging of the grooves with chips, poor quality of the tool, or the pipe diameter is larger than specified.

- Tap failure - excessive force applied in a narrow hole, insufficient chip removal, lack of lubrication.

Self-preparation of parts for threaded connections is quite accessible if you have the tools. In order for the work to be done efficiently, you must follow the rules. The use of sharp tools and accuracy compensate for the lack of professional skills.