The VGP pipe, the abbreviation in the name of which stands for “water and gas pipeline,” is specially designed for laying water and gas communications. Even in our time, when modern manufacturers offer a huge range of pipes made from various materials, such specialized steel pipe products are extremely popular among construction and repair organizations, and enterprises working in the housing and communal services sector.

Pipes VGP GOST 3262-75

You can familiarize yourself with all GOST requirements for steel VGP pipes by downloading this document in pdf format from the link below.

GOST 3262-75 Steel water and gas pipes. Specifications

The relevance of using pipes of this category

The high popularity enjoyed by VGP pipes made from steel alloys can be explained very simply. No matter how exceptional the characteristics of today's popular pipes made of polymeric materials may be, their use in many cases is simply not possible. Such cases, in particular, include installation of a pipeline in the open air, where it will be affected by a lot of negative factors.

The demand for such products is also explained by the fact that, according to generally accepted requirements, pipelines for transporting gas and supplying it to consumers can only be made of steel pipes. That is why VGP pipes are simply an irreplaceable material in any gas industry.

Gas supply to a private home is a typical example of using VGP pipes

How to find out the dimensions of a product yourself

The standards for external diameters and wall thicknesses used in the water and gas pipeline system are established by GOST Z262-75, for electric welded pipes - standard 10705-80/10704-91. The value of the internal diameter can be found by looking at the product labeling. However, if it is necessary to repair communication systems, and data on the internal diameter of already installed pipes is unknown, the formula can be used to calculate the diameter:

- d = D - 2*S

- Where d is the pipe diameter indicator (inner part)

- D – outer diameter indicator

- 2S – double wall thickness

So, in order to independently calculate the parameters, you need to measure the thickness of the pipe wall and its circumference with a centimeter or tape measure.

How pipes are made

The main material from which pipes belonging to the VGP category are produced is carbon steel. The technological process of their production consists of the following stages:

- first, steel blanks are prepared - strips, which are long metal strips with the required thickness and width parameters;

- then a pipe is formed from the prepared strip, for which special equipment is used;

- the joint formed on the resulting product is welded using electric welding.

Stages of production of water and gas pipes

The qualitative characteristics that pipes of the VGP category manufactured using this technology must meet are stipulated by the provisions of GOST 3262-75.

Taking into account the fact that pipes of this category are operated in rather difficult conditions, and very high demands are placed on the quality of the weld being created, the place of the formed joint must be checked using radiographic control methods.

The main influence on the service life of pipelines made from water and gas pipe products is their operating conditions, as well as the characteristics of the substance that is transported through them. This is explained by the fact that the transported substances have different chemical reactivity.

What is the difference between a VGP pipe and an electric-welded pipe?

Of course, such a question is not entirely correct, but for a non-specialist it is quite important. In general, VGP pipe is a type of electric welded product category. Visually, a water-gas pipe differs from an electric-welded pipe only in size, but the state standard dictates different requirements for these two types of pipes. Electric-welded pipes are more often used in main structures, and can also serve as support pillars, frame structures for furniture, fences or enclosures. As with the production of VGP, galvanized steel can be used in the manufacture of electric welded pipes.

The main differences between these types of pipes, according to the relevant GOSTs, are presented below.

Steel VGP pipe: GOST 3262-75

Straight-seam electric-welded steel pipe: GOST 10704-91 (TU according to GOST 10705-80)

No more than 0.4 mm for d 50 mm

2.4 MPa – ordinary pipes 3.1 MPa – reinforced pipes

6 MPa – at d 102 3 MPa – at d >102 mm

It is allowed to produce analogues of steel VGP pipes in accordance with GOST 10704-91, provided they fully comply with the presented standards.

Welded VGP pipes can have both a spiral and a straight seam.

Sheet metal

- Hot-rolled sheet

- Cotton sheet

- Galvanized sheet.

- Profiled sheeting.

- Expanded metal sheet (PVL).

- Stainless steel sheet.

Long products

- Rebar, wire rod.

- Beam, channel.

- Corner.

- Circle.

- Stripe, square.

Stainless steel

- Circle, square, hexagon.

- Stripe, corner.

- Stainless steel pipes.

- Stainless steel sheet.

- Stainless steel hardware.

- Accessories for stair railings.

- Pipeline details.

Hardware and metal raw materials

- Calibration, silver.

- Wire, ropes.

- Mesh, tape.

- Radiators, electrodes.

Non-ferrous metals

- Aluminum, duralumin.

- Copper, bronze, brass.

- Tin.

- Lead.

- Zinc.

There are two types of pipes: solid and welded type. The VGP steel pipe can be made in a standard design or with increased precision; in the latter case, it is used for the manufacture of pipeline fittings; the bodies of gate valves, valves and other regulatory bodies are made from it. The first type of pipe has no seams and is widely used in boiler rooms and heating systems; it has no threads and is tightly welded into the system. The production of all kinds of structures using welding or mechanical connections, where VGP pipes of various lengths and diameters are used as a building material, is as popular as the use of other types of pipe rolling for these purposes. Pipes are characterized by the following characteristics: By type of production. The VGP product is made of high quality steel, it can be of conventional type or high precision. Such pipes are used to transport hot and cold water and gas.

VGP galvanized pipes, types, purpose, characteristics. In many ways, the price of a pipe is determined based on the qualities described above, while the manufacturer’s brand does not have a significant impact on the cost. In everyday life, the use of non-galvanized pipes will lead to the fact that after a few years, as a result of overgrowing, the bore diameter will significantly decrease, and using galvanized pipes is very expensive, and in terms of sanitary indicators it is significantly inferior to PVC pipes. By the presence of anti-corrosion coating: By wall thickness: In addition to these parameters, the consumer can choose the type and presence or absence of threads, pipe length and other parameters, which actually explains the popularity of this material. The use of pipes for installing gas pipelines remains unchanged, and even then, increasingly, the metal pipeline ends after entering the apartment, since it is now allowed to use flexible hoses to connect gas stoves.

This is interesting: Description of steel 40X

The pipe is made of durable steel and is used in public utilities and in various fields of production. All products have a passport, which indicates the norms and standards of the product, the results of tests and trials. A hollow pipe is not inferior in rigidity to a solid metal rod, therefore it is quite often used not only for its intended purpose. For cold water pipelines, a medium-reinforced pipe is used, and then mainly to counteract hydraulic shocks, but gas pipelines are installed from light pipes. High-precision pipes are used for the manufacture of valves, valves, and other fittings.

The production of VGP pipes is regulated by the provision “Steel pipes GOST 3262-75”, which provides for a fairly large range of these products. Water and gas pipes (WGP) at low cost. Electric-welded metal pipe VGP. The connection of seam pipes is carried out both by welding and mechanically through a coupling. Reinforced products are used to transmit hot water, steam, and compressed air. For pipes connected by welding, the outer diameter ranges from 10.2 to 165 millimeters, the nominal diameter ranges from 6 to 150 millimeters, and the weight of one linear meter of pipe ranges from 0.37 to 21.63 kg.

One of the main characteristics is the strength of the pipes relative to the withstand pressure; they are divided into light, regular and reinforced; the choice of one or another material depends directly on the transported medium. If a manufacturer uses its own standards (TU) for production in order to reduce the cost of the product, then this must be indicated in the passport. Electric welded steel pipe is the most commonly used type of pipe for the transmission of water and gas, produced by rolling rolled sheets into a cylinder and further welding. Application. Since pipelines are qualified as vessels operating under pressure, the use of products at civil and industrial sites of increased danger, developed taking into account any other regulatory documents except GOST 3262-75, which regulates everything, including the steel grades used, is strictly prohibited. The standard regulates the maximum test pressure values: for ordinary and lightweight pipes up to 2.4 MPa, for reinforced pipes the pressure value is 3.1 MPa.

The pipes in the system are assembled by welding, which is why the pipes are called electric welded. Pipes can be thick-walled, medium-sized or thin-walled, some of them are galvanized, others are not. Cutting can be done externally with dies or internally with taps; if large volumes of threads are required, cutting can be done on lathes. VGP pipe. A VGP pipe is a cylindrical hollow product made from various grades of steel, including stainless steel, intended for use in energy production and distribution systems. Seamless - characterized by increased resistance to hydraulic shock due to the absence of a welded seam, used mainly in heating systems.

Frame structures are welded from pipes - these are well-known greenhouses, hangars, sheds, light structures; it is used as electrical wiring. In water supply systems, metal pipes are increasingly used only on main lines where a large diameter is required. Depending on their purpose, conventional and lightweight reinforced pipes are used. VGP pipes are used to transport cold and hot water, compressed air, steam, natural gas and other liquid and gaseous media, the chemical composition of which does not affect the integrity of the pipeline walls. The fact is that gas, even despite the moisture content in it, has little effect on the corrosion process from the inside, and if the outside of the pipeline is regularly painted, it will not be replaced soon. Such electrical wiring reduces the risk of electric shock, since the metal body of the pipe also serves as a grounding connection. Technical characteristics of VGP metal pipes, pipe price.

Electric welded pipe or VGP

It is used not only for the transmission of water and gas, but also as a building element. The pipe has a hollow structure, it is stable and in terms of rigidity it can easily replace a metal beam. VGP pipe (Water-Gas-Pipe) - these pipes are used to create heating, water supply and gas pipeline systems. The diameters of VGP pipes are determined according to the assortment, and this also determines the limits on weight and size. In water supply systems where cold water is used, pipes of the usual type are used, and for the transmission and transportation of gas, light pipes are used. Before buying a steel pipe, you must inquire about the passport data, which must indicate the results and date of the hydraulic tests carried out during the production of pipe rolling.

It is connected exclusively using electric welding without the possibility of threading. Types of water and gas pipes, which pipe to buy. A welded steel pipe is obtained by welding a metal sheet in the form of a cylinder. Regular and lightweight pipes are tested at a maximum pressure of 2.4 MPa, reinforced type pipes at a pressure of 3.1 MPa. The hollow design allows alarm and electrical wires to be laid in pipes, protecting them from damage and deformation.

It is a hollow cylindrical product used to supply hot and cold water, steam and gas. Since the weight of the pipe itself is small, it is quite often used to create frame structures, for example, greenhouses. Round pipes are also constantly used for electrical installations; a lightweight version is used here; to protect electrical wiring or alarm wires, lines are laid on top, along the walls of buildings, or in the ground, the pipe body supports the weight of the soil and the cables remain undamaged. Pipes connected using threads are limited in outer diameter from 16 to 74 millimeters, wall thickness ranges from 2 to 3.2 millimeters, while a meter of pipe weighs from 0.69 to 5.59 kilograms. Reinforced ones are used in compressed air systems, steam pipelines and hot water supply pipelines, as well as in boiler piping.

What to look for when choosing pipes

For the end user, who needs such steel pipes to solve specific problems, certain operational characteristics of these products are of interest, allowing them to be selected optimally.

In order to make the right choice of such pipes and use them in accordance with their main purpose, it is important to understand the classification of products. The criteria by which such classification is carried out are stipulated by the provisions of GOST 3262-75.

Important criteria for sorting pipes of the VGP category are the material and method of their manufacture, as well as the method of their processing. So, depending on these parameters, pipes are distinguished:

- made of ferrous metal, the surface of which is not protected in any way;

- pipes whose surface is galvanized.

VGP galvanized pipe DN 57x3.5

Tubular products, on the inner and outer surface of which a thin layer of zinc is applied, even differ in appearance from ordinary ones, as can be seen by comparing their photos. Such surface treatment of pipe products is necessary in order to reliably protect them from the aggressive influence of the external environment. Pipes coated with a thin layer of zinc, due to the chemical properties of this metal, perfectly resist corrosion and can be successfully operated even in the most difficult conditions for a long period of time.

Important parameters of such pipes, regardless of whether they are galvanized or not, are their geometric dimensions: nominal diameter, which is denoted by the abbreviation DU, as well as their wall thickness.

Significant geometric parameters of VGP pipes

All geometric parameters of pipes of the VGP category, including their diameter, must comply with the requirements specified in GOST. All geometric dimensions of pipes produced by modern industry can be selected using the appropriate tables.

Range of produced VGP pipes by size and weight

From the production line, water and gas pipe products can be produced in two modifications:

- without thread;

- with ready-made threads on both ends, which are applied by rolling or cutting.

Decoding the numbers in the designation allows you to find out the exact diameter of the product. Thus, products for which their DU is designated by the number 50 (VGP pipe DU50) have a diameter equal to two inches. And for pipes of the VGP category, the designation of which includes DU25, the diameter is equal to one inch. Accordingly, the markings of water and gas pipes indicate their diameter in millimeters, and converting it into inches is not difficult.

The documentation accompanying the product contains the necessary information

Dimensions

Water and gas pipes are manufactured in accordance with GOST, which sets clear requirements for their sizes and basic characteristics:

- the wall thickness should be 2.5-4.5 mm, the permissible deviation is minimal and only on the condition that it does not reduce the reliability of the product and the quality of the product;

- the conventionally accepted DU for steel VGP pipes is 6-150 mm, while with a length of more than 20 mm, a deviation from the established standard of 2 mm is allowed; if the length is less, then the deviation should not exceed 2 mm;

- the outer diameter of the water and gas pipe can be from 10 to 165 m, the total number of standard sizes is 14, and the basic classification of products is carried out precisely on this basis;

- the length of the pipes varies from 4 to 12 meters, while for each linear meter a two-millimeter curvature of the pipe is allowed;

- Pipe threads must be applied with a aligned cylindrical or knurled end.

Classification of pipes according to their accuracy class

Water and gas pipes are divided into two main categories according to their accuracy classes. The first category includes tubular products of ordinary precision. When producing products of this category, the following parameters are not standardized: the chemical composition of the manufacturing material, its mechanical characteristics. Pipes of this category are quite successfully used for arranging gas and water communications for domestic purposes.

The second category includes water and gas pipe products of increased precision. Galvanized pipes also belong to this category. From such pipes, for which both the chemical composition of the manufacturing material and its mechanical characteristics are standardized, parts for industrial pipelines are made with increased requirements for their reliability.

Requirements for high-precision pipes

Directory of rolled metal products

There are two types of water and gas pipes - black water and gas pipes and galvanized water and gas pipes. Their main difference is the presence/absence of a galvanized coating, thanks to which the water and gas pipe acquires amazing anti-corrosion properties and becomes more resistant to aggressive external factors. Practice shows that non-galvanized pipes are lighter than galvanized pipes by an average of 3 percent.

Possessing high strength, excellent performance characteristics and a relatively simple manufacturing procedure, water-gas pipes are widely used today not only in construction for heating distribution and supplying household gas, but also in mechanical engineering, aircraft manufacturing, the automotive industry, the agricultural industry, and in the construction of various types of metal structures.

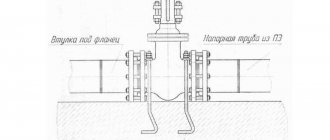

As a rule, water and gas pipes are used together with such additional products as bends, tees, valves, bends, transitions, barrels, plugs and other pipeline fittings.

Depending on the length, the water-gas pipe can be of measured length or unmeasured in the range from 4 to 12 meters. If we are talking about measuring pipes, then an allowance of 5 millimeters is allowed for each cut and a longitudinal deviation over the entire length of about 10 millimeters. In the case of unmeasured pipes, subject to an agreement between the manufacturer and the consumer, it is allowed to have up to 5 percent of pipes in one batch, the length of which ranges from 1.5 to 4 meters.

The accuracy criterion also affects the classification of water and gas pipes. And here there are two types of pipes:

Water and gas pipes of standard precision (manufactured from steels that comply with GOST 1050 and GOST 380).

High precision water and gas pipes (made from steel that complies with GOST 1050).

Products of the first group are in most cases used for the construction of gas pipelines, water pipelines and heating systems. The latter find their application in the production of parts for gas and water supply structures.

This is interesting: Classification of metal threads

The letters after the word “pipe” in the symbol deserve special attention.

Thus, a water-gas pipe with a length of thread is designated by the letter “D”, a water-gas pipe going under thread rolling is marked by the letter “N”, and the letter “P” placed after the size of the nominal bore indicates a pipe with increased manufacturing precision.

When producing water and gas pipes, small deviations in weight (maximum 8 percent) and curvature are allowed. At the request of the consumer, maximum mass deviations for a batch should not exceed 7.5 percent, and for an individual pipe - 10 percent. If we talk about curvature, then it does not go beyond 2 millimeters per meter of pipe length (if there is a nominal bore up to 20 millimeters inclusive) and beyond 1.5 millimeters if the nominal bore exceeds 20 millimeters.

| Name | Diam. mm. (int.) | Thickness Art. mm. | Length mm. | Unit change | Weight 1m, kg |

| Water and gas pipe | 15 | 2,5 | 6000-8500 | tn. | 1,16 |

| Water and gas pipe | 15 | 2,8 | 6000-8500 | tn. | 1,28 |

| Water and gas pipe | 20 | 2,5 | 6000-8500 | tn. | 1,5 |

| Water and gas pipe | 20 | 2,8 | 6000-8500 | tn. | 1,66 |

| Water and gas pipe | 25 | 2,5 | 6000-8500 | tn. | 1,39 |

| Water and gas pipe | 25 | 2,8 | 10000 | tn. | 2,12 |

| Water and gas pipe | 25 | 3,2 | 10000 | tn. | 2,39 |

| Water and gas pipe | 32 | 2,8 | 10000 | tn. | 2,73 |

| Water and gas pipe | 32 | 3,2 | 10000 | tn. | 3,09 |

| Water and gas pipe | 40 | 3 | 10000 | tn. | 3,38 |

| Water and gas pipe | 40 | 3,5 | 10000 | tn. | 3,84 |

| Water and gas pipe | 50 | 3 | 10000 | tn. | 4,22 |

| Water and gas pipe | 50 | 3,5 | 10000 | tn. | 4,88 |

| Water and gas pipe | 65 | 4 | 6000 | tn. | 7,05 |

| Water and gas pipe | 80 | 4 | 6000 | tn. | 8,34 |

| Water and gas pipe | 100 | 4 | 10000 | tn. | 10,65 |

| Water and gas pipe | 100 | 4,5 | 10000 | tn. | 12,15 |

Parameters of water and gas pipes (GOST 3262-75)

| DU Symbol. | Outer diameter, mm | Lungs | Regular | Reinforced | ||||||

| Wall thickness, mm | Weight 1m, kg | Meters per ton | Wall thickness, mm | Weight 1m, kg | Meters per ton | Wall thickness, mm | Weight 1m, kg | Meters per ton | ||

| 6 | 10,2 | 1,8 | 0,37 | 2681,8 | 2,0 | 0,40 | 2472,5 | 2,5 | 0,47 | 2106,4 |

| 8 | 13,5 | 2,0 | 0,57 | 1763,0 | 2,2 | 0,61 | 1631,1 | 2,8 | 0,74 | 1353,4 |

| 10 | 17,0 | 2,0 | 0,74 | 1351,6 | 2,8 | 0,98 | 1019,8 | 2,8 | 0,98 | 1019,8 |

| 15 | 21,3 | 2,5 | 1,16 | 862,7 | 2,8 | 1,28 | 782,8 | 3,2 | 1,43 | 700,1 |

| 20 | 26,8 | 2,5 | 1,50 | 667,5 | 2,8 | 1,66 | 603,4 | 3,2 | 1,86 | 536,9 |

| 25 | 33,5 | 2,8 | 2,12 | 471,7 | 3,2 | 2,39 | 418,2 | 4,0 | 2,91 | 343,6 |

| 32 | 42,3 | 2,8 | 2,73 | 366,6 | 3,2 | 3,09 | 324,1 | 4,0 | 3,78 | 264,7 |

| 40 | 48,0 | 3,0 | 3,33 | 300,4 | 3,5 | 3,84 | 260,3 | 4,0 | 4,34 | 230,4 |

| 50 | 60,0 | 3,0 | 4,22 | 237,1 | 3,5 | 4,88 | 205,1 | 4,5 | 6,16 | 162,4 |

| 65 | 75,5 | 3,2 | 5,71 | 175,3 | 4,0 | 7,05 | 141,8 | 4,5 | 7,88 | 126,9 |

| 80 | 88,5 | 3,5 | 7,34 | 136,3 | 4,0 | 8,34 | 120,0 | 4,5 | 9,32 | 107,3 |

| 90 | 101,3 | 3,5 | 8,44 | 118,5 | 4,0 | 9,60 | 104,2 | 4,5 | 10,74 | 93,1 |

| 100 | 114,0 | 4,0 | 10,85 | 92,2 | 4,5 | 12,15 | 82,3 | 5,0 | 13,44 | 74,4 |

| 125 | 140,0 | 4,0 | 13,42 | 74,5 | 4,5 | 15,04 | 66,5 | 5,5 | 18,24 | 54,8 |

| 150 | 165,0 | 4,0 | 15,88 | 63,0 | 4,5 | 17,81 | 56,1 | 5,5 | 21,63 | 46,2 |

Water and gas pipes are widely used in the installation of water supply, gas and heating systems in residential buildings. Galvanized water and gas pipes are used for installation in aggressive and humid environments, as well as for the manufacture of various structures, machines and mechanisms.

In fact, this type of pipe has become the basis for the work of not only the entire gas service, but also the entire public utility sector. Without them, today it is impossible to put into operation either residential or industrial facilities. All pipes have a specified service life, after which they are replaced with new ones as planned. This is due to the peculiarity and enormous importance of the media transported through them for the life support of residential areas.

Any damage to the integrity of the pipe can lead to a leak of natural gas, hot or cold water. Of course, these accidents differ from each other in terms of the level of danger, but the way to prevent them is the same: timely replacement of water and gas pipes with new ones.

At the same time, old dismantled pipes often do not have any external damage, and their level of wear allows for further use in less critical areas of the national economy. For example, in agriculture for the construction of irrigation systems, or in the manufacture of various landscape structures, gazebos, benches and fences.

Water and gas pipes are made from metal blanks, called strips, by special molding and further welding of the seam. For this purpose, ordinary carbon steel is used without further heat treatment. All water and gas pipes are manufactured using electric welding and mandatory quality control of the weld. It is the seam, as a source of increased danger to the integrity of the entire pipeline, that receives increased attention. To do this, an X-ray examination of its surface is carried out.

Water and gas pipes vary in size. In construction and public utilities, almost the entire range of products of this name is used at the same time. By the way, prices for pipes are based on their weight, or rather per ton.

The dimensions of water and gas pipes are determined by the nominal diameter, expressed in millimeters or inches. In this case, the external size of the pipe remains unchanged, and only the size of the nominal diameter and the wall thickness of the product change. The length of finished products can range from four to twelve meters. In this case we are talking about the measured length. If the pipes have a length from 1.5 meters to 11.5 meters, then we are talking about an unmeasured length. In addition, pipes can have a length that is a multiple of the measured length with a seam allowance of 5 mm. All this allows you to select pipes in accordance with the intended further use. It is more convenient to use ready-made pipes without cutting them specially.

All products are manufactured in accordance with GOST. For ease of installation, cylindrical threads are applied to both ends of the pipe. The pipes are connected using special couplings or welding.

Our country not only produces water and gas pipes in quantities sufficient for domestic consumption, but also supplies them to the foreign market. When choosing such pipes, you should know that a galvanized water pipe weighs three percent more than a black pipe of the same diameter.

In the production of water and gas pipes, a distinction is made between products of normal precision and products with an increased level of precision. In the first case, we are talking about the installation of water supply or heating systems, and in the second case, about the use of pipes in the manufacture of various structures. When marking finished products, the letter “P” must be added, which means increased accuracy of the pipe diameter. These pipes also differ in wall thickness. Accordingly, there are products with a thin wall, called light, or with a thick wall, called reinforced pipes.

Extra options

For the convenience of those who are going to purchase water and gas pipes and use them for certain purposes, the length of such products is also standardized and may correspond to one of the following categories:

- interval 4–12 meters - measured length;

- length of pipes, a multiple of their measured value;

- unmeasured length, which, nevertheless, must be within the limits of the measured value.

Consumers of such products should keep in mind that the price is set not per unit of pipe length, but per unit of its weight. It is also important to take into account that the weight of galvanized pipes is 3% higher than the weight of products made from unprotected steel.

Steels from which high-precision galvanized and non-galvanized pipe products are produced must comply with the requirements of GOST 1050, while the chemical composition and mechanical characteristics of the manufacturing material are not subject to standardization. The welds with which water and gas pipe products are connected after they are formed must be of a reinforced type.

Mechanical properties of rolled products used for pipe production

The range of water and gas pipe products made of black steel involves their production with several options for wall thickness. Depending on this parameter, such products are:

- light class;

- ordinary category;

- reinforced type.

The wall thickness of such products, which can be selected according to the assortment according to the table, is standardized by the requirements of GOST 3262-75. Based on this regulatory document, a range of pipe products is formed; it also stipulates a number of other parameters that such products must comply with: nominal diameter, outer diameter, theoretical weight of one linear meter.

Dimensions of light series pipes intended for thread rolling

Pipes of various classes are designed for operation under different operating pressures. Thus, pipes corresponding to the light category can be operated at a pressure not exceeding 25 kgf/cm2, and reinforced type products - 32 kgf/cm2.

At the request of the customer of a batch of water and gas pipes, long or short threads can be applied to their ends. Galvanized pipe products can be supplied to customers not only with threads, but also equipped with couplings for their installation.

Thread Requirements

Specifications

First of all, you need to understand the difference between a water and gas pipe and an electric welded one.

An electric-welded metal pipe has the official abbreviation ES; it is a straight-seam structure, which is made from high-strength steel by electric welding. Such products roll out rather poorly and do not stretch. The edges of the ES pipes are connected strictly parallel to the axis.

These types of rolled pipes are widely used in construction because, thanks to the reinforced longitudinal seam, they are characterized by exceptional durability and tightness.

VGP pipes are a kind of electric-welded model, but more advanced, since the seam here is maximally reinforced, as well as increased strength and an anti-corrosion coating. That is why VGP is used in construction more often than electric-welded versions of rolled pipes.

The materials used and production technology determined the physical and technical characteristics of VGP pipes. Such designs can be used with hydraulic loads in the range from 25 to 32 kgf/cm2.

The products have increased resistance to heat, in some utilities there is transportation of gas and liquid flows heated to 140-150 degrees, it is obvious that if such a substance gets into the networks located inside residential buildings, then no polymer will withstand such strong heat, and it will simply begin to melt, and in some cases a pipe may even burst.

Galvanized VGP pipes do not have this drawback. In addition, they are characterized by increased strength and resistance to mechanical loads, this has led to the widespread use of the product when laying main pipelines, where there is a maximum flow of moving vehicles.

It should be noted that VGP pipes are characterized by a relatively low price, this is primarily due to the availability of raw materials used for their production and manufacturing technology, which does not require the introduction of advanced technologies and scientific and technological advances.

Carbon galvanized steel is not prone to rust, it has good anti-corrosion properties, so pipes can be used for industrial needs.

If we compare VGP with seamless analogues, we will not find a large variation in consumer characteristics, which allows us to conclude that the products are interchangeable. This is true, but the basic advantage of water and gas pipes is their low cost - it is this factor that has allowed these products to remain leaders in their segment for many years.

Which pipes are considered small, medium, large?

Quite often in many sources you can find a phrase like “Take any pipe of average diameter...”, but no one indicates the specific values of this diameter. To understand this issue, you first need to decide what diameter you need to start from: it can be either internal or external. The first is of great importance when calculating the transport characteristics of water or gas, and the second determines the ability to withstand mechanical loads.

External diameters:

- from 426 mm - large;

- 102-246 - medium;

- 5-102 - small.

If we are talking about the internal diameter, then it is better to check with a special table.

Table of correspondence between nominal diameter, thread and outer diameters of the pipeline in inches and mm:

| Nominal pipe diameter Dy. mm | Thread diameter G". inch | Pipe outer diameter Dn. mm | ||

| Steel water pipes/ gas pipeline GOST 3263-75 | Epoxy-welded straight-seam steel pipes GOST 10704-91. Seamless hot-deformed steel pipes GOST 8732-78. GOST 8731-74) | Polymer pipe. PE, PP, PVC | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | ½» | 21.3 | 20 | 20 |

| 20 | ¾» | 26.8 | 26 | 25 |

| 25 | 1″ | 33.5 | 32 | 32 |

| 32 | 1 ¼» | 42.3 | 42 | 40 |

| 40 | 1 ½» | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 ½» | 75.5 | 76 | 75 |

| 80 | 3″ | 88.5 | 89 | 90 |

| 90 | 3 ½» | 101.3 | ||

| 100 | 4″ | 114 | 108 | 110 |

| 125 | 5″ | 140 | 133 | 125 |

| 150 | 6″ | 165 | 159 | 160 |

| 160 | 6 ½» | 180 | 180 | |

| 200 | 219 | 225 | ||

| 225 | 245 | 250 | ||

| 250 | 273 | 280 | ||

| 300 | 325 | 315 | ||

| 400 | 426 | 400 | ||

| 10 | 3/8″ | 17 | 16 | 16 |

GOST - state standard used in heat - gas - oil - pipelines ISO - standard for designating diameters, used in plumbing engineering systems SMS - Swedish standard for pipe diameters and shut-off valves DIN / EN - the main European range for steel pipes according to DIN2448 / DIN2458 DU (Dy ) - conditional pass.