Steel bends are products that are used to change the direction of various pipelines. They are pipe segments bent at the desired angle. They are usually carried out using special pipe bending machines and are mounted on the pipeline by butt welding. The operational scope of these parts is incredibly wide, but they are most often used in the installation of oil, gas and water supply communications.

Bends for steel pipes are made of stainless steel, alloy steel, and they can also have a protective zinc coating

Scope of use of steel bends

Let's consider the main areas in which these products are used:

- plumbing systems;

- heating communications;

- industrial highways for various purposes;

- oil and gas industry;

- chemical industry;

- pumping stations.

Such products are used for wiring communications for any purpose, however, not all of their types are suitable for certain pipelines. For example, for laying main networks, as a rule, steeply curved seamless, stamped-welded, and bent products made of stainless steel, alloyed, and galvanized bends are used. This is due to the fact that such communications have large cross-sectional dimensions and can operate at high pressure in the working environment.

Helpful information! Welded bends are used for various communications. The pressure in such pipelines does not exceed 2.5 MPa. The cross-sectional indicators in such pipelines are usually more than 1000 mm.

For household communications, steeply curved or bent types of bends are an excellent solution. And point products are very popular when installing pipelines at enterprises that produce various mineral fertilizers.

Such a part as a bend can be found on a pipeline of any type and purpose.

As mentioned above, such a product provides rotation of the structure. Bends are used not only in pipelines, but also in communications responsible for cleaning indoor air. The most popular in this case is a galvanized ventilation outlet.

Selection order

You can buy shaped parts in online stores and in any shopping centers that sell building materials.

What basic rules must be followed:

- request product certificates from the seller;

- choose products from trusted suppliers;

- purchase pipes and fittings produced by one manufacturer - deviations of millimeters in diameter will significantly complicate installation;

- gray pipes and fittings are intended for use inside heated premises, shades of brown in color indicate the possibility of use outside buildings or underground;

- PVC products are not intended for installation in places exposed to sunlight - the plastic will collapse;

- PVC outlets and polypropylene products have smooth internal walls, which facilitates silent removal of wastewater and reduces the likelihood of sediment accumulation;

- cast iron pipes are chosen only for repairing old networks - their price is much higher, they are heavier and more difficult to install;

- if living space allows, it is preferable to use a sewer half-outlet, reducing the likelihood of blockages and reducing possible noise during the movement of drains;

- revisions are installed at turning points;

- for risers, plastic outlets of at least 110 mm in size are purchased, and drains are purchased depending on the connected sources of dirty water;

- When purchasing, pay attention to the side where the exits are directed; they can be left or right.

It is better to make underground communications made of cast iron or corrugated plastic, therefore, purchase fittings from the same material. This will help prevent possible leaks in the future.

Advantages of steel bends

Pipeline fittings are widely used in any installation, and steel turning parts are considered the backbone of any pipeline. Along with tees and transition elements, they play an important role in connecting communications and increasing its strength.

Let's look at the main advantages of these products:

- with the help of these products a smooth rotation of the pipeline structure is made;

- the characteristics of metal bends allow them to be used in difficult operating conditions - they have high strength characteristics and can also be operated at high pressure;

- steel products are resistant to temperature fluctuations;

- the cost of such bends is quite affordable;

- have a long service life when used in aggressive industrial conditions.

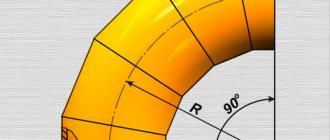

The most popular today are models that are curved at an angle of 45 and 90°.

The most popular parts are those with a rotation angle of 45 and 90 degrees.

Yuefeidi ventilation systems (UFADs), etc.

rain skirt is a small anti-rain conical shell, a dropper, mounted on risers and other air ducts. Installed in the upper part of the riser with the wide part down, often with additional. waterproofing, so that rainwater flowing down the riser does not flow into the flanges, cracks or intakes of the riser.

South-north (roof fans) – K.V. with the constructive ability to rotate the fence to different directions of the world. They rotate automatically using sensors.

YUEFEIDI vent. systems (UFADs) – systems with placement of supply air ducts in underground ducts. Economical.

The tongue is the upper part of the casing (corner) of a centrifugal fan, abruptly turning into a square outlet pipe, forming an acute angle with it. The shape and size of the tongue make a difference when dealing with fan noise.

The core of initial dust concentrations is the area where the dust concentration is equal to its concentration at the outlet of the filter

The flow core is the central part of the air flow (jet), the speed of movement in which is constant and equal to the speed at the end of the jet formation section.

Materials

In order not to make a mistake when choosing a material, experts advise on operational features, as well as the type of working environment for which it will be used.

The following bends can be found on sale:

- carbon products;

- alloyed parts;

- stainless steel;

- bends are galvanized.

For general purpose communications, parts made from carbon steel are ideal. If the working environment in the system consists of aggressive chemicals, then in this case it is recommended to use stainless or alloyed bends.

Alloy steel products can be used at temperatures from −60 to +40 °C. The pressure they can withstand reaches 7.4 MPa. They are often used when installing pipelines in cold climates, as they have high resistance to corrosion at low temperatures.

Stainless steel bends are used in pipelines that transport hot media (water, steam), as well as chemically active substances with both alkaline and acidic conditions. Stainless steel is highly resistant to the damaging effects of corrosion and is therefore ideal for such purposes.

Today, galvanized bends are quite common. The material for such products is galvanized steel. Galvanized steel products are coated with a protective anti-corrosion layer at the production stage.

Parts made from stainless steel are the most resistant to corrosion and therefore durable

As a rule, this layer is represented by zinc, however, others (chrome, nickel, etc.) can also act as protective elements. The galvanized steel outlet can withstand fairly high pressure and is resistant to aggressive environments.

Sewerage

There are much fewer docking methods here.

Cast iron

Traditionally, chasing is used to connect cast iron sewers:

- The pipe is inserted into the socket of the fitting;

- The space between them is tightly caulked with kabalka - oiled organic fiber;

- Then the joint is covered with cement mortar or filled with molten sulfur.

Accordingly, fittings are a combination of bends with the same diameter as the pipes and sockets.

However, new cast iron sewer fittings and pipes are increasingly equipped with rubber seals, ensuring tightness during ordinary joining.

PVC and polyethylene

Both polyethylene and the much more common PVC pipes for sewerage, and fittings for them, are again equipped with rubber seals in the sockets.

There are two subtleties associated with docking:

- It is advisable to remove the outer chamfer from a pipe cut to size. Otherwise, it will be difficult to insert it into the rubber-sealed socket.

- A connection made with sealant is guaranteed not to leak due to drying of the rubber.

Tightness is ensured by a rubber seal; The sealant additionally fixes the pipe and protects against leaks when the rubber dries.

Types of bends

The range of metal bends is incredibly wide, due to their design features and various areas of use. Let's look at the main types of these products:

- steeply curved;

- stamp-welded;

- welded sectional;

- welded sector (segment);

- bent;

- point.

Steeply curved . All main parameters of such products are described in the relevant documentation (GOST 17235–2001, GOST 17235–83). They are produced by pulling a pipe. Broaching is performed through a special mold on pipe bending equipment, resulting in a high-quality part.

Steel bends for steeply curved pipes are usually made of carbon and stainless steel. The angle of the steep bend can be: 30, 45, 60 and 90°. The cross-sectional dimensions of such bends vary from 18 to 426 mm. The pressure to which such a tap is resistant is up to 16 MPa.

Stamp-welded. Such parts are made from sheets by welding. This production method allows us to obtain a thick-walled product with increased strength characteristics. Stamp-welded products can have cross-sectional dimensions up to 1420 mm. They are used in the main communications of the oil and gas industry. Stamp-welded parts are made from alloy or stainless steel and are regulated by technical specifications (TU).

Stamp-welded bends are thick-walled products used in pipelines with high operating pressure

Welded sectional. They are made from separate sections of pipes that are welded together, resulting in a finished part. The price of such bends is quite small, however, their strength and reliability indicators are lower than those of other types. Manufactured from carbon or low alloy steel. The cross-sectional dimensions of such parts vary from 108 to 1620 mm.

Note! As a rule, welded sectional products are used when installing pipelines that have low operating pressure (up to 2.5 MPa). The temperature in such communications should not exceed +425 °C.

Welded sector . Such bends are used in pipelines that have a large cross-sectional size. Such communications have a certain angle of rotation of the flow of the working medium, which is transported under low pressure. The angle of such a product depends on the operational features and can be: 30, 45, 60 and 90°.

Chiseled. This type is made from special cast blanks on a lathe. It is worth noting that spot products have the highest cost. This is due to the very complex technological process of their manufacture.

Their main advantages are:

- are manufactured with any wall thickness;

- resistant to high pressure (up to 100 MPa).

Bent. Such bends, as a rule, are used in cases where it is not possible to install a steeply curved version of the product on the pipeline. Bent parts do not have such a large bending radius as steeply curved parts, and are also equipped with a straight section. The angle of such products varies from 2 to 90°. Their use is regulated by relevant documentation (GOST and TU). Bent bends are installed in communications whose temperature ranges from −50 to +510 °C.

Bent bends are produced by bending hot or cold blanks using special bending equipment

Pressure indicators for such bends reach up to 100 MPa. Bending of such products is carried out using special pipe bending equipment. They can be bent both cold and hot.

Types of parts

Bends for creating sewage systems are classified according to many characteristics:

- material;

- size;

- configurations;

- connection method.

Turns and 90-degree corner connections are called bends; parts that provide a connection angle of 30 or 45 degrees are considered half-bends.

To assemble a single system from parts of different diameters, special adapters are used to eliminate leaks at the joints. They are sold on the market under the name “socket restorer”.

Material of manufacture

In the manufacture of plumbing outlets, various materials are used, which have advantages and disadvantages. Products made of plastic: polypropylene, polyvinyl chloride have become widespread. Old-built houses are equipped with cast iron sewerage.

Products made from these materials do not require the use of any electrical devices during installation. It’s easy to assemble a single structure with your own hands; for connection, one end is made in the form of a socket, and the other in the form of a smooth pipe with a taper.

Installation of polyethylene parts will require the use of special soldering stations. A heating wire is mounted in the wall of the fitting. After joining the parts, voltage is applied to the spiral, it heats up and fuses the components. Such sewer systems are done “once and for all.” The configuration of communications can only be changed by dismantling and subsequent soldering of new connections.

Size of fittings

For internal sewerage of residential buildings, the most popular sizes of pipes and, therefore, branches for them are considered to be products with internal diameters from 40 to 110 or 150 mm.

Plastic bends (polypropylene and polyvinyl chloride) are unified and supplied to the retail network mainly with diameters of 40, 50, 110, 150 mm. For drainage from a washing machine, you can purchase pipes and fittings for them with a cross-section size of 25 mm; the bathtub and dishwasher can be connected to drains with an internal passage of 40 mm. For risers, pipes 110 or larger are used, equipped with bends of 110 and 50 mm.

Cast iron sewer outlets have a nominal internal passage of 65 mm, while the pipe itself is produced with an outer diameter of 81 mm. For risers, a pipe with an internal diameter of 100 mm and an external diameter of 118 or 125 and 144, respectively, is used.

Configuration of fittings

Types of sewer outlets can be seen in the catalogs of any company that produces plumbing systems. The list of products includes:

- one- and two-plane crosspieces;

- tees;

- bends and half-bends;

- audits;

- bends with reduction, where a smaller one is connected to the main pipe of a larger diameter;

- bottles - transitions from a smaller diameter to a larger one.

Bends for turns have angles of 15, 30, 45, 67 and 90 degrees. By combining parts, you can make angles sufficient to assemble a sewerage system of any shape.

Sizes of steel bends

The angles of these products may be different, as well as the diameter sizes, however, all products are subject to certain standards. Standard angles are usually:

- 15°;

- 30°;

- 45°;

- 60°;

- 90°;

- 180°;

The weight of the part can also be different and depends on its diameter. This dependency is shown in the table below.

Table 1

| Du, mm | Weight, kg |

| 820 | 376 |

| 720 | 275 |

| 630 | 219 |

| 530 | 138–153 |

| 426 | 78–97 |

| 377 | 61–75 |

| 325 | 39–56 |

| 273 | 27–35 |

| 219 | 13–20 |

| 159 | 6,1–11 |

| 133 | 3,3–5,7 |

| 114 | 2,2–3,8 |

| 108 | 2,5–3,6 |

| 89 | 2,3 |

The choice of part is made taking into account the size of the pipeline. There are bends of various cross-sections (from 89 to 2000 mm). It is also worth noting that, if necessary, in production you can make an individual order for a rotating element, which will differ in diameter or have a non-standard angle.

Specifications

| Diameter (mm) | Bend 90* | Half bend 45* | Half bend 30* |

| 100 | 173 rub. | 134 rub. | 97 rub. |

| 125 | 201 rub. | 146 rub. | 116 rub. |

| 140 | 213 rub. | 153 rub. | 141 rub. |

| 160 | 220 rub. | 182 rub. | 150 rub. |

| 180 | 230 rub. | 198 rub. | 154 rub. |

| 200 | 252 rub. | 217 rub. | 165 rub. |

| 225 | 300 rub. | 230 rub. | 169 rub. |

| 250 | 328 rub. | 268 rub. | 193 rub. |

| 280 | 386 rub. | 299 rub. | 232 rub. |

| 315 | 477 rub. | 356 rub. | 273 rub. |

| 355 | 664 rub. | 518 rub. | 393 rub. |

| 400 | 806 rub. | 603 rub. | 468 rub. |

| 450 | 1,012 rub. | 734 rub. | 565 rub. |

| 500 | RUB 1,180 | 860 rub. | 636 rub. |

| 560 | RUB 1,563 | 1,084 rub. | 835 rub. |

| 630 | RUB 1,944 | RUB 1,323 | 991 rub. |

| 710 | RUB 2,388 | RUB 1,586 | RUB 1,218 |

| 800 | RUB 2,961 | RUR 2,016 | RUB 1,559 |

| 900 | 4,415 rub. | RUB 2,863 | RUR 2,220 |

| 1000 | 5,432 rub. | RUR 3,376 | RUR 2,622 |

| 1120 | 6,178 rub. | RUB 4,109 | RUR 3,117 |

| 1250 | 8,228 rub. | 4,990 rub. | RUB 3,607 |

Air duct outlets are one of the most important elements of the ventilation system, designed to change the direction of air flow.

Welding of bends

The process of installing a rotating element on a pipe is a rather complicated undertaking and requires special skills in this area. Such welding is carried out only by specially trained welders.

Welding of bends can be performed using different methods, each of which has its own rules

Installation of the outlet on the pipeline is carried out in compliance with the necessary standards set out in the relevant instructions (for example, VSN-006-89).

Important! Before starting welding work, you must make sure that the surfaces being welded do not contain any defects. If any defects are found, they must be corrected.

It is worth remembering that you need to control the displacement of the inner edges. There is a rule in this regard: when welding a pipe and a bend with equal cross-sectional indices, the displacement should not exceed 2 mm. Centering of products is carried out using special devices - rotators.

In manual electric arc welding, processing of the first root weld is performed with direct current. In case of a break, it is necessary to maintain the required temperature at the welding site. After completing the first welding line and after grinding it, proceed to the second seam. The time between these two events should not be more than 5 minutes. This is due to the fact that the second line must pass along the uncooled root seam. Once both lines have been completed, fill grooves and capping joints are made. The facing seam must protrude 1–3 mm above the surface of the pipeline.

Dimensions of sewer fittings and recommendations for installation of sewer lines

The dimensions of sewer outlets correspond to the pipes to which they are connected and are regulated by GOST. It should be taken into account that for external sewerage, special orange-colored pipes are used, which are thicker than internal pipes (2 mm wall thickness of internal pipes and 3.1 - 3.4 mm of external pipes).

Rice. 9 Plastic sewer outlet - dimensional parameters

When laying an external sewer line, the following recommendations must be observed:

- The trench is dug in such a way as to prevent pipes from freezing in winter, while taking into account the slope, which is for a line with a diameter of 110 mm. is 20 mm. per 1 linear meter.

- If the depth is too large, the pipes are thermally insulated (you can use a built-in or external heating electric cable) and raised higher.

- A layer of sand 100-150 mm thick is usually placed at the bottom of the trench; for thermal insulation and reducing the load on the pipe walls, the pit is filled with expanded clay and then leveled to the ground with soil.

Pipe rotator

In production, welding of bends to pipes is carried out using special equipment. Typically, these special equipment are rotators. The parts to be welded are clamped in the device and rotate around their axis, which makes it possible to perform high-quality welding of the outlet.

Let's consider the main advantages of using a rotator when welding a rotary product with a pipe:

- allow you to weld pipes with large diameters;

- the use of an autonomous drive in the rotator design allows you to regulate the rotation speed of the part;

- ensure precise alignment of pipes;

- can work not only with straight parts, but also with more complex, from a structural point of view, elements (for example, tees).

Today, there are many types of bends that allow you to solve any problem when installing pipelines. At the same time, a wide range of these products obliges specialists to study a large amount of information in order to know and comply with the features and rules for using all such products.

Nuances of operation

After commissioning, the sewerage system requires careful treatment and periodic maintenance.

The rules of use are easy to follow:

- It is not allowed to knock on pipes and bends or place foreign objects on them;

- It is prohibited to store containers with flammable substances near pipelines;

- Polypropylene and PVC sewer parts must not be exposed to open fire, for example, for defrosting;

- it is allowed to hide pipelines with easily removable structures;

- During interruptions in use, water seals of plumbing fixtures are filled with water at least once every 25 days;

- It is prohibited to clean plastic pipelines with metal brushes and brushes;

- the angles of inclination of pipes and bends cannot be changed;

- after disassembling the system, change the rubber O-rings;

- when replacing parts, it is allowed to use only similar types - for example, you cannot install a plastic part instead of a cast iron one;

- It is allowed as a temporary measure in case of accidents to place a rubber cuff on the damaged pipe.

The range of products allows you to select pipes and bends to create a sewer system of any complexity and configuration. The technical solutions used make the installation of a water drain feasible for a home craftsman, and simple operating rules extend the period of trouble-free use to several decades.

Source

Forged

They have good strength characteristics. The diameter of the bends varies from 15 to 1400 mm, marking is done by the outer diameter. The blank for the outlet is a piece of pipe of a certain diameter. It is heated in induction units, then the pipe is given the desired shape. The finishing stage is cutting the edges perpendicular to the direction of the axis.

During the process of heating and subsequent cooling, the surface of the fitting is strengthened, and the metal structure becomes denser. Forged fittings are used to connect thick-walled pipes. They are additionally prepared for the welded joint, chamfers are removed to increase the depth of the weld.