It is impossible to imagine any pipeline for industrial, municipal or domestic purposes without shut-off valves. One of its representatives is the gate valve, which is widely used when transporting a certain type of working media.

It is worth noting that gate (knife, guillotine) type fittings are not used in everyday life and are used mainly in industrial pipelines. In this regard, it has a different design and dimensional parameters from similar valves.

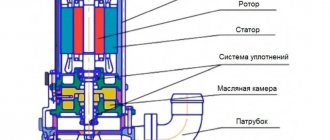

Rice. 1 Gate valve in pipelines

Purpose and application

A ventilation damper is an ordinary damper, a valve, the main purpose of which is to regulate air flow. It can be used to increase or decrease air flow, and, if necessary, to stop it completely. In its most general form, a ventilation damper looks like a flat damper with a thickness of about 1 mm. It is made mainly from galvanized steel sheets.

Of course, the ventilation system will work without a damper, but will it be of high quality? After all, the ventilation of premises under any conditions and circumstances will always be the same. It’s another matter when ventilation systems are equipped with dampers. In this case, it becomes possible to completely control the flow of fresh air and reduce or increase its amount in the room if necessary.

So, having figured out what a damper is and why it is used in ventilation systems, let’s look at what they are like.

Types of ventilation dampers

Modern production offers the most diverse range of valves designed for use in ventilation systems. However, the entire existing set of gate types can be grouped into several categories:

| Category | Types of valves |

| Form | Round, rectangular |

| Design | Retractable, rotating |

| Control type | Manual, electric, pneumatic, hydraulic |

| Installation method | Installation in socket, installation using flanges |

| Material | Stainless steel, alloy steel, chrome steel |

The shape of the dampers is determined by the shape of the ventilation shaft - most often round valves are used, but in some cases rectangular valves are needed:

- There is a need to hide the gate while ensuring the minimum possible use of space.

- When installing ventilation systems that use electric heaters, since they themselves are predominantly rectangular.

Installation method

Installation of gate valves is carried out using four methods:

- Welded - the end parts of pipes and fittings are soldered using welding equipment. The result is a reliable, sealed, but non-separable unit.

- Flanged - if the end parts of the valve are equipped with flanges - round or square plates with holes, flange adapters are also installed at the ends of the pipes. To connect pipeline elements, the flanges are aligned and bolted together to form a detachable assembly.

- Threaded - the pipes are threaded, the connection is made using union nuts. The method is rarely used, since the threaded unit becomes loose due to vibration of the working environment and needs periodic tightening.

- Embedded - the body is laid horizontally between sections of a vertical pipe or shafts, the assembly is cemented. Used only when installing smoke shafts of heating units.

According to the installation method, there are two types of valves:

- coupling - has a full-fledged body with branch pipes, can be connected using flanged, welded and threaded methods;

- wafer - the body does not have branch pipes, in some cases the body consists only of a frame with saddles; such a valve is installed in a section of the pipeline or grooves in the chimney shaft and is connected using a welded, flanged or embedded method.

What is a gate valve

A damper for ventilation is a special valve, the main task of which is to completely or partially block air flows or bulk and liquid materials. Parts of this kind, in addition to ventilation systems, are also widely used in various drainage systems, wastewater channels, etc.

There are two main types of the described mechanism: horizontal and rotary gate. The second is also sometimes referred to as the "throttle valve". Unlike a horizontal type mechanism, it is quite unreliable, so its use is resorted to only in cases where installing a horizontal gate is impossible for technical reasons.

The duct damper is most often used in chimneys made of brick or steel. To ensure complete closure of the channel, it has a perforated shape. These requirements must be met in order to comply with fire safety requirements. It is also worth noting that there are automatic duct dampers with electric drive. The process of closing and opening such a mechanism is carried out remotely by pressing one button.

Classification

Modern industry produces many types of gate valves for ventilation, which differ from each other in many parameters. Gate designs vary:

- in shape - round and rectangular;

- according to its design, the gate can be retractable or rotary;

- by type of control - manual, automatic (electric drive), pneumatic, hydraulic;

- according to the installation method - using flanges or using the method of installation in a socket;

- according to the material of manufacture - anti-corrosion, alloyed or chrome-plated steel.

The external shape of the damper depends on the structure of the ventilation system in which it will be installed. However, in private situations, only rectangular gates can be installed. There are two such cases.

Round

As already mentioned, the shape of the damper used depends on the form of ventilation. Accordingly, the use of a round damper for an air duct is only possible if its shape matches the system pipes.

Rectangular

A rectangular valve for ventilation is used much more often than round valves. In addition to pipes, it can also be installed in chimneys, drains, wastewater systems, etc.

Moreover, in some situations, only a rectangular damper can be used for ventilation. There are two such cases.

- If there is a need to hide the valve, subject to a minimum amount of free space.

- During the installation of ventilation systems, the design of which involves the use of electric heaters.

Design features of the device

The design of a gate valve or “knife” valve is quite simple. It consists:

- From a body that is a tee with a central extension and hollow branches. Can be equipped with a lid.

- Sedel. These elements perform a guiding function and ensure the tightness of the shutter.

- Locking unit (damper). This element is located perpendicular to the flow of the medium and regulates the throughput of the valve.

- A rod in the upper part of the housing, responsible for moving the damper.

- Control mechanism - screw, lever, drive.

- A stuffing box assembly that ensures the tightness of the rod-housing pair.

Gate valve design advantages and disadvantages:

The main advantage of the fittings is their simplicity of design, low hydraulic resistance and the ability to be used for transporting media with solid inclusions.

Disadvantage: low tightness, high construction height. Such products cannot be used to carry hazardous substances, the leakage of which could be critical.

Types of gate valves

- Classic butterfly valve. Such a damper operates due to rotational movement inside the air duct. Such a gate installation consists of a metal body and a removable rotating disk. If used for a long time, it may become faulty, but replacing the part will not be difficult. You can perform this procedure on your own. Even in the absence of certain skills, you can do the entire design of a classic-type throttle installation with your own hands. This type of gate valve is easy to use and does not require constant monitoring by the property owner.

- Air damper for chimney. Refers to control parts that control the amount of fuel in the combustion chamber. Workflow management is carried out automatically.

Scope of application

Gate valves are capable of performing only two functions: shutting off and regulating flow, but due to their design features and versatility, they are used in various fields:

- domestic and industrial water supply and sanitation;

- wastewater treatment systems;

- transportation of gas, oil and their products;

- mining industry;

- production of food and non-food consumer goods;

- ventilation systems for various purposes.

Note! Wedge-shaped valves are most often used in water supply and wastewater systems. For other areas, knife fittings are mainly used, as they are simpler and more reliable.

Chimney gate valve

The very first of the gate valves, the chimney valve, deserves special attention. It has a long history and a very simple design: there is no control mechanism, no seals, only seats and a blade valve.

This is interesting! The device is of German origin, and the name "gate" means "flap" or "gate" in German. Therefore, the entire locking and regulating mechanism and the shutter knife itself are called a gate.

Ancient stoves and fireplaces without dampers were not built, since there were no other ways to regulate the draft.

A knife valve - a rectangular cast-iron plate with a handle - was installed across the chimney. In the walls of the chimney, at a height slightly greater than human height, grooves were made into which a cast-iron frame was installed, allowing the valve to move freely back and forth - it served as a set of saddles. The handle of the shutter plate protruded beyond the smoke shaft, which made it possible to set the position of the gate from completely open to completely closed, smoothly adjusting or completely blocking the air flow in the pipe.

We recommend that you read: How to solder plastic pipes correctly?

When the damper is open, the draft in the chimney is maximum, flue gases are removed in full, but warm air from the premises also flies into the chimney. Usually, the damper is fully opened when lighting a heating device, and then its position is adjusted, achieving optimal draft, at which both the fire burns and the house heats up. When the fuel burns out and the formation of smoke stops, close the damper so as not to release heated air through the chimney.

Modern stoves, fireplaces and boilers, especially solid fuel ones, still need this simple draft control mechanism. But with the advent of diversity in materials for chimney construction, there was also a need to modify the valves. Cast iron gate valves are still popular for smoke shafts and combined rectangular smoke exhaust structures. Round pipes have to be modified by installing an insert with saddles so that the gate can move freely across the chimney.

Note! Round chimneys are also equipped with rotary valves called butterfly valves. Since this mechanism also performs the function of regulating the flow, it is sometimes called a rotary gate. However, such a valve has a completely different operating mechanism, more reminiscent of a rotary valve rather than a classic knife valve.

Design and operating principle

The gate consists of two elements - a fixed body and a movable shutter. Depending on the direction of movement of the shutter, there are retractable and rotary models. The simplest structure of a retractable valve, which is also called a knife gate valve. In it, the shutter moves perpendicular to the movement of air in the channel - a thin plate extends and easily blocks the flow. In rotary (throttle) models, the shutter rotates around its axis, gradually blocking the passage in the air duct. The simpler the structure of the gate element, the higher its reliability and longer service life. Traditionally, retractable valves are considered the most reliable and unpretentious in operation.

Functions, purpose and characteristics

The damper is a partition that is located inside the chimney. It follows the shape and area of its cross-section and, when closed, almost completely covers it. Changing the position of the damper allows you to increase or decrease the opening of the chimney pipe, increasing or decreasing the air flow. Using the damper, you can stop the movement of air after lighting the stove.

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

Important! Do not assume that the valve completely seals the pipe in the “closed” position. According to fire safety requirements, the damper must have a small hole through which weak gas exchange occurs.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

Very important! You can close the chimney with a damper only after the wood has completely burned and the flame has gone out. If you close the damper prematurely, this can lead to a dangerous situation due to the release of large amounts of carbon monoxide into the room. If the damper is closed too late, the efficiency of the furnace will be reduced, because Most of the heat will go out through the chimney.

Rotary throttle

rotary butterfly valve

Rotary valves are not as widespread as the previous version. The operation is based on a rod, which is located in the center. A metal sheet is installed on it with rotation around its own axis. Due to this, the space is regulated and blocked if necessary.

This is a simple design that can be made on your own without any problems. But the moving part of the mechanism cannot boast of high reliability. Periodic replacement is required, which involves additional costs.

For installation, the socket and flange method is used. The differences lie in the fastening elements, which become relevant in each case.

DIY making

Independent production and installation is impossible without the following devices at hand:

- Markers.

- Compass.

- Roulette.

- Kern.

- Welding with electrodes.

- Vise.

- Pliers.

- Hammers.

- Tap and oil to lubricate the threads.

- Drill.

- Cutting and grinding abrasive wheels.

- Bulgarian.

gate manufacturing

It is necessary to have a sheet of stainless steel of the domestic brand 12×18n10t. It is acceptable to replace it with an imported analog AISI304. The cost is higher, but the service life is also longer.

The minimum sheet thickness is 1.5-2.5 mm.

Other materials you will need:

- Rod for a metal frame.

- 2 bolts 8 mm.

- 6 mm stainless steel tube.

Specifications

The design of the dampers completely depends on the location of their installation, the temperature of the air masses and the shape of the air ducts. All valves have an absolutely smooth surface, which is dictated by operation under conditions of temperature changes and the need for regular cleaning. In addition, the damper must be perforated or equipped with a slotted hole. This will not completely block the flow of fresh air into the room and will ensure the preservation of a favorable microclimate.

The gates are retractable and rotary. The first ones are used in ventilation systems with forced circulation of air flows, and are straight valves made of steel. They are installed perpendicular to the direction of flow. This design allows you to control the volume of air passage and, if necessary, change it.

Rotary models, called butterfly valves, can be installed on natural draft ventilation. The models are presented in the form of a plate fixed to an axis, and are activated using a rotary handle. The handle, in turn, is secured to the plate with a bolt and wing nut, and opens the valve 10 degrees with each turn. All valve parts are made of galvanized steel and, if necessary, additionally painted.

In supply and exhaust systems, dampers are installed in the air duct gap in front of the fan. This arrangement of the damper prevents the fan motor from overheating: when the fan starts, the damper is closed, and after the number of revolutions reaches operating parameters, it is opened. In this case, the gate acts as a starting damper, which increases the efficiency of the fan and extends its service life.

The design of a gate valve and materials for its manufacture

The main components of a typical gate valve are:

Frame. It consists of a main part and a cover (in many designs it has a stand with a yoke assembly), connected to each other with bolts. The main materials for the manufacture of body parts are carbon steel grade WCB (analogues of cast steel 20L, 25L, 30L), stainless steel (for example 20Х13, CF8, CF8M, AISI 304, AISI 310, AISI 316), gray (SCh20, SCh25) and high-strength nodular cast iron (ductile iron) grades GG-40 or GG-25.

Exclusive case materials include aluminum, bronze and AISI 904L uranium.

Typically, valve bodies are coated with a blue epoxy or powder-epoxy compound approximately 250 microns thick.

Shiber. Most often, the gate plate is made of corrosion-resistant metal alloys, which are AISI 304, AISI 310 or AISI 316 stainless steel.

Spindle. The element is responsible for moving the bolt plate, usually made of stainless steel (20X13).

Rice. 4 Materials for the manufacture of seals in SMO brand products and their varieties

Seat seals. Main materials of seat seals in gate valves:

EPDM - ethylene-propylene-diene elastomer (EPDM) is used as a sealant when transporting media with an operating temperature of + 90 °C and a maximum temperature of no more than + 125 °C.

NBR is acrylic-nitrile-butadiene rubber, it has a relatively low heat resistance with a maximum threshold of no more than + 90 ° C; when using it, the temperature of the working environment should not be higher than + 80 ° C.

Viton (FKM, FPM) is a class of synthetic fluorinated rubbers (SFK), which have a maximum temperature threshold of + 200 °C, and can be operated for a long time at a temperature of + 180 °C.

PTFE is a well-known white fluoroplastic with a soapy surface to the touch. The material has a very low coefficient of friction and the highest heat resistance among all seals at + 270 ° C. It is mainly used as an oil seal; when used in seats, fluoroplastic does not provide 100% sealing.

Nitrile (Nitril) is a synthetic butadiene-nitrile rubber (rubber), resistant to petroleum products, oils, acids and low concentration alkalis. Withstands operating temperatures up to + 90 °C.

Hypalon (CSM) is a product from DuPont that is a chlorosulfonated polyethylene elastomer (CSPE). Hypalon is a general purpose rubber with good mechanical properties and high resistance to abrasion, wear and aggressive chemicals. The maximum temperature threshold for CSPE-based rubber reaches + 120 °C.

Silicone - organosilicon silicone rubber is an elastic material that can function in the temperature range from - 60 to + 300 ° C (withstands 500 hours). The maximum operating temperature of silicone rubber with a service life of 20 years is + 120 °C. Silicone is resistant to oxidizing agents, oils and organic solvents, has a low coefficient of residual deformation, that is, it easily restores its shape. The disadvantages of organosilicon silicone rubber include its insufficiently high tensile strength compared to other elastomers.

Rice. 5 Design of gate valves according to GOST R 55020-2012

Oil seal packing. In gate valves, the gland provides a seal in the body of a moving flat plate and has an internal surface shape corresponding to an elongated rectangular gate. The following materials are used as its packing and ring gaskets:

- Dry cotton fiber, used in general purpose installations working with solid bulk materials.

- Oiled cotton fiber. It consists of woven threads impregnated with grease. Is a packing for standard shut-off valves operating under pressure.

- Cotton Fiber with PTFE is a general purpose padding made from woven Teflon-impregnated cotton fibers.

- Teflon acrylic fiber. It is a synthetic acrylic thread impregnated with Teflon using vacuum dispersion technology. It is a typical packing for valves operated under pressure in aggressive liquids (oils, oxidizers, alkalis and acids) or with suspended particles.

- Fibrous (lubricated) PTFE. Fluoroplastic fibers with a diagonal weave system can function at high speeds of gate movement in almost any aggressive environment, including those containing solid fractions.

- Heat-resistant graphite fiber is a diagonally woven thread impregnated with a lubricant made from a similar material. The packing is universal, as it can withstand not only high temperatures of vapors, gases and liquids, but also their aggressive chemical composition. Graphite is not afraid of oils, solvents, the vast majority of alkalis and acids.

- Ceramic fiber is used in gate valves that handle high temperature air or gases at low pressures.

- PTFE, nitrile and EPDM are used as rectangular gaskets.

Size calculation

Even an extra gap of a few millimeters can be the cause of improper operation of the air vent.

Step-by-step steps to resolve the issue are as follows:

- First, take a tape measure to measure the size of the internal channel.

- 20-30 mm is added to the result. The result is the size of the outer frame.

- An opening for gas release is required for the finished valve.

- The position for the welding holes is also marked as accurately as possible.

Installation features

In most cases, the ventilation damper is installed immediately before the fan outlet. If their location coincides, then the design is called a starting gate, then its task is to protect the fan power unit from overheating.

You need to understand that you need to start the fan only when the damper is in the closed position. Otherwise, it will be affected by additional load, which in turn will quickly lead to failure of electrical equipment.

Important!

If you decide to install a damper in a ventilation system with a direct chimney with your own hands, then you need to know that it is quite difficult to carry out maintenance and cleaning of such a design in the future.

Like any other design, a gate valve has its own installation features. There are two main ways to install it:

- pipe-to-pipe method - the mechanism is installed in the chimney due to its design, this principle does not imply the use of additional fasteners;

- the shut-off device is mounted in front of the chimney exit or in the stove, respectively, becoming part of the overall structure; in this case, the maximum height at which the damper can be located cannot exceed one meter.

There is also another method of installing the gate - flange. When using it, you need to pay attention to two factors:

- fasteners that secure the smoke exhaust must be located at a short distance from the gate; they cannot be installed together with the main mechanism;

- all fasteners must be located exclusively on one side of the flange;

- During the installation of a flange type connection, additional sealing must be provided.

Using stove valves allows you to protect yourself from carbon monoxide poisoning. Information about the method of preserving heat in a stove is passed on from generation to generation. Everything is very simple, while the flame is burning - the damper should not be completely closed. Once the fire has gone out, the gate can be closed completely.

The valve, however, like any other mechanism, the creation of which does not necessarily require specialized tools, can be made independently without any problems. To do this, it is enough to have minimal theoretical knowledge and basic work skills.

Wafer connection

| terms of Use | Materials used |

| Temperature up to 40 degrees | Sealing tape 'Guerlain' |

| Temperature up to 70 degrees with a round duct section | Mastic 'Buteprol' |

| Temperature up to 60 degrees with a round duct section | Heat shrink cuffs, heat shrink tape |

In addition: it is practiced to seal socket joints with silicone sealants. SNiP does not prohibit their use: at the end of the list of recommended materials, it stipulates the possibility of using sealing methods not included in this list.

Flange connection

| terms of Use | Materials used |

| Transporting air with temperatures up to 70 degrees | Foam rubber, polymer mastic rope, various types of rubber (including porous) |

| Transporting air with temperatures greater than 70 degrees | Asbestos cardboard, asbestos cord |

| Transportation of acid vapors | Acid resistant rubber |

For flange connections, SNiP separately stipulates some assembly features.

- The hanger or support securing the air duct must not rest on the flange.

- All bolts should be located on one side of the flange.

- When the flange is in a horizontal position, the bolts should be on top of it and the nuts on the bottom.

Installation of disc valves on a new pipeline

- Install the valve between the flanges, insert the coupling bolts and studs, center the valve between the flanges, and pre-tighten the fasteners.

- Align the gate valve with flanges along the axis of the pipeline.

- Weld the flanges to the pipeline.

- Remove the valve from the wafer space.

- Attention: it is strictly forbidden to weld flanges to the pipeline when the gate valve is seated between the flanges, as damage to the seal may occur!

- After removing the valves, make final welding of the flanges, then allow the assembly to cool.

- Place the valve in its place along with the wafer gaskets, center it, install and tighten the fasteners.

- Tighten the tie bolts and studs carefully and evenly in a cross pattern. Make sure that the flanges remain aligned and parallel to each other.

Self-installation of a gate valve

If you need to mount a damper for a brick kiln located in the house, you should do the following:

- first of all, lay out the first row of the chimney pipe from bricks;

- then make the next brick row and make a hole in it for a gate valve;

- In one of the bricks laid out in the second row, you need to create a groove for the handle for the valve of the fireplace or stove.

A groove is a recess or slot into which an object of a certain size can fit. This is a simple job that anyone can do.

The gate is also installed for heating boilers. It allows you to control the removal of gas particles, which leads to increased efficiency and economical consumption of fuel resources.

The slide damper is the main guarantee of fire safety when organizing stove heating; it is an essential part in the ventilation pipe, chimney and boiler.

A damper is one of the types of regulating and closing devices designed for installation in a ventilation system. The design of this element is not at all complicated; in terms of its operating principle and appearance, the part is similar to a furnace valve for a pipe.

The main component of the damper is a metal sheet that blocks the air flow if necessary.

Preparation for use

The material must be transported to the work site in sealed manufacturer's packaging. When performing any work on the gate valve, the actuator must not be activated. It is necessary to provide direct access to the valve for ease of maintenance. Before work, the presented products are checked for defects and malfunctions. This is necessary to neutralize the problem in a timely manner.

The following are subject to inspection: • The appearance of the packaging material, its condition; • Condition of the mounting surface; • Availability of instructions and operating documents. It is not necessary to do a leak test. It is guaranteed directly by the product manufacturer.

Frequent errors and problems during installation

There are several problems that most owners of this design face:

- Install handles that do not allow you to track the position of the valve.

- Carbon monoxide has nowhere to escape, there is no hole.

- The surface is not smooth enough.

- The use of thin grades of steel or stainless steel with a low nickel content. Such products quickly fail due to deformation under the influence of high temperatures.

- A metal chimney with a cast iron part inside. Such parts are not compatible with each other.

- A valve is installed in areas with insulation. Thermal expansion causes jamming.

Why do you need a chimney damper?

Chimney damper

The required elements of stove heating are chimney dampers. Traditionally, their main function was to retain heat. A closed valve blocked the possibility of combustion products escaping into the chimney. As a result, the furnace not only heated up, but accumulated heat, due to the fact that hot flue gases could not escape outside and gave up their thermal energy to the channels. But life, as we know, does not stand still and neither does technological progress. Therefore, it became possible to further increase the efficiency of a brick kiln using an element such as a chimney damper.

What does the gate give?

Just like traditional chimney dampers, a damper allows combustion products to open or close access to the chimney. In addition, it performs several other useful functions:

- Regulates traction.

- Reduces fuel consumption.

In old furnaces, a gate, as a rule, was not installed. If you want to make your stove heating more efficient, you should install this simple device. Modern furnaces, as a rule, already have a flange with a gate included, but it can also be purchased separately. The simplest gate can be made with your own hands.

Before buying or constructing a damper for a chimney with your own hands, it is worth understanding the principle of its operation. During combustion of the furnace, the valve partially blocks the cross-section of the pipe, allowing flue gases to escape through the pipe and, at the same time, regulates the draft force. After stopping the fire, by completely closing the chimney damper, the release of gases stops. Regulating the thrust force simultaneously allows you to control and change the intensity and speed of fuel combustion. In modern heating devices, a damper must be installed in boilers.

The gate valve differs from a traditional gate valve in several ways:

- Resistant to high temperatures (withstands heating up to +900 degrees).

- Corrosion resistant.

- The ability to block the chimney during combustion up to 85% of its cross-section.

- Good thermal conductivity.