During a variety of jobs, round pipes need to be given a certain shape. This is often done using improvised tools, but the result is much better if a pipe bending machine is used. Devices are sold in hardware stores. If bending is not going to be done often, it makes more sense to rent equipment.

So, a pipe bender is a device for bending pipes of different cross-sectional shapes: round, square, rectangular. The equipment is considered universal because it bends parts made of different materials: copper, aluminum, brass, carbon and stainless steel. These stationary machines work with a wide range of diameters.

Purpose of the machine

Ordinary and profile pipes , which are bent on a machine, are used in different areas:

- For the implementation of frame structures in construction.

- For installation of pipelines of various configurations.

- For installation of fencing.

- In the automotive and furniture industries.

- For the manufacture of decorative interior elements.

Installation of the pipeline structure can be done using fittings connecting the communication sections. But a node obtained by joining two pipes is considered unreliable, and the risk of a leak increases in proportion to the number of these nodes. In this regard, it is much better to bend the pipe at the required angle without violating its integrity, which is why a pipe bender is used. The drive can be hydraulic or electromechanical. If necessary, you can make the machine yourself.

Advantages

Previously, pipes were bent on special large-sized equipment operating on the principle of induction heating, which implied an increase in the temperature of the part at the bending site to the required value (until sufficient plasticity for bending was achieved). Today's industry produces more advanced equipment that has the following advantages over older models:

- Compactness. The dimensions of a modern machine make it possible not to build a permanent foundation for it.

- The minimum height for loading a part is no more than 140 cm from the floor, and the diameter of the product does not affect this indicator.

- Reduced energy costs.

- No need to heat the pipes.

- No contamination that occurred in older induction machines.

- Comfortable temperature near the machine.

- Reduced noise during operation.

- High bending speed, which allows you to perform impressive volumes of work.

Areas of use and service features

Pipe benders are most common in the construction and housing and communal services industries. The equipment is used less actively in the automotive and petrochemical industries. Pipe bending machines are indispensable when creating hydraulic and pneumatic pipeline structures. The operational scope of the machines is very wide, so they are in demand everywhere.

Bent pipes are also used in the manufacture of:

- Sports equipment.

- Elements of design solutions in residential premises.

- When installing railings, fences, stairs, etc.

- In the manufacture of chairs and other furniture elements.

The machine operator must have an understanding of all the nuances of bending. Preventative cleaning, inspection of the main working parts and preventive maintenance, including lubrication and adjustment of working elements, are carried out monthly. The oil in the pump is also changed, and high-quality oil is selected. It is recommended to purchase spare parts from a trusted supplier.

Types of pipe benders

The main indicator of the classification of machines is the design. Depending on the design features, the following types of machines are distinguished:

- Manual . They work in small enterprises and involve the use of muscular strength during work. Typically, these compact machines are portable, and they are used in the construction industry. Thanks to its mobility, the equipment is used directly on construction sites.

- Hydraulic . Hydraulically driven devices. The design of this equipment is similar to a manual machine, but can be either portable or stationary. These machines mainly differ from manual ones in the presence of a hydraulic booster, which allows processing products with a cross-section of up to 20 mm without serious physical effort.

- Electrical . They are large in size and operate by consuming electricity. When bending, they provide high angle accuracy. An electric industrial pipe bender can also bend products with a large cross-section and thin walls.

Electric pipe bending units are divided into three main types, depending on the degree of automation:

- manual;

- semi-automatic;

- automatic with CNC.

Machines with computerized controls are the most functional. Thanks to CNC, you can program the parameters of the bending angle and radius. These devices are capable of operating in a fully automatic mode, where the processes are controlled by a computer program (in particular, part delivery and mandrel adjustment).

Pipe bending machines for ordinary and profile pipes are different. Manual machines are quite inexpensive, but are much less productive than electric models.

Pipe benders - design and types

If to manufacture a structure it is necessary to bend a profile pipe along a radius, then a pipe bender can easily cope with this, with which you can make a bend up to an angle of 180 degrees. This device is capable of changing the configuration of pipes made of stainless steel, metal-plastic, and aluminum. In this case, the bending is carried out according to the required dimensions and shape.

Pipe bender design

The design of such a tool depends on its type. However, the required elements are:

- hydraulic cylinder - the main part of the machine that performs the power function;

- open or closed frame;

- two pipe stops;

- lower and upper bars;

- injection device, handle and bypass valve located on the rear of the structure body;

- retractable rod, which provides the bending force of the pipe bender;

- a spring with the help of which the retractable rod returns back;

- a trunnion or stop of a structure, the ends of which are inserted into holes in the slats.

On top of the main part of the machine there can be a level check and an oil fill plug. Installation strips, which are a welded structure, are screwed onto the threaded part of the tool. The bottom bar is secured with a locking nut, and the top bar is pressed with two screws and a lock.

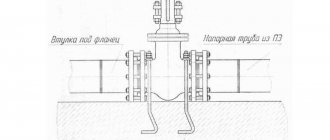

To install supports, special holes are provided on the transverse plates of the device. The bottom of the pipe bender has threaded holes for mounting bolts that are height adjustable.

The bent pipe on such a structure is located on a stream, which is located in the middle of its stop. The bending segments must be made of precision cast steel.

Today, thin-walled profile pipes with thin walls are increasingly used for the manufacture of various structures. Therefore, the design drawing of a pipe bender for such workpieces is somewhat different. To prevent deformation of its cross-section when bending the pipe, profile rollers should be selected with the same cross-section as the product.

Types of pipe benders

Commercially available professional pipe benders can be manual, electric or hydraulic driven.

Electromechanical tools are considered the most convenient

The manual drive design is used for bending small diameter pipes.

Hydraulically driven pipe benders are capable of bending workpieces that can be up to three inches in diameter. Therefore, such a tool is designed to perform large-scale work.

In addition, pipe benders may differ in the way they influence the product, with the help of which it will be bent. These methods include:

- Crossbow method, in which the pipe rests on two stationary rollers and bends between stops under the influence of a template located on the rod.

- Winding - with this method of bending, the workpiece first attaches itself to the roller of the structure. Then a stop is placed at the bending point. The roller begins to rotate and wind the pipe between itself and the stop. In this case, the template and the product are movable.

- Rolling is the simplest way to bend a pipe. On such a device the template is motionless. The pipe is simply clamped and the pressure roller moves and bends the pipe around the template.

- The rolling or rolling method involves the use of three rotating rollers. One of them is central, and two are supporting. The central roller presses on the workpiece, so it must be installed relative to the supporting elements in accordance with the required radius of the product.

pressure from the rod is transferred to the workpiece at the top point of the template

The rolling method has virtually no disadvantages. It is by rolling that steel bends are manufactured in the factory. Using the same method, it is much easier and more efficient to bend profile pipes.

Bending methods

Let's look at four bending methods:

- running in;

- drawing;

- rolling;

- winding.

The latter method is used to bend small cross-section pipes (up to 150 mm). Bending is performed quite simply: the part is wound on a roller, and by acting on its ends, a part is obtained. Previously, this method had a number of disadvantages. The main disadvantage was that the pipe was deformed at the bend (one wall became thinner, and corrugations formed on the other).

Now you can get rid of this drawback by using a pipe bending machine with a mandrel - a metal rod placed in front of the bend in the pipe. This prevents deformation of the workpiece walls. Although models without a mandrel are also popular, they are used to bend pipes with large cross-sections and thin walls.

Pipe bender options

You can bend the pipe using the “home” method, fill the pipe with sand, heat it until red with a blowtorch or gas torch, and then bend the pipe. This method is not recognized as a priority among craftsmen; it is labor-intensive and does not provide sufficient accuracy; creases and deformations may also appear.

To obtain a perfectly bent pipe, in compliance with the standards and specified parameters, without causing damage to the source material, craftsmen use specialized pipe benders in their work.

Lever-type pipe benders have become very popular. This elementary invention works on the principle of a “lever” - the force is concentrated in a certain place, and the bend merges with the shape of the template you created, which can most often be removed and replaced with another.

Most often, the kit of such structures includes a couple of additional templates for pipes of different diameters. There are units of similar design, manual pipe benders, drone or crossbow benders, they allow you to bend short sections of round steel pipes, subjecting them only to cold processing.

Work principles

What all modern machines have in common is that the pipes on them are bent when cold. This increases bending accuracy and significantly reduces the likelihood of wall deformation.

Cold bending also has disadvantages (models without a mandrel). The main disadvantage is the increase in load on the part, which causes a change in the cross-sectional shape. First of all, this applies to alloy steel pipes. Typically, such deformation appears due to tensile stress acting on the walls of the product. It is not balanced by the compressive stress that appears on the inner wall.

The movement of the mandrel when bending an ordinary pipe precludes its use for a profile product with a cross section. The pipe bending machine for profile pipes has a mandrel that differs from conventional ones. Bending with a profile mandrel is carried out as follows: the profiled roller is rolled along a stationary profile pipe. Fixation of the part in this case is hydraulic or mechanical. The same process takes place when using corner pipe bending machines. This equipment is large in size and very functional.

Bending pipes without radius

When creating a spatial frame, designers are faced with the need to manufacture elements in which it is necessary to create parts where sections of pipes are connected to each other at a right angle (90 degrees) or at an acute angle (45 degrees, for example). You can cut the pieces and then weld them together. However, the issue can be solved in another way:

- Make markings for the future cutout.

- Cut out excess metal.

- Perform a bend, connecting the edges of the cut made. Weld the metal along the edges.

Scheme of the technical process of bending at right angles with trimming: 1 – marking; 2 – cutting out excess metal; 3 – bending and welding of edges

This method will allow you to obtain a fairly strong part, in which part of the metal remains intact.

If you do not trim, then the excess metal has nowhere to go. The result is an unattractive appearance of the product.

Direct bending of a profile pipe without trimming

What is the reason for this phenomenon? To understand how simple bending occurs, you should consider the diagram.

Scheme of bend formation in pipes

If a suitable mandrel is available, bending is performed:

- One end is fixed motionless.

- The surface of the workpiece rests against the base surface, relative to which the second end will be moved.

- Force is applied and a new surface is formed.

Inside you can see the central line along which the pipe is bent.

Similar phenomena occur not only in hollow products. Even in solid parts, when layers are displaced relative to each other, similar phenomena occur.

How to make a pipe bender yourself

The first thing to do is to work out the assembly diagram. The machine is made in stages, and when assembling it, you should be very careful. A foundation diagram is drawn up. It is desirable that the frame is made of profile pipes of rectangular cross-section. Do not forget about strengthening the walls, because this is necessary for reliable use. The handle and clamp for the profile are a pin with a lock nut attached to its two ends with a wing nut and a lock shaped like the letter “T”. After making the base, you can make the latch handle. Here you will need jumpers and two metal plates.

Process steps:

- The plates for the handle are selected with a thickness of about 4-5 mm. This is due to the fact that the handle is mounted on the body of the frame axis. Choose metal plates carefully. They are placed on the axis with a margin of approximately 5 mm.

- The handle pulley can be adjusted to simplify assembly of the machine.

- A hole is made. The axle does not need to be secured by welding; it is secured with cotter pins.

- When the handle is made, a pulley is installed on it, which is necessary to drive the drive belt.

- The base of the assembled unit is fixed, for which a vice is usually used.

- Handle plates are placed on the axis of the frame.

- The main pulley is installed. The pin of the fastening element is screwed into the body of the wide nut on the frame. The working pulley is secured to the base axis with tightening belts.

It is recommended to monitor individual elements and their location using measuring instruments.

A pipe bender is a useful device that helps you bend pipes at home. You can buy mobile equipment that costs much less than stationary equipment. However, if you plan to use the machine frequently, carefully study its assembly diagram and make a good and inexpensive pipe bending machine yourself.

How does a pipe bender work?

The specific design of the device depends, first of all, on its purpose, however, a pipe bender must include:

- frame;

- a pair of pipe stops;

- hydraulic cylinder;

- strips (upper/lower).

Note also that the frame can be either open or closed. As for the hydraulic cylinder, it is the main part of the device that performs the power function.

Also in the do-it-yourself pipe bender circuit there is a pressure device, which is located on the back of the body; The bypass valve screw and handle are located in the same place. But on top of the cylinder there is a plug through which oil is poured inside and its level is checked. The unit strip located below is screwed onto the thread located in front of the housing, and then pressed with a special fixing nut. Additionally, the bar is secured with a lock and a pair of screws.

For manual reinforcement, a retractable rod is used, which returns back thanks to a spring located in the cylinder. The pipe bender bars are made as a welded structure. The transverse plates have holes through which stops are installed. At the bottom of the case there are also threaded holes for mounting bolts, adjustable in height.

When considering a pipe bender with your own hands, one cannot help but note the fact that profile pipes with thin walls have become increasingly popular in recent years; moreover, they make it possible to create durable and attractive structures, as well as save on construction work. It is from these pipes that greenhouses and various canopies are made today. What is the difference between a profile pipe and an ordinary one? First of all, the cross section, which in this case is not round, but oval, rectangular or square. This is precisely what explains the design features of a pipe bender for this type of pipe - the rollers must be of the same cross-section as the products being bent, otherwise the cross-section of the latter may be deformed.