Sheds are classified as the simplest structures that are erected on a suburban or summer cottage site. They are used for a variety of purposes: as a parking lot, storage area and many other options.

Structurally, the canopy is extremely simple. This

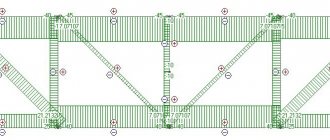

- frame, the main element of which is trusses for canopies, which are responsible for the stability and strength of the structure;

- coating. It is made of slate, polycarbonate, glass or corrugated sheet;

- additional elements. As a rule, these are decoration elements that are located inside the structure.

The design is quite simple, and it also weighs little, so you can assemble it with your own hands right on the site.

However, in order to get a practical, correct canopy, you first need to ensure its strength and long-term operation. To do this, you should know how to calculate a truss for a canopy, make it yourself and weld it or buy ready-made ones.

Drawing up a canopy project

In order to correctly draw up a design project, it is necessary to take into account a number of important factors, without which it is almost impossible to carry out a correct calculation. These factors include:

- Purpose and location of the proposed installation of the structure.

- The dimensions of the area that the canopy will cover.

- The wind force that most often occurs at the location where the frame is built.

- Maximum snow load.

- Dimensions and technical parameters of the material with which the canopy frame will be covered.

- Compliance of the building with the general architectural design of the area.

These indicators will be the basis for drawing up drawings and making calculations.

^ back to contents

Calculation of suspended structure

The drawing should serve as the basis for calculations and further installation of the structure. In addition to the general dimensions, the contours of the key belts must be drawn on the drawing according to the selected type. The belt is selected depending on the angle of the roof and the length of the entire structure. The simplest canopies with a small angle of inclination and a flat or pitched roof can be without a belt.

In order to correctly carry out the general calculation of the canopy , it is necessary to carry out calculations for the following parameters:

the height of the structure, its width and length;

roof shape;

material and its dimensions for the production of frames and supports.

If it is necessary to calculate the total cost of the structure, it is necessary to calculate the brand and number of fasteners.

^ back to contents

Design dimensions

Depending on the location of the farm, its shape and weather conditions, covering is carried out with a certain material: metal profile, polycarbonate, profile flooring, asbestos sheets, etc.

Each of the materials has its own standard sizes. These dimensions can serve as the basis for calculating the total length of the structure and the dimensions between supports. To do this, the width and length of the truss must be made a multiple of the size of the slabs. If the size of the truss is calculated according to the size of the slabs with which it will be covered, this will reduce construction waste. When calculating, the size of the panel must be taken into account taking into account the load that the entire structure will bear.

A characteristic difference may be that in the case when the total length of the truss exceeds 36 meters, it is necessary to perform a construction lift.

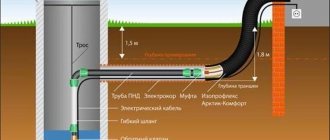

The height of the structure is calculated based on the purpose for which it is being manufactured. The finished structure should not be less than 1.8 meters, the average height of a person. If the structure is mounted under a large car (SUV, minibus), then there must be a ventilation space of at least 10 cm above the roof of the car.

^ back to contents

Installation of pillars

You cannot ignore the installation of brick pillars, which are also sometimes used to support awnings. To install such a support, a foundation is needed. More often it is a columnar structure.

- 1) Dig a hole measuring at least 50x50 centimeters;

- 2) A cushion of sand and crushed stone is placed at the bottom to compensate for loads from the soil;

- 3) Lay a thin layer of cement or masonry mortar to level the site. You can skip this step if you level the area well;

- 4) Now start laying the columns. To support a canopy, laying 1-1.5 bricks is enough.

When the underground part is ready, the side walls of the base are covered with roofing felt or coated with bitumen, then they are buried and the masonry is brought from above to the design mark.

When the racks are ready, installation work begins on installing the canopy ceiling.

- Landscape design

Roof shape and material

The length of the rafters for its installation and the brand of roofing material depend on the angle of inclination of the canopy.

Tilt angle from 22 to 30 degrees. This angle is installed on farms that are installed in regions with high levels of snowfall. Preference here is given to a belt made of a triangular-shaped profile pipe. It is recommended to cover the roof of such a canopy with straight asbestos or corrugated sheets, or various types of metal profiles.

Tilt angle from 15 to 22 degrees. Shed roofs with this angle of inclination are installed under high wind loads and have a gable shape. They have a small windage and are often covered with metal roofing coverings.

Tilt angle from 6 to 15 degrees. The simplest lean-to sheds. They can be covered with polycarbonate or profile covering.

To determine the load-bearing capacity of a roof or the permissible load that it can withstand, it is recommended to use an online calculator.

^ back to contents

How to make a polycarbonate farm ↑

The first stage of making your own trusses from a profile pipe for a canopy is to draw up a detailed plan, which should indicate the exact dimensions of each element. In addition, it is advisable to prepare an additional drawing of structurally complex parts.

As you can see, before you make trusses yourself, you need to be well prepared. Let us note once again that while the choice of product shape is guided by aesthetic considerations, a calculation path is required to determine the structural type and number of constituent elements. When checking the strength of a metal structure, it is also necessary to take into account data on atmospheric loads in a given region.

The arc is considered an extremely simplified variation of the truss. This is one profiled pipe with a round or square cross-section.

Obviously, this is not only the simplest solution, it is also cheaper. However, polycarbonate canopy poles have certain disadvantages. In particular, this concerns their reliability.

arched canopies photos

Let's analyze how the load is distributed in each of these options. The design of the truss ensures uniform distribution of the load, that is, the force acting on the supports will be directed, one might say, strictly downward. This means that the support pillars perfectly resist compression forces, that is, they can withstand the additional pressure of the snow cover.

The arches do not have such rigidity and are not able to distribute the load. To compensate for this kind of impact, they begin to unbend. The result is a force placed on the supports at the top. If we take into account that it is applied to the center and directed horizontally, then the slightest error in calculating the base of the pillars will, at the very least, cause their irreversible deformation.

Material for frame and supports

The canopy frame consists of supports, purlins and sheathing. The dimensions of these metal structures directly depend on the overall dimensions of the farm. These values are established by the requirements of GOST 23119-78 and 23118-99.

The supports can be made of a round steel pipe, with a diameter of 4 to 10 cm, or made of a profiled steel pipe, 0.8x0.8 cm in size. When calculating the installation step of the supports, it is necessary to take into account that the distance between the supports should not exceed 1.7 meters. Violation of this rule can lead to loss of strength and reliability of the entire truss.

The lathing is made of profiled steel pipe, 0.4x0.4 cm in size. It can be made of wood or metal. The installation step of the lathing depends on the materials of manufacture. Longitudinal wooden lathing is installed in increments of 25-30 cm, metal lathing is installed in increments of 70-80 cm.

Purlins for canopies with a span of up to 4.5 meters are made from a metal profile 0.4x0.2x0.02 cm. For truss purlins with a span of 4.5 to 5.5 meters, a profile pipe of 0.4x0.4x0.02 cm is used. For spans of more than 5.5 meters, for manufacturing purlins use a profile pipe with a cross section of 0.4x0.4x0.03 cm or a stronger one 0.6x0.3x0.02 cm.

^ back to contents

Tips for choosing a quality profile

Before erecting any structure, you should decide on the choice of material. When purchasing a metal profile or pipes, you should carefully inspect the workpieces to see if there are any cracks, cavities, sagging, inconsistencies along the seams, or a large number of dented and bent workpieces. When purchasing galvanized materials, it is advisable to check the quality of the coating - whether there are any peelings or sagging.

When purchasing, you must request a copy of the certificate and a receipt. It is imperative to ensure that the pipe wall thickness corresponds to that stated in the documents. You can’t make pipes in a garage on your knees, and there are no fakes, but you can come across poor quality material, so it’s better to buy in fairly large stores.

Calculation online calculator

The calculation option presented above is the simplest. There are many formulas and options for calculating canopies depending on their shape, size, and purpose. For a person with good knowledge of strength of materials and mechanics, it is easy to use the formulas and carry out the calculations. After all, the service life of the canopy will depend on how accurate the calculations are and how low the error is.

If it is difficult to resolve the issue on your own, then it is better to resolve the issue with specialists. Calculating a truss for a profile pipe using an online calculator is not difficult for them. This will make it possible to draw up a project efficiently and correctly, calculate the grade and quantity of materials, and determine the cost of the structure with an accuracy of 90%.

What's the result?

A lean-to canopy made of metal profiles is a standard design, known for its reliability and ease of installation. This type of canopy is most often chosen for dachas and cottages.

Before building a canopy, you need to calculate the snow and wind loads for the area to determine how much load the building must withstand. Based on the numbers obtained, only the brand of corrugated sheeting is usually selected, since calculating the cross-section of columns is very difficult for beginners and canopies are almost always supported on pipes of 80×80 mm or 100×100 mm, which are sufficient to spare.

Making a free-standing lean-to canopy from a metal profile with your own hands is easier than any other type of shelter. This, again, is due to the simple design and minimal number of elements. The entire installation can be completed in 2–3 days, without taking into account the time required for the concrete to gain strength. Just follow the instructions, and very soon you will have your own functional, durable and beautiful canopy on your site.

Sheds made of corrugated sheets attached to the house are the most common. They are reliable and inexpensive, and they are also very easy to build - installation of such a structure will take 1-2 days, and you do not need to hire specialists for it. At the same time, lean-to sheds are a classic that fits well into any architectural ensemble, be it a distinctly rough log house or a house in a modern style.

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Canopy for a house made of metal profiles

How to make a lean-to canopy from a metal profile adjacent to the house - detailed instructions with drawings, diagrams and step-by-step installation instructions.

Carport made of metal profiles

We tell you in detail how to build a carport from metal profiles and corrugated sheets: from choosing the brand and coating of corrugated sheets to drawings and step-by-step instructions for installing the structure.