Features of using asbestos cement products

According to the provisions of fire safety rules and SNiP, it is possible to construct chimneys from asbestos-cement pipes only in cases where the temperature to which the product is exposed does not exceed 300°C.

This is possible if:

- The product is used as the upper part of the smoke channel, into which greatly cooled gases enter.

- Asbestos pipe is used in low-power gas heating devices.

Limitations on the operating temperature are primarily due to the fact that when heated above the specified value, products made from this material burst. Consequently, its use in the initial sections of the chimney, where the temperature parameters are the highest, is strictly prohibited.

Such pipes cannot be installed in smoke shafts to remove solid fuel combustion residues from boilers.

In addition to cracking due to too high a temperature, another feature of the product is significant porosity and, as a result, accelerated absorption of accumulating condensate, leading to the destruction of the flue at the “dew point” - the base of the outer part of the pipe near the sheathing of the rafters and roof. A violation of the integrity of the surface can lead to a fire in the wooden parts of the roof frame in the area of the pipe.

Purpose of asbestos cement pipes

The widespread use of asbestos-cement pipes began during land reclamation. Their main advantage was their low price.

Asbestos pipes

New times have come, land reclamation, as well as agriculture, have sunk into oblivion. Asbestos cement pipes remain. During the period of mass construction of individual housing, many developers began to use asbestos-cement pipes for chimneys, which were not originally intended for this purpose.

DIY installation and insulation

Below are instructions for insulating and installing a chimney. First you need to stock up on materials and tools. Required:

- Several smooth galvanized iron sheets. Their exact number depends on the size of the sheet and riser.

- Insulation. Usually mineral or glass wool and other fibrous materials are used.

- Riveter and rivets 4 mm thick.

- For cutting metal, scissors or a grinder.

- Drill or screwdriver

- Hammer and other hand tools.

The preparatory stage has been completed, it’s time to start insulation and installation.

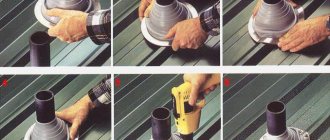

- It is necessary to make several cylindrical protective covers. They are made from a sheet of iron. The height of one segment is 1.5 m, its diameter should exceed the thickness of the outlet by 6–8 cm. The sheet is connected into a ring using folds, and then riveted.

- The outlet is cleaned of dirt, dust and other debris.

- The first iron segment is placed on the lower part of the riser, and the voids are filled with insulation.

- The entire pipe is sheathed in a similar way.

- The chimney ends with a small roof that prevents the ingress of precipitation.

Let's start installation:

- First you need to make the base. The material for it is usually cement and brick.

- Next comes the installation of a revision with a hole for cleaning the system. This is only possible if the asbestos-cement pipe is the top part of the system.

- After preparing the base, the riser itself is installed. Its fixation occurs both below and in the ceiling, between the beams.

- An additional element is installed on the boiler, connecting it to the outlet pipe. It is usually made of metal or heat-resistant ceramics.

Attention! If the temperature of the gases leaving the boiler exceeds 300 degrees, asbestos is installed as an additional section. It should be located at a considerable distance from the exhaust source. The installation procedure is quite simple, the time costs are small, but what about the cost

Subject to the availability of the necessary tools, we will consider only the prices of materials. An asbestos-cement bend 150 mm thick, 4 m long will cost about 900 rubles

The installation procedure is quite simple, the time investment is small, but what about the cost. Subject to the availability of the necessary tools, we will consider only the prices of materials. An asbestos-cement bend 150 mm thick, 4 m long will cost about 900 rubles.

Sheet of smooth galvanized metal 1.2 by 2.5 m another 880 rub. Insulation, for example mineral wool, 500–600 rubles. per package. The exact cost will depend on prices in the city and the size of the chimney.

Why were they popular in the past?

During Soviet times, there was an acute shortage of all types of building materials. Asbestos pipes were a real boon for private developers. The purlins met all safety standards, had no worthy alternative, and were distinguished by their strength, tightness and affordable price. The links were used in furnace making, arrangement of water supply systems, sewerage systems and construction of wells.

Over time, GOST requirements were replaced by TU. Changes were made to the production technology, which negatively affected the quality characteristics of the products.

They can only be used for a gas boiler, installed in the middle and end of the chimneys of saunas and baths. But, it is better to abandon this idea and use pipes made according to specifications for arranging low-pressure communications and protective structures for laying cables.

Which type is suitable for which chimneys?

Recommendations from experts on the use of asbestos-cement pipes in heating systems are brief. Purlins manufactured according to modern technical conditions should not be installed indoors or directly on brick kilns. At any moment, pipes can crack and dangerous carbon monoxide can fill the room.

As for the use of different types of products, they can be installed in the following places:

- Non-pressure. They have thin walls and low resistance to loads and impacts. It is better to install them inside auxiliary rooms and attics. That is, in places where people are not constantly present and there is no likelihood of mechanical damage to the highway.

- Pressure. The products are more durable and pressure resistant. It is advisable to install purlins on the roof where there is wind load. Pressure pipes can be used for fireplaces and stoves, provided that they are heated with wood.

In all cases, it is necessary to pay attention to the device for smoke removal from asbestos pipes, since they tend to become clogged with soot in a short time.

Step-by-step insulation technology

Due to the fact that chimneys come in different types and designs, we will describe how to properly insulate a chimney pipe made of brick, asbestos cement and steel.

Chimneys made of asbestos cement

Asbestos cement pipe

To understand how to insulate a chimney from an asbestos pipe, we will analyze the entire procedure step by step, following the recommendations of professional builders:

First, you need to thoroughly clean the work area from dust and dirt; The next step is to make a special folding casing for the insulation (made from galvanized iron)

When determining its parameters, it should be taken into account that at least 6 cm should remain between the pipe and the iron for insulation; Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m; First of all, you should secure the lower part of the casing and carefully fill it with sealant. Then, the second part is put on and the procedure is repeated. This design must run along the entire length of the asbestos pipe.

This design must run along the entire length of the asbestos pipe.

Thermal insulation diagram from a home craftsman

This is what an asbestos chimney with a casing looks like

Often, many cottage owners do without a casing. The pipe is simply wrapped in a roll of mineral wool and secured with staples. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we seem to have sorted out the asbestos pipes, now let’s see how to insulate the metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, take a pipe of smaller diameter and insert it into a pipe of larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then we can recommend basalt chimney insulation, which in its structure resembles mineral wool, but is much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than an asbestos pipe, so there should be no problems here.

Brick chimney

Brick chimney

Insulating a brick chimney is perhaps the most complex type of all presented in this article. Now we will present several options, from which everyone will choose for themselves how to insulate a brick chimney:

Plastering method. To do this, you will need to attach a reinforced mesh to the chimney. Then prepare a solution of lime, slag and a small portion of cement. Spread the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which should be at least 3 cm).

When the solution dries, you can add a few more layers and immediately cover up the resulting cracks. To give an attractive appearance, the pipe can be whitewashed or painted in the future.

Thermal insulation diagram of a brick chimney

Insulation with mineral wool. To do this, you will need to take a roll of basalt wool and cut it into pieces that correspond to the dimensions of the chimney area. Then, the insulation is glued to the pipe using tape. The last step of the work is to lay insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

The process of thermal insulation of a chimney with mineral wool

Good luck!

Extinguishing with asbestos cloth

Asbestos fabric is often used for fire protection purposes. Extinguishing with asbestos cloth involves performing the following tasks:

- Remove the canvas from the case using special handles and unfold it.

- Cover the fire with a cloth. This will help prevent oxygen from entering.

- Leave it on site until the fire dies out.

- If the fire source is located in an open area, the object must be covered from the direction of the wind.

Carefully inspect the fabric after use. If there are damaged areas, burns or tears, the material must not be reused.

Fire safety measures and risks

When laying an asbestos-cement channel yourself, it is necessary to strictly follow fire safety rules, since the material gets very hot and there is a risk of fire:

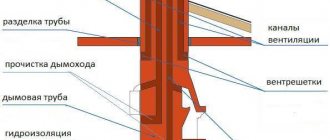

- The installation of a chimney in the ceiling involves making a special penetration in the form of a hole in the ceiling 10 cm larger than the cross-section of the pipe. The resulting distance is filled with non-combustible material.

- You can initially build a “fluff” and fill the gaps with broken bricks and sand.

- To protect the roof from water leakage, the perimeter of the chimney structure must be sealed with a cement compound or a special bitumen mastic must be used. Sealing cracks with silicone is excluded.

It should be remembered that it is strictly forbidden to allow heating surfaces to come into contact with load-bearing structures and sheathing elements made of flammable materials.

Stainless steel casing

Thermal insulation of the furnace using stainless steel casing has several options. Based on orientation in space, front and side screens . The recommended distance from the oven to the screen is from 1 to 5 cm . Thanks to such structures, it is possible to reduce the intensity of thermal radiation from a metal furnace, since the outer surface of the protective screens warms up to 1000 C. In this case, it is possible to reduce the distance from the furnace to the wall to half a meter. Ease of installation and the presence of special legs that allow you to securely fasten the screens make their use especially attractive.

Safety

When building a chimney in a bathhouse, you first need to think about safety issues. After all, if something is done incorrectly, wooden structures can catch fire very easily. The problem must be approached carefully, then the bathhouse will last a really long time, and there will be no risk to people’s lives.

All the necessary requirements that chimneys must meet are established by the relevant sanitary rules and regulations. They specify the distance that must be maintained between the pipe and flammable parts of the roof slabs. This value depends on the pipe parameters. If you are planning to make a chimney in a bathhouse, you should familiarize yourself with SNiP 41-01-2003, which approves the rules for the installation of ventilation, heating and air conditioning

In this case, pay special attention to paragraph 6.6.22, which contains all the necessary information

To ensure that the chimney is completely safe, you need to use appropriate materials for thermal insulation:

- mineral wool;

- basalt cardboard;

- mineralite

Non-flammable mineral wool with long service life

Fire-resistant plasterboard and glass-magnesium sheet are also suitable for this purpose.

Fire-resistant drywall can withstand exposure to direct fire for about an hour

Glass-magnesium (glass-magnesite) sheet (SML), moisture-resistant, fire-resistant, frost-resistant, environmentally friendly

You need to pay attention to some other points

So, it is important to choose the right materials from which the chimney itself will be made - they must be resistant to high temperatures. For example, if you decide to use a metal pipe to construct a chimney, it must be made of non-galvanized material

The fact is that when heated to high temperatures, zinc begins to evaporate, and its evaporation is extremely harmful to health.

For example, if you decide to use a metal pipe to construct a chimney, it must be made of non-galvanized material. The fact is that when heated to high temperatures, zinc begins to evaporate, and its evaporation is extremely harmful to health.

Choice of insulation

The choice of insulation to insulate a chimney must be approached carefully and seriously. You shouldn’t buy the cheapest one, because it should have good thermal insulation properties, be easy to use, not require additional reinforcement of the load-bearing structures of the roof and ceilings, be non-toxic and non-flammable.

Stone or basalt wool is an excellent thermal insulation made from basalt stones.

This insulation can withstand prolonged exposure to fairly high temperatures and does not burn, even when in contact with an open fire. When heated, it does not emit any toxic or unpleasant odors. Such insulation can be safely called an environmentally friendly material.

Heating from DESIGN PRESTIGE LLC View water here resant.ruotoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

In order for the pipeline to serve for a long time and not have any problems with it, it is necessary to initially install the structure correctly, as well as connect asbestos-cement pipes as best and as efficiently as possible, using the necessary connecting elements, fittings and devices designed to compensate for various deformations and vibration processes .

In order to make a choice on a specific type of connecting elements, it is necessary to determine for what purposes the product made from asbestos-cement pipes will be used

It is important to determine the specific function of the pipeline structure

Manufacturing plants produce asbestos-cement couplings with two teeth, which are similar in size to the asbestos-cement elements found in the pipeline structure. These connecting elements are widely used in water supply systems. The process of combining parts occurs in a simple way, using a dense rubber ring.

In the case of connecting pipes that will not be subject to pressure during operation, asbestos-cement couplings are used. They are made from a pipe with thick walls and a large diameter. In addition, in water and gas pipelines that are made from asbestos-cement pipes, “Zhibo” couplings made of cast iron can be used.

For laying cable connections, high-pressure polyethylene couplings are used to fasten asbestos-cement products that will not be subject to pressure.

Fragment of joining: 1,2 - chrysolite-cement pipe; 3 - coupling; 4 - rubber sealing ring

Such a main element in a product as a connecting node must have the following:

1. When working with significant pressure, as well as in the case of the formation of a vacuum space, it must exhibit stable strength and have density properties.

2. Do not be influenced by an unfavorable environment.

3. Show yourself as a convenient and simple material that is not worth spending a lot of time and effort on.

How to choose a cord

When searching for a suitable type of asbestos cord, the following several circumstances must be taken into account:

It is necessary to clarify for what use the material in question is being purchased. The type of heating and its source are taken into account. It is important to choose the appropriate type of cord and its thickness. Too thin will not be able to create a reliable connection, and thick may require replacement of structural elements.

As an example, consider the oven door. A thick thread will require the use of other loops, while a thin thread will allow air to pass through.

If you need to ensure compaction of a cast iron slab, SHAU is suitable. For the chimney it is better to use STEP or SHAON. The use of down cords for domestic purposes is not common.

When selecting a cord, its characteristics matter:

- There should be no signs of damage, tears, bald spots or other similar elements on the surface. In this case, protruding ends of threads no longer than 25 mm are not considered damage.

- The presence of a core makes the cord more durable and elastic.

- You need to take the humidity level into account. The standard allows 4.5%, but for products containing cotton this value should be no more than 3%.

- It is necessary to take into account how much and what kind of asbestos is in the composition. It is permissible to use only the chrysotile variety. The content must be at least 78%.

Do-it-yourself brick chimney for a solid fuel boiler

The construction of the pipe itself is not difficult, especially for those who have already had experience working with similar material

However, during construction it is important to take into account some features that will allow you to create a reliable and durable structure. It will most effectively cope with the effects of condensation and precipitation. The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side

The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side.

If the boiler chimney becomes part of an external wall, the foundation must also extend and be the lowest level of the wall foundation.

- For laying it is necessary to use refractory brick M75 or M50. To fix them, cement mortar or a mixture of cement and lime is suitable. A high-quality chimney can be obtained by performing masonry with bandaging: ensuring that the seams of the previous row overlap the next one.

- During construction, it is necessary to treat the inner surface and rid it of roughness.

- It is better to finish the upper part of the chimney for the boiler with a head protruding 10 cm beyond the brick base.

Ventilation holes can be added under the head to prevent air from blowing in. They must be placed on two opposite walls or on each side.

Compliance with these principles will allow you to create a chimney for a solid fuel boiler yourself, be it a straight pipe through the roof or going into the wall. Each design method has its advantages:

- A chimney passing through an attic or roof will transfer heat to all rooms through which it passes, therefore it is suitable for two or more storey buildings. In addition, it is easy to construct.

- A chimney passing through a wall is compact and safer than a conventional one.

Thus, brick chimneys for boilers are the most optimal when comparing the complexity, cost and reliability of construction. Therefore, having studied all the necessary information, you can purchase materials and begin building a chimney with your own hands.

Recommendations for use

To ensure that asbestos sheet does not pose a danger to humans, it is recommended to follow these rules:

- Use the composition in rooms with a powerful ventilation system. It is important that asbestos particles are completely removed.

- When working with asbestos fabric, use gloves and closed clothing. This will help minimize contact of the substance with the body.

- Keep the canvas indoors. If it is lying outside, it is important to ensure reliable protection from moisture.

- Transport the material in secure packaging to prevent its fragments from entering the atmosphere.

- When disposing of the material, it must be tightly packed in plastic bags. If this is not possible, it needs to be well wetted.

What are asbestos cement pipes used for?

Asbestos cement is a durable fireproof material that combines the properties of asbestos and cement. Asbestos, or, as it is also called, mountain flax, is a group of silicate class materials that look like thin, durable threads. These threads are used as a frame into which other building materials are poured or laid. In the case of asbestos cement, such a building material is cement.

Asbestos gives strength to materials and protects them from fire. There are two types of asbestos: chrysotile and amphibole. The first is widespread in Russia, where there are asbestos deposits. This material has been used in construction for about five decades. Amphibole asbestos used to be common in European countries, but has now been banned due to its negative impact on human health.

Asbestos-cement pipes are intended for those structures where there is water, steam or gas. They can withstand temperature fluctuations and, when installed correctly, last for many years.

Pros and cons of the material

When using asbestos cord, the following advantages can be noted:

- This material is fireproof. It can easily withstand heat up to 400 degrees. This cord is resistant to extreme heat and can be used where the operating temperature is high. After heating to 700 degrees, the fibers become brittle. After 1500 degrees they begin to melt.

- The core is made of a very durable material that can withstand significant tensile loads. Due to its multi-fiber structure, the cord can be used as a regular rope if necessary.

- The cord has good abrasion resistance. To make it more durable, it is strengthened by wrapping it with reinforcement.

- The material has water-repellent properties.

- Absorbs sound well.

- The cord does not rot. It is not vulnerable to rodents and insects.

- High resistance to strong changes in moisture and temperature.

- Flexibility allows you to adapt to almost any shape.

Using a cord to insulate a pipe Source forum.katera.ru

Coil of sealing cord Source trivita.ua

Risks of installing asbestos chimneys

Before choosing a specific product as a chimney, it is necessary to study the risks that arise during its operation and the possibility of using it for certain purposes. So, when installing an asbestos chimney, there is a possibility:

- When exposed to high temperatures, an asbestos chimney may burst. There were even cases when it exploded;

- the appearance of an unpleasant odor that occurs when harmful condensation and soot are absorbed;

- inability to install special hatches for cleaning and monitoring the condition of the chimney;

- difficulties in removing soot that occurs during the combustion process;

- thin-walled material does not contribute to the formation of draft, as a result, the boiler may not work well.

The installation of a chimney should be approached with full responsibility.

After all, this is an element of the heating system, which must work flawlessly. Improper operation of such a chimney can lead to a fire or carbon monoxide poisoning that accumulates in the pipe. That is why, before installing a chimney from an asbestos pipe, it is worth weighing all the pros and cons. And figure out in detail whether it is worth risking your health and property by installing a product that may not be intended for such purposes. vote

Article Rating

Advantages of using asbestos

Let's start right away with the positive qualities of asbestos pipes, which during the development of agriculture could easily be purchased (or stolen, whichever is preferable to anyone) at many enterprises and collective farms for pennies.

- Their comparative cheapness. This was due to the fact that asbestos was mined in large quantities in our country and products from it are easy to manufacture.

- They are light in weight, so they are quite easy to install.

- They have no seams and are not susceptible to moisture.

Asbestos chimney installation

The chimney is installed in the following order:

- An asbestos pipe should never be removed directly from the kiln; it should rest on a concrete or brick base. The supply to the heating unit is made through a metal adapter. This part of the chimney is equipped with a flat damper or disc damper to regulate the draft by reducing the passage in the smoke exhaust channel.

- When installing a chimney, a container is provided in its lower part to collect condensate, which must be periodically emptied of black liquid with an unpleasant odor.

For asbestos pipes, plastic or metal condensate collectors of suitable diameter can be used - The upper end of the chimney must be equipped with a cap, and in the best case, with a deflector.

- At the junction with the chimney, a hatch is cut out in the ceiling, which is at least 15 centimeters larger than the dimensions of the pipe.

A sheet metal damper is fixed to the ceiling below. Basalt wool is placed tightly into the resulting opening from above and covered with the same metal sheet on top. When a pipe passes through the ceiling, a protective box of steel sheets is installed - Crossing the roofing pie is done in the same way. Only on the outside of the roofing you need to install an otter - a device to prevent water from entering through the pipe into the under-roof space. On the construction market it is easy to purchase a ready-made structure that matches the size of the pipe and the slope of the roof.

It should be remembered that chimneys made from asbestos pipes should absolutely not be used when installing heating in a bathhouse due to stoves with extremely high heating temperatures.

Fire safety

The requirements for a safe chimney installation do not differ from those for other systems:

- The passage of the smoke duct closer than 70 centimeters from the load-bearing structures of the building is not allowed.

- Chimneys cannot be painted with oil or enamel paint. If necessary, you can use lime or a special bitumen varnish.

- When a chimney passes through a wall, it must be finished with non-combustible material, and the passage itself must be sealed in the same way as a ceiling passage.

It should be remembered that the industry does not produce asbestos-cement pipes specifically for chimneys and the owner himself bears responsibility for their use in the heating system.

Video: consequences of improper use of an asbestos chimney

An asbestos chimney should be inspected monthly and, if necessary, cleaned of soot.

What is especially important is that for chimneys made of asbestos pipes on solid fuel stoves, some preventive measures aimed at preventing planting are categorically not recommended. Do not use high-temperature fuel (aspen) or walnut shells to burn soot in the chimney, even in pyrolysis ovens

For this purpose, you need to use potato peels, rock salt or a blue mixture, which chemically destroys the soot layer.

Insulation of asbestos chimney

The purpose of insulating an asbestos chimney is to increase the temperature of the flue gases to reduce the amount of condensate released. The possibilities of this technique are not limitless, since at temperatures above 300 degrees the asbestos pipe begins to collapse.

- The outer part of the pipe is insulated with mineral or basalt wool, on top of which a galvanized steel casing is placed. The advantage of this method compared to brick otter is the large difference in the weight of the structures.

- The internal parts are insulated in the same way; the construction of a protective shell is not necessary here.

Why does the chimney need to be insulated?

In the case of a chimney, insulation is not quite the correct term; in fact, we are talking about thermal insulation. It must be done to prevent rapid destruction of the chimney pipe. There are several reasons for this:

- Along with the smoke, moisture enters the chimney and settles as condensation on the walls of the chimney. This leads to the destruction of the material. The greater the difference between the external and internal temperatures of the chimney, the faster condensation will destroy the pipe.

- Water vapor mixes with combustion products, forming aggressive compounds in the form of acids. They also settle on the walls of the structure, gradually destroying the material and shortening the life of the chimney.

- An uninsulated chimney is subject to periodic expansion when heated and contraction when cooling due to the low ambient temperature. This is another reason for destruction.

Without thermal insulation, the destruction of the chimney occurs much faster

Steam compounds with combustion products are poisonous. If they enter a room, they can cause poisoning to the inhabitants.

The essence of chimney insulation is to create a heat-insulating barrier around the pipe, reducing the temperature difference with the environment. First of all, areas passing through unheated rooms and located outside the building should be insulated.

How to insulate an iron chimney pipe

To insulate a metal pipe outdoors, use basalt insulation and metal clamps - the rolled insulation must be wrapped around the pipe and secured with clamps after 30-40 cm. A tool that is useful for insulation:

- Hammer, pliers, screwdriver, clamp, and other plumbing tools;

- Tape measure, metal ruler or square, building level, pencil or marker;

- A cutter or scissors to cut the insulation for chimney pipes to size;

- A device for riveting and rivets that connect the casing. Instead of rivets, short press washers can be used;

- Screwdriver or electric drill, drills Ø 3-4 mm for rivets;

- If the chimney is being plastered, you will need: a spatula and a bucket for mortar;

- To seal cracks and joints - a construction gun and bitumen mastic.

A properly constructed chimney made from an asbestos pipe

The misconception that installing an asbestos pipe as a chimney is not difficult can lead to many undesirable consequences. Boiler equipment is different, each has its own efficiency.

Therefore, before proceeding with installation, you need to carefully study all technical conditions. What a private developer must be prepared for when making a chimney with his own hands is reliable fastening of the structure, arrangement of thermal insulation of the pipe, and compliance with fire safety standards.

Chimney insulation

Fastening a chimney from an asbestos pipe

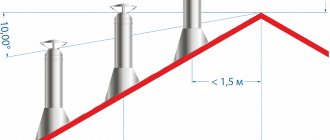

Installation of an asbestos pipe in the general chimney system can be carried out from the area where the temperature of the combustion products does not exceed 300 degrees Celsius. It is permissible to install both a separate riser (external chimney) and a channel passing through the roof. When arranging, you must adhere to the following rules:

- When the pipe extends above the ridge more than 2 meters, it is necessary to use additional clamps and braces for fixation;

- A separate chimney is attached to the load-bearing wall with pipe clamps at intervals of at least half a meter;

- When placing asbestos inside a brickwork channel, additional reinforcement spacers are used;

- The chimney should be secured at the point where it passes through the roof using an asbestos cement bracket.

Extension of a chimney with an asbestos channel

Free-flow asbestos pipes, which are used to organize a chimney, are usually built onto a ready-made part of the chimney made of another more heat-resistant material. The transition from metal to asbestos can be accomplished through a special stainless steel sleeve.

Connecting an asbestos pipe with a coupling

If there is an extension of one asbestos pipe to another of the same type, then the connection is made using a CAM modification coupling. The coupling has two internal grooves for a heat-resistant seal. When building up a brick chimney, the CAM coupling is fixed inside the masonry. It is supported by embedded reinforcement, and the space between the masonry and the coupling is filled with concrete.

Extension of brickwork with an asbestos chimney pipe in the absence of a coupling can be done in another way. To do this, a slab of the same asbestos cement or steel with a hole not exceeding the diameter of the asbestos channel is installed on the last row of bricks. The latter is installed on top of the hole and fixed with a solution.

Thermal insulation cushion device

Asbestos cement has a porous structure. It has poor thermal insulation qualities, so it heats up very much, to the temperature of the gases being exhausted outside. Asbestos-cement chimney pipes must be insulated with fire-resistant material for the following reasons:

- To avoid heating and ignition of flammable materials that make up the structure of the house;

- To avoid the formation of condensation, which is one of the factors that has a destructive effect on the chimney.

Basalt wool

The classic version of insulation is based on the use of basalt wool, which is wound in several layers on the chimney and secured with special clamps or knitting wire. A layer of foil is placed on top of the cotton wool. This must be done to waterproof the pipe and provide an additional fire barrier.

The insulation can be protected using a metal frame. For this purpose, thin galvanized sheet metal or with a factory paint coating is suitable. It is advisable to use such a frame for pipes protruding above the roof, where the foil will look unaesthetic.

Inserting a tee into an asbestos-cement pipe

If the chimney is arranged in such a way that it is necessary to remove it through the side wall, add a condensate drain, or install an inspection hatch to control and clean the chimney, use tees with a coupling-type connection system. After trimming the pipes and putting on the tee, the joining gap should be filled with a composition based on acid-resistant and heat-resistant components.

Sections of the chimney made of asbestos-cement pipes are prohibited from being installed in a strictly horizontal position. When the channel exits sideways, it must slope at least 3 degrees towards the boiler installation.

How to use asbestos cord for furnace thermal insulation

Work related to the use of the material in question does not require special skills. In order to properly install the seal for a metal stove, care and precision are required.

To do this, do the following:

- It is necessary to clean the oven from dirt, dust, drops of grease and the like. If sealing cord has been previously used, it is necessary to carefully remove its remains.

- If the design provides a special groove for the seal, then heat-resistant adhesive must be applied. If there is no groove, apply glue to the place where it will be laid.

- The cord must be carefully laid out so that it goes exactly where it is planned. The ends must be carefully trimmed so that there is no gap between them when they are placed next to each other.

- You need to press the cord tightly until the glue dries. If the seal was installed only on the door, then it needs to be pressed.

After three or four hours have passed, the glue should dry. In order to check the quality of insulation, you need to heat the stove. When laying the cord, it is important that its size exactly matches the gap.

If you need to insulate a chimney to protect surrounding objects from the sparks that sometimes occur there, it is completely wrapped with a cord. This is done in areas where there is an intersection with walls or ceilings.

It must be wound in several layers. In this case, the thermal insulation layer should extend beyond the walls or ceilings by at least 6-7 cm.

The use of asbestos for a chimney. Is it possible

Pipes made from asbestos cement are needed for sewer, water, sewer and sometimes air duct installation.

Can also be used as a cable channel. Good thermal conductivity helps to use them as a casing for a local oil pipeline. When building your own home with your own hands, asbestos is used in many areas. They can be used to make piles for the foundation of a building. Asbestos-cement mixture is perfect for use in wetlands. But they are often used when installing a chimney in the house itself, sometimes in a bathhouse with heating in the form of a stove or fireplace.

Areas of application of asbestos products

Asbestos pipes, initially considered suitable only for the construction of reclamation systems, are now used much more widely. They began to be used:

- during the construction of non-pressure sewerage;

- as casing pipes when constructing wells;

- in sanitary and technical water supply systems;

- when creating drainage systems, storm drainage systems;

- as formwork for bored columnar foundations;

- and during the construction of ventilation systems and smoke exhaust ducts.

The great popularity of the material is explained by its advantages when comparing asbestos products with metal pipes. Asbestos cement is not threatened by corrosive processes. It has a small coefficient of linear expansion, which is acceptable when heated. The cost of asbestos pipes is quite affordable.

These products have no significant disadvantages, but there is a drawback. This can be attributed to their inability to withstand strong impacts. If serious damage is avoided during installation and operation, the pipeline can last 30-40 years.

Technical characteristics and production of products

In practice, asbestos cement is fiber-reinforced concrete. Its production includes the following stages:

crushing asbestos raw materials obtained from mining enterprises; fluffing asbestos with further cutting of fibers; adding water to the ratio of cement to asbestos 85:15; removing the resulting pulp onto a drum with a mesh structure; winding the film on a rolling pin to give the product the required wall thickness.

The production of products takes place only under strict control in accordance with GOST. The weight of an asbestos-cement pipe per 1 m is from 6 to 11 kg. For example, the weight of 300 mm products is less than 500 mm.

The pressure pipe is produced in sections of 3.95 or 5 meters. Its flow section has the following dimensions: 100, 150, 200, 250, 300, 400 and 500 mm. The weight of the product varies from 45 kg for a 100 mm product to 67 kg for a 150 mm product or 19 kg for a 300 mm product.

Just like other products, the 300 pressure pipe is waterproof. The diameter of 300 mm allows for quick and cheap installation of the system.

Non-pressure products are produced in lengths of 3.95 m, the diameter of which ranges from 100 to 200 mm.

BNT 100 weighs 24 kg. Products 150 have a weight of 37 kg. The free-flow asbestos-cement pipe 200, whose weight does not exceed 64 kg, ensures a clean supply of water through the pipeline, which is why its installation is popular in the economic sphere.

Disadvantages of asbestos pipes

Despite its popularity in private construction, a chimney made from this material has many disadvantages.

The quality of the pipeline installation also matters. Let's consider the characteristic disadvantages of asbestos-cement chimneys and the reasons for their occurrence.

Burnout and bursting

Initially, the products were developed for mass production for use in land reclamation, construction of sewers and low-pressure gas pipelines. The designers did not provide for their operation at high temperatures. Emphasis was placed on tightness and ease of installation of highways.

The basis of the material is cement, and it is a porous material. It absorbs creosote, which is a flammable material. With strong heating, the process of its combustion begins, as a result of which the structure of the walls changes, they become thinner and burn out.

With further heating, the pressure of the air enclosed in the walls of the purlins increases. Products crack, burst and even explode.

Maintenance difficulties

The high strength of asbestos cement is a myth that many people want to believe.

Working with links requires increased caution and accuracy. The lack of steel reinforcement makes them extremely brittle and brittle, regardless of diameter and type

And that's not all...

Chimney maintenance is associated with the following difficulties:

- the need for regular cleaning, since pipes literally attract soot;

- the inability to make inspection windows to reach hard-to-reach areas;

- sensitivity of products to shocks and loads;

- Frequent replacement of insulation, which is destroyed by chemically aggressive condensate.

Humidification of the pipeline is fraught with unpleasant consequences, both for communications and for the building as a whole.

Condensate

The main purpose of the products was the laying of open and underground water pipelines of various lengths. Asbestos-cement pipes are resistant to water, but quickly collapse when in contact with chemically active liquids. They are the ones that form on the surface of the chimney during the interaction of soot and condensate.

The aggressive solution flows onto the roof and is absorbed into its surface. As a result, stains, unpleasant odors and cracks appear. Watching the video below will help you understand the extent of the damage caused by condensation. This issue can be resolved with the help of properly carried out insulation.