Modern man is a very heat-loving creature, and cannot exist in a house without heating. A heat generator with a chimney is the most complex and potentially dangerous engineering system. A chimney is a rather bulky and complex structure, and if the stove or fireplace is located near the outer wall of the house, then the most practical option is to install the chimney through the wall.

We welcome our regular reader and offer him information on how to make a chimney outside near the wall of the house with your own hands.

Features of working with wooden walls

Installing a chimney from a sandwich pipe through a wooden wall requires precautions.

- The dimensions of the hole in the wall are selected with a margin of 100 mm between the wall and the pipe. The distance from the chimney to other combustible materials is 450 mm.

- Basalt insulation is laid around the sandwich (it is resistant to high temperatures) and asbolite (or mineralite) around the perimeter.

- To hold the insulation inside the hole, it is covered with a sheet of stainless metal.

- A spark arrestor or umbrella is installed at the end of the chimney for fire safety purposes.

How to install the most fire-hazardous section of the chimney

When installing an amber stove through a wall, sandwich systems are installed with your own hands. The first segment of the chimney is made from a fragment of a smaller pipe. It is fixed in such a way as to prevent overheating of the fasteners; for this it is necessary to retreat a sufficient distance. Basalt insulation is laid from the 2nd bend.

The first segment of the chimney is made from a fragment of a smaller pipe.

Safety regulations

Do not forget that the chimney is a source of danger. Place the flue away from the cable and gas pipe. Contact with other utilities is undesirable. The maximum length of individual fragments is 1 meter. It is important to follow building codes and regulations.

Place the flue away from the cable and gas pipe.

Principle of operation

The principle of operation of a chimney is the ability of heated gases to rise, reducing their density. As a result, the cavity becomes rarefied and is replaced by air coming from outside. The draft increases, supporting combustion. When the gases cool, an acidic precipitate appears. It affects the internal walls of the structure, deforming and destroying them. To reduce the threshold for the formation of acid condensate, thermal insulation materials are used.

Flaws

Although it has many positive factors, the structure also has negative sides. You need to familiarize yourself with them:

- An integral rule for installing a chimney through a wall is to create insulation on the pipes;

- Inside and outside the house you will need to allocate a relatively large horizontal area for the smoker;

- According to some experts, if this outer pipe is for a gas boiler, then the productivity will be low;

- This product will not be in harmony with the overall design, however, this can be played around somehow.

Types and designs of external chimneys

By design, external chimney devices when discharged through a wall are:

- wall-mounted They are fixed to the facade;

- indigenous. They differ from wall-mounted devices in that they are located near the frame house, and not on the facade wall. This is an independent structure with a foundation.

Main chimney

A chimney through a wall in a wooden house is made of fire-resistant materials. Brick, metal, asbestos-cement and ceramic variations protect your home from toxic gases to varying degrees. We will introduce you to the features of the most common types.

Brick

Built from red brick.

The brick is strong, durable, has a good appearance and is wear-resistant.

It has a rectangular cross-section, which is inconvenient for increasing traction force. The surface inside the structure is rough. The chimney is heavy. Only qualified masons can install it. Brick cannot withstand exposure to aggressive chemicals. The porous texture of the material promotes the accumulation of moisture and deposits of soot and soot.

Inspection hatch for cleaning an external brick chimney

Ceramic

A popular design is the ceramic sandwich pipe. It has a long service life. It is easy to install. You can handle its construction yourself. The walls inside the product are smooth, so good traction is guaranteed. The device can be installed both outside and inside the building.

Weight of a 6-8 meter ceramic chimney

Ceramic structures are not afraid of aggressive chemicals: alkalis, acids.

An important disadvantage is the high price.

Ceramic chimney in blocks

Metal

Single-component chimneys are metal pipes of round cross-section. They are not used for outdoor installation because they have high heat loss. Aggressive substances that appear when gases cool down destroy the metal structure. Therefore, the service life of single-layer devices is short. Their disadvantage is the need for expensive thermal insulation.

Sandwich pipes (double-circuit) consist of a large and small pipe and insulation. It also serves as an insulator. The pipes are made of acid-resistant stainless steel.

Smooth walls provide good traction and reduce the amount of soot on their surface. Installing a chimney through a wall using sandwiches is a very common option.

Sectional view of a sandwich pipe

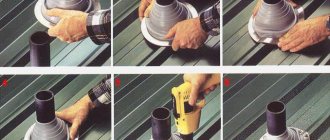

Round chimney passage

If the choice was made in favor of a pipe with a round cross-section, then usually special cuttings with a round cross-section produced at enterprises are used to ensure a tight fit to the roof and eliminate the risk of leaks and heat loss. In appearance, they resemble corrugated cuffs equipped with wide brims. They are made of rubber, but a special one - heat-resistant, synthetic. Aluminum cuttings are also available for sale. The convenience of their use lies in the fact that they easily follow the wavy profile of metal tiles and can be secured both with fasteners and with adhesives.

Chimney seal

A hole is cut into a synthetic rubber penetration that is 20% smaller than the diameter of the pipe itself. Next, it is pulled onto the pipe itself (to facilitate the process, you can use a soap solution applied to the pipe). After this, the rubber product is pressed against the roof and fixed to it with sealant and roofing screws in increments of about 3.5 cm.

Switching from a brick duct to a metal one may be necessary when installing a new chimney or when repairing an old one

Advantages and disadvantages of venting the chimney through the wall

Installing a chimney through a wall has the following advantages.

- It can be carried out after the completion of the construction of the house, and not at its beginning.

- You can install the chimney structure yourself, because installation is simple and consists of several operations.

- Since the chimney device is located outside the building, access to it is open, which facilitates repairs and maintenance.

- It is possible to regulate the traction force.

- High fire safety.

- Gas leakage is excluded.

- There is no need to make holes in the roofing pie.

- Saving space indoors.

The disadvantages of such a chimney include:

- violation of the aesthetic appearance of your home;

- heat loss. It goes into the atmosphere. It is necessary to properly insulate the exit through the wall;

- to prevent water from entering the pipe, it is necessary to install ebbs;

- additional fixation of the chimney to the wall is necessary;

- a large number of bends in the structure disrupt the draft and slow down the release of exhaust gases into the atmosphere.

Product design

The pipeline can cross building structures in two planes. Interfloor ceilings are crossed by vertical pipelines (risers), walls - by horizontal ones (wiring). The figure shows an example of the installation of a product in walls (a) and ceilings (b). Actually, the sleeve consists of a cover (1), for which a steel structure is most often used, packing (2), which can be a soft non-flammable material, but Portland cement is often used (which, according to experts, is undesirable). The cover is firmly fixed. The pipe (3) passes freely through the cover (the diameter of which should be 5-10 mm larger than the pipe) and is fixed in the wall (4) or ceiling (6). Installation and caulking of pipeline sleeves in floors is carried out taking into account the height of the screed (5) or other floor covering, and the length of the product should be at least 10, or even 20 mm, greater than the thickness of the floor. This is important to prevent emergency water masses from penetrating to the lower floors.

This is important to know! The section of pipe where it passes through the wall should not have seams.

The service life of such a chimney

The duration of operation is influenced by factors:

- material. The most short-lived material is galvanized metal. The chimney will last 5-10 years, depending on the intensity of the fireboxes. The service life of stainless steel is 15-20 years. The ceramic design will delight you for about 40 years. The period of operation of a brick chimney is half a century;

- installation. If the pipe is installed correctly, then it can be used for 20 - 50 years;

- heating temperature of the exhaust gases. For a solid fuel boiler it is high - 300 degrees. In a gas boiler it is only 120 degrees. The lower the temperature, the more condensate forms inside the pipe. Condensate contains aggressive substances that corrode the walls and destroy them;

- heating type. Gas boilers are more durable than other heating systems.

To ensure that the exhausted chimney lasts as long as possible, ensure that it is cleaned and inspected.

Features of the operation of brick chimneys

After the construction of the chimney is completed and the pipe has been successfully put into operation, it is advisable to familiarize yourself with the features of using a brick stove. In order for the heating unit to serve for a long time and without accidents, it is necessary to follow simple but important rules.

- The main enemy of brick is sudden temperature changes. It is better to heat more often, but for short periods of time. It is not recommended to make more than 2 fuel loads per firebox. This is especially true for coal, the combustion temperature of which exceeds 1000 degrees.

- Timely cleaning of the pipe from soot unlimitedly extends the service life of the chimney duct.

- If cracks occur on the stove body and chimney in particular, measures should be taken immediately to eliminate them. Neglected cracks tend to progress quickly and pose a threat not only to the integrity of the brickwork, but also to human health. Carbon monoxide, which is colorless and odorless, but poisonous to all living things, penetrates into the living space through small cracks.

- The slightest malfunction in the doors of the firebox or ash chamber (ash chamber) first significantly reduces the heat transfer of the stove, and then leads to an avalanche-like accumulation of soot on the chimney channels. If you find a door, view or valve that does not close tightly, you should immediately repair or replace it.

- At least once a year it is necessary to carry out preventative maintenance on the furnace. It is best to do this at the end of summer, before the start of the heating season. A daily preventative procedure includes opening the blower door for 15–20 minutes. This simple action will allow you to briefly create maximum draft, which will pull the soot deposited on the walls into the external environment.

- The use of damp firewood has an adverse effect on the cleanliness of smoke ducts, especially in winter. It is more rational to use fuel briquettes, the humidity of which is much lower. Firewood should be prepared ahead of time - drying wood naturally is a long process (from a year to two).

General rules for chimney installation

When deciding on installation, follow the established rules.

- It is prohibited to install a chimney near engineering systems: sewerage, electrical wiring.

- For proper operation of the chimney, a deflector is required. It eliminates the impact of precipitation on the traction and the internal casing of the structure.

- It is necessary to install a snow retainer on the roof in the part where the chimney exits the wall. It protects the chimney channel from mechanical damage.

- The pipes must be secured to the walls in increments of no more than 1 m.

- Before installing a double-layer chimney pipe over the furnace firebox, a sandwich start is installed.

- Non-flammable insulation (basalt) around the sandwich pipe protects the wood from ignition.

- The pipe extends from the boiler strictly horizontally, its length to the wall is no more than 1 m.

- The pipe in the passage through the wall is mounted in one piece without joints.

- To avoid emergency situations, it is important to provide open access to it in order to repair it at any time.

Expert advice

The chimney running outside the building should be collected using condensate. If you collect smoke, condensation can get inside the liner, wet the insulation - the pipe will be poorly insulated (the liquid conducts heat well), the outer liner will heat up, heat up the wall structures, which can lead to a fire. In addition, freezing of the liquid can lead to damage to the pipes, and the acid in the condensate can lead to faster burning of the stainless steel inner liner. At the same time, a small smoke leak in the open air is quite safe, but a large one is clearly visible and can be eliminated by additionally sealing the pipe joint with sealant.

Under no circumstances should you reduce the diameter of the chimney duct opening - this will lead to a decrease or stop of draft.

It is necessary to regularly (2 times a year) clean the chimney channel from soot, and the head from frozen condensate, ice and snow.

How to insulate

The sandwich pipe is already well insulated and does not require additional insulation. An exception is where the pipe passes through a wall or partition. For this purpose, different insulation materials are used, if possible fireproof. Glass wool with a low melting point cannot be used for chimneys; basalt wool cannot be used for coal boilers.

The place where the pipe passes through the wall (sometimes through the wooden structure of the roof overhang) must be insulated with basalt or ceramic wool, foamed vermiculite, or asbestos.

Do not think that asbestos is super harmful - the finished products do not generate dust or emit harmful substances, and the asbestos itself will be closed and isolated from the room with a flange.

Features of working with wooden walls

The peculiarity of wooden walls is their flammability. Therefore, installing a chimney in a wooden house is more difficult than in a stone one. When venting a chimney through a wooden wall, it is necessary to very strictly maintain the distance from the wall to the pipe (at least 260 mm) and perform high-quality thermal insulation of the passage through the wall. It is also important to pay attention to treating the walls with an antipyretic.

The installation of a chimney in a wooden house requires insulation of the wall surface near the outlet pipe of the heat generator and the first mounted monopipe. Insulation is carried out with non-combustible materials - plaster, tiles (porcelain stoneware), stone, fiber cement sheets, sheet metal with an asbestos sheet underneath.

Features of brick and concrete walls

Brick and concrete are resistant to fire - this is a big plus. But nevertheless, insulation in the place where the pipe passes is mandatory, the distance to the wall is at least 130 mm. The rules for installing chimneys were invented for the safety of people, and they should be followed in any case.

Fire safety requirements for chimneys

Fire safety rules during installation of chimneys are as follows.

- In places where the sandwich pipe touches wooden walls or partitions, it is important to use insulating materials.

- If solid fuel equipment is used, it is necessary to install a spark arrester made of metal.

- If the chimney height is below 5m, then an electrically driven smoke exhauster is installed.

- The external walls of the house at the location of the chimney structure are separated from it by a basalt lining or asbestos-cement sheet.

Structure of sleeves in walls and ceilings

The first requirement when integrating pipelines, gas pipelines and sewerage into building structures is the continuity of the insulating layer. This requirement is due to the fact that in the presence of cracks, holes and other defects, air and dust begin to enter the pipes, as a result of which they are deformed and destroyed. Naturally, after building a residential building, you do not want to encounter a similar problem, the solution of which will not only take a huge amount of time, but also waste of materials, up to partial or complete re-filling of the foundation (floors). To prevent such moments, there are sleeves for pipelines, sewers, and cables.

The issue with sleeves needs to be resolved during construction, then it will be problematic

Selecting the type of chimney outlet

There are two ways to remove the pipe:

- leading the pipe outwards from the firebox in a straight line. Most of it ends up on the street.

- by lifting the chimney from the stove and bringing it closer to the middle of the wall height or to the ceiling. Most of it is located indoors;

The second method is more economical and effective, because only one elbow is used to install the chimney structure, which improves draft. In addition, soot plugs are minimized.

What parts does an outdoor chimney consist of?

As already mentioned, the most popular and most reliable of the street ones are sandwich chimneys. A standard pipe sleeve must be routed through wood with particularly careful fire protection, which only sandwich technology can provide. At the same time, there should be no pipe joints at the point of transition through the wall! So, what parts does an outdoor chimney usually consist of, which is led out through the wall? This:

- Pipes;

- Tees;

- Elbow for bending the pipeline in the desired direction;

- Chimney support;

- Clamps. Distance between clamps when attaching to the wall: 60-100 cm;

- Tee with revision, i.e. door for cleaning the chimney;

- A condensate collector with a spout for removing it.

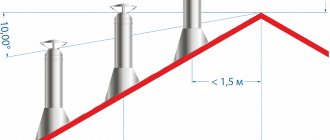

Determining the height of the chimney

The height of the chimney is an important indicator when choosing a design. The thrust and speed of gases moving out depends on it. To calculate the height of the chimney device, the following parameters should be taken into account:

- height of the house. If the height of the house is small - 5 m, then the minimum size of the chimney structure is also 5.5 meters. When it is less than the proposed value, problems may arise: smoke in the building, carbon monoxide poisoning, decreased draft, wear and tear of the heating and fuel boiler. In the case of a long pipe, the efficiency of the boiler installation is minimal. The optimal height of the chimney device is 5-10 m. If the house is high, more than 10 m, then the chimney should be located half a meter above the ridge to prevent turbulence;

- boiler power. The higher the chimney device, the greater the power of the boiler equipment. For power below 20 kW, the chimney height is 5 m;

- roofing material. If the roof materials are flammable, then the distance of the sandwich pipe to the ridge should not be less than a meter.

Building regulations

Chimneys are designed and installed in accordance with SP 60.13330.2012 “SNiP 41-01-2003. Heating, ventilation and air conditioning.”

Chimneys must meet the following requirements:

- The height from the mouth to the grate must be at least 5 meters.

- The internal channel should not have narrowed areas.

- The height above the flat roof is at least 0.5 m (preferably 1 m).

- Head height for pitched roof:

- At a distance of less than 1.5 m from the ridge (parapet) - no lower than 0.5 m from the ridge.

- If the distance to the ridge is from 1.5-3 m - not lower than the level of the ridge.

- If the distance to the ridge is more than 3 m, the height should not be below a line drawn from the ridge at an angle of 10° to the horizontal (down from the horizontal).

- When calculating, you should take into account not only the height of the ridge closest to the chimney, but also the height of the highest ridge of the building (or the highest part of the building).

- Pipes may have inclined sections at an angle of at least 30° to the vertical, with a horizontal pipe displacement of no more than 1 m. The cross-sectional area of inclined sections should not be less than the cross-sectional area of horizontal sections.

Fire safety requirements for chimneys

The distance between the outer surface of brick or any other chimneys (with insulation) and the structures of walls and roof slabs must be at least 130 mm. The distance from the structures to the wooden wall must be at least 260 mm.

If the chimney in the area of the roof overhang passes close to rafters, sheathing and other combustible materials, the passage must be insulated with non-combustible materials.

The chimney of solid fuel, wood and peat heating devices must necessarily have a mesh spark arrestor with a mesh size of no more than 5x5 mm if the roof is covered with flammable materials (bitumen tiles, roofing felt, ondulin) or leaves fall on it. When installing a chimney in a wooden house, be sure to install a spark arrester.

Traction and height

The height of the hog is the main parameter that determines the traction force.

Other factors affecting traction force:

- Sufficient insulation of the pipeline.

- Smoothness of the walls of the chimney channel.

- The thickness of the soot layer on the walls.

- The presence of a head or deflector (which does not interfere with the free exit of smoke).

- Air supply to the firebox.

- Closing the canal with valves, condensate or ice frozen at the mouth.

- Correctly selected internal cross-section.

How to choose a diameter

The diameter of the internal chimney channel must necessarily coincide with the diameter of the boiler outlet pipe (information from the heat generator’s passport).

In SP 7.13130.2013 “Heating, ventilation and air conditioning. Fire Safety Requirements" shows the cross-sectional dimensions of the internal channel depending on the power of the heat generator:

- Up to 3.6 kW – 140×140 mm (diameter not less than 158 mm).

- 3.5-5.2 kW – 140×200 mm (diameter not less than 189 mm).

- 5.2-7.0 kW – 140×270 mm (diameter not less than 219 mm).

How to assemble a sandwich using smoke or condensation

There are two types of element assembly:

- "by the smoke." In it, the lower part is included in the upper component. The upper part is put on top of the lower one. Both pipes are assembled in the same way. If the stove has a high combustion temperature, then this method is suitable;

- "by condensate". The inner pipe is assembled as follows: the upper part is inserted inside the lower one. The outer pipe is mounted differently. The lower part is inserted inside the upper one. When assembling the sandwich, the condensate flows freely into the sump.

Stainless steel for sandwich pipes

The table shows the most commonly used stainless steel grades and their characteristics:

| Brand AISI | Application | Characteristics |

| 430 | For external casings of sandwich pipes | Belongs to economy class. It reacts poorly to elevated temperatures and has sufficient resistance to atmospheric influences. |

| 439 | As an air exhaust from gas boilers and solid fuel installations with a power of up to 30 kW. | The composition includes titanium, which increases thermal stability and resistance to aggressive environments. |

| 316 | The best option for any type of gas boilers. | The composition includes molybdenum and nickel, which increase resistance to acids and high temperatures. |

| 304 | For boilers of low and medium power. | They contain a small amount of nickel and molybdenum. Refers to the economy version of the AISI 316 brand. |

Low-cost models are used for the outer casing; more heat-resistant brands are used for the inside of the chimney.

Step-by-step instructions for installing a chimney through a wall

Let's look at the installation procedure.

For a boiler or stove, it is important to install a stove, non-flammable lining - a podium. You can pour a concrete screed to level the base.

The foundation for the stove, laid on top with bricks

Mark a place for the passage of the pipe and cut it out.

To prevent the wall from catching fire, a protective screen is placed in front of it; it can be made of mineralite. If the boiler is solid fuel, then the protective brick screen is separated from the wooden wall by an insulator - an asbestos-cement sheet.

The chimney is diverted from the pipe at a right angle. The horizontal section is not insulated. The high temperature of the area may cause the insulation to become deformed.

Horizontal thin-walled section of the chimney

Insulation is laid around the sandwich pipe.

Wall penetration

A metal plate is screwed on the outside to protect the wooden wall from overheating.

Mount the tee. It's designed this way. that water flows to the lower part.

Protective sheet PPU and tee

They put up a support.

In some cases, the chimney is supported on a blind area or a separate foundation.

Support for low walls

The chimney is expanded “by condensate”.

Attaching the chimney to the wall with your own hands is done using brackets. The step of their location on the wall is 1 m. Fastening clamps secure the upper part of the gas exhaust pipe.

Mount a deflector or umbrella.

Umbrella

The joints are sealed with high-temperature sealant. We recommend using silicate sealants that can withstand temperatures of 1200 degrees. They have a black or black-gray color and a viscous consistency, harden within 15 minutes after application.

How to choose pipe diameter

For a chimney system, preliminary calculations are required taking into account the power of a boiler or stove operating on solid, liquid, or gaseous fuel. Standard options:

- For a flue from a low-power heating installation of 3 kW, a rolled product with a clearance of 8.5 cm is purchased;

- When the power is over 5 kW, systems thicker than 12 cm are installed.

The minimum thickness of the thermal insulation layer is at least 30 mm (basalt wool), for diesel fuel stoves - thicker than 4.5 mm. The installation process is always preceded by calculations of pipe diameter and thermal insulation thickness.

The installation process is always preceded by calculations of pipe diameter and thermal insulation thickness.

Do-it-yourself chimney installation

The passage of the chimney through the wall with your own hands is carried out exactly according to the instructions. If you know the nuances of construction, are not afraid of heights, and know how to use working tools and equipment, then you can do it.

Drawing and diagrams

Before purchasing materials and starting work, it is necessary to draw a drawing or develop a diagram of the location of structural elements, their sizes, and the distances between them. It is important to determine the list of tools and components needed for independent work. Consultants in stores that sell stainless steel sandwich pipes of well-known and proven brands that are not produced in artisanal conditions can help with this. These include CRAFT, BALTVENT, TERMOFOR, TEPLOV and SUKHOV, VULCANO, FERRUM, PHOENIX and others.

Selecting a place to exit through the wall

The side wall is located under the roof overhang. It gets water from icicles and rain if there are no special gutters. The front wall is located under the roof overhang. Water does not enter the pipe.

It is best to display the structure through the front wall. It is important that there is no balcony or windows under the ledge, so that you do not have to go around them when installing the structure. Any deviation from the vertical is fraught with a decrease in traction.

The device can also exit through the side wall. This solution is much worse, because you will have to make a hole in the roof overhang, assemble and install a drainage system to avoid flooding the sandwich pipe sleeve, getting the insulation wet, and heating the chimney.

How to remove a chimney through a wall

The chimney passes through the wall using a longitudinal unit. A steel flange with a pipe is attached to the wall. First, install the outer flange, pass the pipe through it, and secure it. Insulation is laid between the pipe and the flange, and an internal flange is installed. The flanges are sealed with waterproof sealant.

How to attach a chimney to a wall

Fastening of chimneys - clamps and brackets. The step between the fastenings is 1 m. The lower part is fixed to a bracket mounted on a wall or stand. If the sandwich pipe rises 1 m above the roof overhang, then braces are used for fastening; at 1.5 m, a special rod is firmly fixed to the facade. The device is attached to the rod with clamps.

Insulation

The sandwich pipe is already insulated during production. Therefore, thermal insulation is not performed. The exception is where it passes through the wall. If the boiler system is coal-fired, then the use of basalt insulation is not recommended. Glass wool should also not be used because it has a low melting point.

Sealing

After installing the structure, the joints should be sealed. To ensure a strong connection, the edges of the elements are coated with sealant. The best solution is silicate sealant, which is not afraid of temperatures of 1200 degrees. Flanges and ebbs are treated with silicone sealant. It retains its properties at +250 degrees.

Insulation

According to clause 4.4.4 of SNiP 41-01-2003, chimneys and chimneys must be equipped with thermal insulation, which:

- Prevents burns.

- Reduces heat loss.

- Eliminates moisture condensation.

In this case, the temperature on the insulation surface should not exceed 40°C.

Insulation is used for insulation.

Mineral wool

Under the name mineral wool there is:

- stone made from basalt rocks;

- glass from glass factory waste;

- slag from metallurgy waste.

These options have limitations:

- Glass wool is inconvenient to install, gets wet, absorbs moisture, and quickly loses its insulating properties.

- Slag emits substances harmful to humans when wet and quickly cakes.

Any material needs protection from precipitation. The wool is wrapped around the pipe, secured with metal clamps, and then covered with an outer layer of steel sheet.

Basalt cardboard

At its core, it is stone wool, but the binding material is bentonite clay, and not formaldehyde resins. The material is environmentally friendly. They produce two varieties - with and without a layer of foil.

In addition to the pipe itself, you can protect the wall adjacent to the stove from heating.

Minerite

Cement-fiber mineralite does not emit harmful substances and has excellent heat and sound insulation. Minerite protects stoves and chimneys from flammable walls and objects

The material will help to arrange the passage of the chimney through the wall or ceiling.

Fireproof plasterboard

The sheets have a structure similar to ordinary drywall, but the outer part is impregnated with fire retardants. The material is used to protect wooden walls from heating by stoves and chimney pipes.

Glass magnesium sheet

Glass magnesite sheets are a 5-layer cake. The central one is the thermal insulation filler. It is “covered” with a reinforcing mesh and an outer layer.

The sheets retain heat well and bend easily, which allows you to insulate surfaces with complex geometries.

Possible installation errors

Installation errors affect the correct operation of the chimney. Let's look at some of them to prevent their occurrence.

- If the insulation of the passage through the wall is carried out poorly and the amount of heat-insulating materials is minimal, then the structure will overheat.

- If there is no low tide on the roof overhang, there is a risk of water flooding the insulation materials and compromising their integrity and functioning.

- Incorrectly calculated height of the chimney device impairs draft.

In addition, we recommend using high-quality sandwiches. In cheap and low-quality pipes, the materials are short-lived. Over time, the insulation shrinks and loses its positive qualities. Local overheating creates a dangerous fire situation.

Material

To make a sleeve for sewer pipes, a passage through the ceiling can be used:

- Metal. Steel products are characterized by strength, reliability and durability. They can be installed in any ceiling. Steel products can withstand loads of more than 100 kg per 1 m 2 . Pipeline protection can be installed directly at the construction site and at one of the stages of manufacturing a reinforced concrete structure. Before concreting, the edges are sanded to prevent damage to the polypropylene pipeline.

- Polymer materials. A polymer sleeve is used to arrange the sewerage passage through the ceiling between floors. The material is resistant to wear and low temperatures.

Advantages and disadvantages

Advantages:

- The most important advantage of venting the chimney through the wall to the street is the greater fire safety of the room with the heating unit and the building as a whole.

- An external chimney is safer in terms of smoke from the part of the pipe facing the wall, leakage of exhaust gases and poisoning of residents with carbon monoxide or carbon monoxide.

- Lack of holes in the roof , disruption of the rafter system, or passage of structures in the ceiling. The passage of a chimney through a wooden ceiling always creates an additional fire hazard. The absence of holes in the plank sheathing of the roof and the absence of additional reinforcement of the rafters with timber makes the work easier and strengthens the roof.

- Saving space in the room , a bulky structure indoors does not always fit well into the interior - installing a chimney outside the building makes it possible to decorate a room with a stove or fireplace to your liking.

- When modernizing a building, installing an external chimney is much easier and faster than an internal one.

- Exterior structures are also much easier to repair and upgrade.

Flaws:

- A ceramic chimney requires a separate foundation.

- Sandwich pipes must be securely fastened, especially in the upper part - the structure, despite its low weight, has a fairly significant windage.

- In many cases , water from the roof slope pours onto the chimney when it rains, and in the place of the eaves it is necessary to install special flashings or install additional storm gutters.

- The chimney outlet through the wall must be very carefully insulated with non-combustible materials.

- Sometimes an external chimney disrupts the overall design of the building. And sometimes it gives it some color.

Do it yourself or order it?

You can only make a brick chimney yourself or a structure from an insulated single-layer steel pipe.

But laying smooth and beautiful walls of a brick pipe is more difficult than laying just a brick wall, and you must have the skills of an experienced mason. Single-layer pipes will have to be insulated; the quality of self-insulation is much worse than that of ready-made factory-made pipes.

You can independently install a chimney made of ceramics and sandwich pipes. It is impossible to manufacture elements of such chimneys on your own, but the industry produces many modules that allow you to assemble a pipeline of any design.

The question of whether to install a pipe yourself or hire a team of professionals is quite complicated.

Installing a chimney is quite a complex job, and it is worth thinking about and carefully assessing your capabilities: is it possible to take prefabricated scaffolding or scaffolding of the appropriate height, will you have assistants, do you have the skills to install building structures, how do you react to height.

What you need to know

There are rules that must be followed when installing the system:

- It is important to correctly calculate the diameter of the pipe. It depends on the boiler power and other parameters. If you purchase a pipe of the wrong (small) cross-section, smoke may occur due to reduced draft. High thrust with an excessively wide pipe will increase fuel consumption.

- When passing a chimney through a wall, a right angle (90 degrees) must be maintained.

The optimal distance between fasteners is considered to be 60 cm, the maximum step should not exceed 100 cm.