The chimney is an important part of heating appliances running on gas, solid or liquid fuel. In fireplaces, stoves, baths and boilers, it is important to maintain a certain level of draft in order to clean the air from combustion products. The correct choice of chimney pipe is the basis for the safe operation of the heating device. Errors in chimney construction can lead to life-threatening situations.

What is a chimney and how does it work

The chimney is one of the main components of your heating device, be it an old brick stove or an ultra-modern gas boiler. Your safety and budget depend on the free passage of flue gases through the chimney: with a well-designed and constructed chimney, the stove consumes much less fuel. Previously, chimneys were built by professional stove builders. Current technologies make it easy to do this yourself. Of course, you need to study the issue and carefully follow the drawing and manufacturing procedure.

Required Tools

The list of tools and devices necessary for making a galvanized chimney pipe with your own hands is determined by the properties of tin, in particular softness and ductility. Processing this type of material does not require the special efforts required to work with sheet materials.

Therefore, when producing tin chimney pipes, the following set of tools is required:

- Scissors for cutting metal. This tool helps to cut sheet material into the required pieces without much difficulty, since the largest thickness of the sheet reaches 0.7 mm.

- Hammer with a soft striker. You can also use a wooden hammer, mallet, or a steel tool with a soft rubber grip. However, the latter option is used very carefully or not at all, since it can cause deformation of a thin sheet of tin and ruin the entire work.

- Pliers. With the help of this tool they solve the problem of how to bend a pipe made of tin, because it is steel, although thin, therefore it is impossible to bend it with your hands.

- Crafting table. This device is necessary when cutting material and when applying markings.

- Calibrating element. This can be a pipe product with a diameter of more than 10 centimeters, as well as a corner with edges of 7.5 centimeters. These elements must be well secured, since the joining seam will be riveted on their surface.

In addition to these tools, you should prepare a ruler or tape measure and a marker, which is a steel rod with a sharp sharpening.

What materials are they made from?

Chimneys are made of bricks or pipes; the latter are divided into chimneys made of stainless steel, iron sheet, asbestos-cement, fireclay, glass. Let's look at their design, advantages and disadvantages, and the ability to maintain even traction without jumps.

Brick

The most traditional of all. Advantages: durability; powerful thermal inertia: they immediately provide good traction, and when warming up, they adapt to the operation of the stove; will never give reverse thrust or its pulsation. Disadvantages: unsuitable for boilers, may result in burner flame failure and accident; a rectangular cross-section gives an uneven flow of gases, combustion products settle more strongly; difficult to build and repair; require a foundation due to heavy weight.

Ancient brick pipe with sleeve

Pipes

This is a much more practical type of chimney that can be used in all cases. Depending on the material, the pipes are different.

Asbestos cement pipes

Advantages: round; lungs; cheap; easy to install. Disadvantages: low heat resistance (used for furnaces with low flue gas temperatures, up to 3000); it is difficult to make a curved structure (rubber couplings are a bad solution); porous structure; rapid contamination by soot and, as a consequence, the possibility of its ignition.

Asbestos cement pipes in a stack

Ceramic

They consist of several parts: a chimney made of refractory ceramics, thermal insulation and a concrete body. Advantages: durable; round and smooth inside, so no need to clean them; have thermal insulation and tightness, fire resistance and heat resistance; easy to install; Suitable for any boilers, stoves, fireplaces. Disadvantage: expensive, difficult to repair and difficult to connect into a curved structure.

Ceramic pipe assemblies

Glass

Advantages: even more chemically neutral and even smoother than ceramic; durable. Disadvantages: expensive (100 times more expensive than steel); the rest are the same.

Fragment and chimney made of Schott glass - Rohrglas

Polymer

Are used only for sleeves. Advantages: easy to install, lightweight, flexible, cheap, durable. Disadvantages: fragile and cannot withstand high temperatures.

Polymer chimneys for fireplaces FuranFlex RVW

Lining is the insertion into an old, usually brick, chimney pipe of a liner in the form of a polymer, flexible metal corrugated or metal pipe for the restoration of the chimney.

Lining of brick chimneys with FuranFlex RVW polymer pipes

Steel

Steel chimneys are optimal in terms of price, quality, and ease of installation.

Advantages

With the advent of a large number of factory products for assembling galvanized steel chimneys, the need to make pipes with your own hands has decreased. However, homemade pipes allow you to reduce costs and choose the ideal diameter. In addition, they are used to equip drains, so the ability to make pipes with your own hands will be useful in everyday life. Metal chimneys have the following advantages over others:

- A light weight. Smoke exhaust ducts made from homemade galvanized pipes weigh much less than brick or ceramic ones. Therefore, to install this type of chimney, there is no need to equip a foundation, the cost of pouring which exceeds the cost of material and installation work.

- Fire safety. According to building codes, steel chimneys are completely fire safe. High quality metal can withstand heating up to 900 degrees, so it is suitable even for solid fuel stoves and fireplaces.

- Low cost. Chimney pipes made of steel are the most democratic way to organize smoke removal; the cost of installation is several times lower than the installation of brick and ceramic analogues.

- Easy to assemble. You can easily assemble a chimney made of galvanized steel with your own hands according to the instructions, thereby saving money spent on hiring professional workers.

DIY pipes

Important! The effectiveness of smoke removal depends on the correct assembly of the chimney. Experienced craftsmen advise choosing a predominantly vertical configuration with the least number of turns. Each rotating element acts as an obstacle to the smoke, reducing the draft force.

Types of steel structures

There are two main types of chimneys according to their orientation relative to the heating device: straight (attached) and side (attached).

Straight chimneys

They are placed above the heating device, indoors and pass through the internal ceilings and through the roof. Most often, this is the best solution specifically for stoves. Advantages:

- Acid condensation does not fall out, or falls out only slightly, but the ease of passage of gases through a straight chimney is important.

- Less soot deposits, easy to clean yourself, and therefore less fire hazard.

- Works well without a gate draft regulator.

- Only the pipe on the roof is visible on the house, this is aesthetically pleasing.

Flaws:

- Passing through floors and roofs is more difficult than through a wall.

- Large unevenness of thrust, pulsating and even reverse thrust during gusts of wind. Therefore, for modern boilers with an emergency shutdown device, such a chimney is not suitable, even if equipped with a complex deflector.

A straight chimney passes through the ceilings and roof

Side tie-downs

The axis of such a structure does not coincide with the axis of the heating device. Advantages:

- Installation outside the house with a single passage through the wall.

- Ease of construction.

- The presence of a container for collecting acid condensate, completely eliminating its flow into the heating device.

- Even with the simplest fungus it works stably in strong winds, and if a deflector is mounted on it, the draft will always be direct and stable.

- Makes it possible to precisely regulate thrust due to low thermal inertia. This will always ensure optimal fuel consumption.

Flaws:

- In cold weather, condensation can turn into ice and burst the container. The container may freeze up to the tee, which will block the draft. Hence the need to place a container for condensate inside the house.

- The place through which the chimney exits to the outside is designed as a passage unit. But in winter, the unit absorbs moisture from the air, and the insulation can cake and settle. Then thermal stress will accumulate in the upper part of the assembly, which can cause a serious crack in the wall.

- The weight of a chimney, unlike an attached one, lies on the passage unit; this can also affect the insulation and cause the phenomena described above.

- Cleaning is quite difficult due to the bends of the chimney. A specialist is required.

A side, or attached, chimney runs along the outer wall of the house

Lateral internal

However, side chimneys can be located both inside the house and in the thickness of the wall, then contact with the roof cannot be avoided.

The difference in attached chimneys - outside and in the wall

No one type of chimney can definitely be called the best. Each of them is good in its place and depends on the conditions: type of heating device, roof structure and floor beams, wall material and type of chimney (single-wall or sandwich). The advantage of the attached side chimney is that in this case there is no need to go through the roof. But it is completely excluded in the case of single-wall pipes due to the cold in winter.

The correct chimney for a solid fuel boiler with your own hands

Immediately after installing the solid fuel boiler, you should begin creating a system for the release of gas and smoke. This work can be entrusted to hired craftsmen, but this will cost money. Self-installation will not only save money, but also completely understand the structure of the chimney, which is useful for its further operation and maintenance.

Order or make a chimney for a solid fuel boiler with your own hands - which is more profitable?

The answer to this question is not as obvious as it seems. By design, solid fuel boilers are similar to conventional stoves. And it may seem that installing a chimney is a simple task for him. You shouldn't fall for this misconception. For high-quality removal of combustion products, a well-thought-out, durable and reliably executed design is required. Neglecting these rules is unacceptable, because the lives of people living in the premises depend on it. Loose joining of materials or design errors lead to the penetration of carbon monoxide, which is hazardous to health.

Therefore, in the absence of stove installation skills, it is wiser to entrust such a responsible job to a professional. If you have experience and confidence in your own abilities, you can carry out the installation yourself. However, it is better to order the calculation of chimneys for a solid fuel boiler from a specialized organization.

Chimney device

Regardless of the material used for installation, all chimneys for solid fuel boilers are structurally similar. The smoke removal system consists of the same functional components:

- Chimney. A cylindrical or rectangular section through which combustion products are removed from the boiler. Must be made of durable and heat-resistant material.

- Condensate collector. Everyone remembers from the physics course that heated air, when it comes into contact with a cold surface, forms condensation on it - small accumulations of moisture. To prevent drops of water from flowing into the boiler, the chimney must be equipped with a means to remove them from the system. A condensate collector is equipped in its lower part, which does not contact the boiler directly, but is connected through a tee.

- Gate - a barrier to stop the supply of air to the system from the boiler. The damper is necessary for economical operation - so that after the boiler stops operating, the exit of warm air into the external environment is blocked.

This is a typical smoke exhaust system. When working with specific materials, it may have slight differences and additions. For example, steel chimneys are equipped with a linear deformation compensator. It is responsible for the tightness and reliability of the system, because constant cycles of heating and cooling lead to loosening of the chimney. This reduces the density of components joining.

Installation rules

- Fire safety should be the most important guideline when constructing a smoke exhaust structure for a solid fuel boiler. The distance from the chimney walls to other surfaces must be at least 38 cm. When building an internal type chimney, you need to be extremely careful in insulating the places where it passes through the ceilings.

- The walls should not be narrower than 10 cm, including insulation.

- Height directly affects the efficiency of gas removal and the draft force in the chimney system. It is necessary that the top point of the chimney be at a distance of at least a meter relative to the roof.

- Accurate calculation of the internal cross-sectional area. It is necessary that this value remains constant throughout the entire length of the chimney in order to avoid a decrease in efficiency.

- The maximum length of horizontal sections in the system is 1 m.

- The design must have a condensate collector and doors for maintenance.

How to calculate the chimney diameter for a solid fuel boiler

The correct chimney for a solid fuel boiler with your own hands

How to make a chimney for a solid fuel boiler with your own hands. Types of chimneys for solid fuel boilers. Chimney structure and installation features.

Types of materials

Steel chimneys are made of black steel, low-alloy steel and galvanized iron

Black steel

This is a simple carbon steel without alloying additives. Advantages:

- The cheapest

- Low contamination with soot and easy to clean

- In terms of installation qualities - exactly like steel

- Does not require a foundation for installation.

Flaws:

- High thermal conductivity leads to the fact that the gases quickly cool down and a lot of condensate is formed, which must be removed

- Pipes get very hot, so they require special structures where they pass through walls and roofs

- It is impossible to make an external chimney due to lack of thermal insulation

- In terms of durability, it is much inferior to a steel pipe (service life is only about five years), as it is subject to severe corrosion

- It has low heat resistance - it burns out quickly in high-temperature flue gases.

Black steel chimney parts

Attention! To increase the service life of a black steel chimney, you need to make a minimum number of joints and use thick-walled pipes.

Low alloy steel

It belongs to ferrous metals, but it contains additives of nickel, chromium and molybdenum in quantities equal to those in stainless steel. Advantages and applications: the same as for pipes made of black steel, but low-alloy steel corrodes more slowly.

Galvanized iron

This is the worst of the three previous options. The zinc layer burns out very quickly, and the thin, unprotected iron begins to corrode and collapse.

Galvanized iron pipe is the worst of all options

Stainless steel

Stainless steel is heat-resistant and resistant to acids - combustion products. Such chimneys are durable and strong; resistant to temperature changes, corrosion, condensation; inexpensive, easy to assemble due to its modularity, which allows you to build a system of any complexity; easy to repair; smooth inside, so soot does not settle, and the chimney requires almost no cleaning; They have a low heat capacity, so heating any stove is easy: a stable draft immediately appears. They also come in several types, depending on the alloy of the steel used for the pipe and the design.

Corrugated steel pipes

These flexible metal pipes are made from steel strip and are used for sleeving only. Their service life is limited due to the uneven surface, on which combustion products deposit more strongly: soot, acids.

Corrugated metal pipes - used only for lining brick pipes

Single wall stainless steel pipes

Their wall thickness is usually from 0.6 to 1 millimeter. The advantages are the same as all non-corrugated metal pipes, but these are much more durable than others. The disadvantages are the same as those of non-corrugated metal pipes.

Details of a single-circuit steel chimney

Stainless steel sandwich pipes

The disadvantages of single-wall pipes can be eliminated by a simple design improvement: the manufacture of an insulated steel pipe, or a sandwich chimney. Their advantages:

- Thermal inertia is greater than that of single-wall pipes - flue gases pass quickly, but cool slowly, so little soot and aggressive condensate are formed

- When passing through floors and roofs, there is no need for overly complex thermal insulation units, since such chimneys heat up less

- External installation, without passing through the roof, is possible

- Installation is generally quite easy

Flaws:

- Sandwich pipes are noticeably more expensive than single pipes

- Completely unsuitable for brick kilns. A stove with such a chimney will produce reverse draft during gusts of wind.

But since people are now concerned about the efficiency of their heating devices and traditional stoves are rare, sandwich chimneys have become widespread.

Stainless steel sandwich pipes

Installation

Having planned the design and assembled all the components, you can begin installing the chimney.

Installation recommendations:

- the chimney should not intersect with other communication systems;

- all work is carried out from the boiler to the chimney;

- all connections are “sealed” with a special sealant that can withstand temperatures up to 10,000;

- All clutches use clamps;

- passage pipes made of non-combustible materials are installed in the ceilings; a sleeve must be provided in the wall;

- horizontal sections should be less than one meter;

- the chimney is fixed to the wall using a support bracket, which makes the pipe stable and motionless;

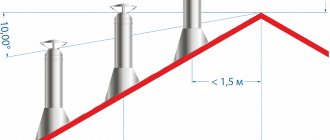

- place the brackets at a distance of 1.5 meters from each other;

- A roof trim is installed directly on the roof slope around the pipe and an umbrella is placed on top of the chimney.

- if there is a roof made of flammable materials, the pipe must protrude at least 120 cm above the roof level; a spark arrester is required;

- If there is a roof made of non-combustible materials, the projection must be at least 60 cm.

Basic requirements for chimneys

- you cannot connect several installations into one chimney;

- the chimney must be sealed to eliminate the possibility of gas leakage;

- should not have roughness or unevenness of the inner wall that could interfere with traction;

- the material must be resistant to condensation;

- the chimney must be warm (insulated);

- the thickness of the chimney wall for a gas boiler is at least 0.6 mm, for liquid fuel at least 0.8 mm, and for solid fuel boilers from 1 mm;

- the chimney diameter must be selected individually for each heating device and range from 100 to 300 mm;

- All installation work must ensure maximum safety.

Work technology

- the necessary turning angles are welded.

- work should begin by connecting the boiler to the adapter leading to the chimney;

- if the chimney is discharged through the wall, then you need to cut a hole with a slightly larger diameter than the pipe itself. This gap is used to install a sleeve that protects the wall from the temperature effects of the chimney;

- the distance between the sleeve and the pipe is filled with expanded clay or asbestos;

- if the chimney is exhausted through the roof, then the ceiling material should be protected with galvanized steel with a layer of insulation. To do this, a hole of a larger diameter is also cut into which the material is installed;

- When crossing ceilings or a roof, the chimney is fixed using a support plate or support ring.

- When assembling the structure, sealant and clamps are used.

Fire safety

- chimney cleaning should be carried out at least 2 times a year;

- the channel should not have sharp bends or defects in the internal surface;

- thermal insulation of the chimney should prevent reaching the “dew point”;

- there should be no soot on the outside of the chimney;

- pipe connections should not be located at the intersections of the chimney with walls and ceilings;

- It is prohibited to place horizontal sections and openings in the attic for cleaning the chimney;

Recommendations from the experts

- Good draft and absence of condensation will be ensured by the correctly selected pipe diameter. To determine it, you can use the documentation for heating equipment or calculate it yourself. According to standards, the pipe diameter must exceed 8 cm2 per 1 kW of heating device power.

- To make a double-walled chimney, it is better to take an inner pipe with a thicker wall, this will provide additional service life for the chimney.

The design of a double-layer chimney and its distinctive features

This is a structure of two steel pipes inserted into each other, different in diameter. The outer one is called the casing. A pyre-resistant insulation is placed between the pipes, usually basalt wool (laid so that the fibers are oriented along the pipe) 30–35 millimeters thick, capable of withstanding heat of a thousand degrees. Mineral wool is completely unsuitable.

Sandwich chimney parts

Expert advice

- Give preference to vertical structures. Minimize the number of turns that reduce the aerodynamics of the contour.

- Choose pipes with a thicker wall, they will extend the “life” of your chimney.

- The first sections of pipes are subject to the greatest heating, which often damages the thermal insulation layer. In some cases, it is advisable to replace this area with a tank for heating water or a heater grid.

- To improve aerodynamic characteristics, every 10 meters the diameter of the pipe is reduced by 3 times.

- At the junctions of sandwich blocks, the insulation does not fit tightly enough, which leads to overheating of the circuit in these areas. The problem can be solved by installing an additional layer of insulation in these places yourself.

How to insulate

A rapidly cooling chimney causes a decrease in draft force and the formation of condensation, which leads to corrosion and gradual destruction of the pipe. The insulation works on the principle of a thermos.

And if coaxial chimneys are immediately made with insulation inside, then single-wall chimneys will have to be insulated yourself. Most often, fire-resistant basalt wool or fabric is used for this, which is wrapped around the pipe in 2-3 layers and secured with iron clamps or steel wire. Waterproofing is laid between layers of wool. The structure is topped with a stainless steel or galvanized box.

Features of using sandwich pipes for baths

Since a bathhouse, as a rule, is built of wood (and if it is made of foam blocks, then it is lined with flammable material), issues of thermal insulation become of particular importance. It is prohibited to use single-layer chimneys for bathhouses - only brick and sandwich chimneys are allowed. All distances from the chimney to flammable objects must be carefully verified and observed in accordance with SNiP. All pyrohazardous surfaces must be insulated with vermiculite or asbestos. It is forbidden to install a deflector on a sauna chimney due to its strong windage. The distance from the chimney to the wall is at least 25 centimeters!

Caution: under no circumstances should a sauna ventilation system be combined with a chimney.

Preparatory stage

First, markings are applied to the sheet of tin, according to which the semi-finished product will be cut. In other words, the necessary part is cut from a certain sheet of tin, from which the contour of the future pipe will be formed. The marking process is carried out as follows: the sheet metal is laid out on a workbench and a segment equal to the length of the pipe is measured from the top edge. A mark is placed here with a marker.

Then, using a square, draw a line along this mark perpendicular to the side edge. Now along this line the circumference of the pipe, the same is done along the upper edge. In this case, about 1.5 cm is added on both edges to form the joining edges. The upper and lower marks are connected and the workpiece is cut out.

To determine the circumference, you can use a tape measure, or you can remember your school geometry course.

Operation, repair and cleaning

You have received a chimney that will serve you for fifteen years. But you need to follow the simplest rules. It is impossible to replace a boiler or furnace so that the temperature of the flue gases is higher than that calculated specifically for this chimney. It is necessary to monitor the condition of the heat-insulating substance in the wall opening and trouble-free drainage of condensate.

Sandwich chimneys on a brick wall

Such a chimney needs to be cleaned approximately once every three months, but it is better not to use a mechanical method at all. In severe cases, you need to call specialists. And your destiny is chemical cleaning. This is a substance in the form of a briquette or powder, which, when burned in the firebox of a boiler or stove, releases chemicals that dissolve soot and other deposits in the chimney.

Chimney sweep powder for cleaning chimneys