How and what to use to fix a leak on the roof near the pipe?

A situation where a pipe on the roof is leaking, or there are leaks in the roof near it, requires immediate intervention. Otherwise, such damage to the roof can lead to harmful consequences. Fortunately, fixing such a defect with your own hands is quite simple. The main thing is to decide how to seal the gap between the pipe and the roof. To do this, you need to choose the right method to eliminate the cause of the leak, determining the location of the leak and preparing the required materials, which must be selected taking into account the type of pipe and roof.

How is it carried out?

If the owner of the property notices that a leak appears near the pipe, then in most cases the cause is poor-quality roof sealing. To avoid leaks, specialists install aprons. Installation must be carried out in accordance with the algorithm:

It is necessary to lay a drainage gutter

. It is required to remove moisture from the pipe.

To ensure maximum joint tightness

roof covering and chimney, an internal apron is used for the pipe on the roof.

You need to cut out the waterproofing backing

, which should be placed under the bottom edge of the apron. If the roof is covered with sheet material, then the edge of the substrate must be brought out between the sheets from below. It is imperative to create a side to direct the water along the slope.

Roof covering must be laid around the pipe

.

The external apron is installed using an identical algorithm

. The only difference is in securing the top edge to the chimney.

Insulating apron

can be created manually or a ready-made version can be purchased. The chimney must pass inside the apron.

Attaching the apron to the pipe On our website you can find contacts of construction companies that offer roof repair services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Repairing pipe leaks on the roof

Before answering the question of what and how to fix a leak on the roof near the pipe, you need to decide what material it is made of. It is very important. This is the starting point for repair work.

The chimney duct can be mounted from the following materials:

When eliminating a leak, you need to follow a certain sequence of actions, which can differ significantly for each chimney material. Therefore, the technology for eliminating such defects for each type of pipe should be considered in detail.

Fixing brick chimney leaks

If a pipe made of red brick is leaking on a roof, then to fix the problem you will need the following materials and tools:

- cement grade M 400 or M 500;

- sand, preferably river or sea, but quarry sand is also suitable;

- water;

- Master OK.

How to seal the gap between the pipe and the roof, having all of the above? You must adhere to the following sequence of actions:

- A cement mortar is made from the prepared materials by mixing 3-4 parts of sand and one part of cement;

- the detected leak site is thoroughly cleaned of dirt and remnants of destroyed bricks;

- The prepared mixture is applied using a trowel to the damaged areas.

It is better to repair a roof pipe in sunny, dry weather. This way the cement mortar will harden much faster.

Repairing metal chimney leaks

If a metal chimney is leaking, then to correct the current situation you will need:

- special clamps with a rubber gasket that can be secured to the pipe where the gap occurs. The diameter of the clamp should be approximately equal to the thickness of the pipe. Its width should be slightly larger than the size of the crack;

- in addition, small cracks can be eliminated using cold welding, instructions for use of which can be found on the packaging.

The specified materials for eliminating metal pipe leaks can only be used as a temporary measure. As soon as possible, the damaged section of the chimney must be replaced with a new one.

Repairing asbestos chimney leaks

If water flows through an asbestos pipe, then you can eliminate the leak by performing a number of the following actions:

- First of all, you need to stock up on cotton fabric and “Iron Lead” paint. You can buy such materials at any hardware store;

- then the chimney, namely the damaged area, should be cleaned of dirt and dust;

- the paint is applied in a thick layer;

- fabric is tightly wrapped over it;

- Then the paint and varnish material is reapplied.

For the most part, such repairs are also a temporary measure that allows you to postpone the replacement of the chimney pipe for a certain period. You should not delay replacing a damaged asbestos chimney.

How to cover cracks in an iron stove/chimney?

I was thinking about Bulleryan, but I don’t want to get into trouble with the installation - I don’t have time for that. And putting Bulleryan in my birdhouse is like matching an expensive watch to a Bolshevik suit :-))

Thanks for any advice!

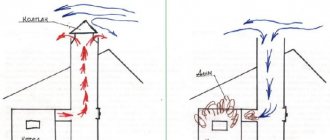

Has the stove always smoked like this or has it only recently started smoking while it’s cold? To ensure there is traction, you can try cleaning both the stove and the chimney from soot - it helps a lot. Make a broom (or brush) - from scrap materials - hang it by a rope and a sinker for weight - lower it into the pipe several times. To prevent soot from appearing, you need to periodically heat it with aspen wood.

Extending the pipe will also help. Especially during gusts of wind, there will be no blowing from the roof planes.

To make the draft appear faster, you can burn a pile of newspapers in the firebox before kindling to create draft. It’s better to burn newspapers not in the firebox itself, but in the cleaning door, which should be located at the base of the chimney.

And if you don’t bother with Buleryan, does it make sense to buy an ordinary potbelly stove on the market? I saw these on the Baltic market (Nosorizhskaya highway, along which I have a dacha), they are inexpensive, it seems there are no special requirements for installation. How are they even drowning?

Thanks to everyone who responded - I read all the answers.

What’s strange is that I’ve never seen a potbelly stove with an ash pit instead of an ash pan :-), like yours. In general, it is good to use the blower door to regulate the intensity of draft/burning, depending on the weather.

Repairing leaks near a pipe

If water flows through the chimney during snow melting or rain, the reason for this is a violation of the tightness in the place where the pipe and the roof are connected. If there is a roof leak near a pipe, there are a number of ways to fix the existing problem:

- apply bitumen tape;

- install rubber cuffs;

- make and install a metal apron.

All of the above methods allow you to close the leak, so they should be considered in more detail.

Using bitumen tape

If a chimney leaks due to rain or melting snow, then the simplest and cheapest way to eliminate the leak is to make an apron from bitumen tape. To perform such work you need to use the following materials and tools:

- bitumen tape;

- scissors;

- metal brush;

- gas burner.

The cracks are sealed by taking the following measures:

- first you need to use a metal brush, which is used to clean the roof around the chimney and its outer lower part;

- Remove any remaining dust and dirt with a damp cloth;

- At the junction of the pipe and the roofing material, pieces of bitumen tape are glued. It doesn't matter which side the gaps are on. You should create a full apron around the entire pipe;

- the glued tape is heated with a gas burner, which is pressed as tightly as possible to the roof and pipe;

- to seal the joint more reliably, the tape can be additionally secured with a wooden block or board (this cannot always be done, it all depends on the roofing material).

Bitumen tape is a universal material. It can be used if a pipe or roof made of any materials is leaking. The tape is capable of performing its functions efficiently for 2-3 years (depending on the amount of precipitation and other factors).

Using the rubber cuff

If the roof is leaking near the chimney duct, then this situation can be corrected by using a rubber cuff, which can be purchased at almost any hardware store. It is installed as follows:

- a cutout is made in the upper part of the cuff, the diameter of which is slightly less than the thickness of the pipe;

- the prepared cuff is put on the outer part of the chimney duct and lowered to the roof level;

- To avoid the possibility of repeated leakage, it is necessary to use sealant at the point where the roof comes into contact with the lower part of the cuff.

Some types of cuffs are not easily glued to the roof. Some models can be screwed to the roof with self-tapping screws, but this is only possible in cases where the roof is not made of tiles or slate.

The main disadvantage of the rubber collar is that it cannot be installed on a square or rectangular pipe. What to do in such a situation? Use any other leak repair method described above and below.

Arranging a metal apron

A chimney leak at the junction of the pipe and the roof can be eliminated by installing a metal apron. This is done as follows:

- An apron is made from a thin sheet of tin, the dimensions of which must match the dimensions of the pipe. A similar product can be purchased at a hardware store;

- the upper part of the apron is attached to the pipe and crimped using a clamp. The crimping process must be carried out carefully. Gaps are not allowed;

- The lower part of the apron is installed on the roof and secured with self-tapping screws. To ensure that the damaged area of the roof does not leak, in the future the lower part of the plate should be secured on top of the roofing material, and the upper part should be removed under the sheathing.

At this point, the manufacture and installation of the metal apron can be considered complete. The sealed area will no longer cause problems. For additional sealing, the metal apron can be equipped with a rubber lining, and the contact point between the cone-shaped part and the chimney duct can be sealed with sealant.

A leaking roof near a chimney can be repaired in many ways. Such cracks are closed in 5-10 minutes, but it is worth understanding that such repairs cannot be considered high-quality. The sealed joints between the roof and vertical elements will certainly make themselves felt in a few years. Thus, such local repairs are a temporary measure. It is designed to protect against moisture entering the room until a full roofing repair is completed.

Elastic apron

It is best if the chimney is insulated before covering the roof with corrugated sheeting. The chimney opening in the roof is made wider by several centimeters, the joint is filled with heat-insulating and preferably hygroscopic material. Next, the chimney is placed in a steel box. Heat-resistant material is placed between the pipe and the box and the first layer of waterproofing is made from a film sheet and fixed tightly.

When the corrugated sheeting is already in place, external waterproofing work is carried out. For this, ready-made sealed elements are used, or everything is done manually. The sealed material is adjusted to the size of the pipe and put on top, its upper edge rises to the walls of the chimney and is attached using a clamp and adhesives, and the lower edge is pressed to the roof using a rigid sealant.

If you don't seal the joint

When removing the chimney, a hole is made in the roof. The gap between the coating and the walls of the chimney is sealed with special aprons, collars and seals. They can be bought at any hardware store. These protective elements are easy to make with your own hands.

If you do not seal the seams on the roof in time, the following consequences are possible:

- Increased wear of roofing material. Water penetrating into the gap ends up on the inner surface of the roof, which causes deformation of the coating.

- Reduced service life of the building frame. Water that is poured into the gap between the pipe and the roofing contributes to the gradual rotting of the wood. This is fraught with deformation and destruction of the rafters.

- The insulation loses its effectiveness. Thermal insulating materials with which the roof is equipped can quickly lose their properties when wet. If hard insulation is not very exposed to moisture, then soft insulation quickly begins to rot.

- Increased humidity in the attic. Increased dampness causes stale, heavy air to appear. This can negatively affect the interior decoration of the attic.

The method for eliminating the gap between the pipe and the roof depends on its size and type of coating. The shape of the chimney is also taken into account. For a distance of less than 5 mm, use a heat-resistant sealant. If the gap width exceeds 1 cm, use cement mortar, an apron or a special sealant.

It is necessary to seal the gap between the pipe and the roof for:

- ensuring insulation of the attic space from atmospheric moisture;

- to increase the efficiency of thermal and waterproofing;

- increasing the service life of the rafter system and the entire roofing structure;

- eliminating cold bridges.

Sealing the chimney on the roof avoids destruction of the roof itself.

The seam between the pipe and the roof can be sealed with silicone, acrylic, polyurethane and bitumen sealants. Special sealing tapes are also successfully used. Each of these types has its own advantages and applications.

Silicone sealant has become a kind of universal material in construction. It is used both for roofing and for sealing window openings. Silicone sealant is often used when working with glass and wood. It is often used to treat the gap around the chimney pipe on the roof. The material does not lose its properties under prolonged exposure to ultraviolet radiation and high temperatures. To seal the joints of roofing material, there is a special subtype of it - roofing sealant.

Acrylic sealant is most often used to seal cracks in walls and floors. Acrylic compounds are also used to repair windows. It is rarely used for outdoor work - it is not elastic enough.

Polyurethane, unlike acrylic, is used for exterior work almost everywhere. They glue metal, concrete, wood, stone together. Roofing is ideal for minor repairs.

Bitumen solutions are ideally combined with roofing work. They are resistant to precipitation, temperature changes, and chemical solvents. The only drawback of this sealant is its toxicity. For this reason, no internal work is carried out on it. They are ideal for sealing roof chimneys.

Main advantages of bitumen:

- super durability;

- low cost;

- elasticity;

- possibility of coloring;

- high moisture resistance;

- high level of adhesion to dry and wet surfaces.

There are several subtypes of bitumen mixtures that are designed specifically for roofing. They are able to ensure complete sealing of the treated gap between the pipe and the roofing.

Criteria for choosing chimney waterproofing products

Previously, roofers used materials unused after roofing work for insulation operations. Today the market offers a wide range of materials and devices, with the use of which you can independently perform high-quality and reliable waterproofing.

Requirements for pipe waterproofing products:

- Highest moisture-resistant and anti-corrosion properties.

- Thermal stability at temperature changes from -20 to 1000 C.

- Low thermal conductivity so as not to overheat wooden roof structures.

- Not sensitive to ultraviolet rays.

- Endurance, wear resistance, long service life.

- Fully compatible with base coat. For roofs made of metal materials, galvanized parts are used, for soft roofs - bitumen.

It is not recommended to do moisture protection using conventional silicone sealing paste, bitumen or cement. The product is selected taking into account the maximum temperature of the chimney walls and the type of roof.

Tape sealant

Tape sealant is a solid material. Many builders consider it the most cost-effective option for roof sealing. Material Features:

- it is based on butyl rubber;

- The sealant tape is highly resistant to ultraviolet radiation and high temperatures;

- it has high adhesiveness, making it easy to install;

- Ideal for sealing joints between chimneys and roofing.

The tape has an aluminum coating, which increases the service life of the sealant for outdoor use. The tape is easy to install and operate. The average service life of the product is 10 years. Thanks to a wide range of colors, the tape can be used to seal various roofing coverings. The sealant has exceptional adhesion to various surfaces. The tape is used when it is necessary to seal wooden, plastic, and metal surfaces. The tape is also successfully used for sealing translucent roofs.

How to use

The surface of the pipe and roof on which the tape is applied must be cleaned and dried. It is important that the area being treated is level. To apply the tape, you need to cut a piece of a certain length, then remove the protective film and press the product tightly against the joint (crack). At temperatures below +5, the tape is first kept indoors at a temperature of 15 degrees for 12 hours.

Using the tape in sub-zero temperatures involves heating the surface to be treated. The tape is not used for surfaces with an operating temperature above 80 degrees or when the roof slope is more than 55 degrees.

Materials used

The materials used for sealing are divided into three types, each of which has its own advantages and disadvantages.

It is a roll or shortened fibers. Positive qualities of cotton wool

:

adheres tightly to surfaces;

resistance to physical impact (shock, vibration);

resistance to chemical attack;

Cotton wool is the most common material for insulation

Roll filters

They are a mullite-siliceous composition that is included in the fibers of the composition. Positive qualities of roll filters

:

it is permissible to use inorganic glue;

the mechanical fastening can be firmly fixed.

On our website you can find contacts of construction companies that offer country house design services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Asbestos and kaolin boards

In production, mullite-siliceous fiber is used. The disadvantage of the plates is their immunity to alkalis and acids at high temperatures. To eliminate the deficiency, additional insulation will need to be installed. Positive qualities of slabs

:

low density, but higher than that of cotton wool;

resistance to physical impacts, such as vibrations;

resistance to steam, water and oils;

resistance to melting non-ferrous metals;

electrical insulating properties will be maintained at temperatures up to 800 degrees Celsius.

Sealing the gap

The traditional method of sealing the gap between the pipe and the roof involves making an apron. To construct it, you will need abutment strips. They are placed at the bottom of the chimney pipe. They are applied to the pipe and marks are made along the top.

A grinder is used to make a groove. Subsequently, the remaining parts of the apron are overlapped around the pipe. The edges of the strip inserted into the groove must be covered with heat-resistant sealant. The lower parts of the plank are trimmed and fastened with self-tapping screws. The gap between the pipe and the roof is sealed in such a way that water flows into the drainage elements.

The roofing part is mounted on top of the laid elements, and an outer tie is constructed around the pipe. When setting it up, it is important to take into account the pattern of the inner tie. The upper strips are not inserted into the groove, they are simply adjacent to the pipe.

If the pipe is round in shape, you can use a special nozzle. It is also used to seal antennas and ventilation outlets. In appearance it resembles a stepped pyramid. If the nozzle is rubber, it can be used in temperatures from -50 to +130 degrees. Silicone models have a wider range - from -70 to +250 degrees.

There should be a distance of 25 cm from the chimney pipe to fire-protected structures. In the case of unprotected elements, it should not be less than 35 cm. The ideal option is to create an air gap. However, such a solution causes a large loss of heat, which is unfavorable from the point of view of thermal insulation.

The installation of a pipe outlet through the roof should be approached with the utmost responsibility. If the work is done poorly, moisture will regularly enter the attic. This will entail dampening of the rafter system and insulation.

High humidity has a negative effect on the condition of wood. As a result, many load-bearing elements of the attic are deformed. This can lead to sagging of the roof and the appearance of cracks in it. High humidity in the attic has a destructive effect on the internal cladding material. The durability of the roof depends on the correct selection and installation of sealant.

How to seal the gap around the chimney?

In the bathhouse, when the chimney pipe (sandwich) passes through the roof, there is a gap. I sealed it with concrete. But there was still a small gap at the pipe. And recently snow slid off the roof and pulled out part of the concrete. It is clear that concrete is not suitable. How can I seal the gap, given that the pipe is hot? A neighbor said it could be done with epoxy. But I don’t know how epoxy behaves at temperature.

Well, in general, cutting should be done there, unless, of course, the pipe is brick, there is an apron. There is HILTI, go to their website in the Fire Solutions section (I think so)

Consequences of an unsealed joint

To bring the chimney through the roof, a larger diameter is cut out into it, so that a gap remains between the walls of the chimney and the roofing material. Regardless of the width of the gap, it is a big problem faced by homeowners and builders. To eliminate this defect and protect the under-roof space from the penetration of atmospheric moisture, use seals, aprons, collars, made by yourself or purchased. An unsealed gap between the roof and the chimney pipe is fraught with the following consequences:

- Increased wear of roofing material. Most roof waterproofing materials offer better protection against moisture penetration from the outside. Moisture penetrating through an unsealed gap gets onto the inner surface of the roof and eventually destroys it.

- Reducing the service life of the rafter frame. The pouring water hits the elements of the rafter frame, which are made of wood. This leads to rotting and premature destruction of the rafters.

- Reduced insulation efficiency. Roof insulation materials lose their properties when wet, becoming less effective.

- Increased humidity in the attic. Increased dampness in the attic causes heavy, stale air and negatively affects the interior decoration of the room.

Important! The method of sealing the gap between the chimney and the roof depends on its size, the type of roofing material used and the shape of the chimney. If the distance is less than 5 mm, it is quite possible to get by with a heat-resistant silicone-based sealant. You can close a gap whose width is 1 cm or more using cement mortar, an apron, or a special sealant.

Why do you need chimney sealing?

The chimney is designed to remove hot combustion products from the combustion chamber of a heating unit - boiler, stove, fireplace. When any fuel is burned, it produces a lot of carbon dioxide (CO2), a small amount of carbon monoxide (CO), sulfur oxide (SO2), a small amount of oxides of some other elements, water, and unburnt fuel particles (soot). All of them are harmful to humans.

Hot water can increase the humidity in the room and lead to the formation of streaks on the walls and ceiling. Soot and soot stains can ruin the finishing of a room.

The temperature of the exhaust gases from solid fuel boilers can reach 600 °C and above, from gas boilers - 200 °C, when cleaning the smoke hog by igniting soot it reaches 1000 °C. A small stream of hot gas from a chimney is a common cause of fire. Even 200 °C for a long time is enough for the wallpaper to begin to smolder.

Therefore, the tightness of the chimney is a prerequisite for its operation. Modern heat-resistant sealants are used to seal the joints of individual elements of prefabricated chimneys. In addition, they are used for emergency sealing of leaks that occur during the heating season, when it is not possible to turn off the heating device and disassemble and replace part of the chimney.

Heat-resistant sealants are even used to seal holes and cracks in traditional brick chimneys. Traditionally, clay was used for this, but it is unreliable as a sealant. In addition, heat-resistant sealants are used to waterproof the exit of chimneys to the roof - this protects the rafters and under-roof structures from getting wet and rotting.

Sealing with mortar

To seal the gap between the chimney pipe and the slate or tile roof, use moisture-resistant cement mortar and a decorative collar. This is the most affordable way to insulate the attic and rafters from moisture with your own hands. This requires dry mortar, water, a mixing container, steel corners and a collar. Installation work is carried out in the following order:

- The gap between the roof and the outer wall of the pipe is lined with stainless steel corners. If the chimney is oval or round in shape, you can use a rubber seal with an adhesive backing.

- A decorative collar made of galvanized steel is put over the chimney head and secured with self-tapping screws.

- A pre-mixed viscous solution is poured into the gap between the collar and the pipe and allowed to harden for 1 day.

- After a day, check the quality of the filling and the degree of hardening of the solution. A surface for liquid drainage is made from a sheet of sheet steel. To do this, a hole is cut out in it, the diameter of which corresponds to the size of the collar, put on the head and fixed with self-tapping screws.

Important! To ensure that the structure is reliable and does not collapse during the first serious downpour, high-quality waterproof cement is used. Otherwise, cracks will appear on it, through which water will leak into the rafter frame.

Sealing round multi-layer chimneys

It is much easier to install sealing on modern round chimneys. The simplicity of the process is due to the fact that no additional equipment is required, since the pipe is already equipped with everything necessary. Installation takes place in three stages:

Prime the edge of the pipe

where the waterproofing will be attached.

Make a hole in the waterproofing

, and then glue it to the pipe using mastic.

The sheet must be attached to the sheathing

. The pipe is passed through a cap, between which a clamp with a heat-resistant gasket must be located.

Round metal chimneys

If there are no caps, then flexible elastic seals for pipes are used instead. The sealant can also be used anywhere else where roof insulation needs to be improved.

This might be interesting!

In the article at the following link, read about waterproofing flat roofs.

Sealing with a steel apron

To seal the gap between the chimney pipe and the roofing material with your own hands on roofs made of metal tiles and corrugated sheets, use special aprons. They are made of galvanized steel in the color of the roof in the form of additional elements. With their help, you can reliably and aesthetically isolate the gap; to do this, proceed in the following order:

- Along the perimeter of the pipe, strips of waterproofing 30 cm wide are laid, bringing the edges up, fixing them on the wall with sealant or adhesive tape.

- To close the gap at the chimney outlet, metal wall profiles are used. The lower fastening flange is tucked under the roofing material and fixed to the rafters with silicone sealant with a moisture-resistant composition. The top shelf is attached to the pipe wall.

- Decorative textures are installed from galvanized steel with a polymer coating. It is a set of additional elements that are overlapped with each other and secured with self-tapping screws to the pipe and roofing material.

Important! You can make your own apron from sheet steel. However, factory products look more aesthetically pleasing and presentable. When working on the roof, special roofing screws are used as fasteners, equipped with a rubber headband, which, when twisted, flattens, closing the hole from water penetration. If there are no such screws at hand, gaskets are cut out of rubber using them with ordinary self-tapping screws.

What are the main points you need to know when cutting?

- The distance between the roof and the rafters (25-30 cm) should be maintained for any roof covering. For flammable roofing materials (tar paper, wood, roofing felt) - 15-30 cm. For non-combustible roofing materials - 10-25 cm.

- What is difficult about the device is the option of passing the chimney through the “roofing pie”. “Roofing pie” is a complex roof structure that includes layers of vapor barrier, waterproofing and a layer of insulation. It is impossible to violate the integrity of the pie, as moisture can get inside and destroy the thermal insulation of the roof.

In addition, the insulating films inside the roofing pie are made of flammable materials. Therefore, a gap is required between the chimney and the roofing pie.

In this case, you need to make a separate box separating the pipe from the roof. The box is made from wooden rafters and a cross beam. The distance between the box and the chimney is 14-16 cm; it must be filled with non-flammable thermal insulation (for example, stone wool, which is not afraid of moisture).

The insulating films of the roofing pie in the exposed places are cut with an “envelope”, pulled up to the rafters and cross beams and secured with nails.

The waterproofing located in the cake is pressed with lathing, the vapor barrier is fixed with frames made for finishing. For absolute peace of mind, the joints of the insulating films and the box can be wrapped with special tapes.

Sealing with rubber aprons

Construction stores suggest using Master Flash rubber aprons or Wakaflex sealing tapes to seal gaps where pipes pass through a roof made of any material:

- Master Flash is an elastic penetration on a rubber base in the form of a stepped funnel, reinforced with aluminum mesh inside. It is suitable for roofs with any slope and any roofing material. The rubber apron reliably protects the gap from liquid penetration. To adjust the apron to the size of the pipe, it is cut to the required diameter. The apron is fixed to the slope with self-tapping screws, and to the pipe using a steel clamp.

Note! To eliminate large gaps, a fiber sealant is first compacted into them, and then filled with bitumen mastic or filled with foam. After this, the passage area is decorated with a decorative collar. Please note that collars are produced with a standard angle, which is selected in accordance with the slope of the roof slope and the diameter of the chimney.

The main condition for long-term operation of the roof is maximum tightness, which is achieved by isolating even minor gaps. Whatever sealing method you choose, remember that reliable protection against moisture penetration is more important than an attractive appearance.

Roof penetrations Master Flash

With the help of such devices, you can quickly and efficiently finish round chimneys. They are much easier to install compared to metal caps. Penetrations are made from silicone and heat-resistant rubber. They allow you to create hermetically sealed structures when the plane is tilted up to 20 degrees. The material can withstand temperatures in the range of 135...240 degrees. The chimney can have a diameter of up to 66 cm.

Roof penetrations Master Flash

Important! You should carefully select the diameter of the penetration, otherwise it may tear (if the size of the chimney exceeds the parameter of the protective element) or not be tightly fixed to the pipe. In the latter case, you will have to use crimp clamps and sealant.

What's good about these products:

- possibility of use on roofs finished with different coatings;

- quick and easy installation;

- resistance to moisture, temperature changes and sunlight;

- budget cost.

Characteristics of the roof passage

Installation technology of elastic penetration.

- A narrow part of the product purchased in accordance with the diameter of the chimney is cut off at a level that allows the device to fit hermetically to the chimney.

- The penetration with the dismantled deflector is pulled onto the pipe until it meets the roof.

- The protection of the self-adhesive base is removed, which is pressed against the corrugated sheet (it must be clean and dry).

- The penetration is fixed using self-tapping screws (roofing). All gaps are filled with sealant.

- Additional protection against leaks and ultraviolet radiation, as well as the aesthetics of the structure, will be provided by a decorative apron, most often made to match the color of the roofing.

Installation steps

As an analogue of Master Flash penetrations, you can use aluminum or steel cone-shaped devices with a silicone connecting part.

When carrying out sealing, you cannot do without sealant. The composition must be resistant to climatic factors and high temperatures.

Prices for Master Flash penetrations

Master Flash penetrations

Metal apron

Brick pipes passing through the roof have expanded masonry ( fluffing ) and ledges ( overlap ), which serve as a heat and moisture insulator. Insulation of a brick chimney from moisture is done using a steel, lead apron, which is placed on the roof trim. First, the space in front of the pipe is covered with a layer of roofing felt with the edge raised to the wall. Corrugated sheeting or tiles are laid.

A steel apron is attached to special grooves on top. Then all joints are filled with sealant. Sometimes the chimney apron is part of an insulating steel wall, which is necessary in some cases (when condensation forms, when insulating walls). At the same time, the steel sheet in the lower part is bent to match the slope of the roof (corrugated sheeting) and has no joints, which increases the level of reliability against leakage. Metal aprons are also placed on round pipes if the temperature of the combustion products at the outlet is over 100 degrees.

Possible problems with poor-quality sealing of the roof passage

Corrugated sheeting is a high-quality roofing material that has a complex layered structure. The following layers are applied to the outer steel sheet base:

- zinc;

- additional anti-corrosion;

- primers;

- polymer (polyester);

- installation protection.

And on the inside, galvanization, primer and corrosion protection are also applied. Thanks to this structure, corrugated sheeting has excellent load-bearing capacity, protection from rust, fire and rot. The building material retains its properties over a wide temperature range.

It is customary to create various openings on the roofs of houses for ventilation and smoke escape. This naturally leads to damage to the waterproofing and other protective layers. Therefore, sealing the joints between the pipe and the roof surface is of great importance. This process must be carried out correctly, otherwise problems may arise:

- Leak. When the pipe is routed through the roof, the presence of uninsulated cracks leads to the penetration of water into the house, living quarters, dampness of the walls, including load-bearing ones, the appearance of mold, etc.

- Destruction of rafters. The roof structure consists of wooden rafters. Moisture entering through the joints contributes to the rotting of the wood and the destruction of the entire structure.

- Corrugated sheeting corrosion. Although the roofing material is protected by anti-corrosion layers, the internal protection is weaker than the outer layer. Corrosion gradually destroys corrugated sheeting, reducing its protective characteristics and attractive appearance.

- Reduced roof insulation level. When water penetrates into the layers of thermal insulation, the latter lose their ability to retain heat and protect from external cold. The insulator loses about 50% of its ability to effectively retain warm air in residential areas.

To be sure of the quality of your roof, you should seal the joints in a high-quality manner. Various sealing methods have now been developed that allow high-quality waterproofing of the gaps between the pipe and the flooring.

How can you eliminate gaps?

The easiest way to solve the problem of how to seal the gap between the pipe and the roof is to install an apron on top. You can do it yourself, in which case you will need to provide strips for connection to the pipe in advance. There is an easier way - to buy a ready-made stainless steel roof passage. Often round passages are made for the chimney, and they are made of stainless steel; a galvanized chimney pipe is also used, most often. The passage is placed on the pipe, and the joint is fixed with a steel clamp.

If you need to seal minor gaps formed between the pipe and the roof, then for these purposes you can use silicone sealant (read: “Which sealants for chimneys are best to use - types, characteristics”). You can find a huge variety of them on sale, but we need a heat-resistant type.

The process of how to seal a roof around a round pipe will differ slightly depending on the type of roofing, that is, in addition to the basic recommendations, there are also algorithms that will vary somewhat.

Round pipe

Many chimney structures for stoves are equipped with round channels made of sheet metal. Such products are multi-layered and are additionally insulated. Such a pipe is sealed in many ways. It’s worth looking at the most popular ones:

- The passage of these structures can be sealed with bitumen derivatives. Quite often, roll materials are used for this purpose.

- Installation of self-adhesive tape. This material has a foil layer.

- Installation of special aprons made in the form of caps. They are also called roof passages. These devices are simple and reliable. They need to be put on a pipe with a circular cross-section and attached to the roof sheathing.

When there is a residential attic space under the roof of a house, the passage for the pipe must not only be sealed, but also thoroughly insulated. The gap formed between the apron and the pipe must be closed using a special heat-resistant gasket. It is attached to the plane of the product.

As you can see, you can install the joint between a corrugated roof and a chimney yourself, knowing the installation features of various structures. In the process of work, it is important to follow technology. This will ensure sealing of the junction.