- Construction changes

The article provides information about the causes of backdraft in a stove chimney, what to do about it, with video examples, as well as a guide to action. We will look at ways to stabilize the situation, ranging from making structural changes, continuing with the use of various devices, and ending with a review of ventilation. And, of course, we will share the secrets of prevention and inspection so that you are warned and armed, and your home is protected.

What it is

During normal operation of the smoke exhaust system, gas generated as a result of fuel combustion is discharged outside. If the operating mode is incorrect, you may observe the opposite situation. The smoke does not go straight up through the pipeline, as it should, but down, it does not go out into the street, instead it pours into the house - that’s what reverse draft is. And it is not just an unpleasant, but a truly dangerous phenomenon, which, if neglected, leads to a fire hazard in the house, or even to severe carbon monoxide poisoning.

Location of the chimney exit from the house

There are also rules for installing a chimney through the roof and wall. Here is an example of installing a pipe directly through the roof:

Maintaining a chimney height of 5 meters from the firebox grate to the top cut of the pipe is not difficult if a one- or two-story house was built. But problems arise if the fireplace was installed on the upper attic floor - the height of the ceiling and attic is insufficient.

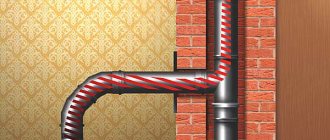

The installation of a chimney through the wall of a house or bathhouse occurs a little differently:

Please note that stoves should be connected to chimneys using chimney pipes no longer than 0.4 m.

Norms

Draft is the movement of smoke up the chimney from an area of high pressure to an area of low pressure. Gas by its nature tends to the zone of least resistance (in this case, up and out), with acceleration provided by the pipe, which acts as an aerodynamic corridor.

If the speed of movement is suitable, fuel combustion occurs as planned: harmful combustion products are promptly and completely removed outside, and a supply of fresh air is ensured. If excessive, the fire may be blown out by a sharp gust due to too much exhaust. If missing, the flame will simply go out.

Therefore, it is so important to maintain uninterrupted operation of the heating system, in particular, stable pressure in the boiler and in the hose area. The norm in this case is from 10 to 20 Pa, depending on the area and height of the premises, the number of rooms and number of floors, and the climatic zone in which the building is built.

Environmental considerations for industrial buildings

In a word, the throughput of the chimney pipe must ensure the unhindered passage of smoke and its release into the atmosphere. Moreover, the environmental aspect is also important here, namely, whether the products of fuel combustion are properly dispersed in the atmosphere.

Thus, during the construction of commercial and factory enterprises, certain sanitary standards are taken into account. And they depend on the weather conditions of the area, the typical speed of air flow, the topography of the landscape and many other factors.

So, what value did you get and is it exactly equal to 5 meters?

How to detect reverse draft in a chimney

Now one of the most modern ways to detect its presence (in non-obvious situations) is considered to be an anemometer test. This is an easy-to-use device, today it is not only mechanical, but also digital: just bring it to the inlet and outlet of the pipe, and it will show the current pressure. If its indicators are lower than the already mentioned 10-20 Pa, it’s time to sound the alarm. There is only one thing: this equipment will take readings only in the presence of a wind flow of more than 1 m/s.

What to do if such equipment is not at hand? Use traditional methods:

- Light a match, or better yet a candle, bring it to the heating unit and see how the fire behaves. If the tongue pulls into the channel, then everything is in order, but when it remains motionless, there is no air circulation; if it goes to the side, there is a problem.

- Visually, that is, see if the room is smoked - even the slightest signs of billowing steam indicate reverse draft. Although this is the most inaccurate way.

- If you bring the combustion mirror closer to a working furnace, it fogs up, which means the steam is not being fully released.

- Pay attention to the color of the flame when burning wood (peat, gas). If it is golden, everything is fine; when it is white, the extraction is too strong; if it is reddish or red, there is a return effect.

- Bring a tape, a paper sheet, a plastic bag to the firebox, holding it by the edge, and see where it moves. If it stays in place, there is no air circulation; if it moves away from you, the system works correctly; if it moves toward you, there is a problem.

Why does backdraft occur in a stove or chimney?

Among the main reasons are the following:

- Incorrect design or installation of the chimney (height, cross-section of pipes, presence of horizontal sections).

- The presence of a nearby tall object (tree or building).

- Violation of ventilation.

- Excessive soot emission and chimney blockage.

All the reasons for its appearance are conditionally divided into two groups:

- Simple - when it is only a temporary problem. The stove was not working for a long time or the weather was cold outside.

- Complex – complex, permanent, global, to get rid of which you need to take important steps. This includes errors in design or ventilation, high objects near a residential building, and clogged chimneys.

Let's consider each of them with the obligatory mention of the degree of its seriousness.

Problems with the design

This is the case when errors were made at the design stage and affect the operation of the equipped heating system. Among the main mistakes:

- Incorrect calculation of the diameter (cross section) of the pipe, due to which the channel for the exit of combustion products is too narrow.

- A large number of horizontal (or inclined, but located at a small angle) sections in the hose, due to which the gas comes out too slowly.

- Insufficient volume of the combustion chamber, due to which harmful combustion products do not have time to completely leave the room. Height.

This is a complex problem that can only be solved through modification and restructuring.

Incorrect installation of the heating device

From time to time a situation arises when the design documentation was drawn up correctly, but mistakes were made by those who installed the equipment. Do-it-yourself assembly is fraught with the following errors:

- Pipes of different sections are used.

- Not all joints are sealed.

- Gaps remain.

- The boiler is not fastened well.

Failure to comply with basic standards when installing a chimney leads to backdraft.

The work often becomes an explanation of why there is backdraft in the chimney, and a simple conclusion can be drawn. Only experienced professionals should be involved in arranging a heating system for a private home, so that later you don’t have to redo it, spend money, or risk your health.

Selection of materials

This point is also key, because if the inner surface of the pipe is rough, steam particles will be retained and go back. If you choose metal with low corrosion resistance, it will rust, which will also worsen the circulation of air masses.

We are no longer talking about the fact that ceramics, brick, stainless steel differ from each other in terms of thermal conductivity and sealing, which means that in the channel made from each of them there will be different pressures. This is a point that must be taken into account when designing, so that later you do not have to make difficult decisions and change or redo part of the heating system.

Ferrum steel smoke exhaust systems meet all technical requirements. On the website feflues.ru you can select a ready-made kit with a quality guarantee from the manufacturer, and also check the price list.

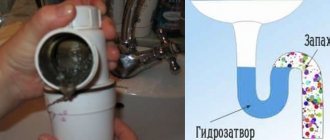

Chimney blockage

A clogged pipe is a common reason why the chimney blows in the opposite direction. The draft deteriorates significantly or stops altogether if a lot of soot and soot settles on the walls, as a result of which the sleeve becomes too narrow or “zero”. When does this happen? Again, when constructing a channel from a material that is not smooth enough, with roughness that literally attracts various contaminants.

In the most advanced cases, even mechanical debris trapped inside prevents the timely removal of combustion products. But this is not the most insoluble problem, the consequences of which can be minimized by regular prevention or prevented at the design stage by choosing a modular design made of stainless steel.

Chimney height

This reason includes several different but common cases:

- the ridge of the roof is located above the level of the chimney, and during heavy gusts of air flow, a “overturning” is observed, that is, the smoke begins to sharply flow into the room;

- taller buildings and structures are located nearby, forming the so-called wind support;

- There are large trees nearby, from which smoke can also be reflected and return to the chimney.

The problem of tall trees or tall buildings standing nearby is not always possible to solve. In this case, an option is offered to make the structure yourself - a cap with a branch. You can make this cap yourself by looking at information and video reviews on the Internet.

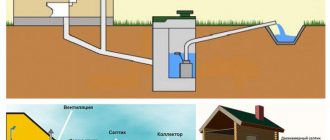

Violation of natural ventilation

Difficulties arise in the absence of air flow, when oxygen becomes less and less (burns out), in order to continue combustion, the pipe “sucks” it from the street. If, due to improper design and/or construction, there are drafts in the room, this changes the movement of flows, under the influence of one of which the gas from the furnace may flow not upward, but to the side.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

Okay, do you know the reasons for backdraft in the furnace, and what to do if, as a result of the appearance and development of any of them, the chimney blows in the wrong direction? It is necessary to stabilize the exhaust gas output, and this can be achieved in almost every situation. Yes, in some places you will have to spend more, in others less, but most cases can be corrected even on your own, without inviting specialists. Below we will tell you what to do and what to do.

Traction force: how to achieve ideal fuel combustion

The traction force itself is influenced by several important factors:

- chimney material;

- foundation height above sea level;

- flue gas temperature at the furnace outlet;

- cross-sectional shape of the chimney pipe;

- smoothness or roughness of the inner surface;

- violation of the internal tightness of the chimney;

- temperature and humidity of outside air;

- ventilation of a room with a boiler or stove;

- completeness of fuel combustion;

- degree of contamination of the boiler (or stove) and chimney;

- type of burner used (modulating or discrete).

First of all, you need to determine the value of the static draft of the chimney, which is measured in the value ∆p [Pa]. Here is the formula for calculation:

h[m]=(∆p·Tp·Tн)/(3459·(Tp-1.1·Тн))

Tp is the average temperature in the pipe, and Tn is the outside temperature. It is measured by default in degrees on the Kelvin scale, but you can also specify it in Celsius by adding +273.

Calculating the average temperature is not difficult. This is usually reported in the technical data for the boiler, but it is also important to take cooling into account. This is 1 degree per meter of brick pipe, 2 degrees per meter of insulated steel pipe and 5 degrees for uninsulated one.

In this case, it is advisable to take the value of the outside temperature that is typical for summer as the most problematic time for traction:

Make an aerodynamic calculation and find out the exact required height and diameter of the chimney. The amount of draft itself means the difference in the densities of air and flue gas, multiplied by the height of the house. It is 5 meters of the chimney that provide vacuum and draft for smoke .

But what to do if the height of the pipe cannot be set higher, and the draft for certain reasons is still insufficient? This often happens when flue gases cool down too quickly, especially in the cold season. Then, to restore traction, the required section of the pipe is simply insulated.

Also remember that real thrust is always less than static due to the resistance to the movement of gases inside the pipe walls. The narrower the flow section of the chimney, and the more bends, horizontal sections, etc. there are in it, the worse the draft will be, because the draft is affected by the loss of pressure along the entire length of the pipe.

Another problem with chimney height is cold air from the fireplace. So, when it is not working, cold air from the street is released from it. This happens when the chimney head is below the end of the ventilation hood, or when the attic is too large and poorly insulated.

Ways to normalize cravings

This includes methods for enhancing low steam output and preventing tip-over. Depending on the state of affairs, you can use either one or several of them at once.

Construction changes

If the problem is due to incorrect design or unskilled installation, the defects must be corrected. The most common things you need to do are:

- Increase the height of the pipe (if it is small) so that its top is at least 0.5 m above the roof level. And this is for a separate building. For a house located close to trees or adjacent to other real estate, this figure is already 1.5 m.

- Expand the channel - when you don’t know how to deal with backdraft, simply increase the cross-sectional width of the chimney so that it is no less than that of the boiler pipe. Then the air masses will circulate more actively.

- Remove too long (longer than 1 m) horizontal sections of the sleeve, replacing them with inclined sections running at an angle of 30°, get rid of 90° turns in favor of 45° transitions.

Using a regulator (stabilizer)

The configuration of the smoke exhaust system largely depends on the type of heat-generating apparatus with which it is planned to be used. Efficiency is affected by natural temperature fluctuations - time of year and weather. In cold weather, significant temperature changes can lead to high vacuum in the chimney. And this will lead to decreased operating efficiency and increased fuel consumption. The regulator stabilizes the pressure to the optimal value and thereby increases the efficiency of the heating device.

Air pressure can also cause back draft in the chimney. It is determined by location (in the mountains, for example, lower than at sea level) and time of day, weather conditions, season - in summer, air pressure is higher than in winter. Thus, the difference between air pressure on a cloudy April day and a clear day in September can be up to 90 Pa.

Deflectors

These are simple but effective devices that deflect air flows that are reflected by trees, walls of neighboring buildings (and other tall objects), and thus prevent the exhaust gases that escape from reentering the pipe. They help to normalize (usually reduce) pressure and increase the aerodynamic effect, and are easy to install. They give results even in strong winds, but in calm conditions they are practically useless, and this is their main disadvantage.

Ferrum produces both a windproof and a regular umbrella, which will also help cope with precipitation and wind, and prevent the draft from tipping over.

Weather vane deflector device

This is a kind of hybrid of two devices, taking the best from a reflector and an air flow amplifier.

Consists of 3 components:

- the lower cylinder is a pipe that, after assembly, is in direct contact with the chimney;

- the upper glass with racks as a structure - catches and changes the direction of movement of the reflected gas masses;

- cap (umbrella) - can be flat, semicircular, conical, protects the channel from debris and precipitation.

Installing a weather vane deflector is the answer to two questions at once: how to eliminate backdraft in a chimney when there is wind pressure and how to increase the normal draft by 15-20%. Its installation is not difficult: just drill holes in the pipe and secure the device with screws. To prevent it from dangling, you can lay a clamp. It can be really securely fixed even on brickwork - with the help of adapters.

Stainless steel rotary gate device

A mechanical regulator, most in demand when arranging steel channels for the removal of harmful combustion products. It is a section of pipe through the center of which a valve passes, partially blocking the chimney.

It is very simple to use: turn the axis, slightly open the valve, and release steam, reduce the gap, and the gas exit speed decreases.

Gate and valve made of stainless steel

Advantages:

- high anti-corrosion properties;

- smooth surface that does not collect soot;

- light weight with the strength of even a thin plate;

- variety of handles and flaps;

- Possibility of installation in both steel and brick channels.

Cast iron gate

Its design and operating principle are the same as the rotary one. The difference is in the raw material: it is made of metal that is susceptible to corrosion. Therefore, if you are thinking about how to remove back draft in a chimney and get rid of it mechanically, you can give preference to this regulator. Just keep in mind that it will be heavy, which means it will only be suitable for a channel that can withstand significant weight loads. In general, the material is considered obsolete, so if you have a choice, you should pay attention to a stainless steel sample.

Rotary turbines

With the installation of one of them - a hybrid of a deflector and a weather vane - you will also stop thinking about how to avoid backdraft in the chimney, because excess gas will be discharged automatically.

The device is a nozzle equipped with steam speed and temperature sensors and, most importantly, an electrically driven screw that forcibly pushes combustion products out. A convenient solution for those cases when it is impossible to arrange a channel of sufficient height.

Revision of the ventilation system

It is necessary to analyze how it is organized, eliminate errors and take measures to eliminate drafts and streamline the masses circulating in the room. It usually comes down to the following steps:

- regular ventilation of rooms (especially those where heating equipment operates);

- installation of window and wall supply valves - to constantly obtain fresh air;

- installation of forced ventilation devices - if previous measures do not help.

Timely cleaning

This is also an effective measure to improve the removal of gases. It is important to regularly remove soot that settles in the channel, because otherwise the soot will make even the smoothest walls rough. You need to pull out any debris that gets into the sleeve and clogs or even tightly clogs it.

Deflectors

A deflector is a device that allows you to stabilize the air flows that occur in the smoke exhaust pipe. The name of this product is translated as a guiding device and fully corresponds to its operational features.

A deflector is a device that helps stabilize air flow in the smoke channel

It is necessary to note one important pattern: the simpler this device is, from a design point of view, the more efficient it is in operation. This is due to the fact that air masses redirected from the roof surface, together with side air flows, help remove smoke from the chimney.

Experts recommend using this device in windy regions, as it is not effective in calm conditions. When choosing this device, you need to pay attention to two main factors. Let's look at them:

- dimensions of the chimney pipe on the roof;

- wind load for a specific case.

In addition, it is worth saying that such a device can be made without much difficulty with your own hands. To do this you will need the following materials and tools:

- square;

- yardstick;

- scissors for cutting metal;

- regular hammer;

- riveter;

- hand-held electric drill;

- set of drills;

- drill-tip screws equipped with a press washer, which has a size of 15 mm;

- sheet of tin or galvanized steel with a wall thickness of 0.3 to 0.5 mm;

- fastening material.

Before assembling such a draft amplifier for a chimney with your own hands, you need to carry out calculations on paper and apply the necessary markings to a tin or galvanized sheet. The assembly diagram for this amplifier can be easily found on the Internet.

The size of the deflector must correspond to the diameter of the chimney

Next, we proceed to the direct assembly of the amplifier for the chimney with our own hands. Let's look at the stages of assembling this device:

- First, you need to cut out the parts of the future deflector from tin or galvanized sheets (based on the markings).

- Then you need to roll up the nozzle body and join the edges together using rivets or self-tapping screws.

- At this stage, the two cones of the product are joined.

- Studs are installed in the lower cone. This is necessary in order to dock the lower cone with the general body of the deflector.

- The lower cone is connected to the device body. It must be remembered that all connections in the device must be strong enough so that the deflector can withstand strong wind currents during operation.

Thus, it becomes clear how to increase the draft in chimneys with your own hands using a weather vane, however, there are still many devices and means that allow you to carry out such an event.

What are the dangers of improper operation of the heating system?

Now that the causes of backdraft in a chimney or boiler and their elimination are clear, let's see what happens if the problem is ignored.

If nothing is done, combustion products will accumulate in the pipe, which will then return to the living quarters. They are dangerous because they contain carbon monoxide, which can cause poisoning or even death. Anyone who does not want to correct problems risks the health of themselves and their loved ones.

It should also be noted that the efficiency of the equipment decreases, and therefore the cost of heating the house increases. This, of course, is not a threat to life, but it is a moment that punches a hole in the budget, that is, it cannot be neglected either.

Effect of altitude

As for the height of the chimney, the higher it is, the better the speed of smoke movement . However, there are also limitations here. A chimney that is too high creates a lot of resistance to smoke movement, resulting in worse draft. That is, it decreases.

The correct chimney height is five meters. The starting point is considered to be the level of the grate. This height is quite enough for any weather. However, experts advise making calculations based on a specific case, because it may be that this height will create excessive thrust. The consequence of this is an increase in the need for firewood. If such a height is planned without taking into account specific features, then you will have to use means by which the draft in the chimney can become less.

There is also one more nuance. Chimney channels can be horizontal. This increases the length of the chimney, which also affects the speed of smoke movement. It decreases because smoke turbulence . Soot always accumulates in these places. It also reduces the diameter of the passage , as a result of which the thrust weakens. To ensure optimal speed, increase the height of the chimney by an amount equal to the length of the horizontal sections.

Temporary backdraft

This is not a permanent problem, but a one-time or periodic one, manifesting itself within a short period of time, literally a few days. In practice, it most often occurs after prolonged bad weather (with dense fog, constant downpours, snowfall) or prolonged downtime of the heating system.

It can be explained simply by the formation of a plug of cold air in the pipe. It can also be easily eliminated - by burning several sheets of paper. This way you will warm up the channel and break through the barrier. It’s even better to install a stabilizer - it will help normalize the pressure in the sleeve.

Prevention and testing methods

We told you why there is backdraft in the stove and what to do to eliminate it, and now we want to share the secret of how to prevent its occurrence. There is no secret in this, you just need:

- clean the chimney in a timely manner;

- regularly heat the system so that it does not stand idle;

- eliminate sources of drafts in residential premises;

- monitor the condition of devices installed on the pipe.

We have already described the testing methods in the section on identifying the problem, so here we will mention cases in which it is worth carrying out tests with a candle, paper or an anemometer. This should be done when the house has not been heated for a long time, there is (or has recently been) bad weather outside - heavy rain, blizzard, gusty wind, thick fog - and you want, for example, to light a fireplace. This is also true if the rooms, despite the kindling, are cold, or you suspect a malfunction.

And as a conclusion to the review of backdraft in the chimney and what to do when it appears, we offer a video - watch a useful video on this topic:

Chimney location and wind direction: how to prevent turbulence

According to all building codes and regulations, the chimney must rise above the roof at a certain distance. This is necessary so that the air on the protruding parts of the roof does not cause reverse draft due to turbulence.

Backdraft can be seen firsthand in the form of smoke that pours from the fireplace directly into the room. But the extra height of the chimney is also not needed, otherwise the draft will become too strong and you won’t get any heat from such a fireplace: the wood will burn to ashes like a match, without having time to give off heat.

This is why it is so important to calculate the height of the chimney as accurately as possible, especially taking into account the direction of the winds in the area:

If the pipe is located too close to dense trees or a high wall, it must be extended with asbestos-cement or steel pipe.

In this video you will also find valuable tips on installing a chimney and solving problems with its height: