Chimneys made from stainless steel pipes are market leaders. Their enormous popularity is due to a number of advantages. Lightweight pipes are quickly and easily connected. They can be used for boilers and furnaces of various types. The smooth surface of the walls promotes good traction. In most cases, such systems do an excellent job of the main task. With proper installation and operation, they can last a long time.

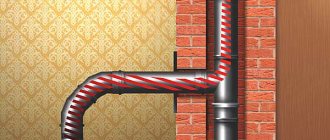

A special feature of a stainless steel chimney is that it consists of separate parts (pipes) that are connected to each other.

Gaps may appear in the joints through which smoke will pass, so sealing must be carried out. The absence of cracks and gaps ensures high efficiency and safety of the system.

When is it necessary to seal a stainless steel chimney?

It is imperative to seal the joints between the pipes at the chimney assembly stage. This needs to be done for several reasons:

- Smoke will enter the room or attic through the cracks. The combustion products it contains can cause poisoning to people in the house.

- If the system is not sealed, cold air will be able to penetrate inside the pipe (the problem is especially acute in winter). This, in turn, will lead to the appearance of condensation, which can destroy even stainless steel.

- Smoke entering through cracks can cause a fire.

Sealing may also be required during operation. If the method or material for sealing was chosen incorrectly, the work was performed poorly or not at all, then over time the chimney will need to be repaired and sealed.

Where does waterproofing begin?

The fireplace heating system will operate normally only if the work was carried out in accordance with the requirements of sanitary standards and regulations. At the state level, rules and recommendations for builders are regulated. By listening to them, you will be able to carry out insulation work without an emergency.

- Rafters and roofs should not be adjacent to each other. The spacing distance depends on the specific material. Combustible isolates should be spaced at least 150 millimeters to 300. Non-combustible (like asbestos and mineral wool) can be spaced between 100 and 250 mm. Be careful with flammables. Some gaskets are easily flammable. When combined with Euro slate, a fire may start, which will be difficult to extinguish.

- It is important to maintain the correct sequence of layers. Moisture should not be able to get inside the layer system, as it will destroy them. In addition, it will begin to accumulate and cause damage to the brick. There must be a mandatory gap between the pipe and the inner layer. Most isolates are flammable even at low temperatures.

- Don't neglect the box. This is the area that is between the roof and the insulation. It must be filled with any non-flammable material, such as mineral wool.

Insulating films should be cut to fit an envelope.

After this, they are pulled to the central beam so that it can be secured with hardware. Waterproofing is mounted on the sheathing, vapor barrier systems are installed on the frames. The joints between the box and the insulation are laid with special tapes.

How is it carried out?

Often after insulation work, the owner of the house notices sudden leaks. For example, they may be in the place where the roof meets the chimney pipe. The reasons for this are natural and always indicate an error.

An error occurred during one of the stages. To avoid leakage, you can install an apron.

When working, you must follow the following sequence:

- Moisture will form in any case - that’s why the insulating layer is needed. This can be avoided by using a drainage chute. This is a long groove into which water flows and is gradually removed to a safe place.

- Waterproofing pipes will be more productive if you install an apron inside to protect against leakage inside.

- A special backing can be cut from the waterproofing to cover the lower edge of the apron. For sheet roofs (profile decking, metal tiles, bitumen slate) it can be brought out between the sheets from below. To drain water, install a side that will direct the flow to the drain from the roof.

- There must be a roof covering around the pipe.

- You can make an apron yourself using ready-made drawings. Factory models are sold in fireplace stores. The pipe must pass inside it.

This instruction also works for exterior splashbacks.

Waterproofing tasks

Waterproofing pipes is the last stage in roofing work. If you ordered work from a team, you should know about laziness. Often developers and roofers neglect this stage because they consider them unnecessary. Indeed, for some time you can use fireplace heating without insulation, but after two winters you will feel a significant decrease in efficiency.

The procedure solves the following problems in the house:

- Increased security. New types of houses always have wood in their construction. For example, the roof sheathing is made of timber, which is a fire hazard. The heat released from the fire also goes into the chimney and can reach several hundred degrees. Solid fuel stoves are capable of developing a temperature that will cause the sheathing to smolder. The isolate will cut the wood and prevent it from igniting.

- Reduced heat loss. Due to the low temperature outside the window, the quality of the brick - thermal conductivity - comes into force. That is, it tries to equalize the temperature and cools the room.

- Condensation protection. Condensation, like moisture in general, is the main enemy of brick. As it accumulates and freezes (the effect of thermal conductivity), it expands by ten percent, which leads to damage to the ceramic structure. It begins to crumble and crumble, becomes loose and after a few years the chimney falls apart.

The waterproofing procedure dramatically increases comfort, as both the efficiency of the fireplace and the appearance of the roof are improved. Interior designers and experienced builders emphasize that properly done insulation makes a home look complete.

Any roofing material can be equipped with a nice apron, which is selected individually by color.

High temperature sealants

To solve the problem, high-temperature sealants are most often used. They are presented in a wide range on the market. They are based on silicate, silicone and other materials. To seal a stainless steel chimney, it is better to use silicone sealant. Its main advantages include the following:

- has elasticity, so it is not afraid of expansion and contraction of the metal during heating and cooling;

- has excellent water resistance;

- have good adhesion;

- It is resistant to ultraviolet radiation and can be used equally effectively for indoor and outdoor use;

- not afraid of high temperatures.

Sealing round multi-layer chimneys

Round chimneys are the most convenient to use. Their sealing occurs as follows.

- The edges of the pipe are primed with a special compound for metal.

- A hole is made in the waterproofing. After this, it is attached to the pipe using mastic. It is advisable to take bitumen. Despite the discomfort during operation, it does not bind to water and will not allow it to reach the pipe.

- The sheet is fixed on the roof sheathing. The pipe is passed through the prepared cap. There should already be a clamp and a temperature-resistant gasket inside.

If there is no cap, then any pipe seals will do.

Depending on the composition, sealants are:

- single-component - based on one substance;

- two-component - characterized by improved characteristics, they consist of two separate components that are mixed before use.

When choosing a sealant for sealing a chimney, it is worth considering that they are heat-resistant and heat-resistant.

For the removal system, you need to choose heat-resistant sealants, since they are designed for higher temperatures and are successfully used not only in the upper part of the pipe, but also in the chimney next to the boiler.

Is it possible to line with a polymer stocking?

You can seal a stainless steel chimney not only with sealants, but also with the help of a FuranFlex polymer pipe. The peculiarity of the polymer stocking is that it consists of three layers:

- The thin-film sleeve inside is made of a material whose properties are similar to polyethylene, but at the same time elastic, like rubber, and resistant to high temperatures.

- The composite layer is made of fiberglass fibers and resins. The layer performs the function of reinforcement - it gives the pipe strength and rigidity. The main feature of the composite material is that when heated, it changes not only its dimensions, but also its structure.

- The outer shell is made of highly durable fabric. It performs several functions: determines the diameter of the pipe, protects the composite material from mechanical damage, and absorbs excess resin when heated.

FuranFlex polymer stockings are successfully used not only to restore the functionality of brick systems, but also the lining of stainless steel chimneys. Since the stocking is initially flexible, it can be inserted into a system of any complexity. Twists and turns when sealing are not a problem. The material is resistant to corrosion at high temperatures, has high strength and can last for several decades.

Can it be sealed with cement?

Previously, cement was used for sealing due to the lack of other materials and solutions. Currently, cement is used only to seal cracks in the roof where the chimney exits. Yes, and then only in cases where the house is covered with slate. To ensure good performance, asbestos is added to cement.

It is better not to use cement to seal joints along the entire length of the chimney. Due to temperature changes, it can crack and quickly lose its properties. It is better to give preference to modern materials that are designed specifically for sealing chimneys and use at high temperatures.

Sealing a pipe on a bitumen roof

Passing a chimney through a Euro slate roof is not an easy task. Its specificity is softness, so it will be quite difficult to use. The best way would be Wakaflex tape. This is an adjacent strip for sealing joints.

It is installed according to the following algorithm:

- The tape cutting is made in advance.

- It is pressed with the help of a case.

- Any gaps are removed using bitumen mastic.

Please note that bitumen roofs are best sealed during the cold season. Under the scorching sun it softens and becomes dangerous. If you move on the roof, there is a possibility of damaging the ondulin.

How to choose a sealing method?

You can seal with sealants yourself. The composition is usually applied to the outside of the chimney at the joints. The treatment areas must first be prepared. If you choose the right material, you can ensure the tightness of the system for a long period. Another advantage is the availability of the method, although there are sealants on the market in a wide price range.

Lining with FuranFlex polymer stocking will cost more. The disadvantages include the fact that it is impossible to carry out the work on your own; you will have to seek help from specialists, since special equipment is required. But the method has many advantages:

- complete tightness along the entire length of the chimney;

- durability – service life up to 30 years;

- can be used for all types of heating devices;

- excellent resistance to high temperatures;

- perfectly smooth surface of the inner walls;

- additional thermal insulation.

Another advantage of using a polymer pipe is that it protects the stainless pipe from the aggressive effects of condensate, which contains acids. Thus, it increases the service life of the chimney.