How to install a damper for a stove chimney?

The efficient operation of stove equipment in a bathhouse or private house depends on the chimney.

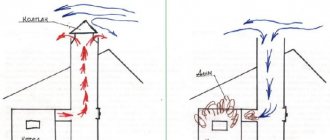

From there, oxygen-rich air, necessary for active combustion of the fuel, enters the firebox. Smoke, soot and exhaust gases are removed through the pipe. Gas exchange in the chimney is based on the draft force - the pressure difference in the upper and lower sections of the chimney. At the top, the movement of air masses occurs more actively, as a result of which an area of low pressure is formed there. Due to this, the smoke from the firebox rises up the chimney by force of traction and comes out. But under normal conditions, heat will also come out of the stove along with smoke and carbon monoxide. To hold it, as well as regulate combustion and draft, a damper is used inside the chimney.

Such a do-it-yourself chimney damper is usually installed along with the construction of the stove, and it happens like this:

- lay out one row of bricks,

- place the gate on a brick row, having previously cut out a place for it,

- a groove for the handle is also cut into the brick,

- the second row of bricks is laid out (place enough mortar so that there are no gaps or cracks).

Greetings, dear guest!

Today's article will focus on a modest element of an individual heating system. Its name is a chimney damper. I wouldn't be surprised if some of you haven't even heard of this name. But this inconspicuous detail can save you up to 25% of fuel. How can this be? Read the following material and you will understand everything.

Main types of gate valves

The damper is a partition that is located inside the chimney. It follows the shape and area of its cross-section and, when closed, almost completely covers it. Changing the position of the damper allows you to increase or decrease the opening of the chimney pipe, increasing or decreasing the air flow. Using the damper, you can stop the movement of air after lighting the stove.

The gate valve is a thin metal plate that is manually adjusted using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or is inserted inside the pipe and fixed with an axial rod.

The damper in the chimney performs the following functions:

- increases traction force in difficult weather conditions;

- increases the intensity of combustion in the furnace due to increased oxygen flow;

- reduces draft when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat loss after the heater has warmed up.

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce the draft and reduce the intensity of the flame in the firebox, it is enough to close the slide valve. To increase traction, on the contrary, it is necessary to open it.

In fact, a gate is an ordinary metal plate that allows you to regulate traction.

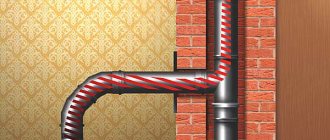

It can be installed both in single-wall and double-wall boiler systems.

If the fireplace and stove are not in use, then during this period the gate valve must be in the closed position.

As a rule, the valve is installed at the initial section of the chimney (on the first meter), since this particular section remains uninsulated.

But on the contrary, it is not recommended to install a valve on a section of a well-insulated chimney pipe. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipe expands, the gate valve may jam.

So, the main tasks of a gate valve are:

- Function of the draft regulator in the chimney.

- Partial blocking of the chimney channel section.

- Regulator of flame burning intensity in the firebox.

- Horizontal retractable gate.

Horizontal sliding gate

The plate located inside the damper extends, due to which the cross-sectional area of the chimney is adjusted. Typically, this type of valve is used for installation in brick chimneys. Often small holes are made on the surface of the plate so that even in the closed position of the gate, it does not block the smoke channel 100%.

Chimney gate valve

which represents a metal plate mounted on a rotating axis. The axis, in turn, is attached inside the chimney pipe. This device has a removable rotating disk, but with prolonged use it may become unusable. However, the design of the rotating mechanism allows you to repair and replace it yourself. The advantage of this type of device is its ease of operation. This type of gate does not require constant monitoring by the home owner.

Due to the complexity of the DIY design, the rotating mechanism is less often used when laying a fireplace or stove.

The gate design is necessary for wood-burning stoves and heating devices operating on any solid fuel.

As for gas boilers and liquid fuel boilers, here the damper rather plays the role of protecting the chimney from precipitation.

Therefore, for a gas boiler, the most practical solution would be to install a rotary mechanism. The temperature of the exhaust gases is less low than when using solid fuel, so the operation of such a mechanism will be the most convenient.

Valve on an insulated chimney

But it is better to refuse to install a rotary mechanism in the bathhouse. The fact is that it will partially allow steam to pass through when closed. And when open, such a mechanism is difficult to clean.

Made of stainless steel, the gate mechanism will not completely block the chimney, but will eliminate the possibility of flames escaping through the ash pan into the room.

There are three options for installing the gate.

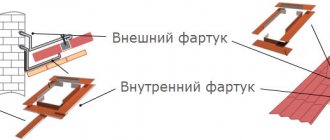

- Installing a damper in a fireplace insert. To do this, the damper is mounted at a distance of 1 meter from the heating device, which ensures simple operation.

- The “pipe to pipe” option involves combining the damper with other elements of the heating structure without the additional use of fasteners.

- Installation of a gate valve in a ventilation pipe. But this option is usually used to protect the fan motor from overheating during operation.

When purchasing ready-made chimneys, the kit will most likely be equipped with a gate valve, which simply needs to be installed according to the instructions.

But even if the finished kit does not come with this element, you can easily make the gate yourself by choosing the most optimal mechanism option for yourself.

- Horizontal retractable gate.

Horizontal sliding gate

The plate located inside the damper extends, due to which the cross-sectional area of the chimney is adjusted. Typically, this type of valve is used for installation in brick chimneys. Often small holes are made on the surface of the plate so that even in the closed position of the gate, it does not block the smoke channel 100%. This complies with fire safety regulations. The advantage of this type of device is ease of installation.

- Rotary gate. It is also called "throttle valve"

A chimney gate valve

which consists of a metal plate mounted on a rotating axis. The axis, in turn, is attached inside the chimney pipe. This device has a removable rotating disk, but with prolonged use it may become unusable. However, the design of the rotating mechanism allows you to repair and replace it yourself. The advantage of this type of device is its ease of operation. This type of gate does not require constant monitoring by the home owner.

We suggest you familiarize yourself with What is a heat exchanger in a sauna stove

Optimal location options

There are several ways to install a gate, each of which has both pros and cons. An important factor is what the chimney is made of. But modern masters prefer to use the three most common options:

- Installation in a fireplace insert.

- Fastening using the “pipe in pipe” method.

- Installation in a ventilation system.

If you install a damper in the furnace of the stove itself or on the outlet pipe, the damper will be located on that section of the pipe that is as close as possible to the heating boiler. It is worth noting that in this case the valve will be built into the main structure of the chimney. This method has its advantages, since the damper will be easier to use. This is due to the fact that the gate handle will not touch either the cladding area or the portal itself.

The damper can be installed in the ventilation system

If the master has chosen the “pipe-to-pipe” installation type, then he will not need to use special fasteners to securely fix the damper with the fireplace elements. The location of the damper in the ventilation system completely eliminates the possibility of overheating of the fan motor during active operation.

Modern manufacturers offer ready-to-install chimneys that are equipped with all the necessary devices (the slide damper is no exception). In this case, the part must be used in strict accordance with the recommendations established by the manufacturer. Otherwise, you can make a chimney damper with your own hands and at a more affordable price.

Principle of operation

In most cases, the gate is made of stainless steel with a thickness of no more than 1 mm. This part can withstand temperatures up to 9000C, is resistant to corrosion and has a low coefficient of thermal expansion.

In order to ensure maximum ease of operation of the chimney and good soot removal, the surface of the damper must be polished.

The joints are joined using the rolling method.

A standard damper covers up to 85% of the chimney, which is the optimal indicator for the effective removal of combustion products.

The damper performs the function of draft regulation - it closes or opens the chimney channel, which allows you to retain heat in the room for a long time. After burning, the valve is closed completely, which is not dangerous, since the devices have a safety gap so that carbon monoxide does not accumulate inside the room.

If there is excess draft, the valve should be closed slightly, allowing the walls to warm up by changing the combustion intensity and trapping the heated smoke in the channel. This way you can also save fuel and at the same time maintain a favorable temperature in the house. When there is smoke or the smell of carbon monoxide is felt in the room, then an inspection of the entire smoke system is necessary, including the damper, which most often in such cases has a deposit of soot.

In most cases, the gate is made of stainless steel with a thickness of no more than 1 mm. Such a part can withstand temperatures up to 900 0 C, is resistant to corrosion and has a low coefficient of thermal expansion.

Due to the movement of the damper, the gate regulates the gap inside the smoke channel. The larger the gap, the greater the flow of air from outside, and, accordingly, vice versa.

If the damper blocks the pipe, the oven stays warm longer.

Required tools and materials

In order for the finished damper to meet all the requirements, the master must prepare certain devices. The main percentage of tools can be found in every home, but everything missing can be purchased at a specialized store. To work you will need:

- Roulette.

- Drill.

- Permanent marker.

- Grinder, as well as a grinding and cutting wheel.

- Kern.

- Vise.

- Stationery compass.

- Welding machine.

- Special tap.

- Pliers.

- High-quality oil for lubricating the tap when cutting threads.

- Electrodes that are designed for stainless steel.

- Hammer.

- Kern.

- Vise.

As for materials, in this case you need to prepare:

- A stainless steel pipe with an internal cross-sectional diameter of 6 mm.

- Two 8mm bolts.

- Stainless steel sheet with a thickness of 1.5 to 2 mm.

- Metal rod or nail.

How to make a chimney damper with your own hands

It is better to make and install a damper yourself during the process of laying a fireplace or installing a metal chimney.

You can also make and install it if a steel chimney is already installed, but a damper was not provided in it. Depending on the diameter and cross-sectional shape of the chimney, the material used, a retractable damper and a butterfly valve can be made.

To make a simple retractable damper, sheets of galvanized or stainless steel with a thickness of 2-2.5 mm are required. Making guides around the perimeter of the chimney will require 6 mm thick wire.

To complete the work you need equipment and tools:

- grinder or metal scissors;

- grinding disc for angle grinders;

- drills and files for metal;

- marker for marking.

It is advisable to do all the work on a special lathe or typesetting machine. If the shape of the chimney is rectangular, you can make the simplest gate damper by simply cutting a piece of sheet steel of the required size. It is recommended to weld the handle or drill a small hole for ease of adjustment of the gate.

Before starting work, we measure the area and cross-sectional shape of the chimney, and use a marker to make marks on a sheet of cardboard in accordance with them. To make the frame, we bend the wire in the shape of the letter P, the width and length coinciding with the cross-section of the chimney. Using a grinder, we cut out the flap using a cardboard template, and sand the edges with a sanding disc.

Making a butterfly valve requires more tools and time. Most often this type of damper is used for metal chimneys for modern fireplaces and metal freestanding stoves.

Set of tools for work:

- Bulgarian;

- drill;

- pliers;

- welding machine;

- compass;

- roulette;

- marker for marking.

To make a gate, you need sheet steel up to 3 mm thick, a stainless steel pipe with an internal diameter of 6 mm, fasteners (bolts, nuts) 8 mm, and a metal rod.

- First, measure the internal diameter of the chimney pipe using a compass.

- According to it, draw a circle on sheet steel.

- Use a grinder to cut out a circle.

- Place the cut fragment into the pipe and check the tightness of the fit. If necessary, rework the valve with a grinding disc.

- Place a metal tube with a diameter of 6 cm on the circle in the center and make marks on it, retreating 3 mm from each side of the circle.

- Cut off the tube with a grinder.

- In the resulting pipe section, drill the threads to 6.8 mm on both sides.

- Drill holes in the steel circle for welding (one in the center, two 1 cm from the edge on opposite sides).

- Weld the threaded tube to the steel circle.

The slide valve is ready, all that remains is to install it in the chimney pipe.

Making a rotary gate yourself

Damper installation option

When using a chimney, it may be necessary to replace the damper, and a standard damper is not suitable for this design. In this case, the damper is made independently according to the dimensions of the pipe.

To work you will need metal scissors, a drill, a grinder and a welding machine.

- A frame for the damper is welded from steel corners with a flange size of 35–45 mm. The size of the parts corresponds to the diameter of the pipe.

- Holes are drilled in the frame to secure the axle. For a gate with straight rotation, they are located in the horizontal plane, and for an angular one, they are located diagonally.

- Bushings are welded from two sections of half-inch pipe, which ensure rotation of the axis.

- The damper is cut to the size of the frame; the material is a steel sheet 2–3 mm thick.

- An axis on which the damper will be mounted is inserted into the holes in the frame. The second part of the metal piece will become the adjustment knob.

- The plate is inserted into the frame and fixed to the axis by welding.

- For safe use, there must be a 1mm gap between the flap and the frame.

- To ensure the plate is fixed in the open state, a limiter is installed.

Drawing of a rotary gate valve

Note! The choice of damper model depends on the design of the chimney and the type of heating system, but its installation is mandatory. The device allows you to regulate the draft level and keep the heating system in working condition.

Features of installation of gate valves

To install the throttle valve, it is necessary to make markings on the pipe in order to drill holes according to the welded valve structure.

To do this, you need to measure the pipe using a measuring tape and make marks for future holes. After making sure that the marks are symmetrical, use a drill to drill holes for the future rotary handle.

The throttle valve is installed as follows:

- A steel damper circle with a welded tube is inserted into the chimney pipe.

- A metal rod is threaded through the drilled holes in the pipe through a small tube, the end of which is secured with a bolt and nut.

- The end of the rod is bent using pliers for a rotary handle.

Next, you can install the resulting structure in the chimney pipe. To do this, the first piece of pipe is put on the furnace pipe of the stove heating, onto which a structure with a gate valve is installed on top. The next piece of metal pipe is put on the gate. All connections are treated with liquid silicone sealant.

Installation of a retractable damper in a brick chimney occurs during the masonry process. To do this, after 6-8 rows of bricks, a layer of cement masonry mortar is applied, on which a wire frame is installed with the open side facing the performer. You need to insert a latch into the frame and bring it into the closed state.

The frame is covered with mortar on top and bricks continue to be laid according to the standard pattern.

We suggest you familiarize yourself with the blind area around the house, how to do it correctly, the installation of the blind area: how to make a blind area around the house, what is a blind area

The valve for a fireplace or stove comes in several types:

- Retractable horizontal installation. In this case, there is a plate inside the gate that extends, as a result of which the cross-sectional size of the ventilation or chimney pipes changes. This type of damper is used when installing brick chimneys; they are distinguished by their horizontal arrangement. The plate has special small holes - even in the closed position they do not completely block the air duct. This feature allows you to avoid future fires.

- Classic butterfly valve. Such a damper operates due to rotational movement inside the air duct. Such a gate installation consists of a metal body and a removable rotating disk. If used for a long time, it may become faulty, but replacing the part will not be difficult. You can perform this procedure on your own. Even in the absence of certain skills, you can do the entire design of a classic-type throttle installation with your own hands. This type of gate valve is easy to use and does not require constant monitoring by the property owner.

- Air damper for chimney. Refers to control parts that control the amount of fuel in the combustion chamber. Workflow management is carried out automatically.

It is not difficult to make a damper for a chimney with your own hands - for this you need to measure the chimney pipe, cut out a fragment according to these dimensions, which will be the damper. For the damper, it is better to choose stainless steel, drill a hole in it or screw in some nice handle, the main thing is that it can withstand a certain temperature.

The next step is to weld the frame for the damper; here you need a corner or metal strips up to 20-40 mm wide. Weld the structure so that the damper moves freely in the corners, adjust the inlet hole to the width and thickness of the damper. Don't forget to weld the retainer. The point is that the valve should not close all the way. Experts advise that when the damper is completely closed, there should be 15-20% of the gap left - for safety.

Making any damper for a chimney with your own hands is not difficult, even a rotary one, but when installing it on finished stoves or fireplaces, you have to dismantle the brickwork. Even when installing it in a bathhouse, you will also have to tinker with measurements and installation.

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

Why do you need a chimney damper - what is a damper, types, installation rules

A damper is a damper, a valve for a stove chimney, designed to improve draft in it. This part is made of metal. It is installed at the stage of construction of the chimney pipe and ventilation passage.

Draft is of great importance for the functioning of the heating unit. When it is strong enough, the fuel burns completely, resulting in reduced costs. When the draft is poor, a fire can occur at any moment, and to prevent this, install a damper for the stove or fireplace.

You can install a damper for a fireplace or heating unit in one of three ways:

- The damper is installed directly in the fireplace insert. It is placed at a distance of 100 centimeters from the heating device, which makes it easy to control.

- Combining the damper with other elements of the heating structure without the use of additional fasteners. This installation method is called “pipe to pipe”.

- The damper is installed in ventilation pipes. It is used to prevent the fan motor from overheating during operation.

Installation must be carried out in the closed position of the gate to prevent excess load on the engine.

Since there are a variety of models of stove units and fireplaces and heating using them is carried out in different ways, each of them requires its own type of valve.

For example, for a stove operating on gas, you will need a classic rotary-type throttle valve or a rotary automatic damper, since they are capable of blocking the chimney pipe completely and then the flame will not be able to escape outside.

At the same time, rotary valves should not be installed when installing a sauna stove, since when closed they will allow steam to pass through, and in the open position they are very difficult to clean.

As a rule, a damper for a fireplace or stove unit is sold as a complete set along with a chimney. But there are smoke exhaust structures without a damper, so you can make one yourself by buying elements for it at a hardware store. The main thing to do before purchasing them is to decide on the required sizes.

t one row of bricks. The gate plays one of the main roles in the chimney, the purpose of which is to regulate draft. Good draft means that the efficiency of the entire heating system will be excellent and fuel savings will be obvious.

When the damper is completely closed, carbon monoxide enters the room - it is not visible, not heard, and sometimes there is no smell. An exception may be a valve with a lock. In a sauna stove, you should not close the damper until the wood has burned out and the coals are covered with a layer of ash.

Before making the design and installing it yourself, consult a specialist who will calculate the draft level of your stove. For this, professionals use a special formula. Take care of yourself!

Functional purpose of the gate

To understand the purpose of this part for the chimney structure, you need to understand what a damper in a stove is. The damper provides a change in the traction force in the unit by adjusting the combustion of fuel in the firebox.

This element has an important advantage - it has low resistance relative to the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed.

Furnace valve design

The furnace valve is a structure consisting of three parts:

- Cast iron body - frame (sometimes steel is used instead of cast iron) with side grooves.

- The locking part is in the form of a panel damper, thanks to the movement along the grooves of which the sealing of the chimney is controlled.

- The control part on the panel damper is in the form of a handle. This makes it easy to operate the panel damper manually.

The shape of the valve must completely coincide with the shape of the chimney; according to this parameter, they can be rectangular, square, or round.

Technical characteristics of the gate

For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes. The thickness of the metal should be one millimeter.

The surface of the part is ground to an absolute smoothness, which has no defects, so that it can be easily cleaned from dirt and soot deposits that accumulate over time. This circumstance contributes to the appearance of good draft in the chimney pipe, since there is no resistance to the exit of gas particles.

Self-installation of a gate valve

If you need to mount a damper for a brick kiln located in the house, you should do the following:

- first of all, lay out the first row of the chimney pipe from bricks;

- then make the next brick row and make a hole in it for a gate valve;

- In one of the bricks laid out in the second row, you need to create a groove for the handle for the valve of the fireplace or stove.

A groove is a recess or slot into which an object of a certain size can fit. This is a simple job that anyone can do.

The gate is also installed for heating boilers. It allows you to control the removal of gas particles, which leads to increased efficiency and economical consumption of fuel resources.

The slide damper is the main guarantee of fire safety when organizing stove heating; it is an essential part in the ventilation pipe, chimney and boiler.

Which material is stronger

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used. It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Cast iron rotary gate with a comfortable handle. This design is suitable for a brick chimney with a rectangular cross-section, capable of supporting the fairly heavy weight of the device

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

Samples of a galvanized steel damper, chimney cross-sectional diameter – 150 mm. Galvanization, unlike ordinary steel, does not react to moisture (condensation) and does not corrode

When choosing a material, you need to focus on the characteristics of the chimney pipe and the features of the interior.

For a country heating stove, a modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.