The main active force underlying the operation of the chimney and exhaust ventilation is draft. This is a physical phenomenon based on the difference in pressure at the top and bottom of the pipe. With the correct calculation of its length and diameter, the system will always have good draft, which removes the combustion products of solid fuel to the outside, and also ensures the supply of fresh air.

But in practice, the chimney/ventilation does not always work efficiently enough. To increase performance and enhance traction, additional devices are used, including deflectors.

What is a deflector and what is it for?

This is a device installed above the chimney or ventilation duct.

Its purpose:

- to protect pipes and heating and ventilation equipment from wind, rain, snow;

- to protect against debris and birds;

- as a spark arrester on a chimney;

- to enhance draft and increase the efficiency of smoke removal or ventilation systems. When choosing a suitable design, the traction force can be increased by 15-20%, while the efficiency of heating devices also increases (due to more complete combustion of fuel).

Principle of operation

Regardless of the size, number of parts and shape of the reflectors, all deflectors operate on the same principle. The aerodynamic device is installed at the top of the chimney. This creates an obstacle to air flow. When hitting the cylinder walls, the wind loses its directional force, breaking up into many small and weaker air currents.

The remaining flows, rising through the body, partially capture the smoke coming out of the chimney. The draft in the chimney channel increases. Since there are no turbulences, carbon monoxide and smoke cannot get back into the pipe and are completely released out.

In addition to their main purpose, deflectors often perform a decorative role. However, the reflector itself will do nothing if it is installed incorrectly. Its effectiveness is influenced by the correctly selected cross-section of the connecting pipe, the chimney installed at a sufficient height and the location of the pipe on the roof.

How does a reflector work?

Deflector in translation means “to reflect.” A reflector is an obstacle to the exhaust gases, changing the direction of their movement. In the simplest model, it looks like a cap covering the diffuser.

Its main components:

- diffuser - the largest cylinder;

- pipe (lower cylinder);

- cap.

The deflector is installed so that it is always blown by the wind.

The principle of operation is based on the Bernoulli effect - when flowing around an obstacle (diffuser), the air speed increases, it becomes more rarefied and helps remove air from the pipe...

Review of popular models

In practice, the following types have proven themselves well: Grigorovich, Volpera, TsAGI, double and H-shaped deflector, rotary weather vane of the “Net” or “Hood” type.

The choice of “wind nozzle” is based on efficiency, cost of the deflector and climatic conditions of the area. Some models are available for self-assembly and installation

View #1 - classic Grigorovich cap

The most common option used in ventilation and smoke removal systems. Due to its simplicity and accessibility, the Grigorovich deflector holds a leading position among analogues.

The device is represented by a pair of umbrellas connected into a single “plate”.

The cap is installed on round pipelines or mounted through an adapter plate on rectangular and square shafts.

Basic equipment: 1 – diffuser in the form of a narrowed cone, 2 – protective umbrella, 3 – return hood. Mounting spacers connect the nozzle elements

Thanks to the design, double air ejection is carried out - in the direction of the expanded part of the diffuser and in the direction of the return hood.

The flow velocity under the lower cone increases due to the narrowing of the channel cross-section, as a result, the pressure difference increases.

Image gallery Photo from A simple umbrella-deflector for arranging a ventilation pipe is easy to make with your own hands from sheet metal. The base, and at the same time the fastening part of the deflector, will be an ordinary clamp or a metal strip with curved edges, tightened with a bolt. The diameter of the cap of a homemade deflector should be 1/3 larger than the diameter of the ventilation pipes Between the clamp fixing the deflector on the ventilation pipe and the cap of the device there must be at least one pipe diameter. A simple deflector for a ventilation pipe. The size of the base for attaching the deflector. The diameter of the metal cap. The distance between the clamp and the umbrella.

Types and designs of deflectors

Wind nozzles are made from the following materials:

- galvanized sheet;

- stainless steel sheets;

- aluminum sheets;

- copper (expensive material and rarely used)

- There are ready-made plastic caps used for ventilation systems.

According to technical characteristics, traction amplifiers can be static (stationary) or rotary (rotating).

Structurally, deflectors are available in the following types:

- TsAGI (Central Hydrodynamic Institute) design model is the most universal,

- rotating model of Grigorovich's design;

- round Wolpert;

- rotating "star" Chenard;

- "Astato" - open type;

- H-type;

- a small, simple-shaped cap also enhances traction;

- Sometimes products are made in the form of a decorative weather vane.

Features of selection

Despite the simple structure and principle of operation, in practice there are many types of wind hoods used. When choosing the optimal model for your conditions, evaluate the following indicators:

- the material from which it is made;

- principle of operation;

- individual design features.

Material of manufacture

The described devices are made from galvanized steel, plastic, stainless steel, aluminum and even copper. They may differ in their design. If you choose a simple model, it will not be difficult to make a deflector with your own hands. From the point of view of practicality and optimal price/quality ratio, it is wise to choose products made of galvanized or aluminum. Copper models are not often found in real life due to their relatively high cost. Pure plastic, due to its fragility, is not very common; most often the base deflector is made from this material. Models made of metal with a plastic coating or its equivalent for the basement ventilation system have excellent strength characteristics and decorative appeal. The chimney deflector is made exclusively of metal.

Varieties based on operating principle

Static. The simplest and most common designs, which are often assembled by users with their own hands. They are installed on ventilation ducts in multi-storey buildings and roofs of small enterprises.

Turbo deflector for ventilation. Their design includes a system of rotating blades. The head of such a device is in an active state, and the base is static.

Making a turbo deflector with your own hands is much more difficult. In the absence of certain knowledge and skills, it is better not to take risks, but to purchase a ready-made option.

Static wind hood with ejected fan. An example of modern developments involves the installation of a static hood, directly under which there is a fan, which is turned on only when a special sensor detects a drop in draft.

Deflector-weathervane. A rotating cap is installed above the ventilation duct shaft - a weather vane, rotating in the direction of the wind, which helps wind flows rush in the desired direction.

Varieties

Even deflectors that are identical in their operating principle may have a number of design differences. Below we have provided a description of the most common models.

Which deflector is better for a chimney?

The choice of reflector is a purely personal matter. Most often they use TsAGI - reliable and unpretentious, suitable for both chimneys and ventilation pipes.

Is it possible to install a deflector on a gas chimney? Need to. You will not only save fuel and increase the efficiency of your gas boiler, but you will also receive additional increase and stabilization of draft and a reduction in the likelihood of reverse draft - a dangerous phenomenon that can occur on very windy days and lead to poisoning by combustion products.

Some popular models

Most often in practice you can find the following types of deflectors:

- Grigorovich - the simplest design, which consists of a pair of umbrellas combined into a single “plate”, it is installed above the flowing wall of the channel. It is these simplest options that can most often be found above the roofs of a garage, basement, or small private house. The Volpert-Grigorovich deflector is a more complicated variation of the previously described device, consisting of a diffuser, a reverse cone and a cover combined together;

- TsAGI deflector. It involves the use of a special attachment - a ventilation hood, which can increase traction. Due to the difficulties of cleaning, this model is usually used exclusively for ventilation systems; it is not suitable for removing combustion products;

- Astato is a static-dynamic deflector produced by the French concern of the same name. The draft is enhanced not only by the force of the wind, but also by the built-in fan;

- Turbovent is a rotational deflector consisting of a movable base and a head, which is a rotating turbine;

- Khanzhonkov deflector. It is an additional wall installed around the pipe; the design is also complemented by a plate-shaped raincoat - an exhaust umbrella;

- N-shaped deflector is a design used primarily by industrial enterprises to improve the properties of ventilation and smoke exhaust systems. One of the key design features is the absence of a protective cap.

Why are chimney deflectors dangerous?

The wind nozzle may freeze or become littered - this will lead to a decrease in draft and the possibility of carbon monoxide poisoning. The possibility of freezing exists in the event of prolonged rain in frost and is extremely rare; the structure should be cleared of debris at least once every three months. In general, the design protects itself and the pipe from freezing and debris.

Don’t be afraid to install deflectors on your chimneys - you increase not only draft, but also the power of heating equipment and ventilation.

Turbo deflector

A frequently encountered problem during the construction of gas exhaust channels is considered to be a weak draft level. Incorrect circulation results in the air from the building not escaping to the outside. Smoke from the boiler can also get inside the room. To get rid of the gap, you need to install a turbo deflector on the chimney or ventilation structure.

The element in question is more suitable for systems with a natural ventilation method. The device includes several components. Its structure includes a head with blades mounted on a base using special bearings with zero resistance. This structure of the device allows it to spin at a stable speed. This property is typical even for working in gusty wind conditions.

The device has a rather interesting principle of operation. Air mass flows directed at the blades move the head of the product from its place. This leads to a discharge of the medium inside the channel and improves traction performance. For the turbo deflector to start working, the wind speed must be at least 0.5 m/s. Consumer reviews indicate higher efficiency of this device than its analogues.

Operating principle of a turbo deflector

The key property of turbo chimneys is that the rotation vector of the device head does not change. No matter which side the air flows from, the device rotates in one direction. This is important when creating outlet structures for gas boilers and water heaters. Even with strong wind exposure, the fire in the unit will not go out.

Rotary deflectors can be installed on channels with different cross-sections.

They are placed on bases of this form:

- flat square;

- square;

- round.

The size of the nozzles produced varies from ten to sixty-eight centimeters.

You can buy a turbo deflector to create boiler chimneys or ventilation structures. The turbine is used both for residential buildings and industrial structures. In agriculture, the device in question is used to remove gases and water vapor. It is also used to save electrical energy. This allows you to greatly reduce energy costs. Turbo ventilation is also suitable for the construction of various sports complexes and swimming pools.

The devices in question, ranging in size from eleven to twenty centimeters, are installed to modernize the ventilation structures of cellars or hangars. For rooms with an area of up to fifty square meters, turbo deflectors from twenty to thirty-two centimeters are needed. Products with sizes up to sixty-eight centimeters are used for large buildings. For example, apartment buildings, warehouses, etc.

Do it yourself or order the device

To resolve this issue, you need to take into account all the factors:

- Your requirements for aesthetics, the purpose of the house, the placement of caps relative to the outside of the house;

- chosen design;

- building roof height;

- the ability to independently carry out work at heights (especially if you are afraid of heights), the presence of a ladder on the roof;

- financial condition.

It is possible to make simpler stationary models yourself - the work is quite complex, but accessible.

It is quite difficult to manufacture a rotary structure; it is easier to buy such a model. The parts of such a cap are manufactured with small tolerances and higher accuracy.

Making and installing a deflector with your own hands

Before performing any work, you need to make a drawing or at least a diagram for cutting parts (pictures), think through the procedure, prepare tools and materials, perhaps make a template of the parts from cardboard and glue the model (this is if you are not at all confident in your abilities).

Here we will tell you how to make and install a TsAGI deflector yourself - a reliable model with a simple design.

To work you will need:

- Stainless steel or galvanized is the most popular material. Thickness is optional. Metal with a thickness of 1 mm is already difficult to bend, and metal with a thickness of 0.5 mm will bend in strong winds if the diameter of the product is large;

- metal scissors;

- bolts with nuts or rivets with a riveter;

- metal ruler, marker;

- electric drill;

- perhaps cardboard and a utility knife.

Size calculation

Before starting work, it is necessary to measure the diameter of the pipe and its height. Consider the planned dimensions of the future product. The dimensions are shown in Figure 1 in the table:

If your pipe has non-standard dimensions, then the dimensions are calculated using the formulas:

- deflector height = diameter x 1.6 (1.7 is possible);

- diffuser height = diameter x 1.2 or 1.3;

- cap diameter = diameter x 1.7 (1.8 is possible),

- where diameter is the outer diameter of the pipe.

How to make and assemble the device

You should start work by making the lower cylinder. Its diameter is set in accordance with the diameter of the pipe (its internal diameter must be equal to the outer diameter of the pipe). Mark, cut out a development - a rectangle (with a margin for folding the joint), bend it to obtain a cylinder shape, connect the edges with a double fold, can be connected with rivets or bolts.

The remaining parts of the deflector are made in the same way. To make a cap, a circle is cut out of a steel sheet, a small segment is cut out of it, one edge is placed behind the other, fastened with a fold or rivets - a cone is obtained.

The part can be connected using rivets or bolts and nuts. The parts are assembled together using brackets made of this steel or thicker.

Before fastening the structure and assembling it with bolts or rivets, it is necessary to drill holes.

Installation features

Only a product that has been pre-assembled on the ground can be installed! For work on the roof, there are special ladders hooked to the ridge of the roof. If the pipe has a rectangular or square cross-section rather than a round one, then you must use a special adapter. You can install the nozzle on the pipe using fasteners and dowels. The option of installation on clamps is possible, especially if the chimney is not lined with brick.

How to install on the roof

Our video shows the entire process of assembly and installation on the roof. It’s better to see all the processes once - this will help you better master some non-obvious working techniques.

Installation rules

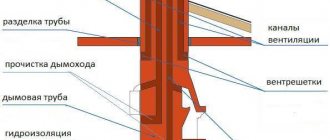

Pipe height depending on the type of roof

Before you begin installing the deflector, it is recommended to study the rules and regulations of SNiP. Particular attention should be paid to the height of the ventilation pipe and hood. You must first make a drawing so that all calculations are made correctly. The dimensions should be as follows:

- 500 mm above the roof ridge, while the air duct must be removed 1.5 meters from the top of the roof;

- if the distance from the ventilation duct to the parapet is 1.5 meters or more, the installation should be level with the ridge;

- when the pipe is removed at a distance of more than three meters, the device is placed near the deflection line at an angle of 10 degrees from the ridge down.

If the roof is flat, the deflector is installed at a height of 50 cm.

Before installing a ventilation shaft next to a chimney, you need to correctly calculate the same height of all air ducts. If this requirement is not taken into account, smoke and combustion products will enter the house.

There are several installation considerations that need to be taken into account:

- The device must not be installed in the aerodynamic area of neighboring buildings.

- The deflector must be installed in an area of free airflow. It is best if the cap is the highest point on the roof.

If a round nozzle is required to be installed on a square duct, an adapter must be used for this.