From the author: Hello, dear readers! If you decide to start arranging a heating system, then you already know that every nuance is important, from the choice between single-pipe and double-pipe options to the material from which the fittings are made. All the shopping trips, pipeline assembly, and installation of heating equipment are already behind us. But the epic is by no means over, because you are faced with a new question: how to fill the heating system in a private house.

The entire further performance of the heating structure depends on a competent approach to this process. When filling out, it is important to take into account several points at once: with what, how and in what sequence. Incorrect start-up of the coolant can cause, for example, water hammer, which can negatively affect the condition of some sections of the pipeline.

In general, as at all previous stages of arranging a heating system, it is important to be patient and have complete information. Fortunately, this is the last step, after which your whole family can finally enjoy warmth and comfort. So gather your strength and make the final push.

How to fill the system correctly

There are two fundamentally different ways to fill water.

Above

This is done using a circulation pump. It is advisable to use electric, especially in systems with a height difference of 10 meters or more.

If there is only a manual device, filling can be done from the top point using a fitting that is connected to the air valve.

The liquid flows by gravity. The drain valve at the bottom must be open. It is blocked as soon as water appears. This helps create a static pressure equal to the height of the circuit divided by 10 atm.

Next, you need to increase the amount of liquid to the working value. A hose is connected to the fitting using a ball valve. On the other hand, an adapter to a pump with a pressure gauge is attached to it. The hose is filled with water with the valve on the pipe closed. It is then transferred to the circuit, creating an air flow from the pump. The procedure is repeated 3-5 times. This must be done carefully so that gas does not enter the pipeline. Otherwise, you will have to clean the system.

From below

For the procedure, you will need a container with a volume of at least 200 liters (more, depending on the system). A pump is placed in it and the necessary pressure is created.

The latter is calculated by the pressure height: the value in meters is divided by 10 and the number in atmospheres is obtained.

The barrel is pre-filled with water. The level must be above the pipe to prevent air from entering. As the pumping progresses, the liquid is added.

When filling with antifreeze, use a small container so as not to contaminate the hose and pump housing. Its amount needs to be replenished more often, periodically stopping the process.

Filling is carried out with open air ducts. The last ones are Mayevsky’s cranes, located on batteries. Objects are placed under them to collect liquid. When it starts to flow, the valves are closed.

Pressure control is carried out using a pressure gauge. If the indicator exceeds the static one (it is taken equal to the pressure length in the circuit divided by 10), water continues to be poured into the system until the required value is obtained.

After completing the process, the pump is turned off. Then the air valves are uncorked. This is necessary to remove gas from the system. In this case, the pressure will drop, so you will need to add fluid.

Attention! Finally, you should inspect the piping for cracks and leaks.

What can lead to traffic jams in the circuit?

The importance of air vents cannot be overstated. Traffic jams in the circuit can lead to different processes:

- circulation disturbance;

- pressure surges;

- reduction in the efficiency of heating equipment;

- corrosion of metal.

Autonomous air vent

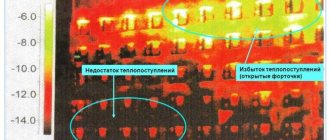

Installing an air vent in the heating system prevents the formation of plugs and pockets. When bumping into them, the coolant stops. Sometimes plugs cut off entire sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air collected in the batteries, the circuit continued to work, only half of the radiator became cold. This significantly reduces the heating efficiency and slightly increases the cost of its operation.

For open systems, one of the most serious threats is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, so there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to remove air from the heating system, oxygen reacts intensively with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to replace it.

The direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

defrosting the system.

Occurs if the valve for bleeding air from the heating system and all sensors are in good working order and working correctly. Due to the increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its quantity in the circuit. After cooling, there will not be enough fluid in the system, and the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on. And from this moment in winter, the countdown begins when the pipes defrost. Depends on how insulated the house is. Sometimes this happens in just three hours. In this case, unpleasant news awaits you at home from work;

boiler explosion.

This occurs if there is a malfunction of the valve for bleeding air from the heating system, or the temperature-controlling equipment. An unlikely situation, although possible. The results of this are very disastrous. At best, repair or replacement of the boiler; at worst, injury;

rupture of the circuit and release of the hot water fountain.

A very likely situation is that the joints may not be tightened enough. As the pressure increases, they cannot withstand and crack. At the same time, hot coolant flows from the pipe like a fountain. Not only does the circuit need to be repaired, but the neighbors also need to repair the ceiling, since you flooded it thoroughly. This is the kind of chain that can be caused by simply airing the system.

Types of coolants

The first question that you have to deal with at the decisive stage concerns what, in fact, you are going to fill the heating system with. The most obvious answer is water. But it's not that simple. It is worth first familiarizing yourself with the properties of all available coolants in order to make the best decision.

Water

Water, of course, is the most commonly used coolant. Such high popularity is primarily due to accessibility. Water is available almost everywhere - at least in our country, its shortage is very rare. In addition, it has excellent characteristics that make it an excellent coolant. The heat capacity and density of water are at a high level; during the cooling process, it releases a large amount of heat.

Safety is also an important factor. Water is absolutely environmentally friendly. In addition, it is not subject to fire and does not emit toxic fumes into the environment. Since we are talking about the use of coolant in a residential area, all this is extremely important. If, for example, an accident occurs and the heating system leaks, then the people living in the house will not be at risk of being poisoned by various chemicals.

Moreover, such a situation will not cause much damage at all - unless, of course, we are talking about a private house and not an apartment building. After eliminating the leak and replenishing the water volume to the required level, the heating system will calmly continue to operate as normal. From a financial point of view, all this is also not scary, since buying a coolant will cost you a very small amount of money.

However, you may have questions about your purchase. Many people believe that they can safely fill up with water from the nearest river. It would seem - an unlimited resource close to home, and completely free. But in fact, this is not at all true. There are two factors that have an adverse effect in this case: the chemical composition of the water and the amount of foreign impurities in the form of sand and similar elements.

Both of these nuances affect the elements that make up the heating system. As a result, the pipes become clogged with scale from the inside, and some also rust. All this significantly reduces both their strength and throughput. This is why taking water from natural sources is highly discouraged.

There are several options for how you can get water that meets the required parameters:

- purchasing distilled liquid. This entails additional costs, and delivery is not always possible. However, such water is ideal for use in a heating system,

- filtration and boiling of natural water. Everything is clear here: with the help of a filter you can clean the liquid from solid impurities, and boiling will help make it softer and change the chemical composition in a more suitable direction. However, calcium and magnesium compounds will still remain, which is fraught with subsequent scale formation in the pipes. Therefore, this method cannot be called optimal. In addition, for boiling you will need heating equipment with a container of the appropriate size, which is not always easy to implement,

- The third way is to collect rainwater. In terms of its composition, it is quite suitable. The only downside is that the process itself is not fast or convenient. In addition, there are regions where there is no rain for a long time, so this method may not be suitable. It’s worth saying right away that many are trying to replace rainwater with well water, considering them almost identical. but this is a rather serious mistake, since the chemical composition of “underground” water does not meet the necessary requirements,

- softening water using chemicals. The latter are successfully served by slaked lime, sodium orthophosphate and soda ash. With their help, all the salts contained in the water turn into a solid state and fall to the bottom of the container in the form of sediment. After this, all that remains is to carry out the filtration procedure. The resulting result will perfectly cope with the role of a coolant without causing any damage to the elements of the heating system.

As you can see, getting suitable water is both easy and inexpensive. However, this coolant has one drawback, which is often decisive - the ability to freeze. If the heating system is stopped for a long time at an ambient temperature below zero, the water will turn into ice. As everyone knows, it is expanding. The consequence of this may be deformation and subsequent breakthrough of pipes or their joints.

Antifreeze

If the possible problem of heating system freezing is typical for your region, then you should pay attention to another type of coolant - antifreeze. It tolerates both very low and very high temperatures. Even in the event of extreme cold weather, the “anti-freeze” will simply turn into a thick gel without causing any damage to the pipeline. After warming up, the antifreeze will again begin to circulate in the heating system, without losing its qualities at all.

From the point of view of its effect on pipes and other elements, this coolant is also good. Various additives are added to antifreeze to prevent the formation of rust, scale and similar troubles. But when purchasing, you should pay attention to exactly what additives are present in this or that anti-freeze product. Some of them are strictly suitable for a certain type of pipe, while having a destructive effect on others.

Also, when choosing, it is worth considering another factor - possible toxicity. Antifreeze is available in three versions; it can be made on the basis of ethylene glycol, propylene glycol and glycerin. The second and third options are more expensive, but are safe for humans and the environment.

But ethylene glycol is very toxic. It is worth considering that antifreeze is generally extremely fluid; it can “escape” from the heating system even with a microscopic chance. In the case of using ethylene glycol “anti-freeze”, the consequences can be very sad, since the toxic vapors of the main substance can very negatively affect the health of people living in the house.

Filling the heating system

The methods for filling an open and closed heating system differ.

How to pour into a closed

The closed system is equipped with a sealed expansion tank, which can be installed at will.

Attention! It is not recommended to use the upper tier of the system to fill the coolant. In this case, the air exits through the coolant layer, saturating it

When heated, air pockets form throughout the circuit.

The best option is to supply coolant through the bottom valve:

- from the water supply;

- from a container or well using a pump.

Photo 2. Diagram of a closed heating system. A sealed expansion tank and pump are installed in it.

The process itself is carried out at the beginning of the heating season or after repair work.

High-quality antifreeze can be refilled every 5-6 years.

If the liquid supply is not from a water supply, then a pump will be needed. The source is a well or container. Filling process:

- It is better to fill the system together, then it will be easier to control the pressure.

- The coolant is pumped when the heat source is turned off.

- All shut-off valves open, only the drain remains closed.

- The radiators are also overlapped, except for the most distant ones in each branch.

- The coolant supply is connected: the circuit, boiler and tank are filled.

- From the beginning of the process, the air outlet is controlled: it must exit through the safety group valve and the diverter at the top point of the line.

Important! It is recommended to install the safety group on a system with any type of boiler and fuel type. The radiators are opened, starting from the first one from the boiler

The taps are opened, the air is released through the Mayevsky tap, and after filling the radiator is closed again. This process is repeated with all branch radiators

The radiators are opened, starting from the first one from the boiler. The taps are opened, the air is released through the Mayevsky tap, and after filling the radiator is closed again. This process is repeated with all radiators in the branch.

- When the batteries are filled, the accumulated air is released from the circulation pump.

- Next, the heat source is activated and the pump is turned on at the same time. The system is being pumped - without radiators.

- When the pipes are hot enough, the taps on each battery are opened. In this case, it is necessary to once again check the air output from each.

- If everything is done correctly, the pressure stabilizes and is no more than 2 bar.

- The process is repeated for each branch; lastly, the coolant is poured into the heated floor.

If the heating is designed with a manifold, then the branches are filled separately, and the air exits through the manifold valves.

Attention! In the case of a branched structure, pumping and heating of the system is carried out only after filling all parts. The process takes a long time and requires care

If the main points are missed, air may remain in the system, which will subsequently create problems with the heating.

The process takes a lot of time and requires care. If the main points are missed, air may remain in the system, which will subsequently create problems with the heating.

How to upload openly

This is an open container with a lid, which is also a convenient entrance for water to enter the system. Fill with a regular bucket or attach a pump. The difference between filling is the pressure in the circuit: it is equal to normal atmospheric pressure. The coolant is in contact with the environment - an expansion tank is installed at the highest point of the circuit.

Photo 3. Diagram of an open heating system in a two-story building. The circuit is filled with coolant through a special tank.

Filling process:

- If a pump is used, you will need a large container to supply certain volumes.

- Water is poured in gradually, with breaks - this way the air will have the opportunity to escape. If the pump is turned on, the pressure in the circuit should not exceed two atmospheres. The water is stopped when the expansion tank itself begins to fill.

- Next, air is released from all radiators and system components. To do this, open the valves or Mayevsky taps until liquid appears.

- Water is then added to the system. The air is mostly removed independently through the expansion tank; after starting the heat source, this process intensifies. In an open system, the problem of air jams is not as acute as in a closed one.

Evaporation occurs from an open tank, so water will have to be added from time to time.

The circuit is filled from below if there is a corresponding connector.

Pressure test

Pressure test diagram.

What is a heating system pressure test? This is a test for tightness, that is, the absence of leaks during the operation of the heating pipeline during the heating season. For different systems, this process may differ in small details, but the general scheme of the test remains the same.

The test is carried out with an initial pressure approximately 1.5 times higher than the operating level. For example, if the working level is 1 atm, that is, 0.1 MPa, then the level for testing should already be 1.5 atm. For other values, the pressure at the test time is determined in exactly the same way, that is, the working pressure must be multiplied by 1.5 times.

Experts advise taking into account that the general system with couplings in pipes can withstand even greater pressure; for many heating devices it can be increased even to 2.5 MPa without damage to the equipment.

Carrying out such work is only possible if all the elements of the heating system are not built into the wall surface; a strong increase in pressure is only used for the open heating system of the house.

Pressure is supplied to the pipes using a special pump, usually a manual one. In this case, air must be completely removed from the pipes, since even its small presence can signal a depressurization of the pipe. We repeat, the heating installation must be completely filled with water; air pockets are not allowed.

Rules and stages for draining water from the heating system

How to properly drain water from the heating system in a house or apartment? It is necessary to take into account the design features of the heating system and follow the procedure.

Draining the heating system in a private house

The heating system of a private house is usually autonomous and draining does not require any permits or agreements with neighbors. It is recommended to drain the heating system in the following order:

- Disconnect the heating boiler from the network.

- The water in the pipes and radiators must cool completely.

- Turn off the cold water tap.

- Open the air valve.

- Open the valves on the radiator and boiler.

- Connect the hose to the drain valve, which is located on the return pipe near the boiler. The other end of the hose must be lowered into the toilet or a large container if the hose is short.

- Open the drain valve.

- Pump out the water until the pressure gauge shows zero.

- Open the Mayevsky tap and let air into the heating system. The air will push out any remaining water.

- Move the hose to the supply valve, open it and drain the liquid from the upper pipe.

A compressor is needed to drain water from the underfloor heating system. It is connected to the inlet pipe, turned on, and the air supply promotes the movement of liquid in the thermal circuit. A drain valve is installed on the return pipe, which opens to remove water. The compressor increases pressure gradually and stops draining when air is released at the outlet. Heated floor circuits have a small capacity and hold no more than 10 liters of water.

After draining the coolant is completed, the necessary actions to repair or reconstruct the system begin. Or they calmly leave the house for the winter, eliminating the risk of rupture of heating pipes.

Draining the heating system in an apartment building

If the radiators in the home have been replaced with new ones, they are equipped with the necessary fittings. In this case, draining the water is not difficult. This is also possible if there are shut-off valves on the path from the riser to the heating radiator. The procedure in this case is as follows:

- Shut off the fluid supply to the battery by turning the control valves.

- Open the outlet valve at the bottom of the battery. Instead of a tap, there may be a plug, then unscrew it with an adjustable wrench.

- Place a bucket to drain the water or connect a hose.

in an apartment building you need to open the outlet valve at the bottom of the battery

Difficulties arise if the battery is old, the shut-off valves are missing or painted over. Then the water will have to be drained from the entire system. It is impossible to do this on your own; you will have to submit an application to the management company. A specialist will turn off the tap in the basement and remove water from a certain riser.

If there is a bypass (vertical jumper between the upper and lower pipes of the radiator) in a single-pipe heating system, the course of action is different:

- Open the bypass valve.

- Close the shut-off valve - turn off the coolant supply.

- Open the outlet valve or plug to drain the water.

Important! If an apartment building is supplied with heat from a closed autonomous heating system, then draining the water yourself is prohibited.

This clause is specified in the agreement with the management company. The system must maintain constant pressure, and self-draining can release this pressure, which will lead to heating problems throughout the house. Therefore, you need to call a specialist to drain the water.

Draining the heating system in an apartment or house is a mandatory procedure before replacing parts of the heating system and carrying out preventive maintenance. During the absence of the owners of a private house in winter, the water must be drained to avoid freezing and damage to the system. To simplify this procedure in the future, the old heating system must be replaced, providing it with all elements of shut-off valves.

If the movement has stopped, what should you do?

Despite the high efficiency of operation, circulation in the DHW lines sometimes stops. Let's look at the main causes and ways to solve the problem.

In private

The main reason is the failure of the circulation pump. The solution to the problem will be to repair or replace this unit. Sometimes the cause of the malfunction is a simple lack of power supply - a broken wire or a false alarm of the RCD.

The second common reason is airing of the pipeline. This is due to improper line assembly where there are vertical bends in the pipe.

Air bubbles gradually accumulate in them, which sooner or later block the entire cross-section and stop the flow. The solution to the problem is to install a Mayevsky crane.

In MKD

The cessation of circulation in the hot water supply systems of an apartment building is almost always caused by the failure of the circulation pump. If a problem is discovered, you must immediately contact the management company so as not to delay repairs.

Another reason for the circulation to stop is the incorrect connection of the heated towel rail to the hot water riser in one of the apartments.

If a shut-off valve is installed on the bypass, it becomes possible to stop the circulation and completely stop the supply of hot water to all subscribers located further down the line.

Filling a closed heating system

A closed heating system is most often used. Its difference from an open one lies in the structure of the expansion tank. In a closed heating complex, the expander is sealed, and the system is filled in a different way.

To begin, prepare all the necessary materials and tools. Including: a volumetric tank, hoses for pumping water from the tank into the system, clamps for firmly fixing the hoses, pliers for installing clamps, a vibrating household pump to forcefully fill the system with water.

Scheme of removing air from the heating system.

Before pumping, you need to hermetically seal the pump with the prepared hoses using clamps. Fill the prepared tank with water and place it near the system filling tap. The pump should also be located nearby. The hose that takes in water should be lowered into the tank, and the hose that supplies the pumped water should be secured with a clamp to the filling valve. Taps and dampers for venting the heating complex must be open. Turn on the pump and start pumping water into the pipes. The pressure on the pressure gauge should gradually increase. When the entire circuit is filled, the pressure gauge readings should reach two atmospheres. Afterwards the pump should be turned off. Disconnect the hoses and turn off the fill valve.

If it is not possible to use a pump to fill the heating complex, then you can use a water supply. The scheme is quite similar to the one described above. It is enough to attach one end of the water intake hose to the water tap, and the other end to the filler in the system and gradually open first the filler and then the water supply. In this case, the pressure will have to be monitored additionally using a separate pressure gauge.

The final operation of filling the system with water will be to remove excess air from its circuit. Modern installations provide special devices for this purpose. You can ventilate the system using this device on the bypass.

Filling the heating system will be most convenient when two people work, since throughout the entire filling process it is necessary to simultaneously monitor the pressure level in the system and the operation of the pump, being near the injection valve, and monitor the tightness and the process of de-aeration of the heating radiators.

Brief installation instructions

A common option is to install the pump on a bypass. This is due to two good reasons: it becomes possible to quickly dismantle or temporarily disconnect the device from the network, for example, if problems arise with electricity.

Bypass piping: 1 – central station; 2 – “American”; 3 – filter; 4 – shut-off valves; 5 – main pipe, “return” or supply; 6 – valve that redirects the coolant to the bypass

Various modifications of ready-made pumping units are available for sale: for welding or flange connection, with places for installing taps or valves, with a special area reserved for the pump.

But if you cannot purchase a ready-made unit or there is not enough space for its installation, you can independently organize the bypass piping and fix all the parts in the places allocated for them.

The following tools and materials are required for work:

- a set of open-end or adjustable wrenches for assembly;

- pliers:

- linen thread or tow;

- Unipak sealant.

American nuts are usually supplied with the pump, but taps, adapters or fittings will also have to be prepared

Attention should be paid to more reliable reinforcement material and product diameter

Procedure:

Assembling units with taps. Two will be located on the edges of the pump, the third will become part of a straight pipe

It is important to measure the “return” section in order to accurately weld the fragment with the tap.

Assembling the pump loop. Tightening the nuts must be postponed until the final stage of installation, but for now they just need to be screwed on.

Trying on a bypass loop

Mark the places where the units are welded into the pipe.

Welding should be left to a qualified welder.

Assembly of the lower unit is on the “return” side.

Connecting the pump to the power supply.

An example is the installation of a GRUNDFOS pump.

Maintenance of the installed pump is carried out in operating mode. It is necessary to clean the filter more often and check the pressure gauge readings.

If the values do not correspond to the norm, the device must be removed and adjusted. It is better to do this in a specialized workshop.

Filling the system correctly

The easiest way is to pump water or antifreeze into pipelines connected to an open expansion tank. To do this, you need to open all the valves (except for the drain) and, by connecting the hose to the make-up fitting, fill the lines and radiators with coolant

In this matter, it is important to take your time and allow the air to leave the system on its own through the expansion tank

Now about how to bleed air from the radiators and pipelines of a closed heating system in a private house. The proposed technique, constantly practiced by our expert, plumber Vitaly Dashko, is performed in the following order:

- Open all shut-off valves of the main circuits (except for the drain).

- Close all radiator valves, excluding the very last batteries at the ends of the loops, so that circulation occurs through them.

- Get an assistant to do the work. Its task is to be in the boiler room and maintain the pressure in the network at a level of 1 bar using a pressure test pump or through a feed branch from the water supply.

- After opening the water supply, fill the main lines, expansion tank and boiler tank. Air must be released through the safety group valve and air vent at the highest point (if equipped).

- Go to the first radiator from the boiler and open both taps at the same time (slowly). Bleed the air through the Mayevsky valve and close the valves again. The assistant at this time does not allow the pressure to drop below 1 bar.

- Repeat the operation on all batteries, then turn on the circulation pump and start the heat generator. When the lines begin to warm up, open all the radiator valves one by one and remove any remaining air from them again.

Important point. Before squeezing air plugs out of radiators, be sure to bleed the air from the circulation pump and turn it on for 5-10 minutes to bleed the pipelines.

After the heating devices have completely warmed up, the pressure in the system should be in the range of 1.3-1.6 Bar. At this point the procedure is considered complete. If the system contains heated floors, then they should be filled last, using the same algorithm (on cold floors!). That is, having pumped up the pressure in the main line, you need to alternately open and close the floor circuits, bleeding air through the manifold valves, and then warm up and adjust the coolant flow.

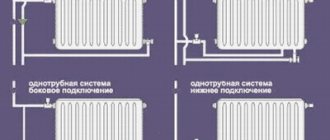

Note regarding the installation of automatic air release valves. Such a device should always be in the boiler safety group, and the second, third, and so on - only when the lines pass above the radiators. With lower wiring in a one-story house, air accumulates in the radiators, since they are located above the pipelines, and it is not necessary to install valves on them.

Closed systems

These are systems in which the liquid does not come into contact with air outside the system. They have a pump for forced water circulation and an expansion tank with a membrane. We have already written in more detail about the heating system with pump circulation here. The tank is a sealed container, which is internally divided into two parts by a rubber membrane. In its lower part there is a coolant, and in the upper part there is air under a pressure of one and a half atmospheres. It presses on the membrane, as a result of which a constant pressure of 1.5 atm is established in the system.

We'll tell you how to fill a closed heating system without errors. It is better for two people to do the job. One will fill the water, and the second will monitor the drainage of air from the pipes. But if this is not possible, you can simply turn on the water under low pressure. The pipes in this system have a slight upward slope from the boiler to the top point. At this point, a valve is installed through which air is released.

Before filling a closed heating system with water, the valve should be opened and a basin should be placed under it.

Next, the pipes should have a slight slope down to the lowest point. A tap is installed at this location to remove water from the system. There is also a pipe for pumping water into it (usually located just below the boiler). It is equipped with a check valve that allows water to flow in, but prevents it from flowing out. If a water pipe with a tap is connected to the pipe, you should simply open it. If there is no such line, another way to fill the heating system is suitable: using a flexible hose. It must be connected to the water supply system (for example, to a regular faucet in the kitchen) and to the pipe. The pressure in the water supply system should be slightly higher than the pressure of the heating system.

When the pipes and heating radiators are filled with coolant, and water begins to flow from the valve at the top of the system, it should be closed. Then you need to bleed the air from the batteries (using Mayevsky taps). The water is shut off when, after complete deflation of air, its pressure on the pressure gauge built into the boiler reaches one and a half atmospheres (or more if the boiler passport provides for higher pressure in the system).

In double-circuit boilers there is a module for feeding water to the heating system. It contains a tap for pumping water. Therefore, there will be no problems with how to fill the heating system of a double-circuit boiler, because it is easy to do. Just open the tap (at the bottom of the boiler). Through it, the heating system of the house will be filled with water. Although modern boilers are equipped with automatic air venting systems, they do not remove all air from the system. Therefore, installing the valve at its highest point is mandatory.

When starting a gas boiler, another important procedure is performed. Remove the front cover from the boiler and find a cylindrical circulation pump, which has a removable cover in the middle. Turn on the boiler and set it to operating temperature. The pump begins to gurgle due to the presence of air. It needs to be eliminated. To do this, slightly (not completely) unscrew the lid using a screwdriver until water starts dripping from inside. As soon as this happens, screw it back. Wait 2-3 minutes and repeat the procedure a couple more times. When the operation of the device becomes quiet, the electric ignition will turn on. The boiler will start supplying heat in operating mode. Once again they look at the pressure in the system, and if necessary, briefly open the feed tap.

This completes the filling of the closed heating system with water, and all that remains is to carry out additional debugging. It lies in the fact that with the help of control valves on the radiator pipes you can slightly tighten the heat supply to the batteries, which are located near the boiler, and increase its supply to distant radiators. Now there will be no problem with how to properly fill a closed heating system with water, and you can do this work yourself quickly and efficiently.

Diaphragm expansion tank

Expansion tanks are used in closed heating systems. Their purpose is to prevent an emergency increase in pressure when the volume of water increases when it is heated.

The expansion tank has an air valve located in it and is like a nipple for inflating car tires. Connect a pressure gauge to the expansion tank and check the pressure indicated in the tank's data sheet. If necessary, pump up air with a pump or compressor until the required pressure is created.

Saline solution

For open-type heating systems with natural coolant circulation, one of the possible coolant options is a concentrated solution of table salt, calcium chloride or other mineral salts. It is used to prevent heating circuit pipes from freezing in winter. Moreover, the stronger the salt concentration, the lower the freezing temperature of the solution.

Technical characteristics of the brine:

- rather low heat capacity - a solution with a salt concentration of 30% gives off 2700 J/kg deg;

- low viscosity;

- very high corrosion activity - steel pipes “burn out” very quickly from constant contact with salt;

- no toxins;

- coefficient of thermal expansion – 0.03%/deg;

- low price of salt.

How to determine the amount of fluid for the system

Scheme of a two-pipe water heating system with natural circulation: 1 – heater;

2 – main riser; 3 – expansion tank; 4 – hot water line; 5 – hot water risers to radiators; 6 – heating radiators; 7 – chilled water drain pipes; 8 – chilled water line (return); 9 – oven. To avoid excessive overflow of water into the heating system or lack of water, which can lead to the destruction of structural elements of the system, boiling of water, and the formation of scale in pipes and radiators, you need to accurately calculate the required volume of water. For this, there is a simple formula that sums up the capacity of all radiators, the heating boiler, the volume of the expansion tank and other additional elements for passing water, including pipes. The formula for calculating the volume of water in pipes is as follows: π (3.14) × r pipes × total length of pipes. About 20% is added to the total value as a margin.

You can also determine the required volume of water to fill the system during flushing by installing a water consumption meter at the entrance to the system. The readings as the system fills must be remembered and used when filling.

Once everything is ready to fill the system, you should prepare or double-check the list of necessary materials and tools.

To do this you will need the following materials:

- gaskets (in case you need to seal pipe connections after checking the tightness of the system);

- sealing tapes for pipes (used to eliminate small leaks from the outside);

- hoses (necessary for supplying water to the vibration household pump and draining water into the heating system);

- plastic container (tank - for collecting coolant before pumping it into the heating system);

- clamps (needed to seal the connections between the hoses and the vibration pump).

Tools:

- pliers (necessary for fixing clamps on hoses to attach them to the pump);

- household vibration pump (used to force water from a container into the heating system);

- pressure gauge (with its help you can easily measure the current pressure in the system).

What pressure should be in the damper

An important characteristic of the hydraulic tank is the working volume of the device, proportional to P and not exceeding the discharge of network water, at the maximum permissible temperature conditions. Before determining what pressure should be in the expansion tank of the heating system, technical data of the heating system is collected.

Initial data for determining the operating parameters of the damper:

- Total volume of coolant, liter;

- water volume of pipes of the intra-house system, liter;

- battery volume, liter;

- boiler water volume, liter.

The resulting total volume is multiplied by the correction factor established for the specific liquid. In this way, they determine what pressure should be in the expansion tank of the heating system.

So for a pipe system with a volume of 100 liters you will need a hydraulic tank with the volume:

- for water coolant: 100x0.2 = 20 l;

- for antifreeze: 100x0.15 = 15 l.

The initial P in the hydraulic tank is set at the manufacturer - 0.75 atm, but this is not enough for trouble-free operation of the networks. The conditions of equipment manufacturers determine the maximum pressure at which it is permissible to operate a solid fuel boiler and auxiliary devices - no higher than 3 atm.

If the volume of coolant in the damper “walks” from 20% to 80%, despite the fact that P in the vessel = 3 atm, then this is considered a normal operating mode. Calculation of the pressure in the expansion tank of a gas boiler depends on the actual indicator in the pipes. If P = 1.4 atm, then the damper should be filled at a coolant temperature of 18-20 C:

Damper P = 1.4 × 0.8 = 1.12 atmospheres.

This will be the operating parameter for the hydraulic tank, which will ensure trouble-free operation when starting the heating of the house.

Advantages and disadvantages

The use of distilled water as a coolant has both positive and negative sides.

The first include:

- accessibility and low cost;

- non-toxic, so safe for others in case of leakage;

- does not require special storage conditions and compliance with safety rules when filling;

- protects heating pipes from corrosion, scale and various deposits;

- has a greater heat capacity compared to other heat carriers (when cooled by 70 degrees, a heat transfer of 20 Kcal occurs).

The disadvantage is the fact that the distillate freezes at temperatures from -10 to -12 ᵒC Celsius. So, when the heating system is turned off in winter, the pipes will inevitably freeze and fail.

If you do not plan to live in a country house in winter, then it is more rational to choose antifreeze as a coolant that does not freeze.

What is the brand of cable

The wire grade is a letter designation that characterizes the material of the current-carrying conductors, insulation, degree of flexibility and design of protective covers. The following designations are used in the labeling of domestic goods:

- The first letter indicates the material of the conductor (say, A - aluminum). The absence of a letter in the brand means that the conductor is made of copper.

- The second letter represents the wire.

- The third is the insulation material (for example, R - rubber, B - polyvinyl chloride, P - polyethylene).

Marks of wires and cords may also contain letters characterizing other structural elements:

- O - braid.

- T - for installation in pipes.

- P - flat.

- F - metal folded shell.

- G— flexible, etc.

Types of wire

How to properly fill the system with your own hands

The first thing you need to do before filling the heating system is to calculate the required volume of coolant fluid. This is done simply: add the volumes indicated in the technical documents:

- Pipes and radiators.

- Boiler.

- Expansion tank.

Choice of filling pump: electric or manual

If you are pouring antifreeze or distillate, you will need a pump that will pump the liquid coolant from the reservoir (bucket, boil-off) into the circuit. The pump can be used either electric or manual. A manual one is well suited when there is no electricity and you need to fill the gas heating system.

Photo 4. Hand pump from the manufacturer Instan for pumping coolant into heating systems.

Using a submersible pressure testing hand pump is convenient not only to pour coolant into the system, but also to pressure test it: check for leaks and strength. The only disadvantage of this pump is the long and labor-intensive pumping process.

Washing, crimping and correcting defects

Before pumping, if we are dealing with a fluid change, we need to remove the waste coolant. To do this, open the drain valve. If the coolant does not come out well, we use a circulation pump.

When changing the coolant, the heating circuit must be flushed. The exception to the rule is glycerin antifreeze. When using it, no rinsing is required.

During the pressure testing process, the system is tested for strength and tightness by pumping water under pressure 2-3 times higher than normal. Monitor the pressure gauge readings: if the pressure is maintained, then everything is in order with sealing. And if it falls, you need to look for where the leaks are and correct the shortcomings.

Important! Before the pressure testing procedure, cover the floors with waterproof polyethylene!

Instead of water

The question arises: what should be poured into the heating system of a private home instead of water in order to improve the performance properties of the coolant? Antifreeze is often used for these purposes. It does not freeze even at temperatures below zero degrees. Thanks to this property, pipes and radiators will not burst if the room is very cold. If you want to use antifreeze, you should install small-diameter pipes and panel radiators to reduce the required amount of this coolant (it is much more expensive than water).

In addition, filling the heating system with this liquid is troublesome. It cannot be pumped from the water supply. And when using a hose, some antifreeze will spill. In addition, if the system is closed, it is impossible to fill the coolant through the tank.

The problem is solved like this:

- Filling from the bottom of the system is carried out using a manual (pressure testing) pump, which will help create a nominal antifreeze pressure in the pipes. An electric pump is not suitable for everyone. We need a special mechanism that can pump more than just water.

- A long hose is attached to the check valve at the bottom of the system. A large container is placed next to it. The second end of the hose will have to be raised as high as possible (to the second floor, attic) to create increased pressure. After filling is completed, the liquid from the hose is poured into the prepared container.