Thermal insulation is one of the important components of underfloor heating systems, allowing for efficient energy consumption. An insulating layer is needed to reduce the load on heating equipment and to maintain the resulting microclimatic parameters. It prevents heat from leaking through the ceiling into unheated areas and sets the required direction of heat flow. Expanded polystyrene copes with the listed tasks better than all known insulation materials: for heated floors it is generally recognized as the best option.

The well-known technical term “expanded polystyrene” combines several types of thermal insulation products. They differ in characteristics, areas of application and installation methods. Information about the differences will help you determine what is best to buy for installing an underfloor heating system with specific technical data.

- 2 Technical and technological advantages of polystyrene foam

2.1 Specifics of foil insulation - 2.2 Expanded polystyrene boards with bosses

Tips for choosing

To make a choice of material that will justify the money spent on it, you need to pay attention not only to the characteristics of the raw material and its parameters, but also to the service life of the material.

. Many types of products that have high performance and properties, unfortunately, have a short service life. As a result, replacing the thermal insulation material with a new one will need to be carried out much earlier than the need for preventive maintenance of any elements of the underfloor heating system. This is especially true for floors where the covering is made with tiles, for example in a bathroom, as a result of which it will be necessary to dismantle the products. Therefore, the minimum lifespan of floor insulation products should be 10-15 years.

Many types of products that have high performance and properties, unfortunately, have a short service life. As a result, replacement of the thermal insulation material with a new one will need to be carried out much earlier than the need for preventive maintenance of any elements of the underfloor heating system. This is especially true for floors where the covering is made with tiles, for example in a bathroom, as a result of which it will be necessary to dismantle the products. Therefore, the minimum lifespan of floor insulation products should be 10-15 years.

As for the properties of the material, which are worth paying attention to first of all, it is necessary to highlight the following:

- coefficient of thermal conductivity;

- level of resistance to mechanical loads;

- resistance to dynamic influences;

- vapor permeability;

- hygroscopicity;

- density of the material.

For rooms with high ceilings, the height of which exceeds 250 cm, you can opt for durable insulation with a rigid polymer base. For wooden floors, it is best to purchase environmentally friendly and non-flammable material. Mineral wool may be a good thermal insulation option in this case. For floors where the heating system is equipped with a cable, the main property of the insulation is the presence of a heat-reflecting layer, regardless of the form in which the material is made.

Choosing a substrate for a warm water floor

Expanded polystyrene for heated floors

Substrate for heated floors purpose and types

Expanded polystyrene is produced in sheets, it is easy to install on the base of the floor. The thickness of the slabs varies from 30 to 120 mm. The greatest thickness of foam boards should be taken when there is an unheated basement under the floor. A slab of 30 mm thickness is installed if there is a heated room under the ceiling. Expanded polystyrene must be protected from moisture penetration with a waterproofing film.

The disadvantages of polystyrene foam include the low strength of the material. Due to the fragility and low strength of polystyrene foam, when installing a concrete screed, it is necessary to reinforce a thermal insulation layer. The advantages of the material include low cost, thanks to which foam boards have become the most popular insulation material, like Knauf warm floors in our country.

Mineral mats for heated floors

Laying insulation under a heated floor

The advantages of mineral wool include the ability of the material to fill the entire space, ensuring the solidity of the heat-insulating layer. The disadvantages of mineral wool include high hygroscopicity. Mineral mats tend to absorb moisture and lose their properties. The mineral wool layer needs high-quality vapor barrier, which is not always possible to provide at a high level on your own.

For the substrate under a warm water floor, you can use mineral insulation from various manufacturers. The line of popular brands includes types of basalt and fiberglass insulation that can withstand heavy loads, which are designed for insulating floors in a house on screw piles, insulating floors on the first and basement floors.

Cork insulation for heated floors

Cork insulation impregnated with wax

To insulate the base under a “warm floor”, you can use cork insulation impregnated with wax. The material is mounted using adhesive compounds. The disadvantages of cork insulation include sensitivity to moisture and biological destruction. Before installation, care should be taken to ensure reliable sealing and vapor barrier.

Insulating the floor with cork and laying agglomerate panels under the floor covering is a good way to reduce heat loss at home. Although cork panels are inferior in terms of heat conservation to synthetic materials, they are quite appropriate.

Choosing the best insulation for heated floors.

Profile thermal insulation mats

Insulation for heated floors. Profile mats

Profile mats are designed for water-type underfloor heating systems. They provide reliable thermal insulation of the ceiling and are covered with a vapor barrier membrane. This eliminates some of the problems in the form of the need for additional installation of a vapor barrier. On the surface of the thermal insulation mats there are protrusions designed for laying and fixing flexible pipes of the water heated floor system.

The main task of the thermal insulation layer is to direct thermal energy strictly upward, that is, into the room for which heating is necessary. The thermal insulation layer prevents heat penetration through the lower floor covering.

What kind of base is it placed on?

Floor insulation with extruded polystyrene foam // FORUMHOUSE

Expanded polystyrene is an affordable type of thermal insulation; it contributes to the normal functioning of the “warm floor” system. The material can be laid on various substrates:

- sand-crushed stone - obtained by compacting soil;

- gravel - which is compacted and protected from moisture;

- concrete - equipped with a waterproofing coating;

- wooden - flooring with waterproofing.

For your information! It is forbidden to use mixtures containing solvent or bitumen mastic as a waterproofing layer on the base of polystyrene; under their influence, the insulation may be destroyed.

Using foam plastic to insulate screeds

The cost of installing a water heated floor and the installation process

Floor insulation with foam plastic under the screed is one of the types of floor insulation.

In order to form a thermal insulation layer, PSB-S-35 is used. To ensure that the joining of the slabs occurs more tightly, slabs with milled edges are used.

Before using polystyrene foam, it is necessary to create a polyethylene flooring. It will promote isolation.

Foam materials are not strong enough to withstand the load of a concrete screed. In order to reduce the load, a dense mounting mesh with a thickness of 40-60 mm is used.

Instructions for forming insulation:

- The dense bottom substrate is covered with plastic film.

- Foam boards are tightly laid around the entire perimeter. The joints are filled with polyurethane foam or firmly glued together.

- A mesh is installed on top of the insulation.

- A screed is placed on top. Its composition can be different; the basis is concrete.

If the floor is installed correctly and there is no unnecessary ventilation, the temperature in the entire room, including the floor, will be the same. After the screed is completely dry, coat. Complete drying time is at least 28 days.

There are several more commandments for forming a heated floor under a screed that cannot be violated:

- Floor insulation with foam plastic must correspond to the parameters of the room. Since the width of the foam and the screed take up part of the height of the room, there is no need to create too wide a layer where it is not necessary. For inter-apartment floors, a slab 2-3 cm thick is sufficient.

- For a more fragile type of insulation, a large layer of screed is used - 5 cm; for a more durable insulation, you can use a layer of 4 cm.

- Do not force dry the surface. The process should take place naturally in the absence of drafts and constant moisture.

- When mixing the solution, the proportions must be strictly observed.

Floor insulation

Recommendations for installation

Before starting installation work, you need to decide on the thickness of the thermal insulation layer. Keep in mind that in a private house you will need a larger layer of insulation (from 1 to 3 cm) than in heated apartments. For apartments, the recommended thickness is up to 1 cm.

Do not forget to lay moisture-proofing layers to avoid the accumulation of liquid in the layers of the heated floor.

Polystyrene foam as a type of thermal insulation is an excellent budget option for installation in all types of houses, combining reasonable prices and good insulating qualities. Do not forget about the rules for choosing and installing materials, this will greatly simplify your task.

- Related Posts

- What should a laminate be like for a warm water floor?

- How to connect a heated floor from a stove?

- How to connect heated floors in an apartment?

- What are the advantages of Gulfstream underfloor heating?

- What is film heated flooring?

- What is a warm floor National Comfort?

What are polystyrene foam boards

How to install a mixing unit for a heated floor with your own hands

The term “expanded polystyrene” means a material made by foaming polystyrene. Plates made from it are the final product for thermal insulation.

The main advantages of expanded polystyrene are its small thickness, light weight, ease of installation and affordable cost.

Important! When installing heated floors using slabs, it is necessary to take into account the load and distribute it correctly!

The advantages of polystyrene foam for heated floors include:

- High heat retention performance. Its thermal conductivity coefficient is much lower than that of polystyrene foam, which makes it possible to lay slabs of smaller thickness.

- Good mechanical strength indicators make it possible to use it as a structural element for loaded structures, a reinforcing layer and an underlying layer.

- The heat resistance of expanded polystyrene makes it possible to use it regardless of temperature.

- Expanded polystyrene boards easily withstand the effects of chemical reagents and adverse environmental conditions.

- When making plates, molds can be used that form so-called bosses, which serve as protrusions for laying between them a heating element (tube), the diameter of which can be from 16 mm to 18 mm.

- The presence of side locks allows you to form boards from slabs without “clearings”, which in turn provides sufficient adhesion and avoids seams that cause thermal acoustics.

- Excellent sound insulation performance.

- Environmentally neutral and does not pose a threat to the human body.

- Absolutely resistant to microorganisms and fungi. Its synthetic base is a reliable barrier to putrefactive processes that can occur on other thermal insulation materials during operation.

- Moisture resistance is the main advantage of the material. Even with constant moisture on the slabs, they will not deform.

- A warm floor laid on expanded polystyrene slabs will not cause harmful fumes from heating the material, since its granules are carbon and hydrogen.

- Vapor barrier indicators are provided by air capsules in the composition of polystyrene foam. They are usually practically closed and impenetrable. Therefore, neither air nor steam can pass through the material. This is a wonderful vapor barrier that cannot accumulate moisture inside.

These advantages of the material became the starting point for installing floors, including warm ones.

Features of thermal insulation of heated floors

The laying of heat-insulating materials for a heated water floor should be carried out after a number of basic preparatory measures, represented by the dismantling of the old coating and high-quality preparation of the base for the insulation flooring. A modern “warm floor” system is not able to fully function without the use of a sufficient layer of high-quality insulation.

During the operation of heated floors in the presence of unsatisfactory insulation, the formation of very characteristic “cold bridges” is noted, which negatively affects the heating of the room and is accompanied by significant leaks of thermal energy.

As a result, the cost of money to pay energy bills increases sharply.

The advantages of a water heated floor system include the possibility of self-installation, a wide price range for the materials used, rapid and maximally uniform heating, provision of a comfortable tactile floor covering and the absence of even a minimal risk of electrical injury during operation.

When arranging the system, it is necessary to take into account the fairly high cost of all components that have the highest thermal conductivity coefficient, as well as a limited selection of materials for finishing.

One of the main advantages of a properly equipped “warm floor” system using high-quality insulation is the cost-effectiveness of energy consumption, which, depending on the area of the heated room, can vary between 10-70%. Any violations during installation of such a system, as well as complete neglect of thermal insulation, minimize efficiency and do not allow optimal heating of the room to comfortable temperature levels.

Where installation is allowed

Expanded polystyrene is recommended as insulation where an increase in the load on the load-bearing floors of the room is unacceptable, and in cases with low ceilings. During construction work, polystyrene foam is used to insulate:

- water pipeline;

- roofing;

- floor;

- door and window slopes;

- walls.

For example, thermal insulation of pipe materials with polystyrene foam for water-heated floors is considered financially justified due to its properties.

In addition, the use of block polystyrene foam makes it possible, in case of problems, to gain access to the pipeline by removing a separate section of the coating. For the same reason, the product is often installed when constructing warm electric floors.

Types, their advantages and disadvantages

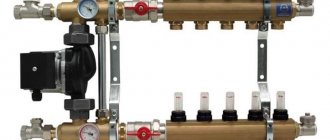

Today, several types of mats are produced, which differ in the material of manufacture, the method of fixing the pipes, as well as their purpose for certain types of premises:

Foil coated mats

Made from foamed foil polyethylene. One side of the substrate is covered with foil; when laying the plates, it is on the outside. Heating pipes are laid on top of the foil side.

Due to their properties, the products are suitable for floors that serve as additional heating. Based on this, they are ineffective for heating the floor covering on the ground floor, under which there is a basement.

The disadvantage of this type of mat is that it is necessary to lay a steel frame on which the heating circuit will be attached. During the process, it is necessary to use various fastening elements.

Backing with film

The product consists of 3 layers: polystyrene foam, foil and polymer film, which performs a protective function. A special marking is applied on top of the film, which indicates the direction. Pipe installation will be carried out in this direction. This marking greatly simplifies the process of installing underfloor heating. The heat insulator has a high density, which ensures strong fixation of fasteners.

The film interacts positively with the screed solution, so there is virtually no risk of cracks. The material is ideal for underfloor heating, serving as the main heat source. Such mats reliably retain heat and are quite easy to install.

Flat polystyrene foam

The thickness of the material is 4-5 cm, the density is about 40 kg per 1 m3, which ensures resistance to deformation. To protect the mats from the aggressive influence of the concrete mixture, before pouring the screed, a plastic film is laid on top of them. The pipes are fastened to the slabs using plastic brackets, which are quite easy to attach.

The heat insulator is suitable for systems that perform main heating functions. The main disadvantage of this type of product is that before laying the heating circuit, it is necessary to make markings.

Mats with projections

The substrate is made by hydropellent stamping, as a result of which bosses are formed - cylindrical protrusions. The products are rectangular slabs, the thickness of which is 1-3.5 cm, and the height is 2-2.5 cm. These protruding elements are placed on the surface of the mat in even rows.

This design provides a fairly simple and quick installation method, ensuring reliable fixation of the pipes and reducing the likelihood of them moving during the process of pouring the screed. There are locking connections along the side edges of the slabs, which make it possible to install the substrate without thermo-acoustic seams. This creates a continuous surface of slabs. Each plate has a ruler that makes it easier to align the mats with each other, thus creating a continuous surface of slabs.

Products with bosses can withstand heavy mechanical loads and provide reliable thermal insulation. The thickness of the material allows it to perform noise-absorbing and soundproofing functions.

This type of substrate comes in two types: regular and laminated. Laminated mats have a vapor barrier coating. This material has one significant drawback - high cost.

What is the thickness of penoplex for insulating a loggia? insulation technology

This material is foamed polystyrene in slabs, which is created by extrusion. It is ideal if you need to carry out high-quality and proper insulation of the loggia with penoplex foam, which involves doing all the steps yourself. In this case, its excellent insulating characteristics and comparative simplicity of installation operations will be useful.

What you will need to purchase for do-it-yourself thermal insulation of a loggia

Here is a list of consumables that will be needed for the work:

- Polystyrene in Penoplex boards. The main insulation layer will be created from it.

- Drywall forms an outer, smooth surface. It is also permissible to use gypsum fiber or glass magnesite analogues. Any sheet options should be selected to ensure good moisture resistance.

- Ready-made dry construction mixture for leveling the floor.

- Vapor barrier film with a foil layer.

- Construction foam. It is recommended to purchase only a product that does not contain toluene.

- Guides (slats) and fastening (screws) elements.

Do-it-yourself technology for insulating a loggia with penoplex

In each specific case, the set of techniques will be different. You will have to take into account certain decorative options and structural features. But the following algorithm can be used as an example, with necessary modifications:

- All outer layers of the floor and walls are removed.

- Window blocks are being installed. All joints are sealed with construction foam.

- Using dowels and plastic disc-shaped attachments, penoplex is attached to the walls and ceiling. Large joints are filled with construction foam. The gaps between the plates are sealed with high-quality tape.

- A vapor barrier film is attached to them with the foil side facing the inside of the room. For this operation, it is necessary to use a polyurethane-based adhesive that is not capable of damaging the penoplex. The joints between these elements are closed with metallized tape.

- A screed for a loggia can be created from a dry mixture with a thickness of 4-5 cm. It is necessary to leave a technological gap of 0.8-1 cm between it and the walls. This is necessary to prevent cracks from appearing when temperature fluctuates.

- Wooden beams are installed on the vapor barrier film and attached to the main part of the wall. They are “sewn up” with drywall.

As it is not difficult to see, all of the above operations can be done by anyone with their own hands. To eliminate possible mistakes due to lack of previous experience, the following recommendations should be used:

- Various heating and lighting devices and communications equipment can be installed on the loggia. The corresponding utility networks are installed before finishing work is carried out.

- There is no need to create a vapor barrier layer between the penoplex and the main wall. This solution will stimulate the accumulation of condensation in the corresponding hidden area.

- If wooden slats or other sheathing elements are hidden in the thickness of the insulating layer, this will impair its effectiveness.

- For such frames there is no need to use metal guides. Such options will create favorable conditions for the penetration of cold into the premises.

How to calculate the thickness of penoplex slabs

You can do a variety of jobs with your own hands. You can also independently calculate the thickness of the foam insulation layer. To make the calculations more specific, we will make the following assumptions:

- Building location: Moscow. According to current standards for this city, the thermal resistance coefficient of walls in a residential building must be at least 3.14 square meters. on gr. Celsius/W

- Main wall: two bricks. Its heat transfer resistance will be 0.99 sq. m. on gr. Celsius/W

Thus, for these climatic conditions it is necessary to improve the existing insulation indicators by the following amount: 3.14-0.99 = 2.15 sq. m. on gr. Celsius/W With a thermal conductivity coefficient of penoplex of 0.028, the following final thickness of the slab will be required: (2.15*0.028)*100=6.02 cm.

If it is inconvenient to make calculations with your own hands, or there is not enough initial data, then you can use special programs, “calculators”. They are posted on specialized websites of penoplex sellers.

Types of thermal insulation

Penofol

Penofol is produced and sold in the form of rolls.

Penofol is foil-coated polyethylene foam. It is a soft and flexible material produced in rolls.

Thermal conductivity coefficient is 0.037 – 0.052 W/m×°C.

Penofol is easy to install and easy to cut. The foil layer effectively distributes heat over the entire surface of the heated floor.

However, this material also has a drawback: under the weight of the screed and floor covering, it can shrink, while the volume of air bubbles included in its structure will significantly decrease, which will entail a loss of thermal insulation qualities.

Important! As a rule, this material is used on the upper floors of apartment buildings, where there is a warm heated room under the heated floor, and the floor slab is sufficiently heated. . This material is not suitable for basements and first floors, as well as balconies and loggias, basements and garages.

Sometimes, however, it is not possible to raise the floor a significant distance, then the use of penofol may be justified.

This material is not suitable for basements and first floors, as well as balconies and loggias, basements and garages. Sometimes, however, it is not possible to raise the floor a significant distance, then the use of penofol may be justified.

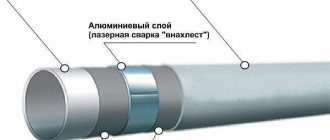

Advice! When choosing floor insulation, look for foil materials with an aluminum foil thickness of at least 30 microns. We are not interested in lavsan coatings with reflective properties, only thick foil!

Cork tree

Balsa wood insulation is sold in rolls, sometimes in the form of mats or slabs.

The thermal conductivity of balsa wood ranges from 0.035 – 0.05 W/m×°C. As you can see, this characteristic is comparable to that of penofol.

However, it is believed that a layer of cork 2–3 mm thick is sufficient to insulate a heated floor. This is certainly a controversial opinion.

The advantage of cork insulation is its naturalness. It consists of absolutely natural raw materials and does not emit toxic chemicals under any conditions.

However, there are also disadvantages:

- high price of material;

- the possibility of rotting, a breeding ground for fungi and mold;

- damage from biological corrosion;

- the cork needs waterproofing.

Therefore, for cork wood we can also conclude that it is only suitable for floors with minor losses and warm heated floors. More often, cork is used as a substrate for laminate flooring.

Expanded polystyrene

Foiled polystyrene foam for thermal insulation of floors with markings.

Expanded polystyrene is the most acceptable option for thermal insulation of floors.

This is caused by a number of reasons:

- The material has a density sufficient for laying under the screed - more than 35 kg/m³;

- Expanded polystyrene slabs have sufficient thickness - 50 mm, thanks to which you can easily arrange effective 100 mm thermal insulation of the floors of basements and basements, first floors, etc.;

- The material has low thermal conductivity - 0.039 W/m×°C, which with a layer of 50 - 115 mm provides complete insulation and reduces heat loss to nothing;

- Expanded polystyrene for floors is covered with a laminated layer of foil from 30 microns thick, which makes this type of insulation optimal;

- The installation instructions suggest simple DIY work, and markings on the foil make it easier to install the heating elements;

- The slabs do not shrink under the weight of the screed and maintain stable thermal conductivity for many years;

- Polystyrene is chemically inert to solutions of salts, acids and alkalis;

- The material is biologically inactive and is not food for living organisms or a substrate for fungi;

- Does not change parameters and does not emit harmful chemicals in the temperature range from – 180 to +180 ° C.

Advice! When purchasing a thermal insulator based on polystyrene foam, look for flooring material, since facade and other configurations may not be suitable for working near heating elements and emit harmful substances or change their parameters and shape.

Expanded polystyrene is especially convenient for warm water floors if it is equipped with special locks for securing the tubes.

Important! According to most experts, it is extruded polystyrene foam with a density of 35 kg/m³ that is the best means of thermal insulation for heated floors, especially on the ground floors and in the case of unheated rooms below.

Characteristics and advantages of polystyrene foam

Expanded polystyrene is better than other thermal insulation products, since its use produces a rigid and durable surface. It is similar to polystyrene foam, but has a denser structure with smaller cells.

The main positive properties of expanded polystyrene:

- the insulation has high moisture resistance and the ability to not allow vapor to pass through, which makes it possible to maintain thermal conductivity at the required level, even when the product is exposed to moisture;

- provides excellent sound insulation, which is an important condition when installing warm systems;

- environmentally friendly and not dangerous to humans;

- insulation prevents the development of fungus and mold;

- resistant to chemicals;

- retains operational properties at maximum temperatures, from - 50 to + 85 degrees;

- It is lightweight, which allows it to be used without the risk of weighing down the structure;

- easy to use: laying, trimming, processing, so you can do all the procedures yourself;

- fits on any base, as its surface is smooth;

- reduced level of thermal conductivity due to the bubble structure;

- has a waterproofing property, as it is resistant to moisture.

It should be said separately about the safety of the material - it does not burn and even has the ability to self-extinguish. But there is also a disadvantage of insulation - the release of toxic substances during smoldering.

How a water floor pie should look like in layers

The preparation of the cake under the floors must be carried out in strict accordance with the manufacturer's recommendations. Installation work is carried out as follows:

- Subfloor - the base must be level. The quality of the remaining work depends on this. The pie can be laid on the floor slabs without pouring a rough screed.

- Thermal insulation - at this stage the insulating layer is installed. Profile polystyrene mats for laying water heated floors are made in slabs 1 by 0.5 m (size depends on the manufacturer). But for greater convenience, you can order a larger single-piece slab directly from the manufacturer. The plastic mounting base is placed exclusively on a leveled base. The design of the plastic system allows the finishing concrete layer to be poured directly on top of the mats. The recommended thickness of polystyrene foam insulation is at least 5 cm. The slabs are fixed using special adhesive solutions, and the joints are secured with polyurethane foam. Additionally, the thermal insulation is secured using “fungi” dowels.

- The reinforcing layer is laid only if a concrete underfloor heating system is used. The lightweight polystyrene underfloor heating system does not require a reinforcing layer. Aluminum guides are laid on the slabs, on top of which a water circuit is mounted. To increase the strength of the floor, plastic substrates are covered with slabs (DSP, GVL, etc.). A polystyrene floor can withstand a load similar to a cement screed, but weighs approximately three times less. A reinforcing mesh must be laid on top of the conventional insulation and, after laying the water circuit, it is filled with concrete mortar.

- Finishing layer – any type of floor covering can be used. Modern systems allow the installation of laminate and linoleum. In this case, it is recommended to comply with special operating rules.

Laying a warm water floor on mats, as shown by a comparison of thermal insulation materials (their technical characteristics and difficulties associated with installation), is more appropriate. The permissible load on the polystyrene foam system is 50 kN/m². The weight of the structure allows installation even in high-rise buildings on the top floors, where the use of concrete pie is prohibited.

Additionally, laminated extruded polystyrene foam with bosses is resistant to moisture, easy to install and facilitates installation of the water circuit. The only drawback of polystyrene material is its cost. But if you consider that plastic mats do not require additional components for fixing pipes and subsequent screeding, then the difference in price becomes not so significant.

Features of laying insulation

When installing insulation, you should take into account the types of mats used, since the nuances of laying the material depend on this:

- A foil backing must be placed on top of the foam. A reinforcing mesh is laid along which the pipes are installed.

- The thickness of the mats varies from 5 to 10 cm. It is allowed that the thickness of the cork sheet substrate be reduced to 2-3 mm.

- The joints of the insulation are taped with tape. The plates are fixed using anchor dowels and adhesive.

- The foil material spreads in such a way as to best reflect heat, i.e. metal side up.

Some installation details are indicated in the operating instructions. Strict adherence to the manufacturer's recommendations is the key to high heat transfer using heated floors.

Which foam to choose for the floor

Of course, if possible it is better to do without foam. After all, why do we need extra chemicals in the house? Outside the house is still tolerable. But it is better not to use it indoors. Chemistry after all...

But if the problem of floor insulation is acute, if there is no way around it, if you have firmly decided to use polystyrene foam for these purposes, then now we will consider this issue in detail.

So, preference is often given to non-press self-extinguishing polystyrene foam - PSB-S (it has already been written about foam brands on Vyborstm.ru). This material has found its greatest application in insulating houses (walls, floors, etc.).

All that remains is to choose the desired thickness and density.

We will consider the example of a case where polystyrene foam is laid on the floor (to insulate it), and a concrete screed is placed on top. This is the most commonly used option.

In addition, it must be taken into account that the concrete screed will have very low vapor permeability, which will protect against the penetration of harmful vapors from the foam into the living space.

Review of manufacturers and models

Mats for warm water floors are produced by many foreign and domestic companies. However, the leading positions are occupied by only four brands, whose products are in greatest demand among buyers.

Insulation materials from the German brand Oventrop have high quality and performance indicators. The model range includes profile mats with bosses, slabs for dry installation, installation roll and folding insulation in polypropylene film.

The slabs with bosses have dimensions of 100 x 100 cm, they are available in two types: with thermal and sound insulating properties, and also without thermal insulation

Another German manufacturer of thermal insulation is the company Rehau, whose mats are also attracting increased interest from consumers. The main products are polystyrene foam mats with bosses, equipped with layers of thermal and sound insulation.

The slabs have dimensions of 145 x 85 cm and are suitable for laying pipelines with a diameter of 14 to 17 mm. The total thickness of the insulation is 50 mm. The delivery set includes clamps for securing pipes

Among Russian manufacturers, the most famous are the products of the Energoflex company.

The model line includes several items:

- foil-coated polystyrene foam boards;

- thin roll insulation with foil;

- expanded polystyrene slabs with bosses.

All heat insulators are marked with a coordinate grid with a pitch of 50 mm.

Foil boards are covered with a protective film, they are available in the form of a roll or book, have dimensions of 100 x 500 cm, the insulation thickness is 2.5 cm

Water floor insulation produced by the Russian brand Ecopol has excellent consumer and performance characteristics.

The manufacturer offers smooth polystyrene foam boards and mats with bosses. The panels are equipped with a locking connection and covered with film waterproofing.

The mats are available in three versions: with 20 and 30 mm thermal insulation and without thermal insulation. The dimensions of the slabs are 115 x 85 mm, the total thickness of the layers is 38 mm

Coolant mounting methods

There are different ways to attach the coolant when installing heated floors:

- Reinforcing mesh - water system pipes or electrical cables are secured to the mesh with plastic ties. In places where the heating elements are bent by 90 degrees, 2 pieces of tie are enough, and when turning by 180, you need to fix them in 3 places.

The advantages of this method are ease of operation and reliability. The disadvantages are the labor-intensive process, the possibility of damage to the pipe materials on the mesh during operation of the system, if they are made of metal-plastic. In addition, the thermal efficiency of the floor may be reduced due to voids between the pipes and the mesh.

- Plastic guides - placed on polystyrene foam with a smooth surface. They can be different in length, connected by inserting one into the other, and secured with clasps. Before fixing them, you should decide on the layout of the heating elements. To secure the guides, plastic brackets are used, which are installed on polystyrene.

The advantages are the speed and convenience of laying out pipe-rolling materials and their reliable fixation. Disadvantages - the marking process is complicated and there is no mesh to reinforce the screed.

For your information! It is possible to make guides yourself from wooden slats.

- Plates with bosses - no additional fixation is required, since the bosses are guide parts, the coolant is laid between them according to any pattern. The mats make it easier to install pipe materials, and the bosses protect them from damage. The main disadvantage is the high price of the slabs.

- The use of Velcro is a new method of fastening. Fixation is done by wrapping the pipes with adhesive tape, which is attached to the base. This method is quick and convenient and does not require additional fixation. The downside is that installation becomes more complicated due to the lack of markings, and slight shifting is possible when walking on the floor.

Everyone can choose a thermal insulation material for heated floors, a method of arrangement and fixation of the coolant according to their wishes and financial capabilities.

People who have experience in working with thermal insulation can install extruded polystyrene foam themselves without foil, fastenings and markings. If you do not have this experience and do not rely on your own strength, then you should invite specialists to install a warm system with a polystyrene foam backing.

The use of expanded polystyrene for thermal insulation of wooden floors

on logs with extruded polystyrene foam includes the following activities:

- Dismantling skirting boards and existing flooring;

- Inspection of the elements of the wooden system, repair and replacement, if necessary, of rotten parts of the support beam, joists and rough flooring;

- Impregnation of all wood areas with fire-retardant and antibacterial solutions;

- Installation of a waterproofing layer. Polyethylene or foil film is placed between the joists, and the edges should extend to the ends of the joists and the side surface of the walls by 10 - 15 cm.

- Expanded polystyrene slabs are used to create an insulating layer between the joists on top of the rough flooring, connecting them to each other with tongue-and-groove ends. Gaps and cracks are filled with polystyrene foam or special glue with pieces of expanded polystyrene;

- Installation of a vapor barrier layer. Sheets of profiled membrane or thick polyethylene film are laid with an overlap, the size of which is 15 - 20 cm, and secured to the joists with construction tape. Seams and edges are taped with special adhesive tape.

- Re-installation of plank flooring in a wooden house, the floorboard of which is pre-impregnated with a fire-retardant and antiseptic composition.

Floor insulation along joists can also be done with a cheaper material - foam plastic, since the main load in this case will fall on the wooden structural elements.

Parameters for choosing insulation, what we pay attention to

When purchasing floor heating from expanded polystyrene, you should take into account indicators such as: quality and variety.

Initially, the quality of polystyrene foam boards for heated floors is determined by their appearance. The following points should be taken into account:

- Color - should be bright and uniform, which indicates compliance with the technological process. Most often sold in blue or orange. The color scheme itself does not affect the characteristics of the product.

- Smell – a strong odor is unacceptable, a slight, slight specific odor may be present.

- The shape is clear geometric, and the edges are smooth and do not crumble.

- The granules are the same size without voids.

- The surface is flat, otherwise the thermal insulation qualities will be reduced.

For your information! Experts recommend especially inspecting the place of the cut or break. If the granules are intact in this area, we can talk about their poor adhesion to each other. In a high-quality slab, when broken, the granules should also be destroyed.