The underlay for heated floors is a mandatory element during installation. Its main function is thermal insulation. In addition, it can additionally provide sound insulation and help level out minor unevenness in the subfloor. On this page you will find a description of all types of substrates, with their pros, cons and recommendations for use.

But substrates are made from different materials. What type of underlay and for which floors is best suited? Let's look into it thoroughly.

Features and purpose

People who want to install heated floors in their home often wonder whether some special lining material is needed for the system, or whether the lining in this case is just a waste of money. In fact, underlayment at the base of the floor is really necessary. It allows you not only to level the floor before laying the final coating, but also performs other useful functions. The underfloor heating is designed to retain heat and prevent its leakage into the lower layers of the system. Simply put, this layer has thermal insulating properties.

In addition, a high-quality and correctly installed substrate allows you to increase noise insulation in the room.

In order for the underfloor heating to cope well with its purpose, it must be selected and laid correctly, focusing on the material of manufacture of both the underlay itself and the final coating. Only in this case will the underfloor heating system work correctly.

General requirements for substrates

In addition to high thermal insulation properties, there are some other requirements for substrates. Depending on compliance with these parameters, thermal insulators can be used as substrates for heated floors, or their use in this area is considered inappropriate.

For example, the substrate should not change its characteristics after getting wet. Mineral wool , although it is a good heat insulator, contact with water is generally contraindicated. Once wet, it loses all its heat-protective properties. Therefore, if it is used as a substrate for installing a heated floor, it is first packaged in plastic film.

Although often such protection does not save. In some cases, substrates are assigned characteristics that are not inherent to them. For example, the ability to hide floor defects.

IMPORTANT: Only rigid sheet substrates made of foamed polymers can level out defects in the subfloor.

But let's get down to business. And so, the substrate for installing a heated floor, in addition to thermal insulation qualities, must have:

- Elasticity.

- Rigidity.

- Hydrophobic properties.

Other qualities are not decisive.

Types of heated floors

Today, manufacturers of heated floors supply them for sale in several varieties. For each specific type of floor, it is necessary to use a suitable lining option - only in this case will it fully cope with its functions:

- Laminate flooring can be warm, however, the installation process is quite labor-intensive and responsible. A distinctive feature of such floors is the need to use two substrates at the same time. When installing a warm laminate floor, a lining is needed to protect against overheating and prevent further deformation of the final coating - lamella panels.

- In some cases, it is necessary to lay a two-level lining under an electric heated floor The first level is laid during rough work, and the second level during final installation. The use of insulation allows you to increase the thermal conductivity of the cable, protect it from overheating, and also save on electricity bills.

- Infrared film heated floors also require mandatory preliminary laying of the substrate. It is this that will allow all the heat from IR heating to be redirected inside the room, and not inside the floor. In addition, walking barefoot on such a floor is much more pleasant. It is worth noting that infrared heated floors are often called film floors. Various materials can be used as insulation.

- A water floor may have a heating function, and in this case the choice of substrate must be taken extremely seriously. Not only the quality of heating, but also the safety of walking on the floor covering will depend on the right choice. It is the lining that can significantly reduce heat loss when hot water passes through pipes and concrete beams.

The underlay is a significant, integral part of the underfloor heating system, regardless of its type.

That is why you should give preference not only to affordable and suitable types of this insulation - it is important to choose from the entire assortment a truly high-quality and safe lining.

Types of insulation and their characteristics

Today, floor insulation, which is used as a substrate, is available in various types. All of them are divided into three large groups depending on their composition.

Natural insulation materials

Such substrates are made from organic materials and are extremely vulnerable to various harmful microorganisms. For this reason, such a substrate must have a special impregnation. Its service life is shorter than that of insulation from other groups. This category includes substrates made from:

- Jute or flax. The fibers are small in size, the insulation itself perfectly absorbs moisture, dries quickly and does not change its original size and appearance. The downside is low thermal insulation.

- Cork insulation is versatile in use, has one of the best sound absorption and thermal insulation properties, does not deteriorate over time, and has reliable protection against harmful microorganisms. Sold in rolls at an affordable price. It has good elasticity and is difficult to burn.

- Felt insulation is made from sheep wool. This material has a thickness of up to 5 mm, does not burn well, absorbs and allows moisture to pass through, and is also a breathable material. This underlay is only suitable for soft floor coverings. Has high thermal insulation rates.

Despite such quality characteristics, natural insulation materials are used quite rarely due to their short service life, tendency to accumulate condensation and change their size.

Synthetic linings are considered the most popular.

Synthetic substrates

The synthetic lining can be foil or regular. Synthetic insulation with foil has a greater ability to reflect heat. It is not recommended to lay them on a concrete floor, otherwise the reflective foil surface will quickly collapse. It is also worth knowing that there are insulation products on sale both with regular foil and those with a reflective coating - multifoil. It is a more modern, reliable and improved material.

Any metallized synthetic base has two big advantages: increased thermal conductivity and complete immunity to any pathogens and bacteria.

Currently, such insulation is made from the following materials:

- polyethylene foam is used as a substrate for any heated floors. It has low flammability, excellent noise-absorbing and heat-insulating properties, does not wrinkle and easily returns to its original shape. It goes on sale in sheets and rolls.

- Polyvinyl chloride foam can be hard or soft. It is rarely used as insulation and only in a rigid modification. It ignites easily, and during the combustion process many harmful chemical compounds are released, so polyvinyl chloride foam is currently used extremely rarely. Sold in rolls and sheets with a thickness of 3 to 20 mm.

- Expanded polystyrene is a foamed synthetic material with good flexibility. It is resistant to fire and is perfect for installation under any heated floors. Sold in both sheets and rolls. On sale you can find both a smooth substrate and with special bosses. The second option is intended only for installation under a water-heated floor.

- The polystyrene backing is simpler when compared with the previous option. It is often used due to its availability and good thermal insulation qualities. Typically sold in sheet form. The backing of this synthetic material can be ribbed or smooth. Ribbed insulation is used when installing water heated floors.

- Mylar backing is a kind of hybrid of expanded polystyrene foam. The fact is that sheets of this material are covered with a thin layer of foil, so the heat-reflecting ability of lavsan is simply amazing. The surface of such sheets is usually smooth, but sometimes a ribbed lining made from it is also available for sale. It is worth noting that perforated lining of any kind in most cases is intended for installation under a water-heated floor. The pimples allow the insulation to adhere tightly.

Some manufacturers produce substrates with markings, thanks to which you can easily understand how and where exactly the sheets or pieces of insulation should be connected to each other. During the installation process, such information must be taken into account.

Mineral insulation

This group includes only one type of substrate - fiberglass or, as it is popularly called, glass wool. The material is not subject to combustion, does not absorb or conduct moisture, but it does not have any thermal insulation properties. From all of the above, we can conclude that it is better to purchase synthetic underlays for heated floors, since they have a longer service life and have better heat absorption than mineral or natural insulation.

How to choose the right substrate

Before you begin installing the heating system, you should decide which underfloor heating substrate will best perform certain functions. Do not forget that each manufacturer tries to sell as many of its products as possible, and often the advertised product does not meet the qualities that were declared.

There are a number of factors that determine a high-quality substrate, and this is what you should proceed from when choosing it:

Thermal conductivity of the material

. The best substrate is considered to be the one with the lowest values, and they are determined by the thickness of the product and the material used. At the moment, there are substrates with improved energy conservation properties; they have a foil coating.

Energy saving occurs due to the reflection of infrared radiation - as a rule, this figure is 20-30%. All materials used in the manufacture of substrates meet the required construction standards for residential premises.

Strength characteristics – resistance to constant and dynamic loads

. There are materials that are compressed due to prolonged constant loads. Because of this, thermal conductivity increases. This effect should be avoided by selecting the correct load so that the mechanical impact over the entire surface is as uniform as possible.

Manufacturability

. Laying the material will be cheaper the easier it is to work with. This characteristic varies quite widely for many materials. It is best to give preference to polystyrene foam. It is very technologically advanced, the lining under a warm floor made from it is often thin, no more than 5 mm, and it is easy to cut with simple scissors.

The underfloor heating pad made of polystyrene foam is flexible, its edges are easy to connect to the walls. This material is easy to measure, cut off parts, make adjustments, and you can simply bend it near the walls. In this case, it is much easier than installing chipboard or OSB.

Additional qualities

. To simplify installation work even more, some manufacturers draw a grid on the front side or leave special bosses that protrude.

This modification greatly simplifies the installation of pipes, making it possible to secure them during the installation of the lining. The result is faster repair work, improved efficiency and longer service life of the heating system. The coolant can be installed at an equal distance, so that overheating in individual zones is excluded, that is, the entire floor is heated evenly.

Price

. This parameter is quite significant. If you have special technical knowledge, you can install heating in such a way as to obtain high heat saving rates, and also significantly save the finances necessary for the purchase of materials.

Environmental friendliness of the material

. Although any of the materials tends to emit toxic fumes, their quantity and intensity are not always the same. Due to the fact that the substrate for underfloor heating pipes will be used in conditions of elevated temperatures, it is worth paying special attention to indicators of environmental safety and harm to human health.

When looking at advertising brochures from various manufacturers about certain lining materials, not everything needs to be taken on faith, and some characteristics may not be paid attention to at all.

Noise-absorbing effect.

Any person who remembers at least something from physics lessons knows that sound is transmitted through air. Since absolutely any insulating material does not allow air to pass through, therefore, the same thing happens with sounds.

UV resistance

. Since the substrate under a heated electric floor, as well as under a water-heated one, is not directly exposed to ultraviolet radiation, this characteristic of the material does not in any way affect its performance. Perhaps it is necessary to isolate the source of X-rays, but this is unlikely to be found in a residential area.

Waterproofing properties

. Let us say right away that the presence of moisture under heated floors, both water and electric, must be eliminated during the heating installation process. If a leak suddenly occurs in heating water pipes, the faster it is repaired, the less expenses the owner will have, and the materials will not be exposed to prolonged exposure to moisture. But in the case of an electric heated floor, the presence of moisture is, in principle, excluded, otherwise short circuits are possible. Therefore, how well the substrate resists moisture does not matter.

Price factor

. In most cases, the cost of the material includes the costs of advertising and product promotion. That is, when buying a product from a well-known company, you significantly overpay for the brand. However, there are many types of quality products on the market at more affordable prices, just not as advertised. A competitive price allows new firms to promote their products on the market, attract the interest of buyers and earn a business reputation.

Thus, all of the listed indicators will help you not make a mistake when choosing a substrate for a heated floor, no matter what design, so that it lasts as long as possible, and you can save on assembly.

Laying technology

It is immediately worth noting that the laying of each type of underlay should be carried out using individual technology, selected depending on the type of heated floor and insulation material. There is a general list of technological work performed sequentially in all cases:

- Removing old flooring or screeding a new floor. If you plan to install a heated floor in a new house, then you must first complete all the rough work, screed the floor in any convenient way, wait for it to dry completely, and only then proceed to the next stage. If there is a need to dismantle the old floor, the covering is completely removed using tools, all debris is collected and taken to a landfill, and the working surface is thoroughly cleaned.

- It is necessary to carefully examine the concrete base for defects such as chips and cracks. They must be eliminated using a cement mixture.

- You need to make sure that the floors are perfectly smooth and free of any flaws. In case of strong differences in heights, it is strongly recommended to fill the entire floor with a self-leveling mixture, the layer of which should not exceed 3 cm.

- In order to level out temperature changes, a special tape is attached along the perimeter of the lower part of the walls.

- A durable polyethylene film is spread along the entire perimeter of the base with an obligatory overlap on the walls.

- The substrate is laid on top in an even layer. Please note that all parts are laid end to end. The substrate should be placed so that the density of the material is at least 150 g/m2. m.

- Then the remaining parts of the underfloor heating system are installed one by one.

Despite the apparent difficulty, laying both the substrate itself and the entire heated floor system is not that difficult. This work requires patience and care, and if you have the right skills, it does not take much time.

Manufacturers

Today, even the most sophisticated buyer can get lost in the assortment of substrates. In order not to get confused at the most crucial moment and to purchase truly high-quality and reliable insulation, it is recommended, first of all, to pay attention to the products of the following manufacturers. Among them there are both domestic and Korean and even Portuguese companies.

All of them are engaged in the production and manufacture of high-quality insulation for underfloor heating, and customer reviews only confirm this:

- Foamed roll insulation is considered one of the best today. It has excellent heat-insulating and noise-absorbing characteristics. During operation, the substrate does not emit harmful substances and does not change its technical characteristics.

- The largest domestic company offers its customers a truly wide range of underfloor heating, made from various materials. The quality and safety of each insulation is confirmed not only by reviews, but also by relevant quality certificates.

- “Izokom” is a series of thermal insulation materials for various types of underfloor heating. In the company's assortment, every buyer will be able to find a substrate that ideally meets all requirements. So, there are more than 4 types of different insulation materials.

- Valtec is a joint Italian-Russian brand that produces thermal insulation products, including underlays for heated floors. Today the brand's assortment includes more than 6 varieties. The distinctive features of this company's products are affordable prices, the highest quality and an individual approach to each customer.

- Premium Cork is a Portuguese manufacturer that produces natural substrates of excellent quality at an affordable price. The assortment is not that large, but the products are really high quality.

Reviews about underlays for heated floors from these manufacturers are the most positive, so it is quite reasonable to study their products first, and then make a decision about purchasing a specific insulation.

Foam pads

This type of substrate is the most common. The determining factor for this popularity was the low price and excellent insulating qualities. This is achieved due to air bubbles that are inside the material.

In this type of substrate, air bubbles also play a negative role. This especially happens in places where the substrate and coating fit tightly. Under the influence of pressure on the surface, the material simply wrinkles and loses its magnificent qualities.

Despite its qualities, the use of such insulation under laminate and parquet is not recommended. This is due to the fact that the floor surface becomes “soft”. During operation, such coatings tend to deform and lose connection in special locks.

Successful examples and options

Warm floors are not only profitable and practical, but also very beautiful, and the photographs only confirm this once again:

- The seemingly ordinary tiled floor in the kitchen turns out to be very warm. Now owners don’t have to worry about the child getting cold while sitting on it. This flooring not only looks harmonious and modern, it is also extremely practical.

- Thanks to a properly installed heated floor and the use of an optimal underlay, walking barefoot on the tiles will be comfortable and comfortable even in the bathroom, and the floors themselves will look as stylish as possible.

- Electric heated floors are most relevant in a children's room. It's no secret that kids most often play on the floor, and in the cold season you simply cannot do without such a warm and safe floor.

A properly installed heated floor not only guarantees coziness, but also gives comfort, beauty and safety.

For information on how to choose a flooring underlay, see below.

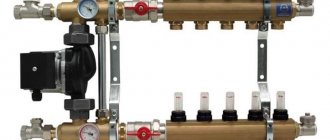

The technology of heating rooms using underfloor heating systems is becoming increasingly popular today. Depending on the type of heating elements, heated floors are available in several modifications, which allows the use of any floor covering. An important aspect of the high-quality and efficient operation of such heating systems is properly performed thermal insulation. To avoid wasting precious heat, an underfloor heating system is used. It is created from materials with a heat-reflecting effect.

↑ What should be the underlay for a heated floor?

Polypropylene or foamed polyethylene, which are covered with lavsan film with a metallized layer, are used as a substrate for heated floors. The metallization layer promotes uniform heat distribution, and foamed polyethylene prevents heat from escaping into the screed.

In addition, the foam backing for heated floors has low thermal conductivity and this prevents heat transfer to the screed and ceiling. The permissible temperature for such a porous substrate is quite high (up to 90°C), which makes it possible to lay heat exchanger pipes or a heating cable directly on a Mylar film with a metallization layer. In addition to high thermal insulation and waterproofing qualities, the substrate has high reflective and sound insulating properties. It should be noted that the markings on the substrate in the form of a grid allow you to lay the heating cable according to the calculated step.

Is it worth laying - expert opinion

The lining plays an important role in the functioning of the heating system: it enhances the thermal insulation properties of the screed, prevents temperature loss in the house and significantly reduces the cost of resources (electricity, gas, firewood, etc.) for heating. A properly selected and installed underlay will allow you to enjoy all the benefits of heated floors.

Thermal insulation for heated floors

[ads-mob-1][ads-pc-1] In addition, the underfloor heating can improve not only the performance of the heating system, but also the performance of the laminate. Special linings under the water floor prevent the formation of condensation under the laminate, which significantly extends its service life. Thus, the lining is an integral part of a modern heating system.

↑ Underlay for laminate flooring

Laminate is a very popular floor covering today. It is inexpensive and easy to install. When planning the installation of a heated floor, you need to consider the use of a substrate that will separate the laminate from the heated floor and base. If you do not do this, over time, play will certainly appear in areas of the floor where there are gaps between it and the base. When walking in such places, the laminate flooring will knock and make sounds.

To avoid these troubles, a special substrate 2-5 mm thick is placed under the laminate. Today, a specialized substrate with increased thermal conductivity is produced under the laminate. It will solve several problems at once: it will become an additional insulation, serve as a shock absorber between the coating and the base, level out residual differences in the base, and prevent damage to laminate boards and the occurrence of squeaking.

The underlay under the laminate will prevent damage to the laminate boards and the occurrence of squeaking.

It is installed between the “warm floor” system and the floor covering – laminate. Most laminate manufacturers recommend rolled polyethylene as the most suitable material for the substrate under the laminate. The underlay for laminate under heated floors made of polyethylene is perfectly compatible with alkaline building materials such as concrete and cement, it is resistant to chemicals and microorganisms (bacteria, mold). Instructions for laying heated floors under laminate.

Special substrates

Due to the fact that underlays are used not only for floor coverings, but also for walls, for wallpaper and other things, there are special types of such insulating material.

In the case of insulating the surface of a parquet floor, it is also necessary to use specialized substrates for this.

There are underlays specifically designed for laying over floor screeds.

↑ Substrate for water heated floors

Warm water floors are very popular among consumers due to such advantages as cost-effectiveness and ease of installation in any room. When installing a water-heated floor, an important point is the use of a special substrate. What materials is it made from?

Rolled cork as a substrate for underfloor heating

On a water heated floor, the substrate can be made of extruded polystyrene foam, rolled cork, isoplat, but the most common material is foamed polystyrene.

Underfloor heating - extruded polystyrene foam

The substrate will direct the flow of warm air upward, ensuring efficient operation of the structure as a whole. Thanks to high-tech production, polystyrene foam underfloor heating has acquired a number of positive qualities, such as:

- thermal insulation;

- soundproofing;

- low level of moisture absorption;

- efficiency;

- ease;

- fire safety;

- ease of installation;

- environmental friendliness;

- resistance to temperature changes;

- durability (service life - 100 years).

Important! The presence of self-centering locks on the substrate makes it possible to easily install foam plates, and their shape allows for convenient placement of pipes in special channels, without the use of additional fasteners.

The bosses on the surface of the foam boards allow pipes to be laid without additional fasteners.

Criterias of choice

Attention should be paid to the thickness and quality of the litter. Try to choose bedding with a small thickness - 2.5–5 mm is enough. Insulating material of this thickness costs on average about 70 rubles/m².

What properties does high-quality litter have?

- High level of thermal and waterproofing;

Cork underfloor heating - High reflectivity;

- It must be environmentally friendly and safe. That is, when heated, the material should not release toxins and other harmful substances;

- Wide operating temperature range. Try to choose only the material that can easily withstand temperature fluctuations in the region of -20 – +80 degrees;

- High sound insulation ability;

- Resistance to mechanical damage;

- Easy to install.

The polystyrene foam lining most closely matches the above parameters. Experts advise choosing it first.

Prices:

- Self-adhesive foil polyethylene (thickness 7–8 mm). Cost: from 90–100 rubles/m². Has good waterproofing and protection against temperature loss;

Comparative table of characteristics of different floor heating systems - One-sided laminated polyethylene is a waterproof lining under a water floor with high-quality thermal insulation. Thickness: 8 mm. Cost: from 65 rubles/m².

- Foamed polyethylene "Tepofol NPE" has excellent heat and sound insulation properties. Thickness 2–3 mm. Cost: from 8 rubles/m²;

- Foil polystyrene is a material with excellent heat-insulating properties. Reflects heat well. The cost depends on the thickness. Average price: from 70 rub/m²;

- Underlay for water heated floors Tuplex (thickness 2–3 mm) has the best waterproofing properties. Also, the lining under the Tuplex water-heated floor muffles the sound of footsteps. Cost: 80 rubles/m²;

- The heat-reflecting lining with lavsan coating has additional protection against chemicals and good vapor and sound insulation. Thickness 2–3 mm. Cost: from 85 rub/m²;

Cork backing (various thicknesses) is an environmentally friendly product with excellent thermal and sound insulation. Cost: from 60 rub/m². [ads-pc-2][ads-mob-2]

↑ Features of laying the substrate under an infrared heated floor

In order for the film heated floor to function in strict accordance with the instructions, it is necessary that all its elements are correctly installed.

The heat-reflecting substrate under the film floor is laid with the reflective side up

This applies primarily to the underfloor heating substrate:

- The substrate for an infrared heated floor can be made of fiberboard sheets or magnesite plates. In this case, it is laid directly on the screed, which was previously covered with aluminum foil.

- If the substrate for a film heated floor is made in the form of a polymer metallized film, it is placed under the film with infrared resistors with the reflective side up. This material is environmentally friendly, thin, flexible and elastic.

- The insulation must be laid in a continuous mass over the entire area. The connection of individual panels is carried out end-to-end, the seams are necessarily taped with tape or adhesive tape. This will create additional vapor and waterproofing. If necessary, the material can be glued.

The seams between the backing sheets must be taped

In conclusion, I would like to emphasize once again the importance of using a substrate when creating a modern heating system in your home. This will give you the opportunity to take advantage of all the benefits of underfloor heating systems. A properly insulated house will retain heat within itself and will not release it into the environment.

Heating systems used in everyday life have different technological capabilities and differ in efficiency. According to many indicators, “warm floor” heating systems take first place in popularity today. In many ways, this attitude towards this heating method is caused by the increased pace of small housing construction. Country houses, cottages and country houses are increasingly becoming objects of permanent residence. Against this background, residents and owners of such housing strive to achieve the most comfortable conditions in their apartments. Laying a water-heated floor is completely capable of satisfying such aspirations.

Heating built into the floor is convenient in all respects. In addition to the high efficiency of the method of heating rooms, such a system opens up wide possibilities for the design of the interior space of residential buildings. However, in order to achieve an acceptable temperature regime inside a residential building and make the heating equipment operate optimally, it is necessary to follow the installation technology and correctly configure the control mode.

Laying a water heated floor is a sequential process in which each stage has its own meaning and sequence. The decisive stage of the entire work will be a correctly made concrete screed for a warm water floor. What is special about installing heated floors at home? Which element of the floor design should you focus your attention on?

Underlay for heated floors. What it is? What is the meaning of this element

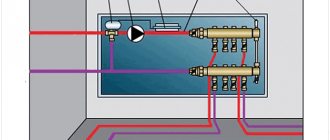

The main condition for the successful operation of a home heating system underfloor heating is not only correctly connected and configured equipment. In many ways, the efficiency of heating depends on how well the underfloor heating substrate is made, how the water heating circuits are laid and, finally, what kind of finishing floor covering is chosen.

Even if you have the most powerful heating boiler, a pumping and mixing station with a lot of auxiliary instruments and devices, a pipeline made of the most expensive pipes, just one detail can neutralize such advantages. Incorrectly laid pipes and incorrectly selected insulation for a water floor will make even the most modern equipment ineffective. Precious heat will be wasted, giving only a small part of the floor surface.

Note: the coolant circulating through the pipes of the water circuit must transfer up to 80% of its thermal energy to the floor surface, uniformly heating the entire floor area in the heated room.

With this we actually answered the question of why a substrate is needed. Thermal insulation is laid on a rough prepared surface, increasing the heat transfer of the water circuit towards the floor surface.

For reference: the substrate consists of a heat-insulating material, thereby creating a “thermos effect”, and a layer of waterproofing, which prevents moisture from penetrating into the subfloor.

It is appropriate to recall here that water floors are usually installed on concrete and wooden floors. A leak resulting from damage to the integrity of the heating pipe, the formation and accumulation of condensation can cause flooding of the basement and lower floor rooms.

Basic materials for underlayment for heated floors

And again we return to polystyrene foam. Why is this material most often used? What are its main features during application?

Traditionally, a warm water floor in most cases looks like this. A polystyrene foam substrate is mounted on the rough base, which is covered on top with a Mylar vapor barrier film and metal plates. Often, instead of plates, foil film is used. The main role played by metal plates or foil is maximum and uniform transfer of thermal energy to the floor surface from the heating pipeline.

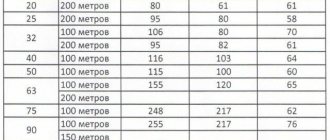

The distinctive features of extruded (foamed) polystyrene foam include one of the lowest thermal conductivity coefficients. According to this parameter, judging by the data in the table, expanded polystyrene is second only to mineral wool.

This material does not allow heat to escape into the subfloor, and by interacting with the metal layer, ideal conditions are created for the uniform distribution of heat over the entire surface of the floor with maximum efficiency. The floor screed, laid on top of the entire structure, becomes a solid heating element with a large heating surface area.

Important! Expanded polystyrene can withstand heating temperatures up to 90 0 C, so pipes can be laid directly on the substrate without fear of harming the insulating material.

Usually, in practice, they work with expanded polystyrene, the density of which is 25-35 kg/m3. Thick foam is used in the underlayment of floors on the first floors, which are located directly above the foundation or above the basement rooms. Here a sheet or plate 100 mm thick is taken. If there are no slabs of the required thickness, foam plastic is laid in two layers (50mm + 50mm).

For interpanel floors, when installing warm water floors in a city apartment, polystyrene foam with a thickness of 20-30 mm is used.

Other materials used when equipping the substrate are:

- foil materials;

- cork covering;

- mineral wool;

- mineral mats;

- Fiberboard;

- penofol.

The choice of one material or another is determined by the condition of the base on which the water loop will be installed in the future and the type of floor covering. A water heated floor that provides heating of the interior space in a separate room must have a substrate capable of performing two functions:

- high reflectivity;

- prevent moisture from penetrating into the subfloor in emergency situations.

It is appropriate to say that recently profile mats, which are universal materials, are being used more and more often. The products have a thermal insulation layer and bosses, with the help of which it is convenient to quickly and accurately lay the loops of water circuits.

However, in this case there are also disadvantages. The waterproofing properties of a substrate made from profile mats leave much to be desired. Therefore, in such a situation it is necessary to lay an additional waterproofing layer.

Important! During the installation process, it is worth remembering that the foil layer must extend onto the walls in order to compensate for the thermal expansion of the screed.

Markings are applied to the substrate, according to which the water pipe is laid. Here it is necessary to take into account the pipe laying step, which for heated floors should not exceed 30 cm.

Characteristics of materials for substrate equipment

In some cases, homeowners try to use any materials that are on hand or that are low cost for thermal insulation.

Let's consider the characteristics of a substrate made of various materials:

- Polyethylene foil, self-adhesive - thickness 8 mm. It is highly reflective, hydro and sound insulating.

- Single-sided polyethylene, laminated - thickness 8 mm. It has good thermal insulation and water resistance.

- Foamed polyethylene (Tepofol) - only 2 mm thick. Average thermal insulation parameters;

- Foil polystyrene of various thicknesses, with applied markings. High thermal insulation, hydro and sound insulating characteristics;

- Tuplex type substrate, branded product 3 mm thick. Has maximum parameters of heat, hydro and sound insulation;

- The base is made of polystyrene foam and lavsan coating, 3 mm thick.

The thinner the thermal insulation, the lower the thickness of the entire layer cake. Accordingly, the height of the flows in the room decreases slightly. The thickness of the screed over a water heated floor can vary between 50-60 mm.

The listed materials are the set that is presented in the retail chain today. The cost of materials may vary. Here, the amount of material used in the work and the intensity with which the floor heating should be carried out are taken into account.

Less commonly used is cork, which is made from crushed oak bark. There is one important aspect here - such material is environmentally friendly. However, if moisture gets in, it can become a place for fungus to develop. This material is supplied in rolls.

The cheapest option is foil polyethylene. Of all the listed materials, foiled polyethylene is the most common today. Despite the fact that the material is characterized by a high degree of thermal insulation and fairly moderate waterproofing, foil polyethylene does not have sufficient rigidity and strength.

In order to achieve quality when installing heated floors, try to use foil polystyrene. You should not pay attention to the cost of the material, it is high, but the obvious advantages will more than compensate for your costs, making the water floor durable and effective.

Electrical

Heating occurs due to the energy released by conductors under the influence of electric current.

By design, heated floors of this type are film, that is, infrared, and cable, which have a heating element in the form of simple flexible cables with conductive elements inside. During the installation of electric floors, complications may arise, so you should take into account all the parameters of the existing wiring in advance, as well as correctly calculate the protective fittings.

For heating to be effective, the design power per 1 m2 must be at least 0.25 kW. It is very important when installing a heated floor that the correct underlay for the heated floor is selected. There are a large variety of substrates, and each of them is designed to perform specific functions.