Using valves with thermal heads

These are the best taps that can be installed on radiators in the heating system of a private home. Tuned to a certain air temperature, the thermal head acts on the valve stem, forcing it to open or close its flow area. In this way, automatic quantitative regulation of the coolant passing through the heating device occurs.

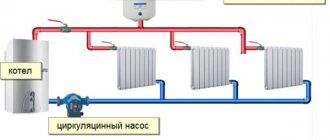

The thermostatic valve is installed on the supply line to the battery, and a balancing valve is installed on the return line. It is a mistake to assume that the system will be automatically balanced by thermal heads; valves are needed in any case. Installation of conventional ball valves instead of them is allowed for centralized heating or in systems with associated coolant movement (Tichelman loop). But it is unacceptable to regulate the coolant flow using a ball valve, and it will not work.

Advice. Most models of thermal valves have a mechanical blocking mode for the flow area. If you received products without such a mode, then to service the battery you will have to install an additional cut-off device, as shown in the diagram:

Ball valve: how to replace it with your own hands?

Due to the fact that it has a slightly different device, installing taps on radiators, as well as replacing them, can create minor difficulties. Although the repair itself does not take much time: after unscrewing the nut, a new oil seal or valve axle box is installed, and then the nut is returned to its place. However, even before repairing the ball valve, you need to prepare the necessary materials.

Materials

To repair a ball valve, you need to ensure you have the following tools:

- screwdrivers;

- pliers;

- hex wrench;

- gloves;

- used spare parts.

Purpose. Characteristic

Taps ensure efficient operation of water pipes. The heating system cannot operate without these devices, and in some situations, using it without them becomes downright dangerous.

When the riser leaks, it is the shut-off valves that shut off the water, which makes it possible to make repairs without stopping the entire system

An important function will also be managing the heat dissipation of the battery.

The minimum set for the normal functioning of a conventional heating system consists of several types of shut-off and control valves. When connecting to the radiator, shut-off ball valves are mounted on the supply pipes, on the outlet and on the bypass. A mechanism is installed on the supply to adjust the coolant pressure. The radiator itself must be equipped with a Mayevsky tap. to bleed air. As you can see, the number of such products is significant and this is by no means an excessive option.

Taken together, this system allows:

- turn off the radiator without shutting off the entire circuit for repair, replacement, or maintenance;

- direct all coolant through the heater with the bypass turned off;

- control the pressure power through the radiator to reduce or increase the temperature;

- drain water, bleed air;

- protect the system from hydraulic shocks and breakdowns;

- regulate the efficiency and level of heat supply, which saves heating costs.

Requirements

The criteria for the variety of types of taps placed on heating radiators are: design, principle of operation and material

It is important to know that mechanisms of this type are divided into shut-off and control valves. What are the best taps to install? It must be taken into account that they have a rather complex structure and must meet a number of requirements in order to function in difficult conditions

- coolant temperature up to 200°C;

- must withstand pressure of 16–40 bar;

- high corrosion resistance;

- resistance to mechanical loads.

For heating systems, such mechanisms are made more stable. Conventional taps and valves for cold water cannot be installed in heating radiators.

Each connection has its own characteristics: there are regular and corner (for the bottom connection) taps. This division allows you to maximize the distribution of pipes when installing a heating system. The design features of the valves allow you to hide the pipes behind the decor, in a screed, or to mount radiators in a small space under a window opening.

In everyday life, the general name is used - “faucets”. But from a technical point of view it is correct to distinguish:

Heating systems also use thermostats; it is not recommended to use dampers or valves in radiators - they quickly become inoperable. If shut-off valves are needed, then ball valves are the best for this. They have only two positions - closed/open. Valves with a cone are designed to control the pressure manually. There are also mechanisms for automatic adjustment - these are thermostats with valves or cones.

Peculiarities

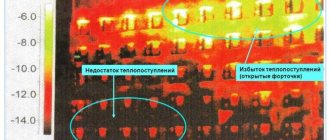

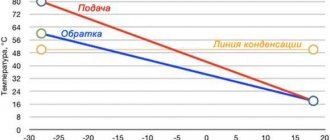

Modern heating systems are characterized by uneven heat distribution across individual rooms. The amount of heat depends on the coolant flow, and the water flow is controlled by the balancing valve. If you do not use this device, the amount of heat received will decrease, moving away from its source. Accordingly, there will be different temperatures at different points in the network.

Previously, in simpler systems, this problem was solved by installing pipes with certain diameters or installing special throttle washers. The latter are characterized by a certain passage size, which ensures the flow of the required volume of water.

The design is a specific valve with which the flow of coolant is regulated. Sometimes, as an addition to this mechanism, two fittings are built in, which measure the pressure in different zones in relation to the control mechanism. Additionally, it connects to a capillary tube to coordinate with other controls.

There are two types of these valves: manual and automatic.

The first type, as you might guess from the name, is controlled manually. The products are inexpensive and therefore are the most common. By changing the pressure difference and water flow, they are able to adjust both individual sections and the entire system. In addition, at control points it will be possible to monitor the indicators of the working environment, and in the event of a breakdown, turn off any fragment and arrange repair work. Unfortunately, the adjustment of such valves is carried out under the condition of a constant flow of coolant. If it changes, the system will not be able to function. Therefore, it is better to install such models in private homes and with a simplified heating system.

Automatic valves are devices that do not require human intervention to operate. They independently regulate the volume of coolant spent or the pressure difference. Some models can work together using an impulse tube to control both flow and differential pressure at the same time. It is also worth adding that very often measuring instruments are attached to balancing valves to make debugging the system less complicated.

Automatic devices are attached to both the inlet and return pipelines. They are connected to each other by a thin tube, thanks to which the valve moves and shuts off the flow of water depending on pressure surges. Such a device is configured once and does not require further adjustment.

Valve models may differ depending on the coolant (steam, water or glycol solution), type of building (private house or ordinary high-rise building), installation location (on the supply or return pipeline), operating environment (at what pressure, temperature and volume of distilled water it operates device). Finally, valves can exhibit other properties, for example, regulate pressure and be equipped with additional devices, such as a measuring diaphragm.

Control valves

Operating principle

A control valve for a heating radiator is a device that allows you to automatically control the movement of the coolant.

The design of such products is quite complex, but they also work much more efficiently than valves for manual adjustment:

The bellows, a container filled with liquid or gas, is responsible for sensing the outside temperature. As the temperature rises, the bellows expands, affecting the control unit.

Please note! The price of liquid and gas-filled devices is approximately the same, but the operating features are different. Thus, gas models react faster to temperature changes, while liquid models more accurately convey the effect on the coolant flow

- The expanded bellows presses on the valve stem, which lowers and gradually closes the valve saddle, through which hot water enters the battery.

- When cooling, the opposite situation is observed: the rod rises and the lumen of the saddle expands.

We set the degree of initial compression of the bellows ourselves, either by setting the temperature value we need on the digital display, or by rotating the mechanical adjustment knob. It is also possible to connect the thermal valve with external sensors - in this case, the movement of the rod is controlled not by a bellows, but by a servo drive under the influence of an electrical or hydraulic system.

Installation of thermostatic tap

Among specialists, the question of whether it is necessary to install taps on heating radiators is practically not discussed. Even installing a simple ball valve provides a number of advantages, and the presence of a high-quality thermostat is even more so. However, the instructions advise following a number of rules when installing such devices:

Example of correct installation of the product

- First, you need to select a suitable valve modification. For systems with one pipe we use products of type RTD-G, for two-pipe systems - RTD-N.

- Secondly, before installing taps on heating radiators, we check the direction of movement of the coolant (indicated by an arrow on the body). If we mix it up, the device will work any way, just not the way we need it.

- Thirdly, we place the thermoregulation head perpendicular to the plane of the battery. so that the heat flow does not affect its operation.

How to regulate heating radiators using taps is also a fairly simple question:

- Having installed the valve on the radiator, we check the tightness and supply coolant to the system.

- Using the handle or dial, set the average temperature.

- After about an hour, we adjust the valve setting according to our feelings and checking the thermometer in the room.

- If necessary, repeat the adjustment again. however, this is usually not required.

The system is adjusted by rotating the handle

After this, it is usually necessary to interfere with the operation of the device no more than once a month - in case of sudden changes in external temperature.

Thermostatic thermostats

By design, the thermostatic device resembles a manual valve. At the same time, a thermostatic head is installed on its valve, which controls its operation. Thermal head includes:

- a temperature sensor that responds to air temperature and is connected to the shut-off head of the valve;

- an adjustment mechanism having a control handle and an adjustment scale.

You can select the room temperature, which will be maintained at a constant level without further intervention, by turning the knob according to the desired value on the scale.

Electronic thermostats

Electronic devices equipped with a control unit, as in the following photo, have maximum functionality. In addition to the electronic temperature sensor, it includes a microprocessor circuit and a panel with buttons and a display. The locking head is moved by an electrically driven mechanical relay based on a signal from a control circuit.

Such thermostats allow you not only to maintain the required temperature with maximum accuracy, but also make it possible to program their operation. For example, every day on weekdays, during the absence of residents in the apartment, the heating level of the appliances is automatically reduced, and before the arrival of the owners, the rooms will be warmed up again to the optimal temperature.

Details about self-installation and configuration of a thermostat for a heating battery are written in this article.

Three-way valve

An unconventional device for regulating the temperature of heating devices is a three-way valve, shown in the photo below. It is placed at the connection between the bypass and the supply pipe that goes to the battery. In order for the device to perform the function of stabilizing the heating level of the radiator, it must have a thermostatic head.

- If the temperature near the head rises above the required value, the supply of coolant to the battery stops, and the liquid flow moves through the bypass.

- When cooling occurs, the valve opens again and the radiator heats up.

This adjustment method is used in single-pipe systems with vertical wiring.

Increasing the heat dissipation of batteries

We found out how to adjust the temperature of heating radiators using thermostats. However, it should be borne in mind that all adjustment devices can reduce the degree of heating of the heating device, but are not able to force it to give off more heat.

If the radiators in the apartment do not need to lower, but increase the temperature, you can resort to measures that can change the situation.

- The minimum intervention that will help the batteries get hotter is cleaning the pipes and filters and freeing the radiators from air pockets.

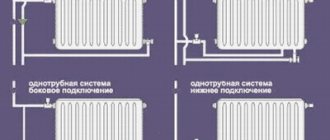

- Changing the connection diagram. Diagonal installation of heating elements is considered the most effective; the largest heat losses are observed with the bottom connection.

- Adding additional sections.

- Installation of a heating element into the radiator.

Why do you need to make adjustments?

Setting the optimal temperature of the heating radiators allows you to create the most comfortable living conditions indoors. In addition, adjustment allows:

- Remove the effect of air in the batteries, allow the coolant to move freely through the pipeline of the heating system, effectively transferring its heat to the interior of the room.

- Reduce heat consumption costs by up to 25%.

- Do not keep windows constantly open if the air in the room is excessively overheated.

It is advisable to set up heating and adjust batteries before the start of the heating season. This is necessary so that later you do not experience discomfort in the apartment and do not adjust the heating temperature of the batteries in emergency mode. Before setting up and adjusting the radiators, initially in the summer you need to thermally insulate all windows. In addition, you need to take into account the specific location of the apartment:

- In the middle or corner of the house.

- Lower or upper floor.

After analyzing the situation, it is advisable to use energy-saving technologies to maximize heat conservation inside the apartment:

- Insulate walls, corners, floors.

- Carry out hydro and thermal insulation of the seams between the concrete joints of the panel house.

Without this work, it will be useless to regulate the temperature of the radiators, since the lion's share of the heat will heat the street.

Heating safety valves

In addition to the heating bypass valve, the normal operation of the system requires the installation of other types of control and safety valves. During heating operation, excess air may appear and the coolant will move back. To prevent these phenomena, it is necessary to provide in advance the installation of an air valve for heating and return.

Types of safety valves

Depending on the functional purpose, there are two types of safety valves - to remove air from the system and to prevent the reverse movement of water in the pipes. Without these elements, the operation of the system may be unstable, which will lead to a violation of the temperature regime, destabilization of pressure and the creation of emergency situations.

Installation of safety valves is carried out in the following areas of the system:

- In places with the highest probability of excess pressure - after boilers, circulation pumps, on collectors;

- A heating ball valve or its petal equivalent must be mounted on the return pipe. It is also necessary to install this component in the circulation pump piping;

- At the highest point of the circuit - to remove air from the system. A Mayevsky tap is installed on radiators and batteries.

Safety valves must not impair the performance of the heating system. First of all, they eliminate possible malfunctions in the heat supply. In the “inactive” state, these system components should not impair the speed of movement of the coolant or affect the temperature regime.

To prevent a sudden drop in pressure in the make-up unit, it is necessary to install a heating drain valve. It will prevent a sharp rise in pressure.

Heating air valve

During heating operation, air pockets may form in pipes and radiators. The reason for this is the high oxygen content in the water and the coolant temperature above +100°C. As a result, oxidation of metal components occurs and the temperature distribution changes. To avoid these situations, it is necessary to install valves to bleed air from the heating system.

Working principle of the air valve

First of all, the air valve for heat supply is mounted in the safety group along with the drain and pressure gauge. In the heating circuit they are located on a straight branch leading from the boiler. This place has the highest coolant temperature, as well as maximum pressure. In the manifold circuit, it is mandatory to install heat supply drain valves on each comb.

Criterias of choice

A radiator valve is, as a rule, a ball-type device that regulates water flow and connects pipes to the radiator. Installed on the bypass, risers, at the top of the battery, in places where air accumulates to bleed it.

Choosing a suitable faucet is not difficult, just know a few nuances:

- the diameter of the pipes to which it will be connected (DN, in millimeters or inches);

- working pressure (PN, in the range of 15–40 and above);

- type of connection, presence of thread inside or outside, American.

The choice should take into account the purpose of the reinforcement, its location, and the properties of the environment

The ratio of the input and output of the valve in the radiator, their relative position is also important

When choosing, you should consider the characteristics of the cranes:

- Ball valves, although the most common and affordable, are not very effective. It has only two modes: closing/opening;

- a cone valve is a more acceptable option due to the possibility of an intermediate position. Disadvantage: the tap must be returned to its original position and constantly monitored;

- An automatic thermostat is the most efficient, reliable, but also much more expensive than others. When installing it on a one-pipe system, a bypass must be present.

How to choose the right one

It is important to know which taps to install on heating radiators. To do this you need to know their main characteristics.

The valve, designed for installation on a radiator, is most often presented in the ball type, which ensures regulation of the coolant flow and its temperature. It is also due to this element that the radiator is connected to pipes, which can be made of different materials.

The installation can be in different parts of the battery, which include the riser or the upper part. Can be mounted on bypass. Areas where air accumulates are selected so that, if necessary, it can be vented.

When selecting an element, you need to consider the following features:

- what diameter are the pipes for which the tap is purchased;

- at what operating pressure the product will be operated;

- what type of connection will be used to attach the tap, since individual elements may have threads;

- what is the purpose of the fittings itself;

- where should it be installed;

- what parameters and characteristics does the work environment have?

- properties of the valve input and output in a specific radiator.

Cranes themselves may have certain characteristics. These include:

The Mayevsky crane is considered the most popular choice because it is widely used, has an affordable price and excellent efficiency; The plug valve is considered an excellent choice because it can be installed in an intermediate position

It is important to regularly return this element to its original position, so you need to constantly review its condition; A thermostat equipped with automation is considered an effective and reliable element, but its price is quite high.

When choosing, you need to pay attention to the following parts of the taps:

- What locking mechanism is the faucet equipped with? Thermostats are equipped with two mechanisms at once: one is a valve, and the other is a valve with a special rod. The second option is considered the most optimal, since with its use the adjustment will be smooth and effective. The required temperature is set manually using a restrictive ring. However, there may also be thermostats with electronic mechanisms, but their price will be higher. The Mayevsky crane has many disadvantages in this regard. This is due to low traffic and the need to use a specialized wrench to use the crane.

- Crane body. The optimal products are those whose body is made of steel or bronze. The most popular are brass structures because they have an affordable price. You can often find faucets made of silumin, which is considered an analogue of brass. However, such options are considered unsuitable because this material is too soft. Polymer products are reliable, but they are usually produced in oversized sizes, so to install them you have to cut out too much of the pipeline. Also considered durable are taps in which gaskets are installed not from rubber, but from suitable polymers.

There are many types of taps that are installed on radiators of the heating system.

They differ in the ability to adjust the temperature, installation method, and various additional elements and parameters.

With the correct selection and proper installation of a tap on a heating radiator, you can increase the comfort of using the system, as well as its safety and efficiency.

Balancing valve for heating system

Existing heat supply systems are conventionally divided into two types:

- Dynamic. They have conditionally constant or variable hydraulic characteristics, these include heating lines with two-way control valves. These systems are equipped with automatic balancing differential regulators.

- Static. They have constant hydraulic parameters, include lines with or without three-way adjustment valves, the system is equipped with static manual balancing valves.

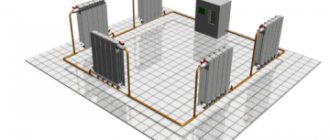

Rice. 7 Balancing valve in the line - installation diagram of automatic fittings

In a private house

In a private house, a balance valve is installed on each radiator; the outlet pipes of each of them must have union nuts or another type of threaded connection. The use of automatic systems does not require adjustment - when using a two-valve design, the supply of coolant to radiators installed at a large distance from the boiler is automatically increased.

This occurs due to the transfer of water to the actuators through a pulse tube under lower pressure than that of the first batteries from the boiler. The use of another type of combined valves also does not require calculating heat transfer using special tables and measurements; the devices have built-in control elements, the movement of which occurs using an electric drive.

If a manual balancer is used, it must be adjusted using measuring equipment.

Rice. 8 Automatic balancing valve in the heating system - connection diagram

To determine the volume of water supplied to each radiator and, accordingly, balancing, an electronic contact thermometer is used, with which the temperature of all heating radiators is measured. The average supply volume per heater is determined by dividing the total value by the number of heating elements. The greatest flow of hot water should flow to the furthest radiator, a smaller amount to the element closest to the boiler. When carrying out adjustment work using a manual mechanical device, proceed as follows:

- Open all control valves all the way and turn on the water, the maximum surface temperature of the radiators is 70 - 80 degrees.

- Using a contact thermometer, measure the temperature of all batteries and record the readings.

- Since the furthest elements must be supplied with the maximum amount of coolant, they are not subject to further regulation. Each valve has a different number of revolutions and its own individual settings, so the easiest way is to calculate the required number of revolutions using the simplest school rules based on the linear dependence of the radiator temperature on the volume of passing coolant.

Rice. 9 Balancing fittings - installation examples

For example, if the operating temperature of the first radiator from the boiler is +80 C., and the last +70 C. with the same supply volumes of 0.5 m3/h, on the first heater this indicator is reduced by a ratio of 80 to 70, consumption will go less, and the resulting volume will be 0.435 m3/h. If all the valves are not set to the maximum flow, but set to the average value, then you can take the heaters located in the middle of the line as a guide and similarly reduce the throughput closer to the boiler and increase it at the farthest points.

In a multi-storey building or building

The installation of valves in a multi-storey building is carried out in the return line of each riser; if the electric pump is far away, the pressure in each of them should be approximately the same - in this case, the flow rate for each riser is considered equal.

To set up in an apartment building with a large number of risers, it uses data on the volume of water supplied by an electric pump, which is divided by the number of risers. The resulting value in cubic meters per hour (for the Danfoss LENO MSV-B valve) is set on the digital scale of the device by rotating the handle.

DETAILED INFORMATION

An application for additional information on this project can be completed here.

| Number 51-078-00 |

| name of the project Construction of pavilions for sectional valves of heating network pipelines with a diameter of more than 300 mm |

| Purpose Equipment and pipelines are located in a pavilion with a monorail with an external console and a stop; the pipelines remain at marks along the profile of the heating network |

| Recommended application Heat supply |

| Description According to SNiP 2.04.07.86 “Heating networks”, sectional valves (see figure) with a jumper device 13 between the supply T1 and return T2 pipelines with a diameter of 0.3 of the pipeline diameter, but not less, are installed on the pipelines of heating networks at a distance of no more than 1000 m from one another 50 mm. The jumper is equipped with two valves and a control valve 4 between them with a diameter of 15 mm. SNiP also allows an increase in the distance between sectional valves with the condition of ensuring the drainage of water (using fittings 9) into the storm sewer 10 through a wet well 11 with a shutter valve 14. For sectional valves with a diameter of 300 mm, a discharge bypass is provided - a bypass pipeline with a valve 12. For To take readings, thermometers 7 and pressure gauges 6 are installed on the supply and return pipelines. Recording flow meters and corrosion indicators can also be installed - two on each pipeline: one for monitoring oxygen corrosion, the other for general corrosion. Pavilions for sectional valves on water heating networks are made both underground and above ground. A special feature of the pavilion for sectional valves with electric drive 8, used on pipelines with a diameter of more than 300 mm, is the need for a monorail with a hoist 2 and a service platform 5. The room must have ventilation (deflector 3), standby electric heating, lighting, a metal door 15, glass block windows . It is rational to place pavilions at pipeline nodes, combining them with branches to heat consumers. In known existing and planned pavilions there are no service platforms, lifting and transport devices (telphers, etc.). When laying underground, pipelines are removed from tunnels or channels to the zero level of the pavilion to the ceiling, as a result of which the height increases, additional U-shaped bends of pipelines appear, i.e. Additional hydraulic resistance arises, the consumption of metal, building materials, etc. increases. The proposed arrangement of equipment and pipelines in the pavilion for sectional valves of large diameters provides for a monorail with an external console and a stop that allows installation and dismantling of equipment and pipelines “from wheels” by suspending them from the hoist. The service area is aligned with the zero mark; the pipelines remain at the marks along the profile of the heating network. The fastening of the monorail suspension to the pavilion covering is made with one bolt, in contrast to the existing standard fastenings with four bolts. This pavilion layout for sectional valves can be recommended for heating pipelines with a diameter of more than 300 mm. |

| Advantages over well-known analogues The fastening of the monorail suspension to the pavilion covering is made with one bolt, in contrast to the existing standard fastenings with four bolts |

| Development stage Put into production |

| Test results Technology ensures consistent results |

| Technical and economic effect The construction of pavilions allows you to avoid additional U-shaped bends of the heating main pipelines, saving the consumption of building materials |

| Possibility of transfer abroad Possible transfer abroad |

| Material receipt date 08.02.2000 |

Features of installation and maintenance of regulators

Thermostat installation diagram

After choosing the optimal model of thermostat or tap for regulating the heating temperature, you should install them correctly. The location of the fittings directly depends on its function and design.

Most often, the adjustment components are mounted in the trim of a specific heating radiator. They are installed on the supply pipe or on the bypass. In order to comfortably adjust the temperature of the radiators, it is recommended to adhere to the following rules:

- The device should not be covered with decorative panels or other interior items;

- The service life of thermostats largely depends on the quality of the coolant. Therefore, a mesh filter should be installed in front of it, which will protect the valve seat from limescale;

- When installing the heating temperature control valve, you must follow the installation diagram. On the body of the device, arrows indicate the direction of movement of the coolant;

- Many thermostats and servos are connected to the electrical network. Therefore, it is necessary to provide power supply to them.

Before installing and further adjusting heating batteries in an apartment, you must read the manufacturer's instructions. It specifies the installation conditions for the operation of a specific adjusting element.

One of the important indicators of apartment heating control valves is the maximum and minimum throughput. They must match the current system parameters.

Maintenance of regulators and valves

Pressure testing is carried out only after installing the control valves

After installation, preliminary adjustment of the taps on the heating radiators should be carried out. To do this, the operating temperature and pressure in the system must be normal. Then, by changing the degree of heating of the coolant, the operation of the control valves is checked. The system is tested in several modes. Alas, it will not be possible to independently adjust the heating in an apartment building using this scheme, since consumers do not have the opportunity to change the degree of heating of the coolant.

In fact, it is possible to check the performance of a specific element only when starting up the central heating supply. Those. Correct adjustment of heating radiators in the apartment is carried out during the heating season.

During the startup of the heating system, the heating system of a private house must be fully adjusted. It should include the following steps:

- Checking the functionality of taps and thermostats;

- Compliance of their actual parameters with passport data;

- If, during the control adjustment of the degree of heating of the heating batteries, a faulty element is detected, it must be replaced.

In addition, you need to remember that the operation of the system is influenced by a number of external factors: the degree of thermal insulation of the house, the climatic features of a particular region. This should also be taken into account when adjusting the temperature of the heating radiator.

The video shows an example of organizing the adjustment of heating radiators in a house:

Installation

The balancing valve, designed to control the heating system, is very easy to install with your own hands. Installation is carried out as if installing a regular ball valve

In principle, it is not particularly important how the valve itself will be placed in space, but the arrow on the body must correspond to the direction of water flow. Otherwise, the valve will begin to create resistance to the coolant

The temperature and pressure of different valves may vary, therefore, after studying the characteristics of your own heating system, it is better to find the most suitable option from the manufacturers.

It is necessary to place special protection in the form of a filter in front of the valve. This device will prevent debris and dirt from getting onto individual elements of the regulator. In addition, it is recommended to install the valve so that there are significant gaps of straight pipe before and after it. This will prevent the appearance of bends that affect the movement of water. Also, before starting installation, the pipes must be flushed.

Installation of the valve begins after checking the condition of the pipes is completed - it is necessary to check their integrity and the absence of debris. Then the location where the device will be placed is determined. The parameters of the straight pipe sections before and after the valve must correspond to the following figures: five diameters before the element and two diameters after the element or even more, this will eliminate turbulence.

Then the valve is screwed into the thread of the pipe, previously equipped with tow.

Design and operating principle

The principle of operation of balancing valves is to block the flow of liquid with a retractable valve or rod, causing a reduction in the cross-section of the passage channel. The devices have different designs and connection technologies; in a heating system they can additionally:

- Maintain the pressure drop at the same level.

- Limit coolant consumption.

- Shut off the pipeline.

- Perform drain functions for working fluid.

Structurally, balancing valves resemble conventional valves; their main elements are:

- Brass body with two through pipes with internal or external threads designed to connect to a line with standard pipe diameters. The connection in the pipeline, in the absence of a threaded fitting with a movable threaded nut (American), is made through its analogues - additional adapter couplings with different union nuts.

- A locking mechanism, the movement of which regulates the degree of blocking of the coolant passage channel.

Rice. 4 Danfoss LENO MSV-B manual balancing valve

- Adjustment handle with scale and setting indicators, allowing you to adjust the flow inside the device.

- Modern models are equipped with additional elements in the form of two measuring fittings, with the help of which the flow volumes (throughput) are measured at the inlet and outlet of the device.

- Some models are equipped with a shut-off ball mechanism that allows you to completely shut off the flow, or have the function of draining liquid from the water supply.

- High-tech modern types can be controlled automatically; for this, instead of a rotating head, a servo drive is installed, which, when power is supplied, pushes the locking mechanism, and the degree of channel closure depends on the amount of voltage applied.

Rice. 5 Danfos AB-QM automatic balancers - design

Is it necessary to “put” the expansion tank on the valve?

It's up to you to decide, but you need to keep in mind that the tank is, as it were, a dead end, and not a through element of the system and can be unscrewed quite simply. Another thing is that to replace the tank you will have to drain the entire system above the tank. But you need to keep in mind that leaving the system without an expansion tank is also very, very dangerous. Then we will be protected from an uncontrolled increase in pressure only by the emergency valve, and we need to be absolutely sure that this valve is working. There is one more nuance associated with the tank. The tank may need to be pumped up. Obviously, it needs to be pumped up at the moment when it is disconnected from the water. If your tank tends to deflate quite often, installing a valve on the tank would be a very good idea!

How can you tell if the tank is deflated? Obviously, if water flowed from the emergency valve or the pressure went off scale beyond 1.5 atmospheres (valve response pressure). In this case, you urgently need to turn off the heating, drain the excess water into a bucket, the tank must be urgently pumped up, and the valve must either be replaced or serviced.

Locking devices

The taps used for installation in the room heating system should be divided into two groups - shut-off and control. This division is largely arbitrary, since shut-off valves also allow you to regulate the movement of the coolant. Naturally, in this case the adjustment accuracy is quite low, but it is possible to cut off the battery from the water source.

Ball design diagram

The simplest and most commonly used type of valves are ball valves:

The ball valve is designed to shut off the radiator. Its design allows the device to be installed in either an open or closed position, so that the adjustment is carried out quite according to the principle “there is heat - there is no heat.”

Ball valves for heating radiators provide two-position adjustment

Please note! In principle, you can fix the valve in an intermediate position, but then the rate of its wear will increase many times due to the friction of particles suspended in water against the shut-off element. So it is better not to do this unless absolutely necessary

- The coolant flow is blocked by the movement of a metal ball with a hole coaxial with the pipe clearance. When you turn the faucet handle, the rod comes into action, which rotates the sphere inside the body, aligning the hole in it with the lumen of the pipe.

- As a rule, faucet parts are made of steel, bronze or brass. PTFE gaskets are responsible for sealing the connections and the locking part, which, if necessary, can be replaced with your own hands.

- Connection to the radiator is carried out either using a regular nut or using an “American” one.

Ball design with American

Unlike ball valves, cone valves make it possible to regulate the coolant flow more smoothly. This is ensured by the features of their design:

Sectional view of the device

- The locking element is a conical rod, on the surface of which a thread is applied.

- When we rotate the flywheel, the rod moves along the thread, moving in a vertical plane.

- In the lowest position, the pipe lumen is completely blocked. The tightness of the overlap is ensured by elastic gaskets that fit onto the annular grooves of the rod.

- By lifting the locking part, we open the gap slightly, and the coolant begins to flow into the radiator.

Please note! The indoor microclimate can only be adjusted approximately by decreasing or increasing the amount of hot water in each battery

Model in polypropylene case

In practice, bronze or brass cone valves for heating radiators are most often used: only systems are equipped with polypropylene, some of the pipes in which are also made of plastic. This is explained by the relatively low strength and wear resistance of polymers compared to sanitary alloys.

On the other hand, polypropylene taps for heating radiators are somewhat cheaper, so in conditions of budget deficit they can be used.

Mayevsky crane

When you pour coolant into the heating system, air gets inside along with water or antifreeze.

To remove it, special devices are used - the so-called Mayevsky taps:

Air release device

- The design of such a product is quite simple: it is based on a shut-off rod installed in a housing with a thread for the radiator plug.

- The rod is driven either by a screwdriver or a special wrench, opening the lumen of the pipe in the saddle.

Please note! If possible, buy valves for a screwdriver, since you will regularly lose the key, which is not surprising - you will have to use it once or twice a year. You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air

In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air. In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

Photo of the installed valve

Thermostat

About 30 years ago, modern devices appeared to control the temperature of the water in the system, which were called “thermostats”. Externally, this thermostatic device looks like a valve, which was modified and a display with temperature indicators was installed on it.

The thermostat must be installed between the battery and the supply. The appliance should be positioned horizontally to limit the influence of extraneous heat sources. The design of the thermostatic device allows mixing hot water from the supply with chilled water in the return. Thus, the optimal temperature is achieved and heating resources are saved.

Balancing valve manufacturers

Models from foreign and domestic manufacturers are widely represented on the construction market; some companies are leading suppliers of energy-saving equipment.

Danfoss, a Danish company founded in Norborg in 1933, is one of the world's leading manufacturers and suppliers of energy-saving systems. The concern produces refrigeration equipment, power electronics, heat pumps, thermal and industrial automation, cable heating systems (warm floors). The product line is represented by shut-off, automatic and manual balance valves of the ASV and MSV series, combined models AB-QM, AB-PM.

Broen is a Danish company founded in 1948 by Swedish engineer Paul Broen and appeared on the Russian market in 1996. The company's plant has been operating in the Kolomensky district since 2010. The concern produces a wide range of pipeline fittings, which include: ball valves, gate valves, check valves and balancing valves (Broen Ballorex), safety valves, cast iron filters. The line of balancing fittings is represented by the Broen series: Venturi Fodrv, DRV, Dynamic, Venturi DRV.

Rice. 13 Balancing fittings from Danfoss and Broen

Giacomini is an Italian supplier of pipeline fittings. The concern was founded in 1951, has a turnover of 170 million euros per year, 3 factories in Italy and 18 branches around the world, employing about 1000 employees. The concern produces control and shut-off valves for radiators, thermostats, manifolds for heating and water supply, pipes and fittings for energy metering equipment, and solar panels. Balance valves are represented by modifications R206 A, R206 B.

ADL is a Russian manufacturer of engineering equipment for the housing and communal services sector and various industries. The company was founded in 1994, and since 2002 it has had its first plant in the village of Raduzhny, Kolomna district, Moscow region.

The company produces a wide range of plumbing equipment: control check valves, pumping units, gate valves, valves and ball valves, circulation and steam-condenser pumps, heating units, separators. The line of balancing valve devices is called Granbalance and consists of models of the DN series.

Fig. 14 Automatic balancing valve Giacomini and ADL

A balancing valve for a heating system is an essential device for maintaining a constant temperature in risers or heating radiators. Their use in everyday life is not entirely justified. The cost of one device from a well-known manufacturer reaches 100 USD; domestic devices are also not cheap. It is more rational to use the devices to maintain the temperature in the risers of apartment buildings with a large number of radiators.

Any heating system must be configured properly. The main goal of this setup is to ensure the same performance in all parts of the network. For example, if this is the heating system of a multi-storey building, then there should be heat on both the top and bottom floors. These indicators should not only be equivalent, but also close to the normative ones. One of the most effective ways of setting is to use a balancing valve, the installation of which should ideally be thought out at the stage of creating a heating system project.

Why use it

Installing balancing valves in the heating system, in addition to maintaining the same temperature of the radiators, in an individual home brings the following effect:

- Precise adjustment of the coolant temperature allows you to set its value depending on the purpose of the premises - in living rooms it can be higher, in utility rooms, storerooms, workshops, gyms, food storage areas, you can set it lower using balancers. This factor increases the comfort of living in the house.

- Changing the coolant flow using a balance valve regulator depending on the purpose of the premises brings a significant economic effect, allowing you to save on fuel.

- In winter, when the owners are absent, constant heating of the home is necessary - with the help of balancing valves, you can adjust the heating system with minimal fuel consumption and maintain a constant temperature in all rooms. This advantage also saves financial resources for the owners.

Rice. 3 Manual balancing valves for heating and hot water supply (DHW) systems in the house

Why are there taps on radiators?

Each heating device is a separate element of the system that requires adjustment and periodic maintenance. If you control the coolant flow through the batteries depending on the heat demand, you can achieve good results in terms of energy savings. That is, radiator valves and heating taps are designed to solve the following problems:

- Complete isolation of the heating device from the system.

- Restriction of coolant flow through the battery.

- Change in coolant flow depending on external conditions.

- Bleeding air from the radiator and piping network.

There are many situations in which it is difficult to do without disconnecting the battery. For example, properly working central heating in the middle of spring, when it’s already warm outside, but it’s just hot in the apartment. Another case is the need to remove a heating device for the purpose of replacement, flushing or repair. In the absence of shut-off valves, carrying out any action with the radiator becomes problematic.

Valves are also installed on batteries in retro style

Restriction of the flowing coolant is carried out in order to balance individual heating in a private house or apartment

No matter what type of heating system you have, without balancing with valves, the first radiators will always receive more water than the last ones. Limiting the coolant flow at the beginning of the network and thereby balancing all devices with each other is the task of the control radiator fittings

Automatic control of the flow of incoming coolant is a way to save energy used to heat the house. If each tap on the heating radiator maintains the set air temperature in the room by controlling the flow of water through the radiator, then in general the system will consume only the required amount of heat, no more. And this is a considerable saving.

Well, the problem of air release when filling the system or during operation is also solved by special air valves installed on all modern radiators. Below is a list of types of shut-off and control valves, listed in the same order as the tasks they solve:

- Half-turn ball valves in straight and angle versions. Made from brass, bronze or polypropylene with a metal insert.

- Balancing valves for radiators – straight and angular.

- Regulating valves with thermal heads (thermostatic valves).

- Air drain valves – automatic and manual.

For reference. Some home craftsmen use three-way mixing valves to connect heating appliances. But such a solution is unreasonably expensive and is rarely used in practice.

Now we should consider in detail which taps are best installed on radiators in various conditions and circumstances. Some options are clearly shown in the video:

Types of cranes

Conventionally, the reinforcement can be divided as follows:

- semi-rotary ball valve;

- balancing valve;

- thermostatic valve;

- flush tap;

- Mayevsky's bleeding valve.

Cranes differ in price, design and application features, which determine where and for what purpose the device is installed.

There are valves with manual and automatic adjustment methods; here the difference is also noticeable in the price of the valve. A system with automatic temperature control works like this: the controller receives a signal from a temperature sensor and sends a command to the servos, as a result of which the size of the flow hole in the tap is adjusted depending on the set mode.

Ball valve

The name of the tap is due to the spherical shape of the valve, which has a through hole. The valve is designed for only two positions - open or closed; it is not intended for quarter-turn operation. When you turn the handle of the faucet, the valve also rotates, and the hole in it is located either parallel or perpendicular to the pipeline.

The body of the device is made of steel, brass, bronze or silumin. Steel is the leader in terms of strength, but it is susceptible to corrosion, so products made of bronze and brass are preferable as they are more durable.

A good choice would be a brass half-turn with thick walls and an American - this is the name of the union nut, which allows you to connect pipes and the radiator without rotating them and quickly.

Balancing valve

The difference between a balancing valve and a ball valve is the ability to smoothly adjust the position of the valve by several turns of the knob. To prevent the valve settings from being lost or someone accidentally knocking them down, it can be fixed in its current position. It is placed on the outlet pipe of the battery, and makes it possible to smoothly regulate the flow of coolant.

Valve with thermostat

The most expensive, but also the highest quality, are thermostatic valves. The thermal head is adjusted to a certain room temperature and affects the valve stem.

Under its influence, the valve increases or decreases the cross-section of the hole for the passage of coolant, thereby regulating the temperature of the radiator. A valve with a thermal head is installed on the inlet pipe, and a balancing valve is placed on the outlet pipe.

Flushing tap

As the name suggests, it is designed to drain water or other coolant from the radiator in order to flush it. It consists of a metal body and a long rod, equipped with a rubber gasket. Opens with pliers or a wrench. The disadvantage of the design is the rapid wear of the rubber gasket and the need to replace it.

Mayevsky's air crane

Modern radiators provide for the installation of Mayevsky taps; some models are supplied with already built-in valves. The Mayevsky valve is mounted at the top of the battery, since compressed air accumulates at the top.

The valve is usually activated by a flat screwdriver or wrench. The air is released until the hissing stops and water begins to ooze from the tap.

Balancing valve

The design of a valve for regulating heating differs from a conventional ball valve in that it can smoothly close the flow area in a few turns. Moreover, after balancing, the position of the valve can be fixed so that no one accidentally violates the settings. This type of control valves is installed at the outlet of the radiator, as shown in the diagram:

Shown here is the connection to a two-pipe horizontal system, most common in private houses and apartments with individual heating. By the way, the principle of installing fittings with a single-pipe scheme remains the same. A regular ball valve is installed on the supply line, and an adjustment valve is installed on the return line. In the case when a two-story house has a system with vertical risers, the installation diagram of the accompanying fittings looks like this:

The principle of product selection is the same as in the previous section

Straight or angular design is accepted depending on the layout of equipment and pipelines; it is also important to use American designs during assembly

Pay special attention to the quality of casting and the thickness of the brass walls of the fittings. If you have networks made of polypropylene pipes, do not rush to buy PPR taps; it is better to install adapters and reliable metal products

Advice. Balancing valves are installed on all radiators, except for the very last one, located at the dead end of the branch. It is enough to install simple ball valves on the connections to it.

Installation

The location of valves with thermal heads is on the supply pipeline. Regulating taps do not require coiling; Unipak paste is used. Rubber gaskets fit tightly to the joint, ensuring complete tightness. If there is a defect at the edges of the faucet, water leakage is inevitable.

While their ball counterparts are responsible only for safety and are able to instantly shut off the water during an emergency, the purpose of control valves with a thermal head is to save energy and provide comfort. On cold winter evenings, on dull autumn days, on warm spring days, the house will be warm and cozy, and the numbers on your heating bills will pleasantly surprise you.

Step-by-step instructions for adjusting temperature

To ensure comfortable living conditions in the room, you need to perform some basic steps.

- Initially, it is necessary to bleed the air on each battery until water flows from the tap in a trickle.

- Then you need to adjust the pressure in the batteries.

- To do this, in the first battery from the boiler you need to open the valve by two turns, on the second - by three, and then according to the same scheme, increasing the number of turns of the valve being opened on each radiator. Thus, the coolant pressure will be evenly distributed over all radiators. This will ensure its normal passage through the pipes and better heating of the batteries.

- In a forced heating system, control valves will help to pump the coolant and control rational heat consumption.

- In a flow-through system, the temperature is well regulated by thermostats built into each battery.

- In a two-pipe heating system, you can control not only the temperature of the coolant, but also its quantity in the batteries using both manual and automatic control systems.

How to remove an air lock

Ideally, gases rise to the highest points of the circuit, where air vents are installed, and are released from there by valves operating in manual or automatic mode. In practice, errors in pipeline design or installation lead to the formation of air pockets in hard-to-reach places.

To remove such a plug, you need to find its location - by the murmur of coolant flowing through the air-filled area, by the relatively low temperature of the pipe or radiator, by the ringing sound when tapping the pipes.

Increasing the coolant temperature and/or pressure in the system will help remove the plug from the autonomous heating system. To apply pressure, it is necessary to open the make-up valve and the drain valve closest to the air lock (in the direction of flow). The water entering the system increases the pressure and causes the plug to move forward. After making sure that the plug has come out through the valve (it stops hissing), the system is returned to normal operating mode.

Removing an air lock from the heating system

In more complex cases, they are affected not only by pressure, but also by temperature. The coolant must not be heated above the maximum permissible values, so as not to damage the heating system.

Important! Regular formation of a plug in the same place indicates miscalculations in the project or incorrect installation. It is recommended to install an air vent in the problem area by cutting a tee into the pipeline