How to paint heating pipes? Can I use regular metal paints or do I need some special compositions? How to prepare risers and connections for applying a new coating? Is it necessary to remove old paint or rust? Let's try to figure it out.

Is this a familiar picture? Then this article is for you.

Copper pipes and types of materials for painting them

During repair work, it is necessary to check the condition of the pipes and evaluate the quality of their surface. Although the pipeline made of copper elements is not subject to rust, you want it to be painted in the same color scheme of the room. Moreover, the paint will serve as protection against external damage.

Engineering communications service Heating, water supply, drainage, sewerage systems

around the clock tel: 8

INSTALLATION, REPAIR, MAINTENANCE, MODERNIZATION, REPLACEMENT

- Heating Maybes + Buderus

- Heating Buderus

- Boiler copper pipe piping

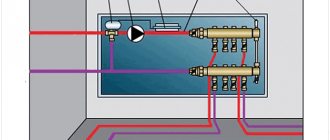

- Collector radiant heating of a wooden house

- Modern heating systems

- Autonomous heating of a private house

- Gas heating of a wooden house

- Heating a dacha with heated floors

Alkyd enamel is used to paint copper heating pipes

To paint copper pipes, you can use different types of enamel. These paints differ from each other in characteristics and their ingredients.

These paints include:

- Alkyd enamel has a structure that is resistant to various impacts. Moreover, it can withstand high heating temperatures (over 100 degrees). However, there is also a negative point - a strong unpleasant odor. It can be maintained until the paint has completely dried.

- Water-based paint has a short drying time and does not emit an unpleasant odor. But it has a short service life.

- Acrylic paint - its main components are organic solvents. It has a glossy shine and does not lose its color with prolonged use. But its application requires additional surface preparation.

Coverage Requirements

First of all, let's decide what we want from the paint, what it should be.

- Anti-corrosion protection is required for any product made of black steel . Even in a relatively dry room, contact with moisture in the atmospheric air and oxygen will cause the metal to rust. Therefore, the new coating must be impermeable to water.

- Aesthetics . Everything is clear here: the color of the pipes should be in harmony with the design of the room as a whole. The exception is if the radiators are located in a niche, and the connections to them and the risers will be hidden by a plasterboard box: here the painting serves a purely protective function.

By the way: hiding any communications with a non-demountable structure is a very bad idea. Sooner or later, both pipes and threaded connections between them and radiators need repair. It is advisable that after this the premises do not need reconstruction.

- The paint must have good adhesion to metals ; Alternatively, its application should be preceded by priming the base.

- Finally, the main feature of radiator paints is that they must be temperature resistant. This means not only the absence of cracks and delamination during repeated heating: the coating should not turn yellow.

Subtleties of work

There is nothing difficult about painting copper pipes. But in order to do this work efficiently, you need to know some of the subtleties and nuances of its implementation.

Such recommendations may include:

- It is necessary to use only smooth rollers and small brushes, and, if possible, a spray. This will help paint even the most difficult to reach places.

- Under no circumstances should work be carried out during the heating season. A hot surface will not allow you to apply the enamel evenly; it will curl and emit a strong odor.

- Work must be done only from top to bottom. This will avoid all kinds of smudges and splashes. Painting must be done over the entire area of the pipe.

It is better to choose a paint that is heat-resistant, abrasion-resistant, long-lasting and non-toxic. It is better to resort to using a composition that contains specialized metal powder instead of conventional dyes. In this case, the heating system will not only have a beautiful appearance, but also a long service life.

If copper pipes are not painted, they will turn black over time. To give them shine, you need to constantly polish the surface.

Therefore, painting pipes made of copper will help avoid this tedious procedure and preserve their surface from oxidation.

Which paint to choose for heating pipes - possible options, characteristics

The heating system is an integral part of any modern living space.

Therefore, the question of its safety and protection from corrosive processes is relevant, as is its aesthetic appearance. The solution to the above problems lies not only in the technology of painting work, but also in the choice of materials. There are many offers in the field of paint and varnish materials on the construction market, which sometimes confuses not only those who have decided to decorate their home on their own, but also those who are professionally engaged in painting work. What paint to paint heating pipes in order to guarantee a high-quality result depends on some nuances.

Before painting heating pipes and radiator batteries, you need to know what functionality the coating will perform. The primary task is to protect the metal product from corrosion. Also, recently the decorative appearance has become of no small importance. Not only metal, but also plastic (polypropylene) pipes of heating and water supply systems are painted.

Sale and installation of copper pipes

| Name and technical characteristics | Qty | Unit. | Materials and equipment, ₽ |

| Copper pipe ⌀ 35 | 1,00 | m/linear | 1 408,80 ₽ |

| Copper pipe ⌀ 28 | 1,00 | m/linear | 634,80 ₽ |

| Copper pipe ⌀ 22 | 1,00 | m/linear | 570,80 ₽ |

| Copper pipe ⌀ 15 | 1,00 | m/linear | 348,56 ₽ |

| Copper angle 45° ⌀ 35 | 1,00 | PC. | 614,00 ₽ |

| Copper angle 45° ⌀ 28 | 1,00 | PC. | 112,00 ₽ |

| Copper angle 45° ⌀ 22 | 1,00 | PC. | 86,00 ₽ |

| Copper angle 45° ⌀ 15 | 1,00 | PC. | 62,10 ₽ |

| Copper angle 90° ⌀ 35 | 1,00 | PC. | 627,00 ₽ |

| Copper angle 90° ⌀ 28 | 1,00 | PC. | 112,00 ₽ |

| Copper angle 90° ⌀ 22 | 1,00 | PC. | 86,00 ₽ |

| Copper angle 90° ⌀ 15 | 1,00 | PC. | 62,10 ₽ |

| Copper tee ⌀ 35 | 1,00 | PC. | 680,00 ₽ |

| Copper tee ⌀ 35*28*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 35*22*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 35*15*35 | 1,00 | PC. | 714,00 ₽ |

| Copper tee ⌀ 28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 28*22*28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 28*15*28 | 1,00 | PC. | 156,00 ₽ |

| Copper tee ⌀ 22 | 1,00 | PC. | 127,50 ₽ |

| Copper tee ⌀ 22*15*22 | 1,00 | PC. | 127,50 ₽ |

| Copper tee ⌀ 15 | 1,00 | PC. | 82,00 ₽ |

| Copper coupling ⌀ 35 | 1,00 | PC. | 214,00 ₽ |

| Copper coupling ⌀ 35*28 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 35*22 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 35*15 | 1,00 | PC. | 317,00 ₽ |

| Copper coupling ⌀ 28 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 28*22 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 28*15 | 1,00 | PC. | 63,00 ₽ |

| Copper coupling ⌀ 22 | 1,00 | PC. | 56,00 ₽ |

| Copper coupling ⌀ 22*15 | 1,00 | PC. | 56,00 ₽ |

| Copper coupling ⌀ 15 | 1,00 | PC. | 34,00 ₽ |

| Brass end cap ⌀ 35*40 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*40 in. | 1,00 | PC. | 1 456,00 ₽ |

| Brass end cap ⌀ 35*32 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*32 bunks | 1,00 | PC. | 1 420,00 ₽ |

| Brass end cap ⌀ 35*32 int | 1,00 | PC. | 1 560,00 ₽ |

| Brass end cap ⌀ 28*25 Amer. | 1,00 | PC. | 720,00 ₽ |

| Brass end cap ⌀ 28*25 ext. | 1,00 | PC. | 720,00 ₽ |

| Brass end cap ⌀ 28*25 bunks | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 28*25 in. | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 22*20 Amer. | 1,00 | PC. | 620,00 ₽ |

| Brass end cap ⌀ 22*20 ext. | 1,00 | PC. | 620,00 ₽ |

| Brass end cap ⌀ 22*20 bunks | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 22*20 in. | 1,00 | PC. | 530,00 ₽ |

| Brass end cap ⌀ 15*15 Amer. | 1,00 | PC. | 396,00 ₽ |

| Brass end cap ⌀ 15*15 ext. | 1,00 | PC. | 396,00 ₽ |

| Brass end cap ⌀ 15*15 bunks | 1,00 | PC. | 130,00 ₽ |

| Brass end cap ⌀ 15*15 in. | 1,00 | PC. | 130,00 ₽ |

| Water socket ⌀ 15*15 in | 1,00 | PC. | 189,00 ₽ |

Heating of private houses in detail by cost

- Heating 100 m² Cost of work 49,500 rub.

- Heating 150 m² Cost of work 52,500 rub.

- Heating 200 m² Cost of work 72,500 rub.

- Heating 250 m² Cost of work 87,500 rub.

Heating 100 m²

| Cost of work | from 49,500 rub. |

| Cost of equipment | from 120,000 rub. |

Heating 100 m²

Heating 150 m²

| Cost of work | from 52,500 rub. |

| Cost of equipment | from 200,000 rub. |

Heating 150 m²

Heating 200 m²

| Cost of work | from 72,500 rub. |

| Cost of equipment | from 250,000 rub. |

Heating 200 m²

Heating 250 m²

| Cost of work | from 87,500 rub. |

| Cost of equipment | from 300,000 rub. |

Heating 250 m²

Heating services: Baseboard heating, Water heated floor, Radiator heating, Warm wall

Installation of heating systems for a private house

Installation

Installation of copper pipes can be done in two ways:

- By connecting using various fittings (detachable connection).

- This is very convenient because installation is quick and easy. However, the cost of the heating system increases sharply, since the price of such fittings is high.

- By connecting pipes using soldering, welding or crimping (permanent connection). This method makes installation cheaper, and therefore more popular.

The most affordable and reliable way to make a permanent connection of copper heating pipes is soldering. Let's look at how you can do this yourself, without outside help.

Advantages

- They can easily withstand heating of several hundred degrees (only at a temperature of 6000 degrees does “annealing” occur, and the pipe begins to lose its strength, acquiring plasticity).

- Capable of withstanding pressure up to 30 atmospheres or more.

- Due to their plasticity, they do not collapse if the water freezes inside.

- Copper has anti-corrosion properties and also does not react to ultraviolet radiation and active chemicals, which increases the service life of the pipe to 50 years or more.

- Do not allow diffusion of air into the coolant through the walls.

- Copper can easily be used at the outlet of a heat generator, because, compared to polymers, it has a low coefficient of thermal expansion (maximum 1.5 mm per linear meter at 900 degrees).

- The internal surface has less roughness compared to steel (but not polymer), which significantly reduces the hydraulic resistance in the system, so less powerful pumps can be used. Due to the absence of roughness, unnecessary deposits do not accumulate inside the pipe.

- Due to the thin walls and fittings, the flow area at the joints remains unchanged, so the hydraulic characteristics of the pipeline do not deteriorate. The entire system is light and compact. Only the outer diameter of the internal section is much larger than that of steel or polymer.

- Copper is safe for humans. It has mild antibacterial properties.

- This is a beautiful material that will not spoil the appearance of the room.

Areas of application

There are several situations when it is better to choose this material:

- The current option for installing a heating system made of copper pipes is connecting to a solid fuel boiler. This is due to the fact that such systems are exposed to prolonged exposure to high temperatures (over 100 degrees Celsius).

- Compared to other materials, copper is better if it has a complex shape.

- Installation will be 100% justified if the owner of the house has enough money and wants to get the highest level of durability.

When considering other options, you need to pay attention to plastic or stainless steel.

Calculation of the number of heating radiator sections:

In order to install heating batteries in rooms, the required number of devices is first calculated. Various heating radiators are characterized by a certain power value of one section.

Types of radiators

Radiator models are divided into groups:

- Cast iron - transfers heat well and is resistant to high pressure in the system. However, they are heavy, and over time they become clogged with rust and silt, as a result of which their heat transfer decreases. In addition, they do not correspond to modern design.

- Steel, the disadvantage of which is poor resistance to pressure changes and susceptibility to corrosion.

- Aluminum

- Bimetallic

Related publications:

Materials for painting copper pipes

Copper has been used for many years in water containers and water storage tanks. It is quite an expensive material. Therefore, pipes made of copper have a high price and are considered elite.

Painting copper pipes is reliable protection against corrosion.

Heating from DESIGN PRESTIGE LLC Type: water here > resant.ru/otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

Copper pipes are painted not only for decorative purposes, but also to protect them from corrosion. Copper pipe paint should not flake off when exposed to high temperatures. This article will tell you how to paint copper pipes correctly.

Materials and tools required for painting pipes:

- masking tape; - painting tray; - brushes; - stiff wire brush; - eye protection glasses; - bucket; - soap solution; - sponge; - primer;

- dye.

Copper pipe painting process

Copper pipes are painted in several stages:

1. Cleaning the surface of the pipes. Before painting, you must carefully remove all old paint and rust from copper pipes. Use a stiff wire brush to remove paint and rust.

2.

Washing pipes. After the work of removing paint and rust from the surface of copper pipes is completed, it is necessary to wash them. Pipes are washed with a sponge and soapy water. After washing, copper pipes must be allowed to dry.

3. Applying a primer. Thanks to the primer, the paint will lie on the surface of the pipes as evenly as possible, and will not subsequently peel off. The primer is applied with a brush.

For copper pipes, red lead primer number 81 is ideal.

4.

Painting copper pipes. A layer of paint can be applied to the surface of the pipes only after the primer layer has dried thoroughly. The ideal option is to use spray paint to paint copper pipes. It is sprayed onto the surface from a distance of approximately 10-15 centimeters.

Paint suitable for copper pipes

You can choose what to paint copper pipes with from the list below of paint compositions suitable for these purposes:

- alkyd enamels; - varnish VL-51; - PF enamels (167, 187, 115, 156, 519, 223); - polyurethane enamels; - GF 0119 enamel;

- ethinol varnish (aluminum powder is added to it).

Also read: Equipment for soldering copper pipes

Under no circumstances should oil paints be used to paint copper pipes.

These paints begin to darken when exposed to high temperatures. If you doubt whether it is possible to paint copper pipes with a brush or whether it is better to use an aerosol spray for these purposes, then give preference to an aerosol. If you decide to apply paint to copper pipes with a brush, then try to spread it over the surface as best as possible, otherwise the dye will lie in an uneven layer.

Calculation of the number of sections of heating radiators

Most likely, you have already decided for yourself which heating radiators are better, but you need to calculate the number of sections. How to perform it accurately and accurately, taking into account all the errors and heat losses?

There are several calculation options:

- by volume

- by room area

- and a full calculation including all factors.

Let's look at each of them

Calculation of the number of heating radiator sections by volume

The value recommended by SNiP is most often used; for panel-type houses, 41 W of thermal power is required per 1 cubic meter of volume.

If you have an apartment in a modern house, with double-glazed windows, insulated external walls and plasterboard slopes, then the calculation already uses a thermal power value of 34 W per 1 cubic meter of volume.

An example of calculating the number of sections:

Room 4*5m, ceiling height 2.65m

We get 4 * 5 * 2.65 = 53 cubic meters Room volume and multiply by 41 W. Total required thermal power for heating: 2173W.

Based on the data obtained, it is not difficult to calculate the number of radiator sections. To do this, you need to know the heat transfer of one section of the radiator you have chosen.

Let's say: Cast iron MS-140, one section 140W Global 500, 170W Sira RS, 190W

It should be noted here that the manufacturer or seller often indicates an overestimated heat transfer, calculated at an increased temperature of the coolant in the system. Therefore, focus on the lower value indicated in the product data sheet.

Let's continue the calculation: 2173 W divided by the heat transfer of one section 170 W, we get 2173 W/170 W = 12.78 sections. We round towards a whole number, and we get 12 or 14 sections.

Some sellers offer a service for assembling radiators with the required number of sections, that is, 13. But this will no longer be factory assembled.

This method, like the next one, is approximate.

Calculation of the number of heating radiator sections by room area

It is relevant for room ceiling heights of 2.45-2.6 meters. It is assumed that 100 W is enough to heat 1 square meter of area.

That is, for a room of 18 square meters, 18 square meters * 100 W = 1800 W of thermal power is required.

We divide by the heat transfer of one section: 1800W/170W=10.59, that is, 11 sections.

In which direction is it better to round the calculation results?

The room is corner or with a balcony, then add 20% to the calculations. If the battery is installed behind the screen or in a niche, then heat loss can reach 15-20%

But at the same time, for the kitchen, you can safely round down to 10 sections. In addition, electric heated floors are often installed in the kitchen. And this is at least 120 W of thermal assistance per square meter.

Accurate calculation of the number of radiator sections

We determine the required thermal power of the radiator using the formula

Qt= 100 watt/m2 x S(rooms) m2 x q1 x q2 x q3 x q4 x q5 x q6 x q7

Where the following coefficients are taken into account:

Glazing type (q1)

- Triple glazing q1=0.85

- Double glazing q1=1.0

- Conventional (double) glazing q1=1.27

Thermal insulation of walls (q2)

- High-quality modern insulation q2=0.85

- Brick (2 bricks) or insulation q3= 1.0

- Poor insulation q3=1.27

Ratio of window area to floor area in the room (q3)

- 10% q3=0.8

- 20% q3=0.9

- 30% q3=1.0

- 40% q3=1.1

- 50% q3=1.2

Minimum outdoor temperature (q4)

- -10С q4=0.7

- -15С q4=0.9

- -20С q4=1.1

- -25С q4=1.3

- -35С q4=1.5

Number of external walls (q5)

- One (usually) q5=1.1

- Two (corner apartment) q5=1.2

- Three q5=1.3

- Four q5=1.4

Type of room above the calculated one (q6)

- Heated room q6=0.8

- Heated attic q6=0.9

- Cold attic q6=1.0

Ceiling height (q7)

- 2.5m q7=1.0

- 3.0m q7=1.05

- 3.5m q7=1.1

- 4.0m q7=1.15

- 4.5m q7=1.2

100 W/m2*18m2*0.85 (triple glazing)*1 (brick)*0.8 (2.1 m2 window/18m2*100%=12%)*1.5(-35)* 1.1 (one outdoor)*0.8(heated, apartment)*1(2.7m)=1616W

Poor wall insulation will increase this value to 2052 W!

number of heating radiator sections: 1616W/170W=9.51 (10 sections)

We considered 3 options for calculating the required thermal power and based on this we were able to calculate the required number of heating radiator sections. But here it should be noted that in order for the radiator to produce its rated power, it must be installed correctly. How to do this correctly or control the not always competent housing office workers, read the following articles on the official website of the Remontofil School of Repair