How to choose a water liner? This is the question people ask when the work on installing plumbing equipment comes to an end. And this is an important point, since the water supply is the main link in connecting to the water supply. Reinforced hoses should easily supply water to any device (faucet, toilet, washing machine, etc.). The reliability of the eyeliner depends on many factors. But, first of all, it is the correct selection of the type of hose, as well as the quality of the manufacturing materials. Since the market exists many eyeliner models, then it’s not difficult to get confused when choosing them. Knowing the features of these parts will help you make the best purchase.

Until recently, connections to the water supply system were made exclusively from pipes. Often this installation method turned out to be extremely inconvenient: in cramped conditions in small bathrooms it is difficult to install rigid pipes. Therefore, an alternative was invented - a flexible hose line.

Unlike plastic or steel pipes, a soft hose has good flexibility, which is achieved through the use of elastic materials. In fact, this is an ordinary hose equipped at its ends with threaded fittings for connection to the water supply system.

The liner is versatile and serves to connect many plumbing fixtures, such as faucets, shower stalls, washing machines and toilets. When installing all of the listed plumbing fixtures, you cannot do without a flexible hose.

And although some craftsmen still use metal-plastic pipes when connecting, such a connection cannot be called reliable and convenient. In most cases, high-quality flexible liner will be easier to install and will last longer.

A flexible hose is also suitable for installing a hydraulic accumulator. It can also be used in places of constant vibration, for example, in pumping stations. Vibrating hoses withstand mechanical loads well.

Flexible hoses are especially useful when installing shower stalls. When cleaning the bathroom, you often have to move them aside to wash walls in hard-to-reach places. The hose makes this easy to do.

Tough

One of the most reliable options for connecting to the water supply network is a hard line. It is made of metal and is a tube. The production material can be:

- steel;

- copper;

- brass.

The method of installing a rigid line is to thread one side of the tube to the pipeline, and the other to the mixer. The metal structure easily withstands high temperatures, as well as exposure to detergents or mechanical loads, shock, friction, etc.

If installed well, rigid liner has the following advantages:

- resistance to rust;

- resistance to chemicals;

- long service life - about 20 years;

- ease of use.

The disadvantages may be the following:

- inability to move;

- complexity of installation.

Depending on the installation method, when connecting the line to the water supply system, additional adapters or special angle valves with connecting elements may be used.

Which option should I choose?

Experts recommend choosing the best option - a “semi-rigid” liner, which is a copper tube nickel-plated on the outside.

This type of connection is already equipped with standard fittings of different lengths for screwing into the body of the mixing valve. Collet adapters are screwed onto the other end of the semi-rigid tube with a rubber gasket around this tube. On the opposite side of the adapter there is a standard (HP or BP) ½ inch plumbing thread.

Connecting a semi-rigid line is very simple:

- The bodies of the collet adapters are installed at the outlet of the pipeline.

- Then you need to screw these semi-rigid tubes into the mixer and install it on the sink.

- Then you need to bend the liner to the desired place so that the tube does not fold, that is, with a large radius.

- After this, you need to mark the required length, put the conical part of the collet adapters on the tube and saw off the excess.

- Before sawing, do not forget to put on a collet clamp, otherwise you will have to file the tube for a long time and remove a long chamfer from it.

- Then the tube is inserted into the collet adapter bodies that are pre-screwed to the pipeline.

- Then you need to throw the conical parts onto the adapter and tighten them very carefully so as not to damage the rubber seals.

For installation, you only need three tools: an adjustable wrench, an open-end wrench from an auto-dialer, and a hacksaw (or a file with a sharp edge).

Semi-rigid liner, unlike flexible liner, does not need to be replaced every couple of years for preventive purposes, and is more resistant to hydraulic shocks and ruptures. By choosing this option, you will significantly increase the reliability of the connection, reducing the risk of rupture or leaks.

Flexible

Installation using flexible hoses is much simpler. The hose is perfect for connecting various types of plumbing equipment. The elastic connection even allows you to connect plumbing fixtures located at a distance from the water supply pipes.

Thanks to the flexible hose, you can install faucets anywhere in the bathroom, for example, at the edge of the bathtub or on the wall, in a corner, etc. Often, when you buy a faucet, the set is already equipped with rubber hoses for connecting to the water supply system. But in most cases, their length is not enough, so you have to purchase longer hoses.

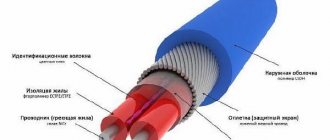

Structurally, a flexible hose consists of a rubber hose of some length, the surface of which is braided with a metal jacket, which is necessary to increase strength. At the ends there are fittings for threaded connections. Provided that rubber is used, the hose is absolutely safe and environmentally friendly.

The service life of the flexible liner is quite long. During use, it does not emit harmful substances. The material itself withstands high temperatures, so the flexible hose can be used in hot water supply or heating. But it’s better to ask the store how to choose wiring for water with temperatures above +950.

The flexible hose can be equipped with a brass fitting; it is connected to the inlet using a special sleeve. Connections to the water supply system are made using fittings or union nuts.

The undoubted advantages of flexible eyeliner include the following:

- possibility of hidden installation. Flexible hoses can simply be hidden in in-wall boxes. Hidden installation is especially important when installing built-in faucets, then the hoses do not spoil the view;

- flexibility of the liner. During the installation of plumbing fixtures, you can freely move them around the bathroom area, and you don’t have to worry about the hose being damaged;

- simplicity and ease of installation and dismantling. All you need is a wrench and pliers;

- high quality and long service life;

- safety in use;

- ease of use.

However, flexible eyeliner has a number of disadvantages, for example:

- careless handling, mechanical damage, twisting and stretching lead to damage to the hose, which will result in leakage and flooding;

- bellows connections are noisy, especially when taps are opened simultaneously in different rooms;

- the metal jacket will oxidize over time and begin to rust;

- not all hoses can withstand the temperature of hot water;

- impossibility of installation near an open flame source.

Connection rules

The liner in different systems is connected through mounting elements at the ends of the hose - union nuts and fittings. The hose model is selected according to its length, type of connection and size of the mounting unit. Fittings are available in sizes from 0.5″ to 1.5″. The hose is attached freely, without tension. Otherwise, deformation of the pressed connecting fittings occurs.

For different diameters of the mixer and pipeline, the supply at one end is connected through an adapter.

During installation, you must follow the connection rules.

- Before installation in the liner, the fastening of the fittings at the ends is inspected, the presence of gaskets, the quality of the thread and braid are determined.

- After connecting, check for leaks within half an hour. When drops appear at the joints, tighten them.

- The bending radius should be more than 5–6 times the outer diameter.

- The hose is not stretched or twisted during installation.

- When tightening, do not apply excessive force: the seal may be damaged. If there is no experience, tightening is done by hand, followed by a slight tightening with a wrench.

- The hose cannot withstand open flame or high temperatures.

- Once every six months, the tightness of the fastening is checked and an external inspection of the liner is carried out.

- To avoid electrochemical corrosion, pairs of the same metal are connected.

- It is recommended to replace the liner every 5 years.

Criterion 1. Hose

A flexible line has a main component - a rubber or caoutchouc hose braided with a metal jacket. It is made from environmentally friendly rubber. When interacting with liquid, the hose does not decompose and does not release toxic substances. Therefore, flexible hoses can be used in drinking water systems. It is also quite resistant to the influence of hot water. The rubber hose can be used when installing hot water heating systems (up to +950). The main thing before purchasing is to make sure that the hose is designed for use in conditions of elevated temperatures. A sign of low-quality rubber is a strong chemical smell. EPDM material has virtually no odor.

History of invention

What is a bellows? This design was invented by an American meteorologist at the beginning of the last century. He came up with a corrugated metal container to trap air particles that could shrink and expand with changes in pressure. He gave the name to his invention from medieval mythology - the spirits of the air were called sylphs. The unique property of the bellows to maintain tightness even with multiple deformations has found wide application in a wide variety of industries. Bellows water line is one of the most common uses of this invention.

Criterion 2. Braid

Another important part of the eyeliner design is the metal braid. Its purpose is to provide increased strength and protect the soft hose from mechanical damage and water hammer.

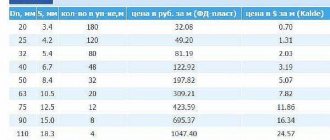

- The shirt is made of stainless steel threads. An eyeliner braid from the middle price category lasts about 8 years. But in most cases, during this period the mixer is changed and the liner is changed in one thing. A metal jacket made of stainless steel threads can withstand water pressure of 10 atm and temperatures up to +950. The specified characteristics are operational; at peak load the liner can withstand higher pressure and temperature.

- The braid may also consist of aluminum threads. Eyeliners with this type of protective jacket do not last as long as their counterparts with stainless steel protection. The braid remains reliable for 3-4 years and can withstand pressure up to 5 atm. Aluminum threads are sensitive to condensation, which leads to oxidation and destruction of the metal. When purchasing, it is easy to identify aluminum braiding - you just need to rub it with your hand and a trace of aluminum will remain on the skin.

- The third type of protective jacket is made from galvanized wire. This type of braid is the most unreliable and is used in budget eyeliners. Its maximum operating pressure is 3 atm. Service life – no more than 2 years. Eyeliner with a galvanized jacket is usually used as a temporary one.

Sometimes you can find expensive, reinforced eyeliners on sale. Their braid is made of nylon or stainless steel threads. Such a shirt can easily withstand a pressure of 20 A) and a temperature of up to 1100. And the service life is at least 15 years.

Which option should I choose?

Experts recommend choosing the best option - a “semi-rigid” liner, which is a copper tube nickel-plated on the outside.

This type of connection is already equipped with standard fittings of different lengths for screwing into the body of the mixing valve. Collet adapters are screwed onto the other end of the semi-rigid tube with a rubber gasket around this tube. On the opposite side of the adapter there is a standard (HP or BP) ½ inch plumbing thread.

Connecting a semi-rigid line is very simple:

- The bodies of the collet adapters are installed at the outlet of the pipeline.

- Then you need to screw these semi-rigid tubes into the mixer and install it on the sink.

- Then you need to bend the liner to the desired place so that the tube does not fold, that is, with a large radius.

- After this, you need to mark the required length, put the conical part of the collet adapters on the tube and saw off the excess.

- Before sawing, do not forget to put on a collet clamp, otherwise you will have to file the tube for a long time and remove a long chamfer from it.

- Then the tube is inserted into the collet adapter bodies that are pre-screwed to the pipeline.

- Then you need to throw the conical parts onto the adapter and tighten them very carefully so as not to damage the rubber seals.

For installation, you only need three tools: an adjustable wrench, an open-end wrench from an auto-dialer, and a hacksaw (or a file with a sharp edge).

Semi-rigid liner, unlike flexible liner, does not need to be replaced every couple of years for preventive purposes, and is more resistant to hydraulic shocks and ruptures. By choosing this option, you will significantly increase the reliability of the connection, reducing the risk of rupture or leaks.

Criterion 3. Connection

High-quality crimping of the tip is a good indicator of the reliability of the entire liner. The tip is one of the most important parts of the structure. The service life of the liner and its safety depend on the quality of its manufacture and crimping.

One type of defect is weak compression of the braid. This can happen either due to poor-quality liner material, or due to the lack of special equipment at the manufacturer.

Manufacturing tips and connections from low-grade metal is fraught with deformation, rapid oxidation and corrosion, which ultimately leads to structural failure. Connections can be:

- brass LS-59 coated with nickel-chrome - lasts up to 15-20 years;

- made of stainless steel AISI-304 without protective coating - lasts up to 15-20 years;

- made of ordinary steel, coated with nickel-chrome - lasts up to 1-3 years. To determine the type of metal, just scratch the surface of the braid. If it is made of plain steel, the scratch will be silver, and if it is made of brass, it will be silver-yellow.

Gas connection

About ten years ago, the question of how to connect a gas stove to a riser was not even faced by the consumer - the standards only allowed connection using steel pipes, and the stove was forever chained to the place allocated to it. The installation was carried out exclusively by gas service technicians. But in the mid-90s. XX century A flood of imported household appliances has poured into our country, including gas stoves, and with it such a convenient means of connecting them as flexible hoses. Along with all this, a, so to speak, revision of priorities came to us: not only “service 04” began to take on the installation of rather complex gas stoves, but also the service departments of organizations selling this equipment (of course, having received the appropriate permission). By the way, in the latter case, the installation of the stove went better and faster - the installers of the trading company knew exactly what needed to be adjusted and how, unlike representatives of the gas service, who, when they arrived for installation, saw some complex models of gas stoves for the first time in their lives. In addition, if representatives of the gas service, in the old fashioned way, tried to rigidly “tie” the stove to the riser, then the “service workers” certainly suggested doing this using a flexible gas line: “When you decide to wash the floor under the stove, you just need to move it aside and then push it onto place". Naturally, such convenience and ease of installation were captivating, and the customer certainly agreed with the proposal, even if it was a little more expensive.

True, the introduction of the new product resulted in numerous explosions and fires. The troubles began when flexible gas lines became available for sale. After all, having been seduced by the ease of installation, almost everyone who has at least once held a wrench in their hands began to consider themselves an expert in connecting a gas stove. And gas, as you know, does not tolerate jokes (one can see before one’s eyes the childhood poster hanging in every entrance: “Don’t joke with gas!”), nor does it tolerate an amateurish approach to itself.

Criterion 5. Fitting

Looking inside the hose, you can see a brass fitting. Its presence is an indicator of high-quality eyeliner. In counterfeit products, fittings/nipples are often made of plastic, which is unacceptable.

The fitting is made only from stainless steel, plain or nickel-plated brass and aluminum.

Low-grade metal should not be used in the manufacture of the nipple, and the thickness of the product should not be lower than permissible. Otherwise, these shortcomings will lead to rapid failure of the entire flexible line.

Bellows

Bellows hoses are more reliable and durable. They are made in the form of alternating rings of different diameters made of stainless steel. During production, the workpiece is selectively crimped, after which it receives a corrugated shape that provides high flexibility. The cost of such a hose is much higher.

The eyeliner is available in two types:

- with fixed length;

- foldable.

The first does not stretch and has a certain size: 20, 30, 40, 50, 60, 70 and 80 cm. For the second, the range of minimum and maximum values is indicated: 140–250, 200–355 mm, etc. It is not recommended to get too carried away with stretching, since this affects the service life of the product.

The disadvantage of a bellows hose is the noise that occurs when water is simultaneously supplied to several consumers, for example, to a faucet, toilet and washing machine. To avoid this, it is recommended to purchase hoses with a plastic coating.

Criterion 6. System temperature and pressure

To correctly answer the question - how to choose a flexible water supply - you also need to pay attention to the technical parameters of the plumbing system. This is, first of all, pressure in the pipes and water temperature. If the eyeliner does not meet the indicators, it will quickly become unusable.

While you can always determine the water temperature yourself, it is quite difficult to find out the pressure parameters in the system. If it is impossible to determine specific indicators, then you can focus on standard figures characteristic of all water supply systems.

- Central water supply - 4 atm.

- Closed heating system with coolant circulation - 1.5-3 atm.

- Centralized heat supply - 2-4 atm.

In the case of heat supply, peak loads are possible, so when making calculations it is better to include a plus of 20-25%.

How to choose a flexible water line and what to check when purchasing

We will give some necessary recommendations in order to understand how to choose a water supply for the mixer.

- Take time to study the label of the product you are planning to purchase. All specifications must meet your requirements and be suitable for the device being installed.

- The eyeliner you choose should not be too light. The very low weight indicates the use of braided aluminum, and the fittings are made of low quality metal. It will not take a long time for these elements to deform.

- If the connection fitting is made of plastic, then this is the worst option of all. Choosing such a product is not the best idea.

- A flexible water line must live up to its name. You should not choose a design that is too “oaky” - its hose will be prone to cracking or may burst at any moment.

- The quality of crimping of fittings must be at a high level, the tubes are inserted all the way, and the sleeves are made of stainless steel.

- Pay attention to the union nuts of the liner you want to select. Too light and thin nuts also indicate low quality not only of themselves, but also of the fitting. This can lead to depressurization of the joint. The ideal material is nickel-plated brass.

- Sniff the chosen eyeliner. If it has a pungent odor, then most likely the hose is made of technical rubber, which will negatively affect your health. Quite often this material is used to produce cheap eyeliners and mixers.

- Look at the colors of the braid. Each eyeliner has its own niche of use. Hoses are available for cold and hot water separately, and there are also universal ones. The color of the braid will also be appropriate - red or blue. Universal eyeliners combine both of these colors.

Criterion 8. Dimensions

When determining the dimensions of the eyeliner, it is important to know two main parameters:

- diameter. When choosing it, you need to focus on the expected water consumption. Standard values for various equipment: for installing a toilet - 8 millimeters, for connecting a faucet in the kitchen - 10 millimeters, in a bathroom - 15 millimeters;

- length. When choosing the length, the distance from the plumbing equipment to the water supply pipe is taken into account. The hose should not be stretched or bent too much. Any mechanical deformation will shorten the service life of the liner.

New eyeliner called Altstream Super

This is not an advertisement, but a review of a new product. Made from high quality material – cross-linked polyethylene. Due to this, increased resistance to pressure and temperatures.

Photo: i6.otzovik.com/2018/11/27/7310470/img/83060743.jpeg

Photo: i6.otzovik.com/2018/11/27/7310470/img/83060743.jpeg

The company’s statement that the eyeliner has a service life of more than 50 years is surprising. Plus

It also helps that the company

labels

the eyeliner itself.

Other analogues only have a tag indicating the manufacturer and characteristics. Once installed, people usually tear them down and throw them away. New eyeliners come with laser marking (company logo). Costs 190 rubles for 50 cm

.

Image: ic.pics.livejournal.com/orlllangur/18753870/522209/522209_600.jpg

Image: ic.pics.livejournal.com/orlllangur/18753870/522209/522209_600.jpg

RepairDom channel: subscription . Thank you for the likes and all the best!