You can’t wash yourself with cold water to your satisfaction. Therefore, one or another system for producing hot water is traditionally installed in bathrooms, washrooms, baths and saunas. In the most ancient baths there was no hot water, which caused some inconvenience. Nowadays no one will dispute the need for hot water in any bathhouse.

It is advisable to use the main heat source to heat water. Most often this is a sauna stove, and for regions where there is no firewood, the tank for hot water in the sauna is placed on a gas boiler. Many options for heating water have been developed; tanks of any size and configuration are available for sale. Here we will look at choosing the best option for your bath or sauna.

Metal

Since water is hot, metal remains the best material for tanks. In addition to metal, wood and plastic are also used. These materials can only be used if they do not come into contact with objects heated above 90 degrees. Basically, the heating of water in the bathhouse is provided by metal tanks.

Here are the main types of such tanks:

- Installed on the chimney;

- Suspended (wall-mounted boiler form factor);

- Built into a sauna stove;

- Built into gas and other boilers;

- Remote for installation on a flat surface, floor and tabletop, as well as suspended.

The choice of a specific option is carried out according to the internal conditions of each bath. The power of the heat source, its type (stove or gas boiler), as well as the required amount of hot water are taken into account.

Another feature is how exactly the hot water in the bath will be used. Will it be a simple hot water tap or showers that require pressure. We will consider each option in more detail.

For metal tanks, there are several options for their design:

- Galvanized steel, painted with heat-resistant paint (not common);

- Enameled steel (the main type of tanks for baths, boilers, kitchen heaters);

- Thick-walled galvanized steel without paint (developed following the example of galvanized buckets and utensils);

- Cast iron enameled (very reliable, but rare);

- Stainless (the best type of tanks).

The most affordable ones are enamel tanks. They are mass produced. They are specially made for heating hot water. For little money you can find options for any capacity and configuration.

Anti-corrosion treatment

For metal tanks, corrosion is the main problem. The key solution is stainless steel, but for now, the price for it remains 10 times higher than usual (in terms of weight). In reality, a stainless steel tank costs not 10 times more than a regular steel tank, but much less. This happens because the thickness of the walls of the stainless steel tank is made smaller. There is no reserve required for thinning due to corrosion.

Anti-corrosion treatment of tanks is carried out in the factory. Technologies in this area do not stand still and are constantly being improved. Zinc has the strongest adhesion to steel. Various protective layers are applied on top of it.

There are two popular options for anti-corrosion protection. This is either paint for a hot water tank in a bathhouse, or glassy enamel, which is applied at high temperature. Enameled tanks are better protected from corrosion and high temperatures than painted ones.

The general technology for their manufacture is the same as for conventional enamel cookware. Glass-based food grade enamel is used for tanks and utensils, without the addition of lead.

Information. In some cases, they carry out independent anti-corrosion treatment of tanks. All homemade structures need it (with the exception of stainless steel). You need to use only specially developed compounds and apply them to a clean and grease-free surface.

Tank parameters

If you are in the habit of doing everything with your own hands, then of course you should try to make the tank yourself. However, you need to make a decision about what type of tank you will make, whether it is suitable for your steam room, what type of heating you will use, what material you will use. It is worth noting that the material is no less important, since if you make it from bad material, then it is likely that you will have to invest a lot of money again in the future.

First, let’s decide what we will use to heat the bathhouse. There are two options: using a stove, and using a water heating heater. And for a more profitable option, you need to calculate how many people will be steaming at the same time. You also need to consider how much water you need, how much time you need for this process and, accordingly, what temperature you need.

For example, for one person fifty liters of hot water is somehow too much. And for the whole family and some other small group of friends you need at least seventy liters of hot water.

Also pay attention to the thickness of the tank walls. This will determine the uniform heating of water and the temperature storage time in the tank. But remember that the thickness of the walls of the tank also affects its weight and overall cost.

For a stainless steel tank with a total volume of up to fifty liters, the normal wall thickness is approximately 0.8-1 mm. For a stainless steel tank, but with a volume of more than fifty liters, the normal wall thickness should be about 1.5 mm.

We must not forget that no matter what material your tank is made of, you still need to make an inlet for water, as well as the most optimal number of outlets. It doesn’t matter where you make the tank, whether you order it from a workshop, make it yourself, or simply buy it in a store. This means that it is very important to take into account all the previously listed parameters. And only then the washing process itself will give you maximum pleasure.

On the pipe

Such a tank has a cylindrical shape and is located around a pipe. Its advantage is the ability to use both a sauna stove and a gas boiler, and the design of the tank itself can practically not be changed.

A water tank for a sauna pipe does not take up space and is suitable for compact buildings.

It is placed high on the pipe, so there is no need to use a pump for hot water in the bathhouse. All water flows by gravity.

The main disadvantage of a sauna pipe tank is its low efficiency.

Many hot gases from the stove escape without giving up their heat to the short section of the chimney where the tank is located.

This is why you rarely see large capacity tanks. They are usually limited to 80 liters.

This is quite enough, even if it is a medium-sized bathhouse.

A pipe-mounted hot water tank requires a robust chimney and stove structure.

At the bottom, the chimney is attached to the brickwork.

At the top, special attention should be paid to the fastening, since there a fragile “soft” connection to the ceiling through a heat insulator is usually used.

For a rigid connection of thermal insulators, more is needed. Rigid structural materials conduct heat very well, which must be taken into account.

Good results can be achieved by using ready-made kits with brackets for chimneys.

Information. A water heating system in a bathhouse with a tank on a pipe requires only a metal chimney. It provides excellent heat transfer. Metal is not necessary for the furnace itself.

According to the material used, the tank on the bath pipe can have only two options. This is ordinary steel with anti-corrosion protection (enamelled) and stainless steel. The second is preferable, although much more expensive.

A water heater on a bath pipe is usually coated with enamel at the factory. Galvanization and painting do not have the same heat resistance. For metal sheets that are constantly exposed to water and heat, enamel is the best protection.

The gradual destruction of enamel is due to the fact that the coefficient of thermal expansion of steel and glass enamel is not the same. Because of this, it gradually cracks, even if no mechanical stress is applied to the tank.

Important! You cannot fire a stove with a tank installed when there is no water in it. Otherwise, the walls of the empty tank overheat and the enamel deteriorates irreversibly. It is not necessary to fill the water to the top.

A tank for a stainless steel bath pipe does not have the disadvantages of the fragility of enamel. This is a very reliable solution. Stainless steel, even if technical and not food grade is used, still has high hygiene and safety for humans. There is no need to treat the hot water tank in the bathhouse.

The only drawback of stainless steel is its high cost. For tanks, it is further increased by the complexity of welding them from sheets, but when purchasing, you need to remember that it gradually pays off due to a long service life.

Stainless steel tanks are practically eternal and fail only due to mechanical stress or poor quality welding. You need to purchase them only from reliable src=”https://rubanya.com/wp-content/uploads/2017/08/bak-trubu.jpg” class=”aligncenter” width=”400″ height=”375″[/ img]

A samovar-type water tank for a bath is taken ready-made.

Making it yourself is only possible if you have good welding machines and welding experience.

The inner pipe in homemade and factory tanks must be thick-walled, as it is exposed to high temperatures and flames.

In addition, the internal lumen of the tank chimney pipe is not protected by anti-corrosion coatings.

A pipe-mounted water heater is also called a samovar-type tank for a bath. The connection to the chimney must be airtight. A flange connection is predominantly used.

The meaning of the shape of a sauna stove

The performance of the unit and how convenient it is to operate depend on this parameter. As practice shows, stoves with a cylindrical shape and a shaped or horizontal design are in high demand.

But the most convenient to use are rectangular units. The reason for this is the presence of corner zones, which rarely become as hot as possible. As a result, there is an opinion that such a frame helps maintain the shape of the stove. In addition, the uniformity of heating of the unit depends on this parameter.

Proper heating also affects the stability of a metal heating structure. This is confirmed by the fact that the walls of round and cylindrical furnaces are reinforced. And although the high degree of stability of the rectangular structure is explained by the presence of cold corners, it still loses its original shape over time.

Sauna stove with water tank

This solution is reliable and durable. If properly manufactured, the efficiency of a tank installed inside the furnace will be higher than for a tank on a pipe. In places where there is no firewood, you can install a gas boiler in a bathhouse with a water tank.

The model is simply purchased ready-made and installed according to the instructions. Gas boilers are also popular. The stove can be either homemade or ready-made, factory-made.

A sauna heater with a water tank is good in a classic layout. Such a stove is made of brick or ceramics with metal. The water tank is located at the top of the stove, which, when installed, will face the wall.

There is space on the front side for stones. Using this scheme, hot water in a bathhouse will heat up much more efficiently and quickly than if you use a tank on a pipe.

In the absence of a ready-made solution, you can organize hot water in the bathhouse yourself. The schemes here can be very different, but the main thing is to ensure the most efficient heat transfer from the stove to the water. Metal tanks with thin walls work best.

An effective combined solution: the tank for hot water in the bathhouse is installed halfway above the firebox of the heater and on the pipe. The chimney elbow is welded into the metal tank. The chimney outlet from the firebox is made horizontal. The front part of the firebox is necessary for heating the stones.

Heater with water tank for gas bath

The design is almost no different from a standard unit that runs on wood. Gas sauna stoves are easy to use. They can be connected either to the main gas pipeline or run from cylinders.

When installing a stove with a water tank, you need to take into account the following elements that distinguish it from other models operating on other types of fuel:

- fuse (the ability to control proper operation);

- gas chamber (sealed);

- thermostat (allowing you to regulate the temperature);

- gas cylinders.

An approximate calculation of fuel consumption shows that to ensure high-quality heating of the room for 12 months, you need to have 65 gas cylinders (50 liters each).

The operating principle of the furnaces is based on the passage of gas through a special chamber in which oxygen saturation takes place. It is supplied through a special pipe connected to a central gas pipeline or cylinder.

If a sauna stove with a heat exchanger for heating is heated by gas cylinders, they should be located in a specially designated area. It is best to install them outside the premises so that residential buildings are located at a great distance.

Boiler for a bath

Boilers are effective in regions where there is no firewood. Gas and solid fuel options are popular. It is better to prefer solid fuels on peat. Unlike coal, they do not pollute the surrounding area.

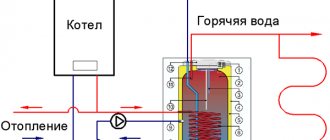

There are two options with boilers. Either connect the tank to the heat exchanger in the bathhouse (the heat exchanger is placed in the combustion chamber of the boiler), or install the tank on the boiler itself.

Information. Unlike stoves, boilers are not assembled from bricks, but are purchased ready-made. The design with a heat exchanger has maximum efficiency; by the way, it can be implemented without a ready-made expensive boiler. This is discussed below.

You can use homemade boilers for a bath from a pipe, but this requires good quality welding work, which is the main difficulty. A common option is to manufacture the boiler and tank from large-diameter stainless pipes.

Wood-burning sauna boilers with a tank are produced ready-made. Structurally, they are designed in the same way as a regular sauna stove and differ in size. Their water capacity is usually larger, and the area for installing stones for soaring is smaller.

Made of brick

Perhaps one of the most difficult options, requiring not only a good supply of patience and endurance, but also knowledge of various subtleties when organizing brickwork. On the plus side, it provides very high-quality heating even for a large room. In other words, if you decide to make such a stove in a bathhouse, then no one will definitely be cold, since the brick thoroughly warms up even the most secluded places in the steam room.

- first, the foundation is built - it should be no more than 2 standard bricks in height, fine gravel and sand are mixed and poured into the prepared area;

- after that, the finished foundation is covered with sheets of roofing felt and the so-called starting row is laid out, which experts call zero - this is a base that must be extremely even, so you need to carefully monitor this moment using a level;

- we continue the laying and build the first 2 rows - they determine the desired shape of your stove, it is best to use fire-resistant red brick for these purposes - it has excellent fire safety, but it is at this lower level that the temperature will reach a critical level;

- we fix a dense asbestos-cement sheet to decorate the ash pit and begin to lay the third row;

- when moving to the laying of the fourth row, we first make a niche under the heater - this will be the basis for the future combustion chamber, for this purpose it is best to choose not ordinary, but fireclay brick, since it has excellent fire resistance, do not forget about the grate;

- the fifth row of masonry is a sequential expansion of the firebox with the design of the heater's ceiling, do not forget to leave a small compartment at the very bottom - water will flow into it in case of excess water;

- as soon as you move to the seventh row, lay the stones and mount the door for the combustion chamber;

- the next row allows us to design the necessary channel, which will serve as a connecting element between the firebox itself and the heater;

- before you start laying the ninth row, fix the horizontal valve for the gas duct;

- while laying the tenth row, you can safely install a vertical valve, which will help separate the chimney and heater;

- we lay a row of stones and cut out a steel sheet (thickness - at least 0.1 cm) - it will serve as a lid for the stove;

- all subsequent final rows are laid in order to build up the future furnace and prepare its base for the intended pipe;

- The final touch is installing the pipe and water tank.

All stages of building a brick sauna stove are shown in the photo. We also offer drawings that will help you complete the work more accurately if you do everything yourself.

Mounted

This design option is hung on a standard metal sauna stove. The presence of metal walls of the furnace is mandatory, since heat is transferred through one of them to the water in the tank. This design is not widely used due to low efficiency, but its main advantage is maximum simplicity.

A hanging tank for a bathhouse is usually made of thin stainless steel. It is placed outside the stove and located in a visible place in the bathhouse. Stainless steel is not only an ideal material for water tanks, but also has a beautiful appearance.

When you need the simplest tank for hot water in a bathhouse, wall-mounted installation is best. With it, you don’t even need to do pipe routing. The tank is delivered completely ready.

The bath tap for hot water is also included with the tank upon purchase. The spigot is located at the center of the lowest point, and the bottom is usually flat or has a conical stamping.

The inconvenience of this location of the tap is the small distance from the floor. In addition, the stove is often placed in the corner of the bathhouse. One side of it is occupied by the door, and the other by the tank. Thus, it turns out that the tap is in a very inconvenient place. This problem is solved by installing a pump.

Information. For a wall-mounted tank, the sauna stove should be standard. This is either a ready-made structure, or a home-made one, but having at least one flat metal wall of the appropriate size for the tank.

Wall-mounted tanks have either a removable lid or a filler neck with a diameter of at least 10 cm. A filler neck is much more common. It makes cleaning and processing the internal space somewhat more difficult, but makes the structure more durable.

The cheapest designs of hanging tanks are welded from sheet steel and galvanized. The service life of such structures is short. Stainless steel thin-walled structures are gaining popularity.

Due to their small wall thickness, they are affordable. Steel enameled tanks are rarely used as hinged tanks on the stove.

Basic safety requirements

Correctly hitting a brick

The brick is hit with a pick in a direction away from you, placing it on its edge. The tool must be firmly seated on the handle (wedged) and secured with a nail or self-tapping screw. Handles should not have burrs or chips.

Scaffolding and decking must be securely connected to be stable. The materials for the solution are filtered to remove small pieces of glass and sharp stones.

Remote with heat exchanger

Heating water in a bathhouse using a heat exchanger is highly efficient. This method is used in boiler houses of any size. The heat exchanger is located in the furnace flame. Water circulates through it; this heating of water is the most effective of all possible. The only thing that limits the use of this system for baths is its complexity and the resulting high cost.

Advantages

A remote tank for hot water in a bathhouse is placed in any convenient place. Heat is transferred to it through circulation pipes if a stove or boiler is used. Remote tanks are also ideal for electric heaters.

Compared to a tank directly on the stove, heat is transferred to a remote tank in a more complex way. The length of the pipes can be several meters. Of course, this causes additional heat loss, but also provides many advantages:

- If the tank is remote, then a highly efficient heat exchanger is necessarily used to heat the water;

- The installation location can be any; large volume containers can be installed;

- It is convenient to install at a height, for example, in the attic of a bathhouse for a ceiling shower.

Connection, installation, materials

The connection of the tank in the bathhouse through a heat exchanger is carried out according to the same scheme as in a conventional heating system at home. Even the main components can be taken the same.

Radiators are not required; instead, water heated in a heat exchanger in the flame is stored in a tank. It turns out to be a remote tank for a bathhouse. Installation of a remote tank in a bathhouse can be carried out in any convenient place.

Attention! The requirements for materials for an external tank in a bathhouse are lower than for tanks on a pipe and in a stove. Unlike them, it is not exposed to temperatures above 90 degrees. Theoretically, even wooden bath utensils can play its role, but this option is not recommended.

A remote tank for a bath with a heat exchanger is often located so that the water flows by gravity. This requires the tank to be located at the top, which is fraught with serious consequences if it falls or depressurizes. This installation of a remote tank in a bathhouse is only suitable for small containers. For options over 50-70 liters, this method is definitely not recommended.

Making a furnace firebox

Basically, doors are purchased in advance and ready-made. Because making them yourself is very difficult. Grilles are also purchased. To create the firebox itself, you will need a pipe, the length of which must be at least 2 meters.

Thickness parameters are allowed from 5 mm, but it is better to set it to 10 mm, since it is more reliable and will last longer. It is divided into two parts.

The first is necessary directly for the firebox itself, as well as the heater. The dimensions of this segment should be at least 0.9 m. The second part will be used to create a tank, the dimensions of which will be 0.6 m.

Next, a small hole is cut directly in the pipe itself. Its width will be 0.2 m, length - 0.5 m. After which, using a welding machine, a metal plate is attached on which the grate will be located. It is advisable to buy it in advance.

Remote large capacity

The water tank for the bathhouse is remote; if a large container is used, it is installed on the floor. For baths with several sinks and showers, a pump must be installed.

It creates the required pressure, which makes it possible to use any modern plumbing fixtures, spray showers, hydromassage cabins and much more.

When installing the pump, care must be taken to ensure that it does not cause excessive noise.

It is reduced by the use of plastic pipeline fittings and the pipes themselves.

Also, the pump installation should be carried out outside the bathhouse.

Nowadays pipes are inexpensive, and you can make an elbow for the pump in any convenient place, for example, in a plumbing hatch, next to the water meter or in the utility room of the bathhouse.

The “water tank with heat exchanger” type arrangement for a bathhouse is suitable for heating the largest volumes of water. The tank capacity can exceed hundreds of liters. In other heating systems, such options are difficult to implement.

Information. All pipes, connecting fittings and pump must be heat-resistant (if plastic is used). For metal, ordinary ½ or ¼ inch steel pipes are optimal.

Device Specifications

The volume of the tank should not be too large relative to the furnace.

Two characteristics are important for operation: system capacity and productivity.

When making a simple stove for a bath, you need to know that 1 m² of heat exchanger, which is exposed to an open fire, is capable of “taking away” a power equal to 10 kW from the stove.

On average, a homemade stove produces 6–7 kW of heat; the heat exchanger should not be made too voluminous. There is a risk that most of the energy of the burned fuel will be spent on heating the water rather than the steam room air.

It is known from practice that for the entire complex of paired procedures one person needs about 10 liters of water at room temperature or about 5 liters of liquid heated to 80 °C. Based on this volume, water heating systems are manufactured.

Heat exchangers

The easiest way to heat water in a bathhouse through a heat exchanger is to use ready-made blocks from heating systems. The heat exchanger is the most complex and critical component. It is placed in the flame of a gas boiler in a bathhouse, in the flame of a sauna stove.

The heat exchanger requires good heat resistance.

The best material is cast iron. Castings made from it have thick walls and last a long time.

Steel heat exchangers are also common.

They can also be recommended for baths.

In terms of the average daily number of operating hours, the bathhouse is inferior to a conventional boiler room or kitchen heater.

Therefore, its heat exchanger may well be steel with a small wall thickness. Thus, hot water in the bath will be obtained as quickly as possible through the heat exchanger.

A heat exchanger for hot water in a bathhouse is purchased complete with a boiler, stove, or removed from worn-out equipment. There are many sources for obtaining such elements.

These are gas hot water heaters, single-circuit and double-circuit boilers. Refrigerator and air conditioner condensers are not suitable for flame heat exchangers.

Important! When using components from dissimilar systems, care must be taken to ensure their structural compatibility and overall circuit tightness. Use new adapters and all connecting fittings.

A sauna tank with a heat exchanger is made from different materials. It is only necessary to ensure compatibility of the diameters of the connecting fittings. Kits from heating networks are optimally suited. Kits from hot water supply systems are also optimal.

Instead of a heat exchanger that is placed in the combustion chamber of a boiler or furnace firebox, you can purchase a heat exchanger for a bath on a pipe. This is a special factory-made design. In appearance, it resembles an ordinary pipe tank, but of small capacity. There is no such tank casing inside.

Information. The advantage of using a heat exchanger on a pipe is that there is no need to redesign the furnace. The disadvantage is lower efficiency compared to a flame heat exchanger.

conclusions

All methods of heating water in a bath described in this article are widely used. They are structurally thought out, safe and comfortable. It is only necessary to ensure their high-quality implementation. Like any other water systems, sauna water heaters must be sealed.

The tank for heating water in the bathhouse is installed in one copy. Using one tank with a large capacity, which is designed with a margin, is more profitable than several smaller tanks. In the construction of a bathhouse, we recommend that you read other articles on our website.