A beautiful, stylish kitchen-dining room is a necessity for every family, but it requires careful cleaning. The times when the kitchen was simply whitewashed and repainted every year are gone. The cooking process is always accompanied by the release of moisture and combustion products that settle on the walls, furniture, and ceiling. A hood helps get rid of this problem.

But another problem arises: the hood and exhaust pipe in the kitchen do not look very aesthetically pleasing, they try to disguise them and make them as compact as possible. We welcome our dear regular reader and offer an article on how to select and install an air duct from a range hood with your own hands.

Use of ventilation pipes in everyday life

Residential buildings must have ventilation. In the process of breathing, a person emits carbon dioxide and moisture, cooking - moisture, soot, fat, carbon dioxide, sanitary appliances - a lot of moisture. Moisture settles on walls and furniture, which leads to the formation of mold. Carbon dioxide and combustion products, odors from cooking lead to rapid fatigue, irritation of the respiratory tract, deterioration of well-being, and decreased performance. Some of the substances formed during frying are carcinogens.

In old Soviet-built houses with small apartments and loose doors, ventilation in the kitchen and bathroom simultaneously removed some of the air from the living rooms. Ventilation ducts were built into the building structure. In private houses, ventilation was not provided at all - the situation with carbon dioxide was saved by a stove with a chimney: the air for firing the stove was taken from the house and removed, along with the products of fuel combustion, outside the living space. Fresh air entered houses and apartments through leaks in wooden windows and doors. The smoke and soot simply settled on the walls and ceiling - they had to be whitewashed every year.

In apartments there are ventilation ducts in kitchen hoods, additional ventilation in bathrooms and toilets.

In modern houses, in addition to the hood, additional ventilation systems are often installed - exhaust and supply and exhaust. In passive and energy-efficient houses, supply and exhaust ventilation with heat recovery is a mandatory component of the house design.

How to hide an air duct

Ventilation can look very bulky and detract from the ambiance of the kitchen. To make the pipe less conspicuous, it is usually laid above kitchen cabinets or near the ceiling. If the air duct is plastic, the simplest thing you can do is paint it to match the walls or furniture. All these are half measures. To hide it from strangers, you will need materials and time.

- If the ventilation does not pass through the entire wall, it can be hidden in a wall cabinet by drilling holes. It is good when the entrance to the ventilation duct is located directly above the hood. It is convenient to hide such a straight air duct in a decorative box made of metal to match the color of the hood or plastic.

- When the pipe is very long, you can make a box under the ceiling from moisture-resistant plasterboard. And to justify its presence, decorate it with decorative lamps.

- If ventilation is installed during renovation, then you can hide the air duct in multi-level ceiling structures - suspended or suspended.

Now, having understood the features of kitchen ventilation pipes, you can choose an air duct to suit your requirements. Knowing the nuances of installation, you can assemble it yourself. By understanding how to properly remove it, you can ensure good ventilation in the kitchen.

Differences between a kitchen exhaust system and ventilation

A kitchen hood is a local exhaust ventilation system with artificial impulse and is fundamentally no different from ventilation. There are differences from general indoor ventilation: general ventilation in apartment buildings is designed with natural impulse and operates without the participation of fans. In addition, general ventilation serves to ensure air exchange throughout the entire apartment, and the hood removes polluted air in a specific place and only when necessary.

Calculation of diameter and dimensions

The diameter must correspond to the cross-section of the outlet pipe on the hood. Since the dimensions of the outlets and pipes are standardized, this is easy to achieve. For plastic it is 10, 12.5, 15 and 20 cm, for corrugated pipe – 10, 12.5 and 15 cm. It is recommended to take a pipe whose cross-section is slightly larger than the cross-section of the pipe.

The ideal length of the air duct is no more than 3 m. If the pipe is longer, install a more powerful fan.

Valera

The voice of the construction guru

Ask a Question

It is usually not necessary to calculate the diameter of the pipe, since it is determined by the pipe and the ventilation hole. In rare cases, when the hood is not equipped with a fan, multiply the volume of the kitchen space by 12 - this is the recommended air exchange, and by 1.3 - the power loss coefficient. The resulting value is multiplied with the cross-section of the pipe and the maximum rate of air removed. As a result, the minimum permissible pipe cross-section is obtained.

The importance of kitchen ductwork

The existing general ventilation does not remove combustion products and evaporation specifically from the stove; it serves to replace air throughout the entire volume of the room.

Modern housewives are not happy with this situation. We want high-quality and durable repairs in the kitchen; a working woman does not have time to regularly wash the walls, ceiling and furniture. Demand creates supply - local ventilation units have appeared above kitchen stoves - hoods. But polluted air must be removed outside the room, and air ducts perform this function.

Advantages and disadvantages

There is only one advantage of the air duct: it is impossible to remove carbon dioxide, water and soot without it.

Disadvantages of air ducts:

- They take up space.

- They spoil the kitchen interior.

- Poor installation results in increased fan noise.

- They require regular washing on the outside and periodic cleaning on the inside.

Is it always possible to install a hood?

There may be situations when installing a hood is prohibited by the operating rules for gas appliances.

If there is a gas water heater (boiler) or a gas heating boiler with an open combustion chamber in the same room as the hood, a hood with air removal (circulation) cannot be installed. Removal of combustion products from the boiler occurs without force; when the exhaust fan is turned on, the draft may overturn and toxic combustion products may be thrown into the room.

It is allowed to install a flow-through exhaust device only if a boiler with a closed firebox is installed (with a coaxial chimney and combustion air intake from the street).

You can install circulation-type devices with filters that clean the air from grease and soot.

Is it possible to do without an air duct?

Hoods are produced as flow-through and circulating:

- Flow-through systems remove exhaust air from the room.

- Circulating filters purify the air without removing it from the room.

Circulating hoods are installed above the stove; the air passes through a housing with a carbon filter and is cleaned of grease. These devices do not require air ducts; they are compact and easy to install. But they have other disadvantages - the need to frequently change filters, insufficient air purification, and lack of removal of moisture and carbon dioxide.

Pros and cons, scope

Plastic air ducts are perceived negatively by many, as they are not sure that plastic does not emit harmful substances during operation. Poor quality plastic may be unsafe, but even household appliances contain so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here are the most difficult operating conditions - high temperature, large amounts of fat, evaporation of chemically active substances.

Even open laying of plastic pipes does not spoil the appearance

In general, experts recommend installing plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow, you need heat-resistant ones made of special plastic. Especially if the inflow is heated or recuperated.

Where can I use it?

Another reason why plastic ducts are not recommended is fire service concerns. There have been cases where permission to use gas equipment was not signed if the ventilation was made of plastic. But it was a frame house, and there the requirements are different. If in doubt, it is best to check with your local fire inspector. In general, there are recommendations in regulatory documents.

Extract from SNiP 41-01-2003

According to SNiP 41-01-2003, paragraph 7.11, plastic air ducts can be used in low-rise residential, public, administrative and industrial buildings of category D. They cannot be laid in basements, undergrounds, attics and technical floors, in rooms with regulated fire safety conditions.

Advantages and disadvantages

Plastic air ducts have both supporters and opponents. Their main disadvantages:

- Flammability. Everything is clear here. Only metal air ducts do not spread fire. Although not all plastics burn and spread combustion, such materials with “reduced” flammability are expensive. Therefore, plastic air ducts are allowed only in one-story houses.

- The accumulation of a static charge, which leads to the accumulation of dust (it can flare up again). In fact, much more dust accumulates in corrugated areas. To reduce its amount, it is necessary to install a plastic air duct after completing “dusty” construction work and install filters that catch most of the dust. In addition, plastic ventilation pipes are treated with a special compound. It forms a film on the surface that prevents the accumulation of static charge.

An example of using plastic air ducts to connect a kitchen hood - With low quality workmanship, thin walls or a large cross-section, gaps may form at the joints due to changes in geometry. This can be fixed, but there is such a drawback.

These are the disadvantages of using plastic ducts. There are more than enough advantages:

- Easy installation. The presence of fittings and shaped elements allows you to create a system of any configuration. Plastic is easy to cut and weighs little.

- Due to the perfectly smooth walls, the air encounters less resistance.

- Easier to ensure tightness. For reliability, the joints can be coated with sealant.

- Modern plastic air ducts are joined using end-to-end joints without overlaps, which reduces resistance to air movement.

- Low noise level. With a capacity of up to 100 cubic meters per minute, air movement is almost silent.

- Not subject to corrosion.

This set of shaped elements allows you to create a ventilation system of any complexity from plastic pipes

Overall, plastic ductwork is not a perfect solution, but the ease of installation and good performance outweigh the disadvantages. In general, experts recommend installing plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow, you need heat-resistant ones made of special plastic. Especially if the inflow is heated or recuperated.

Also, when selecting, you should proceed from the operating conditions. For example, it makes sense to use a plastic air duct for an exhaust ventilation duct from wet rooms, since galvanized ones are susceptible to corrosion, and stainless ones are very expensive.

Types: materials and characteristics

For the installation of small home ventilation systems, the industry produces a wide range of pipes and components.

Air ducts for domestic ventilation are divided into:

- By material - plastic, aluminum or galvanized steel.

- Shape: square, rectangular, round.

- According to the degree of flexibility - flexible or rigid. Flexible boxes are made of corrugated aluminum or galvanized steel. Rigid air ducts made of metal are not used due to the complex installation and complexity of manufacturing galvanized pipes of small sizes (from 100 to 150 mm in diameter or section side length). Aluminum pipes of suitable sizes are expensive, there are no special advantages in their installation, so they are also not used for kitchen hoods.

Plastic

Plastic air ducts are round, square and rectangular with a smooth surface. They come in white and painted in different colors - it’s easy to choose a shade that matches your furniture set or wallpaper.

Plastic boxes are very smooth - they are easy to clean, and less grease and soot accumulate inside. Smooth walls provide the least air resistance - therefore, such pipes vibrate and make less noise. Plastic boxes are the quietest compared to corrugated boxes.

.

Made from flexible corrugated aluminum pipe

A very practical option for an air duct is a corrugated aluminum pipe of round cross-section. The flexible pipe is easy to install; it does not require rotating elements - it can simply be bent. An aluminum pipe is durable, but it is very difficult to clean it from grease and soot deposited on the walls. The corrugated inner surface creates great resistance to air flow; the pipes make more noise when the hood is operating.

Metal

The corrugated pipe can be made of galvanized steel. This pipe is a little stiffer and stronger, but otherwise its installation is as simple as for aluminum corrugation.

Places with a damaged zinc layer rust, the rigidity of the pipe complicates its installation, so steel corrugation is rarely used for internal household ventilation systems.

By degree of flexibility

Aluminum corrugation is more ductile than steel, it is easier to bend, stretch and compress.

Plastic air ducts are used only for rigid ones; corrugated plastic pipes are not suitable for transporting hot air.

Main characteristics of plastic parts

You need to know the properties of pipes in order to correctly design and install a ventilation system in an apartment or house. The characteristics of the elements may vary depending on the installation location (above a plasterboard ceiling, in a closet, in the attic) and on the geometry of the room.

Let's consider what features become decisive when choosing.

Air duct material

On sale you can find products for creating ventilation structures made from four types of materials, which in everyday life are commonly called plastic:

- polyvinyl chloride;

- polypropylene;

- polyurethane;

- polyethylene.

Polyvinyl chloride. Lightweight, inexpensive, easy to install, PVC air ducts are the most common material for the construction of household ventilation structures. They are durable, airtight, but have some limitations.

They cannot be heated to 160°C, since chlorine, which is harmful to all living things, begins to be released, and according to standards, the upper heating limit without risk to human health is +120°C.

PVC pipes are suitable for installation in the kitchen or bathroom; their use is prohibited where there is a possibility of heating up to 160-180°C - for example, in saunas or in rooms with a fireplace

When the temperature drops below +5°C, PVC becomes brittle, so for installing a ventilation system in premises with temporary residence it is better to choose another type of pipe, for example, made of polyethylene or vinylurethane.

Polypropylene is an excellent dielectric, non-hygroscopic, and has high resistance to aggressive chemical environments. The tensile strength is approximately 4 times higher than that of products made from high-density polyethylene.

The main disadvantage is flammability, the maximum possible temperature is +85ºС. However, there is a fire-resistant variety with fire retardant additives - PPS.

Polyurethane in its characteristics resembles PVC, but can withstand higher temperatures - up to +280ºС.

Viniurethane reinforced with a steel spiral is considered especially durable. It is suitable for exhaust hoods as it has excellent resistance to mechanical damage and flexibility, allowing the duct to be rotated at any angle

HDPE – low-density polyethylene. It does not crack over time and, unlike PVC, withstands negative temperatures more easily (relevant for houses with temporary residence). Possible heat resistance – up to +80ºС, cooling – up to -50ºС. Easy to process, like all types of plastic products.

Polypropylene and polyethylene pipes for household ventilation are rarely used; PVC products are in the lead.

Image gallery

Photo from

Exiting the fan riser to the street

Marking the wall for installing clamps

Installing clamps into fixed dowels

Construction of a riser from sewer pipes

Types of pipes by degree of flexibility

There are two categories of plastic ventilation pipes for hoods - rigid and flexible. Sometimes a combined option is necessary, but much less often. If the hood is installed next to the ventilation hole, there is no need for a complex design.

When purchasing rigid pipes of round or rectangular cross-section, you must also purchase a set of additional parts to design turns or transitions.

To assemble a short duct for the hood located above the kitchen cabinet, rectangular PVC ducts and connecting corner elements made of a similar material were used

Along with rigid straight pipes, corrugated pipes are used - flexible products made of polyurethane or aluminum, which make it possible to do without corner parts.

The use of a corrugated aluminum pipe as an air duct, which has two advantages over plastic analogues: fire resistance and higher strength

Corrugated products are more economical, but lose in design. To preserve the beautiful appearance of the interior, it is better to disguise them under hanging structures or place them in a “blind” zone - on cabinets against the wall.

Varieties of elements according to sectional shape

Depending on the pipe configuration, the following types of air ducts are distinguished:

- round;

- rectangular;

- flat.

The cross-sectional shape largely affects the technical characteristics and method of installation. For example, straight round pipes have better throughput and excellent noise insulation, since air moving along smooth walls encounters virtually no obstacles (with the exception of corner sectors).

However, due to the cylindrical shape, installation problems may arise.

An option for installing a round pipe leading from the hood to the ventilation hole on the adjacent wall. Installation elements: 4 pieces of pipe, 3 round 90º elbows, gearbox (+)

Rectangular air ducts fit tightly to any flat surface (walls, ceilings, kitchen cabinet walls), so they are much easier to install. But there is one drawback - the uneven distribution of air, which causes loud noise.

The optimal solution for installing ventilation above a suspended ceiling: lightweight rectangular plastic pipes with a set of adapters and a round outlet pipe (to reduce noise levels)

Flat air ducts are the same rectangular ones, but with a large difference in the dimensions of the width and height of the section (for example, flat ducts 110 mm x 55 mm). Due to their compactness, they are often used for installation when there is a shortage of free space (for example, above suspended structures or above high-hanging cabinets).

How to choose the section size?

The size of the section is more important than its shape, since the efficiency of air exchange in the room depends on this parameter. There are standards that take into account the specifics of various rooms, and when choosing ventilation elements it is better to focus on them.

Rooms with high humidity and high levels of dirt in the air (bathroom or kitchen) should be ventilated more often and more intensively than relatively clean and dry rooms (bedroom, living room) (+)

According to SNiP, the volume of air flow in houses and apartments must be at least 3 m3/hour per 1 m2 of living space, and the number of people living is not taken into account.

The volume of circulating air for people permanently staying in the room is 60 m3/h, for people temporarily staying - 20 m3/h (meaning places of work, for example, offices).

It is not possible to accurately calculate the cross section on your own, but there are simplified calculation methods. However, perfectionists are better off using the services of an engineer or a special program that will require the following data:

- shape of air ducts;

- pipe material;

- internal resistance;

- indoor temperature.

There is a way to determine the size of the ventilation hole based on the area of the room. For every square meter of room there is 5.4 cm² of air duct cross-section, and the pollution coefficient is important.

To accurately select the pipe cross-section, we recommend contacting professionals who perform calculations using complex formulas based on specific data.

What does exhaust ventilation consist of?

To install air ducts, pipes alone are not enough; shaped elements are needed - fittings for various purposes. They serve to hermetically connect parts into a single system, provide smooth transitions of pipes of different diameters, connect the air duct with the hood and ventilation hole, and allow you to create 90º angles.

Shaped plastic parts for assembling a rectangular air duct: connecting and horizontal elbows, plugs, holders, grilles, reducers, straight connectors, plates, tees

One of the important elements is the transition (adapter). It is necessary in two cases: when you need to connect pipes of different cross sections or air ducts that differ in size.

They are used for assembling structures in rooms with complex geometries, and sometimes for parts built into cabinets.

To prevent the reverse draft effect from occurring and the used air not returning to the room, the air ducts are equipped with a check valve.

This is a built-in frame with a dynamic blade that opens only in one direction - along the direction of air movement into the ventilation shaft. The valve does not act as a connecting element, but as a part that increases the efficiency of ventilation.

The small section assembly involves two pieces of rectangular pipe, a wall plate, a duct outlet connector, and an angled horizontal elbow.

To ensure 100% sealing, it is necessary to select fittings strictly according to the size of the pipes: for example, for ducts 150*100 mm, elbows of the specified size are also required.

Advantages of plastic and metal air ducts

Advantages of plastic boxes:

- Little air friction and power loss when air passes through pipes.

- Easy to clean; Less grease and soot settle.

- Fits beautifully into the interior.

- There are many varieties of components available that allow you to assemble a system of any configuration.

Advantage of metal corrugation:

- Fewer adapters and angles required; smooth turns reduce the efficiency of the system less.

- The ability to stretch and contract makes installation easier.

- Small price.

Which option is better

Plastic boxes are better - they have less resistance to air flow, they fit better into the interior and are washable.

But in some cases, when laying hidden, flexible corrugated pipes are necessary.

Performance characteristics of plastic

The production of ventilation ducts is carried out using high-tech equipment. The finished product goes through several stages of testing. The products comply with the requirements of GOST and SNiP. During its production, all necessary environmental safety standards are observed.

Plastic is inert to aggressive chemical environments and is not at risk of destruction due to exposure to sunlight. Its service life can exceed 50 years.

PVC exhaust structures eliminate air leakage. During their assembly, silicone lubricants are used to ensure the tightness of the connection.

The plastic box for ventilation must be placed away from open sources of fire, boilers or hot water pipes. In extreme cold conditions the product becomes fragile. When exposed to high temperatures, it loses its tightness and can melt. Therefore, systems designed to pump hot or cold air are best assembled from heat-resistant material.

Tips for choosing

When choosing a pipe type, they are guided primarily by aesthetic considerations. Before making a choice, it is determined whether the box will be mounted openly or covered with furniture, a box, a false wall, or a suspended ceiling.

Corrugated shiny pipes spoil the kitchen interior; more often, when laying air ducts openly, smooth plastic pipes are chosen - they are easy to clean and can be painted in the desired colors - white or colored to match the ceiling or walls. Rectangular and square boxes fit better into the interior; round plastic boxes have minimal resistance to air flow.

When laying hidden, corrugated pipes are chosen - they are easier to install, no adapters or corners are needed, they are easier to bend when avoiding obstacles and for turning. Masking metal pipes will require additional costs. If problems arise, it will be difficult to get to the hidden pipe.

Diameter and shape

The diameter of the round pipe should be equal to the diameter of the outlet pipe of the kitchen hood.

Round boxes provide minimal resistance to air movement.

The ideal shape for an air duct is straight. Sharp corners when installing air ducts are unacceptable.

Dimensions and cross-section

The cross-section of a square or rectangular pipe must be equal in area to the cross-section of the round hood pipe. Narrowing the cross-section will lead to deterioration in system performance, fan overload, increased noise, vibration and loosening of fasteners. It is better to take a pipe with a slightly larger cross-sectional area. A large excess of the cross-section will lead to increased costs and difficulties with masking the pipe.

A slight narrowing of the cross-section is permissible only if the fan power is taken “with a reserve” and the hood is rarely turned on at maximum power.

Optimal duct length. If the duct length is longer, the fan power must be increased.

Diameters of corrugated pipes used in domestic ventilation: 100 mm, 125 mm, 150 mm.

Dimensions of plastic boxes: 80×80 mm, 100×100 mm, 125×125 mm, 55×110 mm, 50×120 mm, 60×204 mm, 90×220 mm.

Diameters of plastic pipes: 100 mm, 125 mm, 150 mm, 200 mm.

Calculation of the minimum required size

Calculation of the cross-section of the hood duct is not necessary. The cross-section should be equal to the cross-section of the hood outlet pipe. If the hood was purchased with a power reserve and it is not planned to turn it on at maximum power, then the cross-section can be narrowed.

The minimum cross section is calculated using the formula:

Smin=Srab *(QrabQmax), where

- Smin is the minimum possible cross section.

- Srab is the nameplate section of the exhaust pipe.

- Qwork is the required volume of air removed.

- Qmax - maximum volume of air removed (according to the hood's passport).

- Qwork is calculated using the formula:

- Qwork = kitchen volume x 12 times x 1.3 per m³.

In accordance with sanitary standards, 12 is the air exchange coefficient (the air in the kitchen should be changed 12 times per hour), 1.3 is the power loss coefficient in the air duct and ventilation shaft.

Plastic pipes for kitchen hoods

Material. PVC.

Diameter. The cross-section of the pipe can be round or rectangular. The latter is also called flat. The most popular diameters: 100, 125, 150, 200 mm. As for rectangular ones, the following sizes are in greatest demand: 55-60 mm by 110-204 mm.

Resistance. The plastic is smooth, so an air duct made of this material has low resistance to air flow. If you compare a round one with a rectangular one, then the air will move a little faster along the first one.

Exploitation . The operating temperature of the plastic is up to +70. It is not subject to corrosion and does not require cleaning: grease and dirt do not stick to the smooth surface.

Noise level . The plastic air duct is smooth inside, there is nothing for the flow to cling to, so ventilation occurs silently.

Assembly . Installation is simple, but connecting with adapters takes time. A plastic air duct cannot “replicate” an overly complex configuration of kitchen furniture and walls: sharp and frequent bends impair ventilation.

Price . It’s not high, but the cost is increased by adapters, which you can’t do without.

Appearance . PVC pipe in the kitchen looks aesthetically pleasing. This is especially true for those that have a rectangular cross-section. In addition, the plastic can be painted in a suitable color.

Connection rules for all types of pipes

Recommendations:

- The duct must be carefully sealed at all joints.

- The system must contain a minimum number of adapters, turns, and narrowings - they lead to a decrease in efficiency.

- The boxes must be securely attached to the walls and ceilings using special clamps. If the boxes are moving, the system will vibrate, the noise level will increase and the seal will be broken.

Rules for laying the air duct from the hood to the ventilation shaft opening

For proper installation of the air duct, it is necessary, if possible, to select the shortest path from the hood to the hole in the ventilation shaft. If the air duct is too long, you need to consider another possible way to remove polluted air - for example, to the street.

The shape of the air ducts should have a minimum of turns. . If possible, it is necessary to smoothly rotate the pipe using two 135° bends or different-angle bends (see 6 in the figure). You cannot turn the box at an acute angle - this will completely stop the movement of air in the pipeline.

If the length of the air duct is too long, it is necessary, with the help of specialists, to recalculate the power losses in the air duct and the required fan power.

Features and nuances of do-it-yourself installation

Installing ventilation pipes from a hood is a simple task, quite feasible for a home craftsman even with little experience. If you carefully follow our advice, the installation of ventilation ducts will go without problems.

Required tools and materials

To complete the work you will need:

- Drill.

- Screwdriver.

- Hacksaw or grinder.

- Sealant.

- Boxes, bends, adapters of the required section.

- Check valve.

- Ventilation grille for connecting ducts to the ventilation shaft.

Indoor air duct installation

To install the boxes, it is necessary to carefully mark and measure the entire route of the system. The grate on the hole in the shaft is dismantled, and if necessary, the shaft is cleaned of dust, soot and cobwebs.

After installing the exhaust equipment, connect the box to the exhaust pipe. All joints are coated with sealant. Heat-resistant sealant is not needed - the temperature of the exhaust air is not too high.

Then the system is assembled by inserting individual elements into one another. The pipes are shortened to the required length by cutting with a hacksaw or grinder. The box is fixed to the wall using special holders or clamps. The distance between fastenings is no more than 500 mm.

The grate is attached to the shaft wall with dowels. It is more practical to use a grille with a hole for the box and a hole for natural ventilation. A check valve must be installed in the system - if the hood is not working, it will prevent air from flowing back into the room from the ventilation shaft.

To install the system, only industrially produced pipes, adapters and connectors are used - there is no need to reinvent the wheel, the industry produces fittings for any geometry of ventilation ducts and transitions from round to rectangular pipes.

After installation of the system, it is tested:

- If a leak is detected, coat the gap with sealant.

- If rattling occurs when the system comes into contact with any structures, in this case it is necessary to lay a gasket made of polystyrene foam or polyethylene foam.

Thermal insulation of pipes in the attic

Water must not enter the air ducts. If water gets in, the fan will quickly fail. In order to prevent moisture from settling on the walls of ventilation pipes and ducts, it is necessary to provide insulation. For this purpose, slabs of polyurethane foam or mineral wool are used. The insulation is covered with roofing felt or fiberglass on top and secured with wire.

How to hide equipment

The hood can be covered with a decorative screen or an imitation of a kitchen hanging cabinet.

How to hide pipes from the kitchen hood

There are several options for hiding pipes:

- Covering suspended ceiling structures.

- Route through kitchen cabinets.

- Laying over cabinets and covering with a decorative screen.

- Painting or decor to match the color of the walls and ceiling.

- Closing with decorative boxes.

- Covering with a screen that imitates a wall, for example, made of plasterboard.

When installing boxes behind a false wall or suspended ceiling, you should take into account the fact that disassembling and cleaning or repairing the system will not be easy - you will have to disassemble the wall or dismantle the ceiling structures.

Installation of a hood without a duct

Circulation-type hoods are more compact than flow-type hoods, and their installation is simpler. A hood without pipes is simply attached to the wall or suspended from the ceiling (if the stove is placed in the middle of the kitchen on the island).

Video

All the details of installing a hood box can be seen in our video:

Metal pipe

Material .

When talking about a metal air duct, most often they mean aluminum corrugation. This flexible pipe can also be made of plastic, but due to its low cost, it is aluminum that is most widespread. It is made of multilayer foil folded like an accordion. Inside it has a frame - rings made of steel wire. Diameter _ The cross section of the corrugation is only round. The following diameters are in greatest demand: 100, 120, 125, 150 mm.

Resistance . Although the corrugation is stretched during installation, the grooves still retain air a little. It moves faster on a smooth surface.

Exploitation . Operating temperature - +300 and above. The corrugation is resistant to corrosion, but requires periodic cleaning. Fat and soot stick to the ribbed inner surface.

Noise level . The air “clings” to the rings inside the pipe. This causes it to vibrate, creating noise. Therefore, a metal air duct is louder than a plastic one.

Assembly . Installation is very fast: it is simply stretched over long distances. The flexible sleeve can be extended by 4.5 times. The duct can be easily rotated in any direction, which means no L-shaped adapters are needed. The corrugation “adjusts” to any furniture configuration and protrusions on the walls.

Price . Cheaper than plastic, plus savings on adapters.

Appearance. Flexible metal ductwork is not as attractive as plastic ductwork.

Duct outlet options

There are several options for using and connecting the air duct in the kitchen:

- Connect one or two air intake points to one air duct.

- Take the box outside or into a ventilation shaft.

In any case, general ventilation must operate in the room.

With one entrance

When connecting one air intake point to the ventilation system, the possibility of natural ventilation must be provided. If there are two ventilation shafts in the kitchen, the hood is connected to one of them, and a hole (with a grill) is left in the second shaft for natural ventilation.

If there is only one shaft, then a tee is installed near the entrance of the hood pipe to the ventilation shaft with the ability to switch between the hood and the hole for natural ventilation. There are grilles with holes for natural ventilation and a check valve that does not let air from the shaft back into the room.

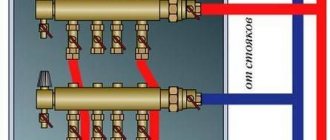

With two inputs

If it becomes necessary to connect two air intake points to one system, then check valves must be installed between the tee and the fans, otherwise the fans will interfere with each other’s operation. It is also advisable not to turn on the fans at the same time. A third check valve is installed near the grille.

Outside

If you decide to take the box outside, you need to cover the outlet hole with a grill to prevent birds or animals from getting into the pipe. It is also necessary to install a check valve to prevent cold air from entering the room.

Installation of round corrugation

To assemble flexible ventilation, adapters are not needed, because the corrugation bends and turns at any angle. The corrugation is put on the exhaust pipe and tightened with a clamp. Then they stretch it as much as possible so that it does not sag over time. The other end is inserted into the flange of the ventilation grille and secured with a clamp. The ends of the corrugations are not sealed for two reasons. Firstly, because the flexible pipe needs to be cleaned inside from time to time. Secondly, because during operation it vibrates, which can cause cracks to appear. Along the entire length of the corrugation, every 1-1.5 m, it is secured with clamps so that it does not swing.

The best manufacturers and models

Most popular models:

- Vents channels made of white PVC with a diameter from 100 to 200 mm. Length - 350–2500 mm. The cost of a linear meter of construction is 150–200 rubles.

- , rectangular Equation model The channel is ergonomic, the average price for 1 m is 300 rubles.

- The Equation round duct with the popular channel size of 100x1500 mm is suitable for domestic ventilation systems. Costs about 200 rubles.

- supplies flexible aluminum models. The material is fire-resistant and not afraid of mechanical stress. A channel 3000 mm long with a diameter of 150 mm costs 250 rubles.

- Elikor corrugated pipeline is suitable for residential and industrial premises. The price of a channel with a diameter of 120 mm and a length of 3000 mm is 700 rubles.

These models meet all safety requirements and are suitable for installing ventilation ducts in domestic exhaust systems.

Ventilation elements

The complete structure consists of the following components:

- air channel (round or rectangular);

- connectors;

- adapters;

- knee (90 degree rotation);

- splitters;

- wall linings (inserted into the wall and connected to the channel);

- holders (for ceiling mounting);

- protective grilles.

Plastic ventilation elements are assembled sequentially from small blocks into a single system. The fastening points are insulated with a special compound and sometimes sealed. This is necessary so as not to disturb the air channel; any unplanned hole impairs the flow rate.

Features of the arrangement

Regardless of the type of ventilation, it consists of two components:

- Supply channel;

- Exhaust pipe.

The purpose of the pipes is to ensure air circulation, which is carried out due to the difference in pressure outside and inside the building, or by a fan.

Installation is carried out after drawing up a wiring plan for all rooms of the building. When making calculations, it is important to take into account many factors: flow speed, system performance, air movement, etc.

After precise planning and calculations, the installation of plastic air ducts begins. This process is quite simple, but has a number of features:

- Vertical (exhaust) pipes should not have horizontal branches. If they are created, they should be included in the calculation of the overall system performance.

- Plastic parts must be tightly adjacent to each other. All cracks are coated with sealant.

- In difficult places, the use of corrugations is allowed. But it is often not recommended to use them, since they have low aerodynamic properties. Corrugations are used without reserve so that the cross-section does not change during use (affects the overall resistance).

- Plastic parts are installed after preliminary cleaning of the installation site from dust. All connections are treated with an antistatic agent to prevent small particles from clogging the free space.

- When purchasing material, you need to count on a certain supply - both the pipes themselves and the fasteners. It is very likely that during construction some areas will need to be further strengthened.

How to lay a plastic ventilation duct with your own hands

The process of installing air exhaust pipes from the hood to the ventilation duct is not a difficult task, so you can do it yourself, without any experience. To do this, just follow the tips below.

First you need to prepare tools and materials, which should include:

- box;

- corners, adapters of a certain section;

- bends;

- return valve;

- grid for connecting ducts to the ventilation shaft;

- drill;

- hacksaw;

- Bulgarian;

- screwdriver;

- sealant.

Detailed diagram of the assembly of a plastic air duct for exhaust hood.

In order to install an air duct for a kitchen hood indoors, you should carefully measure the entire air route. The grate located at the entrance to the shaft must be dismantled. The channel itself must be cleaned of dust, fumes and cobwebs. After installing the hood, it is necessary to connect the box with the exhaust pipe. In this case, all joints should be coated with sealant. In this case, a heat-resistant agent is not needed, since the temperature of the air that is removed is low.

Next, the system is installed sequentially. To do this, one element is inserted into the other one by one, and the pipes are shortened to the required size, cutting off the remains with a grinder or a hacksaw. Then the box is fixed to the wall using special fasteners or clamps. The distance between them should not exceed 500 mm.

The grating is installed on the shaft wall using dowels. A grille with a hole for a pipe and for natural ventilation is considered more practical. The system should also be equipped with a check valve, which will prevent air from the ventilation shaft from flowing back into the room if the hood fails.