The dacha period ends almost with the onset of winter. To avoid a malfunction of the pumping station in the spring, and to have an uninterrupted water supply, you need prepare the pumping station for winter

Right. To do this, you need to follow the recommendations of our instructions on this issue.

Preparing the pumping station for winter

includes the complete draining of water from the station itself and the water supply of the country house. To do this you need to perform the following manipulations:

- The first step is to disconnect the pumping station from the network.

- To completely relieve pressure, open the drain valve or tap. Before this, the suction hose must be removed, taking into account that the water remaining in the system will flow out.

- Then you need to remove the pressure hose.

- It is recommended to measure the air pressure in the accumulator, but if you don’t have the necessary device for this, don’t panic. Any pump will be suitable for this purpose, without stopping pumping until water stops flowing out of the suction hose. This procedure must be done, because the hydraulic accumulator of the pumping station may fail, and this will undoubtedly lead to additional costs for the next year.

Successful result of preparing the pumping station for winter

, there will be a complete absence of water in the pump and system pipes. And only after this can you easily assemble the pumping station and hide it in a safe place until spring. If you follow the advice in this manual in detail, you can rest assured that the pumping station is not afraid of either cold or frost.

This need arises when pumping equipment remains connected to the water supply system of the dacha. In winter, the remaining water in the cavities will freeze, and the ice will expand and break the device. But before you drain the water from the pumping station, you need to study what professionals advise about this. The preservation procedure is simple, but has a number of features.

Preparing the cottage for winter: draining the water

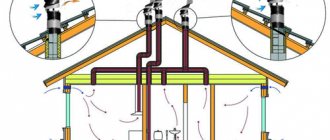

All properly designed water supply systems in country houses for seasonal residence, regardless of the material of the pipes, shut-off valves, operating pressure and location of the pump, are basically the same:

- The pipes have a slight slope towards the well or well.

- The pipe through which water enters the house has a check valve (in the well or in the house, next to the accumulator). In operating mode, it prevents water from draining.

To drain all the water from the water supply, the owner of the dacha must stop the operation of this valve, then the water will return back to the well, or, if a well is used, it will drain into a special drain. Therefore, a drain valve is installed on the pipe between the check valve and the hydraulic accumulator (a valve with a long handle is placed in the well so that it can be opened and closed from the surface of the ground).

When the check valve is installed on a pipe in the house, next to the accumulator, the drain valve is installed on a parallel pipe.

Sometimes the system is not installed quite correctly, and there is no parallel pipe with a drain valve. There is no other way out - all that remains is to disassemble the water supply unit and drain it manually.

After draining the water, you need to disassemble all the filters that are installed in the system in front of and behind the hydraulic accumulator, remove the cartridges and send them for storage.

Option two: inside tap with extended switch

This scheme is more complex to implement, but no less effective. The point is that only one faucet is installed, and it will be located indoors.

PHOTO: bestlj.ruAnd in order to use it, the control knob must be brought out through the wall

If the walls are very thick, this is problematic.

PHOTO: bestlj.ru If not, then you can solve the problem not only by installing an extended switch, but also by installing an electromagnetic switch that will control the tap using a button from the outside

How to drain water from a pump for the winter

The next important part of the system is the pumping station. If it is installed in the house, be sure to empty the water from it. If it’s in a well or borehole, then, theoretically, you don’t have to do anything at all - the freezing depth in the Moscow region is 1.5 meters, and pumps are installed deeper.

The main thing is that the hose can withstand temperature changes. If it holds up, then there is no problem.

But in practice, when using a well or well seasonally, FORUMHOUSE participants, at the end of the summer season, pull out the pumps and take them to the city so that the equipment can winter in a warm room.

At the end of the season I sort everything out. The pump and automation are stored at home at positive temperatures.

Construction of the caisson

If you want and have the opportunity to install a water supply system according to all canons, then you need to build a caisson. It will allow you to deepen the well to the freezing point.

Manufactured in different forms. Round ones are suitable for constructing wells. Caissons are made from concrete, metal or polypropylene. A unit made of polypropylene is the easiest to install; you can install it yourself, with your own hands. In terms of price, plastic caissons are cheaper than metal ones, but the most durable ones can cost tens of thousands of rubles. The cheapest ones are made of concrete rings. Installation includes preparing a pit, installing a container, installing the appropriate equipment in it, and setting it up. A hatch is installed on top. The caisson also serves to protect the well from the penetration of groundwater and rainwater.

Preserving a well for the winter will make it possible for it to remain clean during the winter and ready for use by the beginning of the spring season.

Video

Sometimes land owners try to find out whether it is possible to leave the pump in the well for the winter. There is no exact plan of action, because... it all depends on the type of pumping equipment, its installation method and the nuances of operation.

If the well pump is planned to be used in winter, the well should be insulated.

How to drain water from a water heater

Having dealt with the pump, we move on to water heaters: storage heaters are usually installed in summer cottages, and on the eve of winter, the water from them must be completely drained. The heater is not intended for operation at subzero temperatures, and if even a little water remains in the device, it will not survive the winter.

Unfortunately, dacha owners often make mistakes when draining water in heaters and leave some water inside the device.

This is what happened to a user of our portal with the nickname megakino: he has a storage heater under the sink in his dacha. The instrument panel did not survive the first winter - it was squeezed out, and after the second, frozen water tore the entire hull.

Our user does not understand what happened: it seems that he drained the water according to all the rules and left the taps open for the winter.

Here's how FORUMHOUSE participants explained this mystery: the water from the heater was not completely drained; it was prevented by the check valve installed on the water supply. To accurately drain ALL the water from the water heater, you need to blow it out. The main thing here is not to confuse the cold and hot water inputs:

- open the cold water drain and supply hot air into the hot water pipe. The cold water inlet is located low, and when blowing into it, all the water can be displaced without any residue.

If you do the opposite, you will get nothing but bubbles in the heater volume.

You can do it easier and install a water heater drain tap.

This is how the heater drain is equipped for our participant with the nickname Liftanuty.

How to drain water from a washing machine and dishwasher

If a washing machine and dishwasher are left to spend the winter at the dacha, then they will also need to be dehydrated. There can be difficulties with dishwashers, as our users say, “they have real labyrinths for water inside.” Therefore, if the manufacturer’s instructions do not directly indicate that the device can be wintered in an unheated room, and the preparation steps for such wintering are not outlined, it is better not to take risks.

With washing machines everything is simpler. To drain the water from the washing machine, you need to:

- Disconnect the machine from the water supply and sewerage. Place the ends of both hoses into a low basin. Turn on the "drain" mode. Wait for the work to finish.

- Disconnect the machine from electricity. Place a flat container like a cat litter box and unscrew the drain pump cover.

But some models of washing machines have containers inside in which water may remain, and if not, access to them is possible only through partial disassembly.

How to bleed the water supply system at your dacha

To be completely sure that there is no water left anywhere, the dacha water supply system will have to be purged. Even a small amount of water in winter, turning into ice, can burst a pipe.

For the winter, I always blow all the pipes with air step by step, along different lines, because when simply draining, “bags” of water still remain.

Blowing is done with a valve to which a car compressor is connected. It is screwed to the ends of pipes or flexible hoses unscrewed from the water heater.

Here's why this is done: almost always, the shut-off valves in country water supply systems are ball valves, and in their design there is a cavity where water can remain. For the same reason, you need to unscrew the shower head, shake the water out of it and put it into storage.

Advice from experienced people

Alisher Yakupov

The tips above really work and are used by many runners. For example, Alisher Yakupov advised wrapping a bottle in foil or wearing a small running backpack under a jacket, and also reminded that there are special thermal packs for drinking systems.

Denis Tkalich

Denis Tkalich, one of the authors of the blog “Run, Lifehacker, Run” and a future ultramarathon runner, advised drinking enough water throughout the day and drinking a glass immediately before running. In the future, he plans to take water with him on winter runs in a thermos.

How to mothball a well

The well is preserved for the winter so that in the spring it is completely ready for use. This means that throughout the winter we will not be able to use it; access to water will be completely blocked. We have already done the main work: we drained the water from the pipeline, heater and plumbing fixtures, and removed the pump.

Now the well is not in danger, the main thing is to close the wellhead correctly: screw on the head, which will protect sheets, etc. from rain, snow, and seal it tightly with film.

In a water supply system arranged according to all the rules, a caisson is made - it deepens the well below the freezing point, protecting it from rain and groundwater. A well with a caisson will survive any frost, the only thing is that this device is not cheap.

A FORUMHOUSE user with the nickname Lesha-Samurai has a fairly standard situation: there is a well 75 meters deep (self-flowing 10-15 m3 per hour), which will not be used in winter, and a categorical reluctance to install an expensive caisson.

According to FORUMHOUSE administrator Andrey 203, a caisson is the only reliable option in a leshy case.

A caisson is needed to move the wellhead below the freezing depth of the soil.

However, a successful method of caisson-free well conservation has yet been found. Using this technology, Lesha-Samurai and his friend have been preparing their well for winter for several years now.

- Take 6-7 soda bottles (there should be some drink left in each bottle), shake each bottle to create pressure in them.

- Remove the head of the well and insert bottles into it.

- Put the head back.

- Pump air into the well using a car compressor through the nipple (pump for about 10 minutes). This will ensure that the water level in the well is reduced to the level of soil freezing.

- Shut off the air outlet from the well with a ball valve.

You can take a plug for 1, use a drill to make a hole of a suitable diameter in it and insert a nipple into it with oil.

Even if air leaves the well through elements of such a structure and the water level rises, the bottles will prevent its expansion.

Extreme situations

If water is not drained from the pipeline in a timely manner, the system may freeze. What to do in this case?

The method to solve the problem depends on the type of pipeline installation. It happens:

If an open type pipeline is used, solving the problem of pipe freezing is quite easy. To do this, you need to heat it up easily. A blowtorch can easily handle this.

If the pipeline is buried in the ground, and also hidden by a layer of insulation, solving the problem of pipe freezing is much more difficult. To do this, you need to connect a hose to the warm water supply system. It should be placed inside the pipeline and moved along the pipe to the place where the ice appeared. Then the warm water tap opens. The water will melt the resulting glaciation.

To avoid problems with freezing of the pipeline, it is necessary to drain the water in the pipes in a timely manner.

Source

How to insulate a well

Modern wells are made from reinforced concrete rings. This is a material with high thermal conductivity, and it will freeze. There is a particularly high risk of freezing in shallow wells, with a water level no higher than 1.1 - 1.2 meters, and in wells located in cold regions.

In regions with a temperate climate, it is enough to simply close the well tightly for the winter, or make a reliable house on top without cracks - the cold penetrates through the cracks, falls down and thus freezes the shaft.

In a tightly closed well, the rings in frost are approximately 0.5-0.7 meters below ground level. The concrete rings themselves will not “conduct” the cold to the bottom.

But insulation of wells is also welcomed in the Moscow region. Frozen water in a well can damage pumping equipment, displacement of rings, and discrepancies in the joints between them.

If you have a blind area, you can insulate it too.

You can buy a ready-made “shell” for insulating wells, or you can insulate the structure with polystyrene foam or extruded polystyrene foam (these options are used by FORUMHOUSE members more often than others.

Why do pipes freeze?

The risk of water freezing in the pipeline exists regardless of the material of manufacture. But in steel structures, active ice formation begins earlier than in plastic ones. This is due to the high thermal conductivity of the metal, which cools much faster in the cold.

This is how pipes burst in the cold

Freezing of water in a pipe is observed at temperatures from -7 ° C. Provoking factors:

- laying the pipeline above the soil freezing level or in the open air;

- non-compliance with the slope, due to which the pipes are constantly in a filled state;

- improperly functioning taps, taps and valves that delay the outflow of water.

A very unpleasant phenomenon is pipe rupture, which is caused by the expansion of water during the transition from the liquid phase to the solid phase. In this case, you have to replace the damaged area, which is not the easiest thing to do in low temperatures.

Recommended insulation for a well made of concrete rings

| Type of insulation | Features of the material | Installation technology |

| Styrofoam | Inexpensive, has good thermal conductivity, does not deform, and does not absorb water. Not resistant to rodents and insects. Sold in the form of ready-made elements corresponding to the sizes of reinforced concrete rings. | The walls of the well are cleaned of debris, façade glue is applied tightly, without gaps. Styrofoam is attached. If the foam does not adhere well, you can secure it with concrete dowel nails. Any barrier insulation material is laid on the foam. The trench is filled with earth and compacted. |

| Extruded polystyrene foam | Resistant to low temperatures, aggressive environments, and withstands loads well. Approximately 20% more expensive than polystyrene foam, produced in the form of slabs. | Installation is no different from installing foam plastic. The joints are sealed with polyurethane foam. The insulation is wrapped with rolled waterproofing material. |

We invite you to see how a member of our portal with the nickname pdp000 insulated his well

The insulation of the blind area is made of EPS, the walls of the ring are insulated with expanded clay. An insulated lid-liner is also made.

You can insulate a well with a little blood. Here are a few methods tested on FORUMHOUSE.

- Our user with the nickname Accurate covers the concrete ring of the ring with plastic film. Since then, the water supply pipe has not frozen even once - it was heated by well water, and the water did not freeze because the film did not allow the cold to pass through.

- Our participant with the nickname Hodok has been insulating a well from the inside for 40 years. Attach two frames made of thick wire in the form of inverted letters P to the last ring at a distance of 25 cm from each other. They descend to ground level. On them, Walker places two semicircles cut out of iron - this creates a flooring on which a plastic film is placed. He covers all the cracks with the same film, puts old clothes inside and leaves the well until spring. But this needs to be done when stable frosts arrive, so that the improvised insulation does not get wet from the fumes from the well.

Do-it-yourself septic tank conservation

In year-round country houses, the septic tank does not freeze, but when the owners leave for the whole winter, work on its insulation cannot be neglected.

To preserve a septic tank for the winter, you need to:

- disconnect it from electricity;

- disconnect pumps and air compressors;

- pump out the liquid from the septic tank by ¾ (or add water, but the septic tank should be a quarter full!).

- pour bacteria into the septic tank (this will get rid of unpleasant odors after re-opening)

- insulate the septic tank lid and pipeline with any insulation.

This is the neck liner for insulating a septic tank made by our participant with the nickname Ice9avalon.

If there are still concerns that the walls of the septic tank may freeze, throw a five-liter bottle half filled with water into each section.

Then the ice, expanding, will compress the plastic of the bottle, and not the plastic of the septic tank.

Having completed all this work, you can leave the dacha with a clear conscience until spring - in spring the autonomous water supply and sewerage systems will work like new.

PREPARING WATER PIPES FOR WINTER

How to properly prepare your water supply for winter?

If the house will not be used in winter, then the water from the water supply system - right up to the well or well caisson - must be drained. Please note that the number of drain valves depends on the system configuration. If there are no “bags”, then one drain tap at the lowest point is sufficient. And if there are loops or bags (say, a pipe reaches the door, and then passes above or below it and returns to its previous level), then taps will have to be installed on each of them, otherwise a stagnant zone may form, from which it will not be possible to remove water , and in winter it will damage the pipe.

Blowing will help here if the height difference is no more than 30 cm, and the pipe itself is thin (1/2-3/4 inches), but for this it is better not to use a car compressor - it is rather weak, but a special construction one, giving about 6-8 atm. The same unit is also useful if the pipe has a long horizontal section or a counter-slope towards the drain. It is worth disconnecting the flexible hoses from the faucets (after all, water may remain in them), and leaving the faucets themselves in the open position.

TOOLS FOR HOME AND GARDEN, HANDCRAFTS, ETC. PRICES VERY LOW

If during the winter period you plan to visit the house only on weekends and holidays, then in order not to drain the water supply system every time, it is better to heat the house too, or rather, maintain the temperature in the rooms around 5-10 °, then the water in the pipes, taps and boilers won't freeze. Many modern heating boilers allow you to set this operating mode. In addition, it is worth installing a leakage protection system in bathrooms. The DHW recirculation system, if present, can be turned off to save money.

Are there modern materials that can withstand ice pressure if water remains in the system?

The ice will definitely break metal-plastic pipes, copper and steel. As for polypropylene and polyethylene, there is no clear answer: it all depends on the diameter of the pipes and the method of their connection. For example, a polypropylene pipe will probably not be damaged; some threaded connection or brass tap will burst first. HDPE pipe may hold up, but the compression fittings will most likely fail. However, if the water supply is frozen and has not burst, it is necessary to carefully inspect it and replace the damaged areas.

What areas of the water supply system are most vulnerable? How to insulate them so they don't freeze? Is it necessary to insulate a well?

If the house and the engineering systems in it are properly designed, such places should not exist. But sometimes water is introduced into the house above ground level or pipes are laid through cold unheated basements, garages, and verandas. These errors must be corrected before they cause damage. The pipes are insulated with foam rubber or polyethylene foam in 2 layers, any heating cable is laid under the insulation, and the outside is protected from water and UV rays. The cheapest way is to wrap it in fiberglass and paint it thickly with oil paint; you can use modern protective shells like ENERGOPACK. But of course, such technology will only protect if electricity flows without interruption. Another trick to prevent water from congealing in pipes is to constantly leave a small stream of water flowing.

The well, if the water is higher than two rings from the ground level, is insulated with 10-centimeter slabs of expanded polystyrene, wrapping them on the outside with fiberglass. A good insulation is snow. Some owners completely fill their wells with snow.

If the caisson is made correctly, the well does not need to be insulated. If it is small, it is prepared for winter in the same way as a well.

The builders laid water pipes at a depth of 0.5 m. Is it possible to insulate them somehow?

The depth of soil freezing is a value that depends on many factors: temperature, snow cover thickness, and the density of the soil itself. In the Central region, the depth of soil freezing is 1.4-1.5 m. But this is only possible if there are frosts in the region of minus 28-30° for a month and there is no snow at all. In practice, over the past ten years, in places where I had to work with soil in winter, it did not freeze deeper than 0.6-0.7 m. If the pipe is laid at this level or higher, thermal insulation slabs (expanded polystyrene 10 cm thick) are laid on top. , covering them with film or fiberglass. You can also add additional snow on top.

The check valve is installed in the underground and cannot be reached. How to prepare such a water supply system for winter?

The simplest answer is that there is no need to install a check valve where it cannot be replaced or repaired. Usually they are installed immediately after the pumps, that is, where

they are really needed. If you have a situation where the valve is located in the underground, you will now have to find a way to get there and dismantle the area that is potentially dangerous to the system. Otherwise it will cost more.

Do I need to drain the water from the boiler? There is an opinion that this cannot be done, the tightness of the connections will be broken...

What is a boiler? This is essentially a barrel in which a heating element is installed. Leave a barrel of water outside for the winter and see what happens in the spring.

How to prepare the summer water supply that we use for irrigation for wintering.

The scheme is, in general, the same. Water is drained from it if the pipes are buried in the ground. In the case when they are laid on or above the ground, they should be dismantled for the winter period, then the safety of the water supply can be guaranteed. That is why, when arranging something similar on the site, it is worth immediately providing for detachable connections.

Preparing heating at the dacha for winter

Another system that requires careful attention is the heating system.

Before the start of the heating season, it is necessary to check the pressure in the heating system, the functionality of the pumps, clean the filters, bleed air from radiators, pipes and pumps, and check the draft in the chimney. It is also necessary to perform boiler maintenance.

All weak points must be repaired in advance: the antifreeze liquid is very fluid, and even a small gap in the connection can lead to unpleasant consequences.

There is one more feature when working with coolant - you need to monitor its service life (it is indicated on the canister) - 3-5 years, as a rule. After this, the liquid must be replaced, otherwise you may encounter many troubles, such as sediment on the walls of the boiler and boiler heat exchangers, on the pump impeller, and clogging of filters. Preliminary cleaning of the pipes is not necessary here. How to dispose of used antifreeze? It is best to hand it over to specialized companies that deal with this. But on the site, in a ravine or into a sewer, it cannot be drained.

If the system has been filled with water, it is enough to simply drain it and add antifreeze liquid. The main thing is that the pipes do not stand dry for a long time: they rust and clog faster.

As for the boiler, servicing should be done twice a year, at the beginning and at the end of the heating season, and for diesel and solid fuel boilers even more often (determined by the degree of contamination of the boiler heat exchanger) and the color of the smoke. The smoke from a well-regulated boiler looks like steam, but black puffs warn of problems. It is better to entrust this work to professionals. If you consider yourself one, then you need to find the service instructions for your boiler and carry out all the work specified in it. Just keep in mind that the boiler operating instructions intended for the user, which comes in the box along with the boiler, and the repair and maintenance instructions, intended specifically for service specialists, are two different documents. None of the manufacturers of modern boilers will pass on such instructions to the end user of their products - only to authorized service centers.

Composition and order of preventive work

To maintain the functionality of water heating, there is a whole range of measures. Certain types of work are carried out at different intervals.

Performed annually:

- Preventive inspection of gas boilers.

- Checking the functionality of the automation.

- Boiler room alarm test.

- Chimney inspection/cleaning.

- Heating pipeline inspection.

Once every 3-5 years the following may also be carried out:

- High pressure system testing.

- Chemical flushing of the system.

- Replacing the coolant.

- Calibration of automation devices.

It is clear that the frequency of some work is a purely individual concept. For example, when using well and borehole water for heating, it is recommended to carry out annual flushing without chemicals, and if you have a plunger pump, test the system annually with high pressure. More specific recommendations are provided by equipment manufacturers and the organization that installed the system.

PREPARING THE SEPTIC FOR WINTER AND WINTERING

So, how to prepare a septic tank for winter? Whether you have a simple storage tank where wastewater is accumulated, or an overflow septic tank is installed - a system of two or more tanks with soil post-treatment, where wastewater is settled and partially purified, or a sealed container of a deep bio-treatment station - these rules for pre-winter preparation of the system are the same for all types of treatment facilities.

The main thing is not to pump out the septic tank completely; it should be filled to 2/3 of its volume. Firstly, this will protect the structure from floating in the spring, when the groundwater level is high. Secondly, it will reduce the pressure on the walls of the septic tank and prevent its depressurization. Thirdly, bacteria living in the drains will “heat” the septic tank.

In the fall, the local autonomous sewer system must be inspected and cleaned. The stations are made so that they can be serviced independently.

Having opened the lid, inspect the operation of the station, the compressor (if it makes noise, it means it’s working),

drainage pump (must pump out water), airlifts (pump liquid between chambers), aerators (air bubbles rise from them).

Take some water from the aeration tank (the second chamber after the receiving chamber) into a transparent container and let it settle. If the sediment is more than 30%, you need to pump out 1/3 of the sludge from the aeration tank using a drainage pump.

Then open the mamut pump. Most deep biological treatment stations have it. This is a standard pump with a plug, in simple words - a hose that is under pressure.

Remove the plug and use a drainage pump to pump out the processed sludge into a container, bucket or onto the ground (the sludge can be used as fertilizer for flower beds and rose gardens).

And the last thing to do is to remove and wash the main pump, coarse sewage filter, hair trap, damper (removable parts). For this purpose, you can use a high-pressure washer or a regular hose from a water supply or pump. You also need to wash the walls of the station and the air filter by unscrewing the compressor cover. Remove all inorganic waste (plastic bags, rags, toys, kitchen utensils) from the receiving chamber.

If the biorefinery station will be operated in winter, it is best to insulate the cover from the outside. Isolon, penolin, polystyrene or any other insulation, including the simplest polystyrene, are suitable for this purpose (but to protect it from water, you need to wrap it in plastic film and press it with bricks). Only the air intake is left open. This will be enough for the station to function normally in winter.

If you plan to leave your country house until spring and, accordingly, turn off the station, you will have to “mothball” it. For this purpose, 20% of the liquid is pumped out from each chamber. Taking four empty plastic bottles, fill them 1/3 with sand, close them, tie ropes to the necks, tie them together so that it is convenient to remove them in the spring, and place such a “float” in each chamber. This technique should be used in any type of septic tank. The bottles will take the blow when the water, frozen, presses on the walls, and thereby keep the septic tank intact.

For the winter, remove the drainage pump and compressor from the station and place it in a dry, warm room, and cover the station itself with film. In the spring, it will be enough to open the station, connect the electrical equipment, remove the “floats”, add clean water to the operating level and turn on the station - and the septic tank will be ready for the new season.

APPROXIMATE DIAGRAM OF AERATION STATIONS (BASED ON THE EXAMPLE OF TOPAS STATION) A – receiving chamber; B – aeration tank; B – sludge stabilizer; G – secondary settling tank; D – purified water chamber (not available in all models); E – control unit; 1 – wastewater input; 2 – coarse fraction filter; 3 – receiving chamber aerator; 4 – main airlift; 5 – aerator of the aeration tank; 6 – airlift recirculation; 7 – secondary settling tank (pyramid); 8 – airlift circulation; 9 – airlift of stabilized sludge; 10 – compressors; 11- device for collecting non-recyclable particles; 12 – cover of the aeration station; 13 – air intake; 14 – purified water output; 15 – mamut pump hose for pumping out sludge

Authors: E. Gushchin (TeploVodoKom) and O. Stanislavov – septic tank maintenance specialist

This need arises when pumping equipment remains connected to the water supply system of the dacha. In winter, the remaining water in the cavities will freeze, and the ice will expand and break the device. But before you drain the water from the pumping station, you need to study what professionals advise about this. The preservation procedure is simple, but has a number of features.

Treat basement and cellar for mold

The end of the summer season is the right time to treat the cellar and basement so that a “mold kingdom” does not develop in them over the winter. First of all, in dry weather, take all the jars outside and dry the room, and then treat the walls and other structures with an antiseptic (this procedure must be repeated every few years).

As an antiseptic, you can use a solution of copper sulfate (100 g per 1 liter of water).

Those who like to solve problems in a radical way recommend using a sulfur smoke bomb to treat the basement. Seal all ventilation holes in the empty room, cover metal parts (if any) with polyethylene. Check that there is no one in the house (you will have to leave it for a day), and then light the fuse of the checker, go out and close the doors tightly. Upon return, thoroughly ventilate all areas.

Draining water and preserving the pumping station

The sequence of actions is as follows:

- The pumping equipment is disconnected from the electrical network.

- The hose through which the liquid is sucked in is disconnected.

- All valves and outlet taps open, the water should drain completely.

- A pumping station is different from a pipeline; the remaining liquid drains from the pipes.

- The pressure in the hydraulic tank is checked (the norm is 1.5 bar, as indicated in the data sheet).

When the pressure is insufficient, it is necessary to pump out the remaining water from the pumping station using another pump. If there is any liquid left anywhere, you will have to throw away the equipment in the spring and buy a new one.

In addition, it is necessary to walk along the contour of the system, checking that there is no water in any of the nodes. The boiler is emptying. The storage tank, circulation pump, and filters must be empty. During this period, it is convenient to check the cartridges, wash the screens, and carry out preventive maintenance. In the spring, when you have to start the system, it will be enough to connect the pump, fill the pipes and press the start button.

Most plumbing equipment has special shut-off valves designed to drain water from the working chambers. But if the valve is not provided, you will have to disconnect the equipment not only from the electrical network, but also from the pipes connecting the device to other devices.

Recommendations

It makes sense to leave the devices open for a while and let the moisture dry out. This can be done indoors where there is no wind and dust does not fly. This requirement is especially significant for equipment that is sensitive to solid particles. Breakage will not happen, but the abrasive will damage the mechanical components.

It is necessary to drain any water from flexible hoses that may remain in the kinks. To do this, the hose must be lifted sequentially until liquid stops flowing from the end hole. There is nothing complicated. The main thing is to show a little attention, and the spring mood will not be overshadowed by anything.