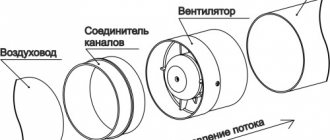

In order to maintain an optimal microclimate in a residential or public space, it is important to install the correct ventilation system. One of the main elements is the air duct, which is a ventilation duct that provides a continuous supply of air in one direction.

The editors of the YaNashla website have prepared for you a rating of the best air ducts for ventilation for 2021.

Varieties

Air can move through various means, for example:

- Natural ventilation requires mounting holes or slits to allow fresh air flow into the room. It is also possible to use windows; to do this, you just need to open the window. In this case, the spent elements leave through ventilation shafts.

- When the temperature outside is high, the previous method is not effective. Then forced ventilation is used. The influx of air masses is carried out by a fan, which is installed in a convenient place.

- There is also a more advanced system: supply and exhaust. In this case, two air ducts are installed, one is responsible for the supply of air, and the other is necessary for its removal.

In each building or room they try to create an individual ventilation system. Therefore, various air ducts are used, which differ from each other according to certain technical parameters.

Installation method

There are two varieties:

- Internal ducts, also called ventilation shafts;

- External. They are installed on buildings.

Installation of an air duct for a kitchen hood: main rules

To maximize the efficiency of the hood, important rules must be followed when choosing materials and directly when installing the air duct for a kitchen hood:

- Select sections and adapters so that they fit tightly into each other. In the case of aluminum corrugation, high-quality tightening of the clamps is required.

- Avoid using sections of different sections. When attaching a rectangular duct to a round hood outlet, you can install a special adapter, but then it is advisable to assemble the air duct from sections of the same shape and the same cross-section.

- Avoid corners. The fewer angles, the less throughput is reduced. Sharp corners are not allowed!

- Provide for the possibility of disassembly, because the internal surface of the air duct requires periodic cleaning of grease and dust.

- Attach the air duct to the ventilation shaft only using a two-section cover with a grille, otherwise the natural ventilation of the kitchen will be lost.

- Use an anti-return valve. This valve eliminates reverse draft, but does not interfere with the ventilation of the room when the hood is turned off. They place it directly on the air duct or buy a cover for the ventilation shaft with such a valve.

- Use sealing compounds. This is especially true for the installation of a plastic air duct for a kitchen hood.

- Avoid using aluminum corrugation if the distance from the hood to the insertion point into the ventilation shaft is more than a meter. An air duct made of plastic corrugation can reach three meters, but in this case the performance of the channel will drop by 15-30% (5-10% for each meter).

What material are they made from?

Today there are at least 4 popular materials available that determine the scope of application. In addition, each differs in price and service life. So, most manufacturers produce models from the following materials:

- Cink Steel. This option has good corrosion protection and is not susceptible to some chemicals. It is highly resistant to humidity. Therefore, it is suitable for installation in bathrooms, baths, swimming pools, etc.

- Stainless steel. The product can withstand temperatures up to 500 degrees. Therefore, the main area of use is manufacturing enterprises; for example, stainless steel air ducts are actively used in metallurgy.

- Polymer products are lightweight and low cost. They are practical to use, as they can withstand humid climates and alkaline environments without problems. However, they should be used carefully, as they are not able to function at high temperatures, which is why they begin to melt. Mechanical damage can also disable the model.

- Metal-plastic. This option is a combination of metal and polymer devices. Their beautiful appearance allows them to be installed in any modern interior. Technical characteristics are no worse than galvanized steel. However, there is also a drawback - high cost.

Types of air ducts for kitchen hoods

It can be divided according to three main parameters:

- by cross-sectional shape;

- according to the material used to create the outlet channel;

- by configuration.

Below we will look at each of these parameters separately.

Choosing the shape of the duct

According to the cross-sectional shape there are:

- Rectangular. They are compact and, when positioned correctly, almost invisible. To install a rectangular air duct for a kitchen hood, it is enough to purchase the necessary set of sections and adapters at a hardware store. In this case, you can lay the air duct along the wall or along cabinets, completely corresponding to the given trajectory. The main disadvantage of rectangular pipes is reduced productivity.

- Round. Round air ducts are characterized by the highest performance, but they are not compact and therefore immediately catch the eye. Most often they are hidden behind decorative structures. In addition, these round-shaped parts, due to their bulkiness, cannot always be installed in rooms with low ceilings: they simply do not fit into the space between the ceiling and wall cabinets.

- Oval. They are a cross between rectangular and round structures. They have fairly high performance, but are less cumbersome.

Let’s take a closer look at flat rectangular air ducts, since this option is the most popular among consumers today. And builders are increasingly giving preference to rectangular systems, since they fit perfectly into any kitchen design.

When installing an air duct for a kitchen hood, designs with standard parameters are used:

- 11x5.5 cm;

- 12x6 cm;

- 20.6x6 cm.

The performance of flat air ducts is directly related to their cross-sectional area, so the choice of material must be made taking into account the exhaust power. So, for low-power units (with a capacity of up to 300 m3/h), a cross-section of 11x5.5 cm is sufficient, and for hoods with a capacity of 300-350 m3/h, it is more advisable to use sections with a cross-section of 12x6 cm. More powerful exhaust devices need to be equipped with an exhaust system with a cross-section of 20.6x6 cm.

Choosing material for making the air duct

When installing an air duct for a kitchen hood, the following materials are most often used:

- Plastic (polyethylene, polyvinyl chloride, fiberglass). This is perhaps the most convenient material to use. It is lightweight, durable and inexpensive. Plastic creates a minimum of noise and does not rust, which is very important for the channel through which hot air will flow. The dimensions of the finished sections and adapters are standardized, so no adjustment is required. Usually there are no problems with selecting elements, although sometimes the store does not have “that same” tee or elbow. The main disadvantage of polymers is toxicity: under normal conditions the material is safe, but when too hot air is removed, the plastic begins to release dangerous compounds.

- Aluminum. The second most popular material when installing an air duct for a kitchen hood. Aluminum corrugation is cheap, resistant to heat and easy to install (just cut a piece of the required length, stretch the pipe and secure it with clamps to the fittings of the hood and ventilation window). The disadvantages of aluminum include external unattractiveness, high thermal conductivity (causing condensation accumulation) and poor resistance to deformation under mechanical stress. In addition, corrugation quickly accumulates dust on its surface and requires special care when washing.

- Steel (galvanized or stainless). Steel is characterized by a fairly low price, enviable mechanical strength and immunity to high temperatures. The use of this material when installing an air duct for a kitchen hood allows you to create a durable and perfectly smooth structure. Dust does not linger inside steel pipes, and the outer surface is easy to clean from dirt. However, steel air ducts are gradually losing popularity. This is due to the complexity of installation (requiring cutting of pipes and the use of special sealant), high dead weight and noisy operation.

Selecting the duct configuration

According to their configuration, air ducts differ in 2 types:

- Flexible. As a rule, this is corrugation. It is usually made of aluminum, but in recent years manufacturers have offered plastic models reinforced with metal wire. Flexible structures are light in weight, easily stretched and take the desired shape, but are quite bulky and unsightly. In addition, they reduce the performance of the exhaust system, which is why it is not recommended to make flexible air ducts too long.

- Tough. Can be made of plastic or metal. Easy to use, aesthetically attractive, with a minimum of restrictions. However, rigid structures are more expensive than corrugated ones.

Section shape

Mostly models sold are round or rectangular in shape. These are the most popular options that are suitable for every occasion. Some manufacturers abandon this solution and produce air ducts with an elliptical cross-section, which increases efficiency.

Round ducts are low cost because they are easier to produce. In addition, this design guarantees fast movement of air flow, while the noise level is minimal. Installation will take a minimum of time, and the external design is beautiful and aesthetically pleasing.

Rectangular models are distinguished by the fact that they are easy to install in any room. Even if an unusual design is used, installation will not take much effort and expense. The only disadvantages of this element are its large mass and high price. Therefore, this option is not suitable for everyone.

Design differences: shape, size, material

The most common and popular sizes of channels and pipes are as follows:

For round pipes:

| Name | Dimensions (mm) | Letter on the drawing |

| Internal diameter | 100; 125; 150; 200 | D |

| Length | 350; 500; 1000; 2000 | L |

For square:

| Name | Dimensions (mm) | Letter on the drawing |

| Height | 55; 60 | a |

| Width | 110; 122; 204 | b |

| Length | 350; 500; 1000 | L |

Diameter, length, width and height of the air duct elements Source blog-potolok.ru

Additional designations D1, b1, a1 are indicated to display the wall thickness. As a rule, they are 3-5 mm.

Material

The term “plastic” hides a group of polymers with different characteristics and properties. The most important indicator is the range of temperature differences withstand.

| Plastic | Temperature difference | Peculiarity | |

| PVC | -30 | +70 | Cheap |

| PVDF | -40 | +140 | Good chemical resistance and fire retardant properties |

| PP | -20 | +120 | Insoluble in acids, alkalis and does not react to organic matter |

| HDPE | 0 | +40 | High flexibility, protection against mechanical damage |

PP is excellent for kitchen hoods. The material perfectly resists chemical damage and is easy to clean. If there is a heating element in the room (stove, radiators, etc.), then choose PVC or PVDF.

See also: Catalog of companies that specialize in ventilation and air conditioning.

Differences in manufacturing technology

Only three versions are sold:

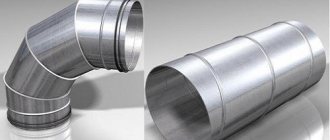

- Straight-seam. Such a structure is made from a solid metal sheet, and its length should not be less than 1.25 meters. The ends are connected by welding. The rectangular shape is characterized by the presence of an additional seam, which gives rigidity and is located on the fold.

- There is another option - spiral welded. They are made from a long metal strip, which is twisted overlapping and joined by welding.

- Spiral wound. In this case, a tape made of galvanized steel is used. Its width should not be less than 13 cm.

Where are plastic air ducts used?

In any home or industrial premises there must be free circulation of air in accordance with current regulations. It is provided by ventilation systems assembled from special pipes.

Plastic air ducts are used for:

- kitchen hoods;

- ventilation systems in apartments and houses;

- designs for forced ventilation of premises in enterprises.

Plastic air ducts are used for kitchen hoods.

Shopping centers, canteens and restaurants also prefer systems made from plastic. It is cheaper and more durable. Air exhaust structures operate almost silently.

By hardness

This point should be given special attention. There are 3 varieties in total:

- Flexible. Simple products that are made of steel wire, and the walls are made of foil. The main advantage of this option is simple installation and transportation. The product connects easily with other products, making it easy to use. The corrugated pipe can be installed at any angle, as it easily bends and unbends. Among the shortcomings, poor noise insulation and low strength characteristics are mainly noted. In some cases, air may become trapped inside this element.

- Semi-rigid models are made from steel or aluminum tapes; the connection occurs using a spiral seam. This product has good flexibility and good strength. However, such an element can only be stretched once. Therefore, such work must be done responsibly.

- Tough. These are excellent models that are made keeping in mind the user's requirements. They have high strength and good noise insulation. However, they are expensive and complex to install.

Selection of elements and calculations of a plastic ventilation system

Plastic ventilation has several undeniable advantages: a wide range of components, ease of assembly, and good technical characteristics. All these qualities will fully manifest themselves only if they are assembled correctly.

Before proceeding directly with installation, it is necessary to draw up a project for the air duct network and determine what components will be required.

Main elements of the system:

- plastic ventilation duct;

- reverse draft valve;

- pipe connection parts;

- gratings and plugs;

- optional equipment.

The selection of components depends on the specified system capacity and layout. The number, diameter, and cross-section of air ducts can be calculated using a specialized computer program or contact a specialist for this.

When drawing up a diagram, it is important to decide what plastic shaped elements will be required. Plastic pipes for kitchen hoods are additionally equipped with fittings in cases where the hood is diverted into a common house system or outside.

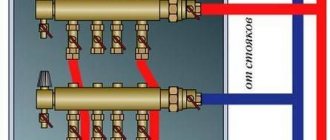

Recirculation models do not require installation of an air duct. Based on the type and functionality of shaped elements, they are distinguished:

- short straight sections (couplings);

- adapters;

- bends;

- ducks;

- tees.

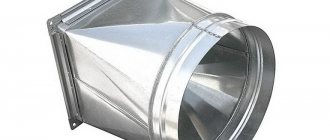

Adapters are used when connecting parts that differ in diameter. Outwardly they resemble a truncated cone (for round-shaped pipes) or a pyramid (for rectangular products).

You can choose transitions with lateral displacement, gradual increase or decrease in diameter to install a ventilation system of complex shape.

The outlet is used when there is a need to change the direction of air flow at a right angle.

The check valve consists of a circuit with a petal that allows air to flow in only one direction. Helps prevent cold air from entering the exhaust duct.

Decorative ventilation grilles cover the openings of the channels and protect against the entry of small debris and insects, and improve the appearance.

Tees are used to create complex branches in the ventilation system; there are models that allow you to connect parts with different channel diameters.

When assembling the air duct, it is important to remember the low heat resistance of plastic and not connect heating elements (heaters and recuperators).

Optimal pipe size for air duct

To calculate the required volume, you will need the help of a specialist or you should follow the recommendations that are present in SNiP 41-01-2003. This will allow you to avoid making mistakes in your calculations and buy the appropriate option. In addition, the recommendations also indicate the maximum air speed: for residential premises - 1 m/s with natural ventilation, 3-5 m/s if forced ventilation is used.

Finding the right size is not difficult, since modern enterprises produce hundreds of different models. Therefore, you can easily select an air duct not only for residential premises, but also for construction sites or public buildings.

- The maximum size of a round product is up to 2 meters;

- Structures with a rectangular cross-section are available in the range from 10 cm to 3.2 m.

Operational requirements for air ducts

Any air circulation system must perform its functions and be user-friendly, and therefore meet certain requirements. So, the air ducts must:

- be completely sealed;

- aerodynamic noise arising during operation of the air handling unit and air movement through the air duct system must not exceed established sanitary standards;

- ensure the required performance of the ventilation system, i.e. the possibility of free passage of air masses at the required speed;

- during operation of the ventilation system, withstand the air pressure created by the air handling unit;

- comply with thermal insulation standards;

- fit harmoniously into the interior;

- occupy minimal space in the room.

Depending on specific conditions, other requirements may be imposed on air ducts, but these are basic.

Air ducts - the “transport system” of ventilation

How to clean the air duct?

The ventilation system will do its job well only when it is correctly installed and assembled. But we also must not forget about timely maintenance, since from time to time garbage can get there. It is not necessary to dismantle the device to clean it.

- Mechanical method. This option is suitable for hard structures, as it uses vacuum pumps that can damage soft walls. In addition, hydromechanical tools are often used to thoroughly remove any contamination.

- The chemical method is designed to remove traces of fat that often accumulate in the kitchen and catering areas. However, only appropriate compounds should be used to ensure that the components do not corrode the exterior and interior of the duct.

In addition to constant cleaning, pipes should be disinfected, since pathogenic bacteria and sometimes parasites are constantly forming inside. If they get into food due to improper use or untimely cleaning, the person will be poisoned. Disinfection should be carried out using powders or liquids based on hydrogen peroxide.

If a person does not have special means with which to clean the sewer, it is better to call the appropriate service. Workers always have effective devices that will clean the air duct in a short time and do it efficiently.

Where to hide the hood duct?

Even plastic communications do not always fit into the kitchen design, so after installing an air duct for a kitchen hood, people often think about masking the pipes. There are several ways to do this:

- Decorative box. You can make it yourself or choose a ready-made design in the store. The range of shapes, sizes and colors of such “camouflage” casings is quite diverse.

- Suspended or suspended ceiling. Modern ceiling coverings reliably hide communications. To do this, the horizontal section of the air duct is laid as high as possible. The vertical part is lined with the same material that is used on the ceiling.

- Wall cabinets. If the wall is covered with closets that fit tightly together, it makes sense to buy a built-in hood and run the air duct inside the cabinets, cutting holes in them in advance of the required shapes and sizes.

- Self-adhesive film. To make the air duct stand out less from the background of other interior items, it is finished with self-adhesive film to match the furniture or walls. However, you should choose a heat-resistant film, since the communications will heat up during operation of the hood.

Rating of the best air ducts with a flexible channel

ERA 12.5PF 125 mm

An excellent flexible option that is suitable for installation in various rooms. The product is made of polyvinyl chloride, which allows it to be placed in the bathroom. The pipe is flexible, so it can be installed at any angle. The only drawback of the design is the high noise level, so the area of use should be approached more selectively.

Sold at price: 250 rubles.

air duct ERA 12.5PF 125 mm

Advantages:

- Durability;

- High service life;

- Good flexibility;

- Does not corrode;

- Low price;

- Easy transportation.

Flaws:

- Poor strength properties.

ELIKOR VG-1

Flexible model made of aluminum. The product may change the connection side. Installation will take a minimum of time, while the reliability is slightly higher than that of the previous model. The only drawback of this design is the high cost. But it completely pays for itself with strength indicators and better sound insulation.

Sold at a price: from 400 rubles.

air duct ELIKOR VG-1

Advantages:

- Corrosion resistance;

- Good flexibility;

- Strength indicators;

- There is sound insulation;

- High service life;

- Easy maintenance.

Flaws:

- High price.

TDM ELECTRIC SQ1807-0068

High-quality corrugated air duct that can be installed in the kitchen or bathroom. The product is characterized by good strength and resistance to corrosion. At the production stage it is treated with special materials that increase its protective properties. Flexibility is maintained at a high level, allowing connections to be made faster and more efficiently.

Average cost: from 240 rubles.

air duct TDM ELECTRIC SQ1807-0068

Advantages:

- Low price;

- Efficiency;

- Strength indicators;

- Protective layer;

- Corrosion resistance;

- Long service life.

Flaws:

- Not detected.

Diaflex DFA 203mm

Long design, which is intended for use in production areas. The main feature of the product is the ability to withstand air currents whose speed is 26 meters per second. In this case, the maximum operating pressure is 0.024 bar. The equipment can be operated in a range from -30 to 140 degrees. The length is 10 meters, with a weight of only 1.94 kg, which has a positive effect on transportation.

Sold at a price: from 1,280 rubles.

air duct Diaflex DFA 203mm

Advantages:

- Durability;

- Strength indicators;

- Length;

- Low cost;

- Withstands strong air currents;

- Suitable for industrial enterprises;

- Small mass.

Flaws:

- The design is too noisy.

Airone A2(Hard) 508 mm

A more expensive device designed for installation in various factories. The hole diameter is 508 mm. The design is capable of not breaking at an air flow of over 20 meters per second, which is a positive result. Maximum positive pressure – 3000 Pa. It is recommended to use the product in places where the temperature is -40...130 degrees.

The length of the entire air duct is 10 meters, while the weight is 9 kg, which is within the permissible zone and makes transportation more convenient. In addition, the pipe easily bends and unbends without deforming, which simplifies installation.

The average cost is 5,000 rubles.

air duct Airone A2(Hard) 508 mm

Advantages:

- Strength indicators;

- Withstands temperatures up to 130 degrees;

- Efficiency;

- Maximum positive pressure 5000 Pa;

- Suitable for production;

- Packaged in individual packaging;

- Thickness is 65 microns;

- Good turn-to-turn distance;

- High-carbon steel wire is used as the frame;

- 5 layers of aluminum.

Flaws:

- Not detected.

How the diameter is selected

When designing, engineers carry out mathematical calculations and then compare all the values according to the table. Below is a table comparing parameters and air flow speed.

Detailed calculation guarantees the efficiency of the system Source stankoforum.net

The diameter of the duct is determined based on the volume of the room or the performance of the overall system. The volume and speed of air circulation is controlled according to regulatory documents. The picture shows air exchange rates per 1 family member for the premises of a private house.

Each room has its own air exchange rate Source homemyhome.ru

The types and sizes of plastic air ducts for ventilation are selected individually based on engineering calculations. It is important to consider system performance and airflow speed. If it is exceeded, there will be a regular draft, otherwise air stagnation occurs.

Rating of the best air ducts with a rigid channel

Gamart F150 1 m 0.5 mm

A round ventilation duct that can withstand high loads. Manufactured in Russia. The product is made of galvanized steel, the thickness of which is 0.5 mm, this is enough to provide good sound insulation. There is no auxiliary protective layer, since equipment without this is highly reliable and resistant to corrosion.

Average cost: from 230 rubles per meter.

air duct Gamart F150 1 m 0.5 mm

Advantages:

- Good sound insulation;

- Easy installation;

- High service life;

- Diameter 150 mm;

- Made from galvanized steel;

- Corrosion resistance.

Flaws:

- Not found.

ERA 10VP 100 mm

A high-quality pipe with good rigidity, which is suitable for use in conditions where the temperature does not rise above 150 degrees. For the manufacture of the air duct, an accessible and cheap material was used - PVC. But despite this, the strength characteristics remained at a high level. At the same time, the product does not deteriorate from high levels of humidity and is able to withstand high air flows without consequences.

Average price: from 90 rubles.

air duct ERA 10VP 100 mm

Advantages:

- Low cost;

- Durability;

- Strength indicators;

- Efficiency;

- Withstands large flows;

- Good thickness.

Flaws:

- Not found.

Blagovest-S+ Spiral-wound air duct d125

A high-quality model with a good connection of channels that provide sealing and high strength. The product can be used in industrial or civil construction, which makes it universal. The product contains round channels with special seams. The maximum operating temperature is 70 degrees. It is made of galvanized steel, the thickness of which is 0.5 mm.

Sold at price: 780 rubles.

Blagovest-S+ air duct Spiral-wound air duct d125

Advantages:

- Durability;

- Reliable connection;

- Universal application;

- Material;

- Strength indicators.

Flaws:

- Not found.

VENTS 2005 125 mm

A budget model that is only suitable for organizing a ventilation system in a residential building. The design is rigid and made of durable PVC plastic with great thickness. The duct is soundproofed and can withstand standard air flows.

Sold at a price: from 100 rubles.

air duct VENTS 2005 125 mm

Advantages:

- Price;

- Rigidity;

- Easy installation;

- Corrosion resistance.

Flaws:

- Not for all premises.

Titanium VSN Ø250 L=3000

A reliable model that is suitable for installation in industrial enterprises. The length is 3 meters, while the diameter is 250 mm. It is made of galvanized steel, the thickness of which is 0.8 mm, which increases strength characteristics.

The average cost is 2,730 rubles.

air duct Titan VSN Ø250 L=3000

Advantages:

- High quality material;

- Easy installation;

- Tightness;

- Strength indicators;

- Durability.

Flaws:

- Not found.

Air ducts for ventilation made of plastic

Plastic, unlike aluminum or galvanized steel, is a relatively cheap building material.

Despite the low cost, it has a number of advantages:

- maintains a presentable appearance for a long time;

- fits easily into any interior;

- unpretentious in maintenance.

Plastic air ducts are actively used in low-rise construction.

Such complexes are suitable for installation in:

- one- or two-story country cottages;

- ground garages;

- outbuildings;

- utility buildings;

- buildings for keeping animals.

With proper care, a plastic ventilation pipe will last fifty years, maintaining its original appearance, color and characteristics.

Features of check valves

Stainless check valve

To avoid the backdraft effect, a check valve should be installed. Even with the hood turned off, the air from the ventilation shaft will not pass back into the kitchen. The valve will not allow dust from the street to pass through. Such devices are divided into types:

- valves with electric drives;

- with spring-loaded blades;

- with damper;

- with membrane.

If the exhaust ventilation duct goes through the wall to the street, then it can be equipped with a valve. It will look like a butterfly with blades that are held in place by springs. The blades will serve as a barrier to the supply air, as they block the air duct.

The passing “exhaust air” acts on the springs and blades of the valve - they are reduced to its central axis. After the air flow passes through the springs, the blades return to their original position.

Advantages and disadvantages

Compared to other materials, plastic products have the following advantages:

- Low price .

- Easy to install.

- Prefabricated structure with a butt system.

- Good aerodynamic properties .

- There is no hum (iron structures hum a lot).

- Do not rust.

Disadvantages include:

- Flammability . When a fire occurs, acrid smoke appears. The integrity of the structure is compromised and harmful gases quickly spread throughout the room.

- Electrification . Due to constant movement, plastic accumulates a static charge and attracts dust. This increases the fire hazard level.

The main problem is the high risk of fire. Because of this, according to SNiP requirements, it is prohibited to install plastic ventilation in large buildings and underground. In the event of a fire, the plastic will melt and acrid smoke will spread through the air ducts throughout all rooms.

Plastic easily ignites, therefore it is prohibited and is not used in the ventilation of large buildings Source cs.aviarydecor.com

Diaphragm valves

Diaphragm valve to be replaced

Under the influence of a gust of “exhaust air”, the membrane in the diaphragm valves moves away. After air passes through, it falls into place. When the air purifier is turned off, natural ventilation is not disturbed, since this is facilitated by the “clacker.” This installation is mounted at the entrance to the air duct. In the first position of the valve, the hood does not work and the curtain blocks the ventilation pipe.

However, the ventilation hole in the ventilation shaft remains open. If the hood is turned on, then the gust of passing air moves the curtain and blocks the ventilation holes, so there is no reverse draft effect. Modern hoods may contain check valves. Therefore, you don’t have to spend money on buying them.

Installation of corrugated aluminum ventilation ducts

Convenient and maneuverable when laying a ventilation duct of any complexity. You can mount it at the required angle. There is no need to use rotating shaped elements. These types of pipes are sold in small pieces. You can stretch the “accordion” up to 3 meters. This length is enough to install a kitchen ventilation duct. Don't make channels too long. This contributes to a decrease in ventilation performance in general.

Steel accordion duct is suitable for simple systems

Important! Corrugated aluminum air ducts can withstand temperatures from -30 to 250 degrees. Therefore they are considered fireproof.

The corrugation easily attaches to the hood pipe, as it has a standard size. The clamp easily secures this connection. If the cross-sectional diameter is rectangular, then the corrugation can be easily bent, giving it a rectangular shape. You can go the other way and buy an adapter.

A prerequisite for installing a flexible pipe is stretching. The air passing through encounters resistance in the form of an “accordion” along its path. In such pipes, waste products settle inside, so over time, plaque and a decrease in clearance are guaranteed. Additional moisture can also form on the ventilation duct - this is condensation that appears due to temperature differences. Aluminum is a conductor of heat, so dew points will appear during the winter. A pipe in an extended position can be easily deformed. Therefore, it is better to hide it under a decorative box.

Differences between a hood and a ventilation system

At first glance, it is difficult to say how a kitchen hood differs from ventilation. To find the answer, you need to understand the terminology in detail.

Sanitary requirements today require the installation of special units in residential premises that ensure the proper level of air exchange. To meet these standards, a ventilation system is installed in multi-story buildings. The latter is presented in the form of a pre-designed chain of channels, which are located in the walls and facilitate the discharge of air masses to the roof.

The ventilation ducts themselves are needed to remove waste air flows outside the residential building. In turn, fresh air naturally enters the room through joints and cracks in window and door openings. However, one must take into account the fact that such a system is not able to quickly eliminate various unpleasant odors that often appear during cooking in the kitchen.

To get rid of such troubles, a special ventilation system is installed, which functions forcibly. In common parlance it is called a “hood”. The principle of operation of such devices is slightly different - they absorb vapors emanating from the cooking surfaces, and then, using an air duct, discharge them into a special channel of the ventilation system.

Materials for the production of plastic pipes

The construction market offers ventilation pipes made of several types of polymer materials.

The consumer is offered:

- Polyvinyl chloride (PVC) pipes can operate in a temperature range from -30° to +70° Celsius. They are used primarily in domestic and residential construction for heated and cold rooms. PVC is a non-flammable, thermoplastic material, melting point 165-200 degrees. Good dielectric. The inside has a smooth surface. It does not tolerate frost well; at a temperature of 15° below zero, it loses its properties.

- Fluoroplastic ventilation ducts (PTFE) have high heat resistance and can withstand heating up to 260o Celsius. Air ducts are used to transport air mixtures with a high content of acidic and alkaline ingredients. Fluoroplastic is used in industry for the manufacture of high-strength ventilation networks.

- Air ducts made of polypropylene (PP) have an affordable price and are resistant to aggressive air components: acids and alkalis.

- Polyethylene pipes (PE or LDPE, HDPE) are lightweight, flexible, and elastic, but do not withstand negative temperatures well. The material is neutral and does not interact even with acids. Polyethylene does not emit harmful substances and is considered absolutely harmless.

Polyethylene pipes are designed for a long service life. The internal smooth surfaces offer virtually no resistance to air flows moving along them.

European countries have recognized PP as a technically obsolete material. You can still purchase air ducts made of polypropylene in the Russian retail chain.

Polypropylene pipes are used in highways to move aggressive gases that cause metal corrosion

The purchase of products made from this material for a residential building will be justified for use in utility rooms or when there is a lack of budget funds.