Cable Samsung EP-DG930I, USB Type-C (EP-DG930IBRGRU), black, 1.5 m

448 ₽ More details

Smartphone Samsung Galaxy A52 8/256GB, Black

32990 ₽ More details

Samsung robot vacuum cleaners

Increasingly, in residential, office, and industrial buildings, special equipment is used to organize a proper ventilation system. Installing duct fans is a task that a novice master can handle. It is important to install the fan correctly and connect it to the power supply.

Duct ventilation design.

Features of exhaust fans

Several modifications of exhaust fans are available. They come with cords, with timers, motion sensors, mode switches, etc.

The most popular exhaust fan options come with built-in humidity sensors. They pull stuffy air out of the room, control moisture levels and consume a small amount of electricity

The most effective models are those with a humidity sensor - they turn on automatically when the humidity level in the room rises. Manufacturers of exhaust systems have released such “smart” variations of fans to increase the level of user comfort - after all, after taking a shower, you may forget to manually turn the fan on or off.

How does a fan with a humidity sensor work?

Now let's talk about how the humidity sensor installed in the exhaust fan works. The internal structure and operating principle of such devices are practically no different from standard exhaust devices. When the engine turns on, the blades begin to spin. This sets the air in motion and draws it, along with drops of moisture, into the hood.

The hood with a sensor can be mounted on a ceiling or wall ventilation shaft. The body and parts of the product are made of waterproof materials. Electrical parts have high-quality insulation.

The most expensive models of exhaust systems with a humidity sensor are additionally equipped with lighting, as well as a special check valve, which does not allow unpleasant odors and dust into the room from the air duct

The humidity sensor in the fan can operate either on a timer or automatically. In the second case, the exhaust system turns on when the humidity level in the room exceeds the norm.

Diagram of the operation of a fan with a sensor that controls the humidity level. When the moisture level rises, the product turns on and operates until the indicators return to normal. Shutdown occurs using a delay timer

In general, a humidity sensor or hygrostat in a fan is a special element that allows you to measure the level of humidity in the air and start the exhaust device without human intervention. And all this thanks to the high sensitivity of the sensor to condensate. It works on the principle of a thermostat; ventilation is turned on only when the humidity is above 40%.

Exhaust systems with a built-in hygrostat are ideal for installation in bathrooms, laundry drying rooms, and toilets. Can be used as basement ventilation in private homes.

Types of built-in humidity sensors

Models of axial duct fans are usually equipped with humidity sensors. A small board is mounted in the product body. The hygrostat has two limits: upper and lower.

In order for the fan to work properly for a long time, you need to configure it correctly. The sensor structure contains a regulator, which is equipped with a humidity scale. The moisture level is set by rotating the potentiometer

Some variations are set from the factory and cannot be adjusted. On the rest, the response range can be set independently.

Types of sensors:

- Resistive - when the humidity level changes, the product changes resistance and starts the fan motor.

- Dielectric - has a capacitor in its design. When the humidity between the plates of the product increases, the dielectric constant of the medium changes.

- Thermistor is an improved analogue of a resistive sensor. Has increased accuracy.

- Optical – determines the humidity concentration based on the transparency of the air.

- Mechanical - when there is more moisture in the room, the length of the material from which the sensor is made changes.

When the humidity level reaches the programmed values in the sensor, the relay is activated. It closes the electrical circuit of the engine and the fan begins to spin.

Some practical tips

When choosing which fan to prefer in your ventilation circuit, you need to

firstly , focus on the shape and cross-sectional area of the air ducts secondly , on the power of the fan itself ; thirdly , on the desired ventilation intensity, i.e. how many times per day the air in a given volume should be replaced.

It is not difficult to calculate this indicator: you just need to divide the fan power by the volume of the room. This is simple, but you also need to take into account such a detail as air flow speed. Experts recommend choosing devices that provide air movement at a speed of no more than 14 m/s, but not less than 11 m/s.

At a lower speed, ventilation will be ineffective, and at a speed of more than 14 m/s. Unacceptably loud noise may occur.

Of course, it is better to entrust the installation of duct fans to specialists. This is not due to the particular complexity of the work, but to its thoroughness. They must be carried out so that:

- There were no loose wires near the rotating parts of the fan.

- All connection wiring was securely fastened and covered with a plastic box.

- Free space was left near the duct fans for their preventive maintenance and repair.

- The fastening of the air ducts should not be rigid so that vibration is not transmitted through it.

In general, don’t skimp on specialists. The fan is the heart of the entire ventilation system and it will be very unpleasant if it suddenly starts acting up soon after installation.

Back to news list

1. General Provisions

1.1. This User Agreement (hereinafter referred to as the Agreement) applies to the website of the online store stv39.ru, located at 238311, Kaliningrad region, Bolshoye Isakovo, st. Starokamennaya, house. 35, and to all relevant sites associated with the site stv39.ru.

1.2. The website of the online store stv39.ru (hereinafter referred to as the Website) is the property of I.V. Savelyev.

1.3. This Agreement governs the relationship between the Administration of the website of the online store stv39.ru (hereinafter referred to as the Site Administration) and the User of this Site

1.4. The site administration reserves the right to change, add or delete clauses of this Agreement at any time without notifying the User.

1.5. Continued use of the Site by the User means acceptance of the Agreement and the changes made to this Agreement.

1.6. The User is personally responsible for checking this Agreement for changes to it.

Full version

document

Electric center

An online store selling lighting and electrical equipment, cable and wiring products, as well as professional electric and petrol tools.

st. Starokamennaya, house. 35 Kaliningrad region, Bolshoye Isakovo 238311 Russia +7(4012) 55-55-14 [email protected] [email protected]

Duct and ductless fan - what is the difference

The fundamental difference between a duct fan and a ductless fan is in the place of its installation. Duct, as the name suggests, is mounted directly inside the ventilation duct. The ductless unit is installed at the outlet of the shaft, on the roof or directly in the window (in the wall hole) of the ventilated room - at the border of the external and internal air exchange environment.

Ductless ventilation has low power and is suitable for small rooms where there are no high levels of humidity or air pollution. These are utility garages where there are no strict requirements.

Ductless fan

Conclusions and useful video on the topic

The construction of a ventilation duct for autonomous ventilation of a toilet and bathroom with only one shaft is clearly shown in this video:

Connecting a simple fan is described in detail here:

To summarize, we can say that it is quite possible to independently arrange an effective ventilation system in an apartment, but you need to be careful and think through everything carefully in advance. If you are not confident in your abilities, entrust the job to a specialist, because mistakes in working with electrical wiring can lead to dire consequences.

Have you ever installed a fan in a bathroom or toilet? Please tell us what connection diagram you used and were there any difficulties in installation? Leave your comments, share your experience - the communication block is located under the article.

Criteria for choosing a high-quality duct fan

When choosing a duct fan, the following technical parameters of the equipment must be taken into account:

Air flow speed (performance). For domestic purposes, 100-150 cubic meters is sufficient. m. per hour. If the value is lower, the device will be ineffective even in a small room. Please note that as speed increases, so does noise.

Performance calculations should be carried out professionally - using a special calculator, or by contacting managers online or by phone;

Noise level. If you are looking for equipment for installation in a technical room, this criterion does not matter. For residential areas, you should purchase silent duct fans.

We remind you that with the impeller blades bent backwards, the device makes virtually no noise;

Type, design

When purchasing, you need to pay attention to the shape of the air duct and the purpose of the equipment; Additional functionality. Recommended option - check valve

It can be self-closing, controlled (connected to the network and triggered to close and open thanks to a sensor) or passive (works with low efficiency under the influence of gravity).

Another useful function that may not be present is a timer (provides the ability to set the duration of ventilation);

Case materials. Metal cases are made from bronze, aluminum or steel. Both metal and plastic will have their own degree of resistance to open fire, moisture and heat. Future operating conditions must be taken into account.

If you are looking for equipment for installation in a bathtub, kitchen or other room with high humidity (or dust), purchase a duct fan in a moisture-proof casing. If moisture gets inside the machine, a short circuit may occur.

conclusions

Modern duct fans have the following advantages:

- don't make noise;

- compact;

- have high performance;

- they can be easily and quickly installed in the duct.

When selecting a device, the following indicators are taken into account:

- Operating temperature range;

- performance;

- noise level.

When purchasing and installing it yourself, you need to follow all the nuances that were listed above in the article.

Types of duct fans

Depending on the design of the device, there are 3 types of duct silent fans:

- axial (asynchronous);

- centrifugal;

- combined.

In axial models, air movement coincides with the direction of rotation of the fan shaft. The efficiency of such ventilation devices is 75%.

Centrifugal (radial) devices extract air from industrial and domestic premises. A fan is installed in the bathroom, the blades of which are bent against the direction of rotation.

The operating efficiency of this device is approximately 80% and does not produce much noise when operating.

Combined models contain structural elements of both axial and centrifugal ventilation devices. The operating efficiency of such equipment is approximately 80%. The body shape can be rectangular, round or square.

Combined devices have high performance. This figure is higher than that of axial products, which is why such models are installed not only in multi-storey buildings, but also in industrial facilities.

Duct fans are also divided into two large classes (types):

- traditional;

- wall-mounted

Wall-mounted devices are complex devices that are configured during production. However, their installation process is much easier and faster.

Also, duct ventilation can be single- or multi-speed. Most ventilation devices have 1 speed, although two-speed devices are often found on sale.

Design features and characteristics

In a long air duct, only a radial rather than an axial duct fan is installed. This is due to the fact that very often such devices are installed far from the exhaust opening of the ventilation duct.

As a result, the axial device, unlike radial models, does not effectively remove air flows from the bathroom and kitchen and does not eliminate unpleasant odors.

Duct fans have the following characteristics:

- productivity - up to 5330 m3/hour;

- power consumption - up to 3.5 kW;

- pressure - up to 900 Pa;

- flanges have a diameter of 100-400 mm;

- low noise level;

- the electric motor is equipped with an external rotor;

- equipped with speed regulators;

- Installing the device is a simple and quick process and does not require special experience.

It should also be noted that preventive inspection and cleaning of the ventilation device does not take much time.

Fan to duct connection

The fan connection must be made with maximum tightness and tightness. Loss of air flow is unacceptable, as it can cause a sharp drop in pressure in the system and disruption of operation. Duct fans have different types of connecting elements:

There are different options for connecting duct fans. The main difficulty encountered during installation is the need to install a device with round connecting pipes to a rectangular duct, or vice versa. There are also difficulties with different diameters or sizes of channels. Let's consider the most common situations:

Installation of fans in a square duct

Square ducts can be connected directly to the fan if the dimensions of the connecting pipes and the duct completely match. It often happens that the shapes of the pipes do not match. In these cases, it is necessary to use connecting adapters - fittings. There are different types and sizes that allow you to connect devices of different cross-sections.

The standard sizes of connecting units and adapters are standardized, so you just need to select the appropriate fitting that provides the transition from a round section of the required diameter to a square or rectangular section of the required dimensions. Sometimes there is a need to switch from a square section of one size to another. In these cases, it is also necessary to use connecting fittings of the required cross-section.

Installation of fans in a round duct

Air ducts with a round cross-section are preferable due to their operational properties. They do not make noise, do not create strong aerodynamic drag, and do not accumulate dust or debris.

The fan is installed in a round air duct either directly, if the connecting nodes and dimensions match, or an appropriate adapter is used - a connecting fitting.

The length of the fitting must be no less than the maximum diameter of the fan so that the transition unit does not create sudden changes in diameter. Such transitions are capable of forming turbulences that change the parameters of the air flow, producing noticeable noise and vibration. In some cases, flexible air ducts can be used, which have their own sets of fittings and are convenient for installation in rooms cluttered with equipment or equipment.

How to install a duct fan in a pipe

Installation of a duct fan in a pipe is carried out in the same way as in a circular duct. The only difference is that the diameters will most likely not match. Therefore, you must immediately prepare the appropriate adapters.

Where should the fan be installed?

Duct fans, as a rule, are designed to work in only one direction - either to exhaust dirty air or to bring in fresh air. Their functional purpose is dictated by their location:

- if a duct fan must provide air flow, then it should be located closer to the room

- if a duct fan is configured for exhaust, then it should be located as close to the street as possible (for example, in the attic).

On the supply side of the fan there will be a straight section equal to at least 1 diameter of the air duct; on the exhaust side, the same section must have a length of at least 3 mm in diameter.

If this rule is violated, the efficiency of the device will sharply decrease due to the resulting pressure difference. In order to avoid this, it is necessary to take into account the following points when installing the air duct system:

On the air supply side, the distance to the nearest wall must be greater than the input diameter. The cross-section of the duct inlet should be no more than 112% and no less than 92% of the fan inlet. At the inlet, the air should not encounter any obstacles. From the exhaust side: The angle of reduction in the cross-section of the air duct should be less than 15%. The expansion angle of the duct section should be less than 7%. The length of the straight section after the air duct fan must be at least 3 duct diameters.

When is it necessary to increase the performance of a chimney?

Poor draft is not always the only reason for chimney work. It may be necessary to increase the rate of carbon monoxide removal if additional equipment is connected to the hood from the stove.

It is allowed to use a chimney to connect a column if the equipment is located on the same floor. And if the chimney has a sufficient smoke removal volume for operating the gas heater.

Another reason to increase the draft in the chimney is to install a more powerful heater. The required parameters of the chimney are indicated in the product data sheet.

It is also worth paying attention to how quickly you can light a fire in the stove. For example, if the draft is weak, damp wood will not burn. If the volumes of gases removed do not match the capabilities of the existing system, then the chimney needs to be modernized

If the volumes of gases removed do not match the capabilities of the existing system, then the chimney needs to be modernized.

Application area

Duct fans are used in households and commercial premises (shops, catering establishments, etc.). For narrow industrial purposes, models with special properties are designed. There are models adapted for high humidity conditions, such as bathrooms and toilets. You can organize the hood mount so that it turns on simultaneously with the lighting. One of the supply conductors is opened and connected to the switch. If the latter has two buttons, do it differently: one of them is connected to the lighting device, the other to the ventilation device.

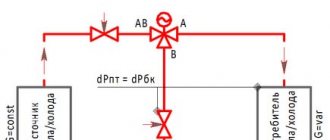

Serial connection of fans

In some cases, in a network with high resistance, instead of replacing the fan with a larger standard size, it is advisable to install an additional fan. In this case, the fans operate sequentially on a single network. Typically, axial fans with relatively low pressures are switched on in series.

This is a multi-stage fan with identical impellers, between which straighteners are installed to spin the flow to the axial direction before the next impeller. There are known cases of sequential operation of duct fans. It is extremely rare to use sequential operation of radial fans with a spiral casing due to the complexity of the layout.

When two fans operate in series, they have the same performance. To obtain the total characteristics of a system of two fans, it is necessary to add their pressures (ordinates) at a fixed performance.

To simplify the analysis of the joint operation of fans, we will not further take into account the increase in network resistance when installing a second fan. The aerodynamic characteristics of the total operation of two identical fans are shown in the figure.

Sequential operation of two identical fans:

1, 2 – characteristics of additional and main fans

3 – characteristics of the joint operation of two fans

Both fans have LP capacity, the operating mode of each fan is point A, and the system of two fans is point B, the pressure at which is equal to the sum of the pressures of the two fans.

Let's consider the joint operation of two fans that have different aerodynamic characteristics (Fig. a). Fan 2 is the main one, and fan 1 is an additional one, which serves to increase the performance of the main fan. The operating mode of the fans is point C, the operating mode of the main fan is point B, and the additional fan is point A, while each fan has a performance of LP. If the main fan worked alone, then its operating mode would be point D, and the fan performance would be LD. Due to the installation of an additional fan, productivity increased by Lp—LD. As you can see, if the performance of the main fan when operating in a given LD network is less than the maximum performance of the additional fan L1MAX, then installing an additional fan leads to an increase in performance.

Sequential operation of two fans with different characteristics:

1, 2 – characteristics of additional and main fans

3 – characteristics of joint operation of two fans

Let's consider the case of an unsuccessful choice of an additional fan, the maximum performance of which L1MAX is less than the performance of the main fan LD when operating alone (Fig. 6). The mode of joint operation of the fans is point C. The operating mode of the main fan is point B, and the additional fan is point A, each of the fans has a performance of LP. If the main fan worked alone, then its operating mode would be point D, and the fan performance would be LD. In this case, the additional fan operates in “turbine” (“vane”) mode and acts as an aerodynamic drag for the main fan. This leads to the fact that the performance of the main fan when installing an additional one decreased by the amount LD - LP. But it must be remembered that, in addition to reducing the performance of the main fan, the additional fan consumes corresponding power.

enginerishka.ru

Connecting the fan to the power supply

Diagram of connecting the fan to the electrical network.

What about connecting to the power grid? You need to find the terminal box on the case, it is intended for connection. Before starting work, you must familiarize yourself with the diagram provided by the manufacturer, since individual equipment models may require different actions. The terminal box may be located in a different part of the housing, but the basic connection steps remain the same.

It is necessary to connect the electric motor and the ground wire. This location can be easily found on the equipment body by the corresponding icon. The connection process itself must be performed through special start-up protection equipment. It includes a thermal relay for current and a magnetic starter. It is important that the connection is made for a network with a rated current corresponding to that for which the equipment is designed.

After the connection is made, it is necessary to turn on the fan briefly to check whether the impeller rotates correctly and whether its direction corresponds to the required one. If the direction is wrong, the terminal box phases should be reconnected. For single-phase 220 V power supply, the direction of movement is set at the factory; you cannot change anything yourself.

Duct fan is equipment that is used quite often in residential, office and industrial enterprises. Its installation is extremely simple, but it is important to immediately determine which air duct the work will be performed on. This can be a round or rectangular air duct. Working with each one will be a little different.

Installation process

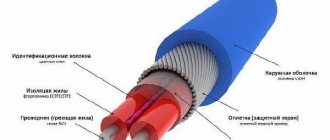

Installing and connecting an exhaust fan with your own hands is quite simple. Minimum skills and a standard set of tools are required. The work consists of the following stages:

- Cable supply. At the stage of renovation of the premises, it is better to lay the cable in a groove. If this method is overly complicated or the walls have already been repaired, it is better to use a cable channel. Typically a two-core cable is used for connection. If the device requires grounding, it is necessary to use a three-wire one. The switch is installed only for models with the simplest electrical circuit. If the device has built-in motion or humidity sensors, it must be constantly supplied with voltage.

- Connection. Work can only be carried out on a de-energized line. The device must be installed in a place prepared in advance for it. The wires are connected in accordance with the type of contacts located on the device body.

- Fixation of the body. Most overhead models are simply pressed against the wall using self-tapping screws; for this purpose, special mounting points are provided in the body. Channel models are most often fixed with special glue.

- Installation of decorative grille. Overhead models are usually equipped with a decorative trim that covers the ventilation hole.

In case of difficult air exchange, installing a fan in the air duct helps to significantly improve the ventilation parameters of the premises. For long service life, it is better to choose high-quality models. The type of device is determined by the operating conditions, and its performance is determined by the volume of the room. Self-installation and connection will not cause difficulties even in the absence of special skills.

We invite you to familiarize yourself with Calculation of the ventilation system, online calculator

Tags: fan, air duct, axial, installation

Designs and principle of operation

Depending on the intended tasks and operating conditions, it may be necessary to select a fan model of a certain design. Exhaust fans for premises are classified according to their operating principle and installation option. In accordance with the task, you can choose one of two types of device:

- Axial fan. The most famous variety with the simplest design. The movement of air masses is carried out using an impeller, on which the blades are mounted at an angle. The blades, rotating in a cylindrical casing, capture air and push it in the axial direction. This method is characterized by high productivity, since it allows you to distill significant volumes of air in a short period of time. The main disadvantage of this design is its inability to cope with large aerodynamic loads. Axial models can only work effectively in conjunction with large-diameter air ducts that are not contaminated with a significant amount of waste. If the building is tall, then on the lower floors devices of this design may not cope with the assigned tasks.

- Centrifugal fan. It has a more complex design, which was previously found only as part of industrial ventilation systems. The device body is made in the form of a spiral casing. Inside, a wheel with blades fixed to a cylindrical surface is installed on the shaft. The shape of the casing is of key importance in the operation of the device. During operation, air is captured by the blades and begins to move from the axis of rotation to the periphery. At the same time, pressure increases as a result of compression of the air mixture. Under the influence of rotation and centrifugal forces, compressed air moves along the spiral of the casing and is thrown into the outlet connected to the ventilation duct. This principle of the device cannot provide high performance, but it creates acceptable pressure that allows you to push exhaust air even into a narrow and dirty air duct. Devices of this type are recommended for installation on the lower floors of buildings.

There are also less significant differences in the design of the devices. In centrifugal fans, the blades can be inclined either in the direction of rotation of the wheel or against it. Rear-facing blades will save energy. Forward curved blades provide greater pressure, thereby increasing work efficiency. If energy savings are not necessary, a model with forward-inclined blades may have a smaller wheel diameter or lower rotation speed for the same performance. This way you can reduce the noise level.

We recommend that you read: Air ducts as part of a smoke removal system

The configuration of the device, which is selected in accordance with the intended installation method, is also of fundamental importance. Fans of both operating principles can have two versions:

- For outdoor installation. This is the variety that is most often used. The device is placed in the air duct opening. From the outside, the mechanism is closed with a decorative grille. The main disadvantage of this placement method is the increased noise level during operation.

- Duct. The design involves placement inside a ventilation duct. The further the device is from the ventilation grill, the lower the noise in the room. This feature allows you to install higher power devices without the risk of excessively loud noise. The disadvantage of devices of this type is the increased complexity of installation. Sometimes the shape and configuration of the air ducts do not allow the installation of duct models.

Installation Features

Before starting installation, it is necessary to register and approve this project with the government agencies responsible for the operation of the building. It should list the conditions for using the entire future ventilation system, the procedure for performing the work, the materials used and the layout of the ventilation air ducts and shafts.

Duct fans can be installed anywhere in the air duct and at any angle; the most cost-effective option is the rectangular cross-section of all air ducts, which saves free space.

For ventilation of any size bathroom, one duct product is sufficient. To ensure tightness, special components are used, and to eliminate unwanted vibration, gaskets made of a material that absorbs the negative effects of vibrations and reduces noise from the operation of the device are used.

To implement the necessary control over the parameters of the product, tracking systems are installed, if such actions are necessary. The control panel is placed in a convenient place; special thyristor-type devices are used to adjust the rotation speed.

Model selection

To choose an exhaust fan, it is not enough to determine the principle of its operation. There are a number of additional factors on which the efficiency of the device in specific conditions, durability and ease of use depend. In order for the purchase to meet your expectations, you need to study and analyze all the features of the device.

Work productivity

It is generally accepted that in one hour the entire volume of air in the room should change ten times. The device passport must indicate the power consumption. However, this does not mean that a more powerful exhaust fan is always more efficient. Work productivity is usually measured in cubic meters of air moved by the device during an hour of operation. Now this parameter is indicated in the accompanying documentation of most devices.

To select the optimal device model, you should calculate the volume of the room in which you plan to install the device. The resulting value is multiplied by the required frequency of air changes. A device with a high performance value will satisfy the needs for air exchange.

Materials used

The vast majority of devices today are made of plastic. At the current level of development of the chemical industry, high-quality plastic can provide decent strength characteristics, reliability and durability.

However, you should pay attention to the workmanship of individual parts. Visually distinguishing fragile cheap plastic can be quite difficult. A thorough inspection of the surface of all elements can help. Cheap products usually have traces of poor-quality casting, uncleaned seams and other minor defects. They are best visible from the inside of the housing, impeller and other elements. If the device looks sloppy, it is better not to buy it.

Noise level

The noise of the device during operation does not in any way affect the efficiency of the device, but it may cause some inconvenience. It is advisable not to use devices whose noise exceeds 40 dB. In relation to household models, this requirement has lost its relevance, since they are characterized by significantly less noise. Expensive models can work almost silently.

We recommend that you read: Ventilation grilles made of metal and metal alloys

Rotating elements can be mounted on a shaft using bearings or bushings. Bearings are not only more durable because they are subject to less wear, but they are also less noisy. Bushings that wear out over time may begin to rattle. The appearance of extraneous sounds may be a sign of imminent device failure.

Protection from dust and moisture

Often a household fan is exposed to high humidity, so it would be useful to pay attention to its degree of protection . It is identified by the IP marking, which consists of two numbers. The first digit determines protection against mechanical penetration of foreign objects and dust, and the second shows protection against liquids.

Dust protection is not critical for fan operation, so it may well be zero. Moisture protection is more important. If the fan is installed in the bathroom, preference should be given to models with moisture protection above 4. This indicator indicates protection against directed splashes. It is also possible to use the device with lower values if the device is placed high under the ceiling, where it is inaccessible to directed water flows. In the kitchen and toilet, protecting the device from moisture is not so important.

Simple Ways to Increase Traction

As a last resort, completely replace the chimney. It's worth starting with simpler methods.

First, the old chimney needs to be cleaned of soot and dirt. Special metal brushes are used for this.

If the channels and pipes were not insulated at the construction stage, it is worth doing so. Warm gases are removed more efficiently than cooled ones. In addition, it is necessary to exclude convective flows inside the chimney, when air flows down along the cold wall, interfering with the upward flows.

Another effective way to increase draft is to reduce the number of bends in the smoke removal system. Partial reconstruction of the chimney is cheaper than a complete replacement of the system.

A popular way to increase draft in a chimney is to install a deflector. The wind becomes a helper rather than creating gusts of reverse thrust

A rotary turbine can also be used. When there is wind, the turbine spins the impeller, which provides additional vacuum at the chimney outlet.

An equally effective way to increase draft is to increase the height of the chimney. The speed of movement of gases and, accordingly, the performance of the system as a whole depends on the height of the chimney.

We looked at passive ways to increase traction. But there is another effective method, which is discussed below.

Installation according to all the rules of duct fans

The rules for installing duct fans directly depend on the design of the device, the type and cross-section of the air duct, and the purpose of the room where the installation is taking place. In domestic conditions, the possibility of using duct fans is limited; they are mainly used in not very large rooms. In order to choose the right device for the required performance, you need to find out the room’s need for air supply or exhaust.

The necessary data can be found in SNiP, or simply found on the Internet. It is also necessary to consider in advance the possibility of access to the fan for maintenance, repair or replacement. The need for such actions may arise at any time, and the device must be located in easily accessible points with the possibility of access. In addition, the fan must be securely mounted to a support structure, wall or ceiling, so that it does not rest solely on the duct. Otherwise, a noticeable hum will appear during operation, and the load on the air ducts may damage them.

Advantages and disadvantages

The devices are attractive due to their ease of installation and wide range of applications. Most of them operate quietly. They do not require special care - it is enough to wipe the body and blades from dust every few months. The electric motor is protected from voltage surges, which minimizes the likelihood of failure.

The downside of fans is the lack of an air filtration option. If there is a need for it, it is advisable to install other devices, for example, air purifiers.

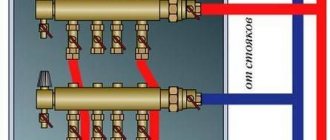

Installation of supply and exhaust ventilation

Supply and exhaust ventilation is an effective system that is based on the principle of replacing exhaust air with fresh air. That is, it provides an influx of fresh street air and removes stale air from the room. It is based on the creation of only two counter flows. A supply and exhaust ventilation system can be created based on air exhaust and completely independent supply subsystems. It can also be designed on the basis of just one installation, which will work for exhaust and air supply.

The convenience of the air conditioning system lies in the ease of installation of ventilation and operation, as well as in the specific additional properties of these systems. One of them is heat recovery, that is, a process in which the temperature of fresh air automatically increases due to the heat of the air extracted from the room. Thus, we get savings in electricity, which is not spent on heating the drawn air, but is spent only on organizing and controlling air flows.

The air can also be heated using water or electric heaters. Installation of ventilation systems has the following advantages: provides automatic forced air circulation in the room; produces heating and purification of air. Some modern systems also include humidification, which is made possible by introducing moisture into the fresh supply air stream. The problem of condensation in the room is solved in the same way.

The disadvantages include the noise that occurs during operation. But it can be minimized by using a special noise-proof box. In addition, most of these systems do not provide forced air cooling. If the system does not have a humidification function, you will have to worry about regularly draining the resulting condensate.

Round or square?

Duct fans are always built into air ducts, which, as a rule, are installed secretly: behind false ceilings, in decorative columns, etc. Moreover, the cross-sectional shape of their channels can be different - both rectangular (most often square) and round. Which one is preferable? Let's compare:

| Round duct fan | Rectangular duct fan | |

| Where is it used? | In air ducts with a circular cross-section | Used in profile rectangular air ducts |

| Advantages | Allows the use of flexible ducting | Allows efficient use of even limited ceiling space |

| Flaws | Has a lower throughput compared to rectangular | Allows more significant air leaks than in a round air duct due to the non-sealing of the channel |

In general, the option with a round cross-section is more popular, since it has another important advantage over the rectangular one. In a rectangular duct, the box in which the fan is located acts as a resonator - and thereby increases the noise it produces. Therefore, the round option is also preferable in this sense.