Standards and rules for placing gas pipes in an apartment

The transfer of a gas pipe is possible only with permission from the gas industry.

The rules for installing a gas main in housing are prescribed in the text of SNiP 2.04.08 - 1987.

Principles for locating pipeline sections:

- decoration on walls made of flammable materials is protected by plaster or metal panels;

- the shut-off valve cannot be removed from the pipe; it is located in an accessible place;

- the gas pipeline is painted in a contrasting color with the wall with waterproof compounds;

- laying in the thickness of walls and horizontal ceilings is done using a case with a shock-absorbing insert.

Devices and installations are connected to the gas pipeline with rigid fastenings. A technical specialist gives an opinion on the possibility of altering the gas distribution.

Underground

The distance from the house to the gas pipe in the embankment cannot be less than 5 m. There are special provisions of SNIP, according to which the distance can be reduced by 50%, but they are regulated by the characteristics of the terrain and the passage of the gas pipeline. For example, laying pipes between houses, arches, in very limited areas, etc.

The distance to the gas pipe from the outer walls of the well, chambers or other equipment of utility networks should not be less than 30 cm. Laying must be carried out in compliance with technical requirements and conditions. Only this can be a guarantee of safety. By the way, this is why independent transfer or organization of the gas supply system is not allowed.

The distance to overhead communication lines, as well as electrical external networks, cannot be less than 2 meters. The same applies to the gap between the gas pipeline and heat transfer channels. The distance from the gas pipe to the fence, taking into account the underground laying of the pipeline in villages, must be at least 50 meters. SNIP provides for a reduction in the gap, but only if certain standards prescribed in the regulations are taken into account.

The depth of laying the gas pipeline must exceed 0.8 m for highways and roads with heavy passenger traffic and 0.6 m for roads with low traffic.

Reasons for moving gas pipes

The reason for moving pipes may be their emergency condition.

The official program of government agencies allows for major repairs and replacement of gas main risers in old apartment buildings free of charge.

Reasons for work:

- gas emission was detected when the tap was closed (repairs are being done in the apartment);

- damage to pipes and welds is visually distinguishable;

- The service life has expired (for houses built more than 50 years ago).

Utility workers report a planned replacement of the supply pipeline, and the organization is developing a work schedule. Residents are given access to equipment within designated periods.

Repairs must not be prevented, because masters work with gas pipelines that are in common use and are on the balance sheet of the utility organization.

Redevelopment

Replacing pipes may be associated with the purchase of new furniture for the kitchen.

A frequent reason for altering the gas distribution in an apartment is the purchase of a kitchen unit that has a built-in heated panel or oven. For installation, it is necessary to shorten or lengthen sections of pipes in order to supply gas to the installation site.

It is recommended to contact a licensed design firm to draw up a plan for redevelopment, movement of equipment and laying a gas pipeline from the common input. In apartments, it is prohibited to move risers, slabs, and pipelines into rooms. Coordination is also necessary to combine the living room and kitchen.

Major renovation

Before starting repairs, housing and communal services inform residents about the inspection and the start of repairs. Carrying out dismantling and installation work causes discomfort for residents of the apartment. Residents are concerned that experts may damage furniture or finishes and are trying to negotiate additional agreements with contractors.

The organization invited to redo the gas pipeline is not required to draw up an agreement with the owners of each apartment. Owners provide access to the replacement site as part of the utility equipment replacement program. Residents do not have the right to refuse, so as not to provoke further emergency situations. In the absence of cooperation, the gas workers turn off the common tap on the riser.

Alteration of gas wiring

Flexible gas pipes cannot be carried by yourself.

Sometimes a gas pipe runs where kitchen cabinets are hung. The owners cut the back walls, make holes in the furniture, and move the cabinet away from the wall using spacer bars. Such actions entail a reduction in kitchen space. Specialists can weld the line at a different height from the floor so that furniture installation takes place without obstacles.

The area where the sink is installed may coincide with the installation location of the gas pipeline. Technical specifications (TU) do not allow laying a gas pipe under the sink, so the gas pipeline rises above the cabinets, and a vertical section is made above the stove.

Installation of a stove in a private house

The installation of a gas stove in a private home is not regulated by separate rules and regulations. It is not much different from placing an appliance in the kitchen of an apartment building. However there are a few additions:

- installation is allowed in a room with a height of up to 2 m inclusive, if it has a volume of at least 1.25 times greater than that specified in clause 6 of the section “Requirements for premises”;

- in a house without a dedicated kitchen, the volume of the room should be 2 times greater than the figure specified in paragraph 6 of the section “Requirements for premises”;

- if there is a sloping ceiling with a height in the middle part of at least 2 m, installation is carried out in the part where the ceiling height is at least 2.2 m;

- when installing the device outdoors, under a canopy, make barriers to prevent the flame from being blown out by the wind;

- The same requirements apply to the placement of gas stoves in summer kitchens as for ordinary premises.

The installation and location of gas boilers intended for heating and hot water supply are subject to increased safety requirements. They are reflected in SP 402.1325800.2018.

Preparatory stage

The flexible hose should also not be changed independently. Extending the length, cutting and moving the gas pipe in the kitchen is carried out by the organization. The owner of the property should also know the sequence and other features of the work in order to prevent illegal actions.

Usually 2 people work, who begin the rearrangement a week after the project is completed and approval is received. By the time work begins, there is already information about the areas that will be converted. There is a diagram of the new location of additional gas appliances, for example, a heating column.

General gas supply requirements

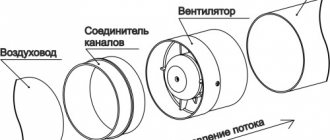

Correct connection of the gas hose

Pipes can only be installed horizontally or vertically; rotation is allowed at 90°. Laying diagonally or in a curved arc is not permitted.

Rules for running the supply line:

- internal wiring is carried out in an open way, decorative elements are made removable and with identification markings;

- It is prohibited to carry it through ventilation risers, window and door openings;

- rigid elements are used, the length of flexible hoses for connecting the plates cannot exceed 3 m;

- Pipes are connected by welding; detachable contacts between two sections are prohibited.

Work begins with shutting off the valve on a house or a certain area. The service provider is responsible for interfering with the gas supply.

Getting permission

Errors when moving pipes can lead to a gas explosion.

Illegal redevelopment or connection of slabs or water pumps will result in general administrative and criminal penalties, depending on the situation. The minimum fine is 2 thousand rubles, and if due to arbitrariness an accident occurs or people are injured, the culprit faces up to 5 years in prison.

The owner offers his own option for rearranging the pipe, and the technicians of their utility service allow or not the specified redevelopment. To call a specialist, the owner contacts the office at the place of registration. Sometimes it is necessary to involve additional companies, which will be reported by management employees.

Premises requirements

Gone are the days when tiny Khrushchev-era kitchens quietly placed four-burner gas stoves by the window, next to hanging curtains. Now the situation has changed . A new regulatory document has been approved and put into effect - SP 402.1325800.2018 “Residential buildings. Rules for the design of gas consumption systems."

It includes a number of requirements for premises in which gas stoves are allowed to be installed:

- purpose of the premises - kitchens, kitchen-dining rooms, corridors;

- ceiling height - at least 2.2 m;

- the presence of natural ventilation, an exhaust ventilation duct and a window with an opening sash or window;

- the door from the room opens outward;

- there is a gap of at least 0.02 m² between the floor and the door leaf (for air flow);

- minimum room volume: for two-burner stoves - at least 8 m³, for three-burner stoves - at least 12 m³, for four-burner stoves - at least 15 m³;

- window glazing area - at the rate of at least 0.03 m² per 1 m³ of room volume (glass acts as an easily removable enclosing structure in the event of an explosion).

These requirements apply to both free-standing and built-in devices.

Work order

If an oven or stove is connected, the owner purchases a bellows sleeve at his own expense. Craftsmen bring metal pipes with them, because... their cost is already in the contract estimate. The kitchen is cleared of unnecessary furniture and utensils to avoid delays in work.

The owner has the right to demand the provision of certificates from the gas organization. The workers' qualification certificates are checked and only after that they can begin re-equipping the gas pipeline.

Tools and materials

Copper pipes for gas pipelines

Cutting and welding sections of the gas pipeline is carried out using special devices, units and tools that the craftsmen bring with them. The work is carried out in accordance with safety requirements.

The following types of collectors are used for the gas main:

- copper;

- steel;

- polypropylene.

The materials are durable and have the required properties, ensure tightness and prevent leakage. Steel pipes are taken of the low-carbon variety St2, St4, which can withstand excess pressure. During major re-equipment, shut-off valves made of gray cast iron, steel, bronze and brass are used.

Dismantling an old pipe

The line in the working area is purged after closing the general valve on the supply pipe in order to remove remaining gas from the collector. When transferring, you need to cut off a piece of pipeline and weld a new section in the required direction. To remove an unnecessary section, the master uses welding, a pipe cutter or a grinder. Previously, a metal file was used, but in modern conditions it is time-consuming and ineffective.

An area is left where the shut-off valves at the entrance to the apartment are located. This section cannot be dismantled; the gas valve can be moved if the line in this place is severely damaged.

Change options

Gas pipes cannot be recessed into the wall - they must be constantly accessible.

The area around the pipes must be open so that residents know about the leak in time and take action. It is prohibited to recess pipes into the wall and seal them tightly with plaster or other materials.

Placed to fix the pipe:

- crimp clamps;

- hooks;

- mounting brackets;

- pins or pendants.

If electrical wiring runs nearby, it should be no closer than 25 centimeters. The electrical distribution panel is placed no closer than 0.5 meters from the gas pipeline. For the liquefied gas main, a slope of 3° from the entrance is provided. If there is a meter, the slope is calculated from this place.

Work process

Welding is used to connect pipe sections.

Rubber hoses or rubber-fabric products are used less frequently, because Bellows adapters are gaining popularity.

The following actions are performed:

- The hole is welded after trimming the area.

- At the point where the new section is connected, a hole is drilled in the pipeline using a power tool and a drill with a metal tip.

- A piece of pipe is attached by welding, and a tap is mounted at the end if necessary.

When connecting the tap, tow or sealant is used, and sealing tape is applied. After this, connection is made to the gas appliance with a flexible hose. Check for gas leaks using a soap solution.

Replacing the gas riser

During the procedure, there should be no strangers or smokers in the workplace. Before starting the replacement, the specialist will post a warning sign about the dangerous nature of the work. Simultaneous replacement of the riser and installation of wiring in the apartment is not allowed, because A spark can cause an explosion.

The type of riser welding is selected depending on the thickness of the main wall. More often, steel elements with a diameter of 21.3 - 42.3 mm, with a wall thickness of 4 mm, which are connected by gas or electric welding, are used for feeding.

Features of transfer in the kitchen

Gas pipes are located so that after installation there is the possibility of their repair, preventive inspection or replacement. The insertion into the pipe is carried out so that during chemical analysis the presence of oxygen in the gas mixture is no more than 1%.

Gas should come out of the pipeline evenly, without jerks, jolts or pops. The check is carried out by purging the system, and you need to make sure that during the process the gas does not enter the atmosphere of the room, ventilation shaft or chimney. Before the first start, window openings are opened to ensure effective ventilation of the kitchen.

Checking the entire system for leaks and operability

Leaks are checked using a soap solution.

The test is done after installation is completed, leaks and operability are diagnosed. First, the general appearance of the system is inspected, the connections are checked, the fittings are tightened, and compliance with the design diagram is checked. Gas emissions are detected at connections and assemblies.

A soap solution is used to coat the joints of pipes with a hose, the interface between a flexible hose and a stove or oven. If bubbles form, the node requires revision and re-diagnosis. The master draws up a report of completed work describing the features, changes are entered into the technical passport.

Coordination of work on moving a gas pipe

The owner contacts the gas service employees, explains the situation and receives advice. The application is drawn up and submitted in person when visiting the organization’s office. Based on this document, the company sends a specialist to discuss the details.

The specialist examines the system, correlates the client’s wishes with the actual situation, and answers questions.

Sometimes the customer’s plans are violated because his wishes go against safety regulations.

The organization draws up an estimate for the work and a plan for re-equipping the gas pipeline in the kitchen. The customer pays for the service, and the company approves the start of work.