Various internal communications are an integral part of any home today. Many of them can be hidden using ordinary drywall. There are special requirements for the maintenance of gas pipes in an apartment or your own home, because the life and health of people directly depends on it.

It is worth agreeing that the condition of gas pipeline communications must be treated with special responsibility. Therefore, the paint for them must be selected with special care, because it must protect the metal structure well from corrosion. True, gas pipes, painted according to the generally established standard, often spoil the design of the room.

We will talk in this article about when it is required to adhere to the standards established by law, and in what cases they are not required. From it you will also learn how to select paint for gas pipes and paint them. In addition, we will tell you the secret of how to correctly determine the required amount of paint for painting pipes.

Reasons why gas pipes need to be painted

They need to be painted not only for a beautiful appearance.

The main reasons why they need to be painted are:

- highlighting the gas pipeline with color from other internal communications;

- protection of metal from moisture, which significantly increases the service life of pipes.

The organization servicing the gas pipeline has the right to disconnect a residential building or any apartment in it if the gas pipes are in poor condition.

According to the standards approved by our legislators, all gas pipeline networks of high-rise buildings must be on the balance sheet of the housing and communal services. In individual apartments and individual houses, responsibility for their condition falls on the owner of the property.

Painting pipes in an apartment yourself - quickly and easily

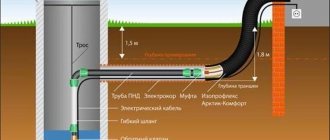

It is impossible to imagine modern residential buildings and industrial structures without all kinds of communications: water pipes, gas pipelines, cables, and so on.

Currently, many pipelines (for example, cold and hot water supply) are made of plastic. However, metal pipes continue to be used. To increase service life and improve appearance, these pipelines need to be painted. As a rule, the reasons for deciding to paint pipes are:

- Unsatisfactory condition of the pipe surface.

- Corrosion protection.

- Improving the interior of the room.

What is stated in the regulations?

They indicate the color that gas pipes should be painted. In accordance with the color standard cards, they must have yellow color N205-206 (GOST 14202-69).

Street sections of the gas pipeline must be painted one yellow color. Gas pipes may be painted to match the color of the house façade if the appropriate permit is obtained from the organization servicing the gas pipeline. The color of pipes inside housing is not regulated by regulations.

Special requirements for the color of pipes are not a special whim of gas workers. This is a special coloring that shows what substance is transported through the laid pipes. With its help, if a gas leak occurs, emergency service specialists will quickly find the problem and fix it, which will allow them to prevent a strong gas explosion or fire.

If the pipe is painted any other color, then in an emergency when the owner of the house is not present, emergency service specialists will be disoriented and will not be able to quickly fix the problem, which can lead to tragic consequences.

The “Safety Rules for the Gas Distribution and Gas Consumption System”, clause 2.3.9 PB 12-529-03 also states that paint must be applied to pipes in two layers. In this case, they must first be coated with a primer and other preparatory work must be done.

Regulatory documentation for identification painting of pipelines

In each industry, there are a number of regulatory documents regulating the issues of identification painting of pipelines, however, all these documents either refer to or repeat the requirements of the main standard for identifying pipelines in the Russian Federation - GOST 14202.

This unification of markings makes it possible to unambiguously determine the contents of a pipeline at any facility - from a small modular boiler house to a nuclear power plant and an oil refinery.

Exceptions to which the requirements of GOST 14202 do not apply are pipelines with medical gases, ship and aviation pipelines.

Persons responsible for painting the gas pipeline

There is always a responsible person. It is indicated in the contract concluded for gas pipeline maintenance.

In high-rise buildings, apartment owners are required to paint gas pipes. The street gas pipeline must be painted by gas service or housing and communal services workers.

In individual houses, pipes located on the land plot must be painted by the owner of the property. Pipes outside the site must be painted by specialists from the organization servicing the gas pipeline.

Color solution

What color should you paint gas lines?

According to the source of information (Safety Rules for the Gas Distribution System), painting occurs as follows:

1. A gas pipeline passing above the ground must be painted with two layers of yellow paint. Varnish and enamel of a similar color are also allowed. The dye must meet the requirements of the substance for work on the outside of the product. Color marking is necessary to identify an object.

2. The gas system, which runs over the facades of the structure, may have the color of the structures that enclose it.

Painting of internal gas pipeline structures inside residential premises and the color scheme for them are not provided at all.

Owner search

Who is responsible for painting the gas pipe?

Many people ask this question. Unfortunately, the person responsible for such a process has to be found separately in each individual case. In such cases, you must be guided by the gas pipeline line maintenance agreement.

In certain areas, responsibility is distributed in this way

:

1. In apartment buildings, pipeline lines inside each apartment must be painted by the owners of the apartments. Those gas pipes that run along facades, entrances or streets must be painted by the gas supply companies or local utility service (the terms of the service contract must contain such obligations). To divide the zone, you must be guided by the walls of the apartments

It must be taken into account that such duties relate only to painting pipes. But maintenance actions regarding the shut-off elements of the valves should be performed only by the gas service. 2

In private houses, the gas pipeline located on a private plot is painted by the owners of the house. The gas pipeline located in a public area was painted by representatives of the gas service. A gas pipeline that runs through the private territory of a house may be controlled by an organization that supplies gas, but then such an authority may require house owners to pay for the service of painting gas pipeline structures

2. In private houses, the gas pipeline located on a private plot is painted by the owners of the house. The gas pipeline located in a public area was painted by representatives of the gas service. A gas pipeline that runs through the private territory of a house may be controlled by an organization that supplies gas, but then such an authority may require home owners to pay for the service of painting gas pipeline structures.

Choosing paint for gas pipes

Gas pipelines and metal structures are often painted with alkyd paint. Designated according to GOST - PF-115. It is made from resin, so it has a certain viscosity.

It must be remembered that it does not have a very pleasant smell. Another important disadvantage is that she is afraid of fire.

Its main advantages: strength and resistance to adverse influences (moisture, aggressive substances, etc.). Another plus is the low price.

When choosing paint for painting pipes in your apartment, it is not necessary to pay attention only to the recommended compositions.

It is allowed to apply the following compositions to them:

- polyurethane paint - has a fairly elastic structure, excellent adhesion and a long service life;

- epoxy paint - has a long service life, although it is not elastic;

- electrically conductive substance - is the most reliable composition due to its good anti-corrosion characteristics and long service life.

Today there are paint compositions that can be applied directly to rust, although it is still recommended to first clean the pipes from it: first of all, you need to clean them of old paint and rust, then degrease the treated surface, and then apply a high-quality primer to it.

Paints for gas pipes are designated by a complex abbreviation, so the word “paint” is often not on their label, which makes it difficult for the average person to choose.

The most popular paints for gas pipes today are:

- Epostat is an epoxy enamel for metal with excellent anti-corrosion properties. It is able to withstand elevated temperatures and frosts, while sleeping quickly;

- Zinconol - reliably protects metal structures in all climatic zones, while having good adhesion;

- Nerjachim - protects metal products from corrosion. It can be applied to rust. It dries quickly;

- Polyurethol - for its application it is not necessary to pre-prime the pipes. It is resistant to acids, moisture and petroleum products.

The technology for painting gas pipelines is practically no different from applying paint to other metal structures. There is still one peculiarity - it is prohibited to use heating devices to remove a layer of old paint.

Identification painting of pipelines

Protective painting of pipelines

is the main way to prevent corrosion and aggressive environmental influences on the pipe material. The main task of protective painting is to prevent contact of the pipeline with the environment throughout the entire range of operating parameters of the pipeline.

A completely different, but no less important function is performed by a mandatory element of pipeline marking - identification painting of pipelines

. It is designed to quickly identify the substance transported through the pipeline and the degree of its danger.

Features of dyeing technology

Before painting these pipes, it is necessary to carry out preparatory measures.

First you need to clean them of old paint and rust with a wire brush. The use of solvents facilitates this procedure. To protect your respiratory system from harmful fumes, you must wear a respirator.

After cleaning the pipes, their surface must be thoroughly degreased. The consumption of the degreaser per 1 m² can be found on its label. Next, you need to apply two layers of primer to the pipes. This should be done with a brush.

Then you need to wait for the primer to dry, which takes 24 hours. If the room temperature is less than 15°C, it will take longer to dry. Then you need to apply paint evenly to the pipes so that drips do not form.

It needs to be applied in a thick layer. After the paint has dried, you need to apply the next layer. This painting technology allows for maximum protection of metal structures from corrosion.

Gas workers recommend painting gas pipes with yellow paint. True, this does not apply to pipes located in apartments and individual houses. They can be painted to match the design used in the home.

The pipe must be painted with a soft brush, and the coloring composition must be applied in small portions so that drips do not form. In this case, the brush must be held perpendicular to the surface to be painted. To apply paint to hard-to-reach areas of the pipe, you need to bend the brush. It is better to paint the pipe before wallpapering the walls or finishing with other materials.

When painting with alkyd paint, the second layer must be applied after 4-6 hours. Modern paint compositions can dry faster, so you need to look at their packaging for the exact time.

Formula for calculating the required volume of paint

There are no general standards for paint consumption for coating pipes. The container of any paint indicates how much is needed to cover 1 m² of surface. It is necessary to take into account that it must be applied in two layers.

The formula for exact calculation is:

S=π×D×L

D is the pipe diameter;

π is a constant mathematical constant (3.14);

L is the length of the pipe.

This formula is used when painting various pipes.

conclusions

GOST 14202-69 clearly states what color gas pipes need to be painted. Thanks to this, emergency services will be able to quickly find the source of potential danger and eliminate it, thereby avoiding tragic emergencies. In addition, with the help of high-quality paint it is possible to reliably protect metal pipes from corrosion.

What is this for?

Gas pipelines pose a potential hazard due to possible gas leaks and therefore require color coding.

It is used in industrial enterprises and when laying overhead networks.

Anti-corrosion coating of the gas pipeline.

For short communications and for external networks, continuous identification painting is performed. Marking areas are located at connections, branches, inputs and outputs of production facilities. The corresponding marker is present in the painting of gas pipes passing through the ceilings and walls of buildings.

In addition to its signal function, this finish provides anti-corrosion protection to metal surfaces. For this purpose, heat-resistant oil and nitro-enamel paints are used, resistant to temperature changes and the influence of precipitation.