Ventilation is the key to safe and efficient operation of equipment

Ventilation in the kitchen with a gas stove or boiler protects not only people’s health.

For high-quality combustion of gas, oxygen is required. If it is deficient, a lot of carbon monoxide and under-oxidized substances are released into the air during the combustion process. You can notice this by the yellow color of the flame, high with abundant soot.

The efficiency of gas equipment decreases - the same amount of fuel burns, but less heat is released.

An even greater danger is posed by natural gas itself, which can get into the air in the room, for example, if a draft blows out the fire on a burner, the gas supply hose to the stove cracks, or the gas boiler breaks down.

The choice of a gas ventilation system in a private house or apartment depends on the type of boiler and the characteristics of the boiler room.

Pros and cons of the two systems

Natural ventilation

To equip such a hood yourself you do not need any special skills, but it has a number of advantages:

- The absence of mechanisms makes such air exchange reliable and durable.

- There is no need to spend money on purchasing devices.

- Easy to use.

- Quiet during operation.

At one time, such a hood fully met its requirements, but with the advent of new gas equipment, the view on this changed.

The following significant shortcomings were discovered:

- Dependence of optimal air circulation on the season and climatic conditions.

- Inability to regulate air flow.

- Penetration of foreign particles through the system.

Purpose of ventilation

Boiler room ventilation consists of two functional subsystems: the influx of atmospheric air and the removal of flue gases from the heating boiler.

Purpose of the smoke exhaust system:

- Supply of oxygen in the air in the required quantity for complete combustion of fuel. Oxygen deficiency reduces the efficiency of the boiler plant due to losses caused by incomplete combustion of fuel. In addition, unburned fuel particles pass through the gas path of the boiler and smoke exhaust channels, causing premature wear of equipment surfaces, introducing soot into chimneys and polluting the environment.

- Removal of harmful flue gases formed as a result of the combustion process. If the technological rules for operating boiler equipment in terms of combustion modes are not followed, carbon monoxide enters the room with the formation of a dangerous concentration of harmful substances in the air, which is a threat to the health of others.

- Performs the functions of extracting a gas boiler in a private house in case of emergency leaks of flue gases or natural gas into the combustion chamber. This situation is possible in the event of a violation of the integrity of the gas pipeline, separation of the gas flame from the burner, as well as a drop in vacuum in the furnace.

Types of exhaust ducts for gas-fired boilers

A classic brick chimney has a decent mass; first of all, a strong foundation is built under it. It is better to calculate this at the stage of building a house, but sometimes it is necessary to equip old buildings with them. The surfaces inside are made smooth.

The stainless steel exhaust structure resists chemical and mechanical action. It is designed according to the sandwich principle: a smaller pipe is placed in a larger diameter pipe. The space between them is filled with non-flammable material - stone wool. Manufacturers recommend a variety of device models.

A ceramic chimney consists of some blocks that are mounted in a concrete frame. The system is equipped with thermal insulation, which is why it is not afraid of temperature fluctuations. It is strong, not afraid of fire and moisture. During installation, it is necessary to properly connect the modules.

GAS connection and chimney. movie - 22

In a coaxial hood, the smaller ventilation duct is placed in the middle of the larger one. One by one, the air necessary to maintain the combustion process is supplied, and the other, the combustion products are removed. The system has good safety and environmental characteristics, and increases the efficiency of the equipment’s workflow.

The selection of a chimney pipe depends on the specific situation. Any exhaust pipe for a gas boiler must comply with SNiP standards. They must be observed from design to installation, because an incorrectly installed design threatens the safety of people. The following requirements apply to products:

- good traction, ensuring complete removal of exhaust gases;

- resistance to high temperatures;

- impermeability of joints between individual elements;

- the presence of a condensate collector to remove liquid.

In structures with turns, hatches for inspection and cleaning are installed in such places. Branches to the side should not be longer than 1 meter, and the maximum number of turns is three. Joining of individual elements is not permitted at the passage of the ceiling. A gap of 5 cm is left between the pipe and the non-flammable surface, and if it is fire hazardous - 25 cm or more. The chimney must rise above the ridge of the roof for good draft. The hood provides natural ventilation of the room.

To install a forced system, a duct fan is used. It consumes electrical energy, so to save money it is installed exclusively on the exhaust or supply side. Grates are placed at both ends of the pipe to block the path for rodents and third-party objects. Automation will make it possible to turn on the device along with starting the boiler.

Requirements for ventilation in a boiler room with a gas boiler

When the power of a gas boiler exceeds thirty kilowatts, it is necessary to design a special room to house the boiler room. In this case, it is necessary to ensure SNiP standards number II-35-76. Among the main requirements:

- ventilation for a gas boiler requires an exhaust pipe outlet on the ceiling of the boiler room;

- the chimney channel must have a separate additional entrance for cleaning, located 250 mm lower from the main entrance;

- when calculating the area of the supply channel from the street per kilowatt of unit power, take 8 cm square of the ventilation grille cross-section;

- when organizing supply ventilation from adjacent rooms, the open cross-section of the grille should be thirty square meters. cm per kilowatt of boiler power.

Installation of a boiler hood

Exhaust pipes for gas boilers can be installed independently. In this case, it is necessary to be especially careful and carefully check the tightness of the connections. To install exhaust ventilation you will need:

- fan with check valve;

- lattice;

- air duct of suitable diameter.

Using a hammer drill, holes are made where the pipe enters the wall. Then they expand it to the desired size and insert the pipe. A fan is installed in it. All seams and cracks are filled with polyurethane foam. The last thing to install is the grille to give the structure a finished look.

Supply ventilation is installed according to a similar principle, only the fan should work in the opposite direction. The test is carried out indoors using a sheet of paper, which is applied to the inlet of the ventilation duct. With good traction, it should touch the grille. If a blockage occurs or the installation was performed incorrectly, the sheet of paper will fall to the ground.

Installation of a chimney for a gas boiler and turnkey ventilation in a frame house.

Watch this video on YouTube

Is ventilation necessary in a gas boiler room?

gas boiler room of a private house

Even a small amount of carbon monoxide can worsen the well-being of residents. Chronic fatigue, headaches and pain in the eyes are the least that people feel who often inhale combustion products. Leaks of explosive and flammable fuel are no less dangerous.

Poorly designed ventilation not only threatens the life and health of people, but also reduces the performance of equipment.

Operation of a gas boiler is possible with a constant supply of oxygen to the boiler and timely removal of combustion products. When there is not enough air, fuel burns worse. While consuming the same amount of gas, the boiler produces less heat in a poorly ventilated room.

Weak ventilation exhaust in a boiler room with a floor-standing gas boiler leads to the accumulation of burning and soot inside the equipment, the cross-sections of the air ducts are reduced, the draft worsens and some of the combustion products are drawn into the room.

Equipment for a gas boiler room in a private house

Gas boilers use air from the boiler room. If the boiler room is separated from the main house by wooden unsealed doors or has old-style windows, air entering through the cracks in the frames is sufficient. But if modern windows and doors are installed, air will not come in from outside. When fuel burns in the room, the air will be discharged and the efficiency of the boiler will decrease. The fumes from the boiler can go into the boiler room and from there into the living rooms. Therefore, it is necessary to think about how to ventilate the boiler room.

Principle of operation

The principle of operation of ducted supply ventilation

The equipment is an installation of exhaust or supply ventilation for processing air flows and supplying it to the boiler room. The device is a component of the heating system and is often connected to a central pipe. The air comes directly from the street or through the air ducts. A complex system consists of metal boxes or pipes, between which functional devices are mounted. External elements are protected from atmospheric action.

Working elements of the system:

- A fan with a two-phase electric motor supplies air to the boiler room or to the common air duct.

- Filters purify the air using coarse types or the method of electrostatic sedimentation. Coarse elements are placed in front of thin filters, protect them from damage and are easily replaced.

- Heating or cooling devices change the temperature of the incoming stream. Heat pumps, electric heaters or evaporators are used.

Balancing devices, shock absorption and sound insulation in the system eliminate vibration and reduce sound during operation. The vibrations are isolated and damped by obstacles, and the fan is placed on spring supports.

Requirements for ventilation in a private house with gas

Wall-mounted gas boiler

In addition to the presence of ventilation, special requirements are imposed on the premises of a gas boiler room.

The boiler room may be equipped with:

- in the extension to the cottage;

- in the attic;

- in a separate building;

- in a specially designated room.

If the equipment is designed for liquefied gas, the basement or basement will not be suitable. Liquefied gas has a higher specific gravity than air. Therefore, when there is a leak, it sinks to the lowest parts of the house and here it can explode. This feature of the fuel must be taken into account before ventilating the boiler room.

Low-power gas boilers (no more than 30 kilowatts) do not require a special boiler room; you can hang or install them in the kitchen if the room meets the following requirements for ventilation of the boiler room of a private house:

- area from 15 sq. meters;

- ceiling height at least 2 m 20 cm;

- window area from 3 sq. cm per 1 cubic meter of room volume;

- the window opens or is equipped with a window;

- for the flow of air from neighboring rooms, holes are made in the lower part of the door;

- the equipment is installed near a wall made of non-combustible material at a distance of at least 0.1 m.

According to the requirements, supply ventilation in a boiler room in a private house is required. If the equipment power is above 30 kilowatts, a separate boiler room is installed.

Other requirements when calculating a chimney

Let's consider other requirements that must be observed when calculating the chimney duct for a gas heating device

- The smoke exhaust pipe for a device operating on gas must end in a vertical pipe. This is a necessary rule for the normal removal of combustion products;

- in such communication a certain inclination is allowed (up to 30°). The deviation of the chimney pipe to the sides should be no more than 1 m;

- the cross-sectional indicator of sections located at an angle should in no case be less than the similar parameter of vertical pipes;

- the cross-sectional indicator of the channel must be no less than or exceed the same parameter of the exhaust pipe of the heating device;

- the chimney segment, located in a horizontal plane, must have a slope towards the boiler (2 cm per 1 m of channel length);

- horizontally located segments of the smoke exhaust duct must be equipped with inspection windows (revisions);

- at the lowest point of the vertical communication, a connecting element must be installed - a tee, equipped with a hole for removing condensate;

- round chimneys have minimal resistance and provide the highest quality removal of combustion products from gas heating equipment;

- the presence of chimney joints at the level of interfloor ceilings is strictly prohibited;

- At the turning points of the system, as in the case of horizontal sections, it is necessary to install inspection hatches.

For a chimney, it is important to avoid a large number of bends and turns; there should be no more than three bends

Note! The maximum number of connecting elbows for chimney communication is three.

Guided by the above rules, you can perform a high-quality installation of a chimney structure for a gas heating unit.

Gas boiler room ventilation standards according to SNiP

Exhaust fan

All requirements for ventilation of a gas boiler room are set out in SNiP 2.04.05, II-35.

- There must be ventilation in the gas boiler room; the air duct outlet is located on the ceiling;

- Near the chimney channel, another one is made, 30 cm lower. It serves to clean the chimney;

- Air flow is provided from the street through a ventilation duct or from the adjacent room through openings in the lower part of the door;

- The air flow for ventilation is calculated based on the boiler power: inflow from the street: per 1 kilowatt of power - from 8 sq. centimeters of air;

- influx from the neighboring room: per 1 kilowatt of power - from 30 sq. centimeters of air.

The remaining rules for equipping a boiler room in a private house can be found in the relevant regulatory documents.

Conclusions and useful video on the topic

The video will introduce you to the basic requirements of gas services for the ventilation equipment of boiler houses in the Russian Federation:

Installation of exhaust equipment requires precision. But you need to understand that each gas service has its own interpretation of norms, standards and laws.

Before installing the heating equipment of a private home and the ventilation system in a gas boiler room, it is better to consult the gas service from which you will have to obtain permission for commissioning.

Tell us about your own experience gained during the installation of a gas boiler room. Share the technological nuances that helped you create a trouble-free air exchange system. Please leave comments in the block form below, post photos related to the topic of the article, and ask questions.

Natural ventilation with gas boiler

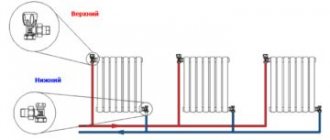

Scheme of natural ventilation of a gas boiler room.

Usually, natural draft is used to ventilate the gas boiler room of a private house. So, with a boiler with a power of up to 30 kilowatts, a vent with a diameter of 15 cm is sufficient for the influx. A plastic pipe is inserted into the vent, and the entrance is covered from the outside with a metal mesh to prevent the penetration of rodents and debris. Inside, a check valve is attached to the pipe, which prevents air from being drawn out into the street.

The hood is also done. An umbrella is attached to the upper end of the exhaust pipe to protect from rain and snow. Some craftsmen also install a check valve on the exhaust pipe to prevent air from entering the house through it.

To ensure that clean air enters directly into the combustion chamber, the supply air duct is installed behind the fuel compartment. The exhaust pipe is placed directly above the boiler, where combustion products rise.

The above ventilation device for a boiler room in a private house is very simple to implement and in most cases quite effective. But the system cannot be controlled and this is its main disadvantage. According to SNiP ventilation in the boiler room, the air must be renewed three times per hour. It is impossible to calculate the air exchange with the natural ventilation system of the boiler room. In addition, air exchange depends on pressure, outside air temperature and wind strength.

Tips for use

For normal operation, clean and inspect it before each heating season. It is possible to replace some parts and elements. Deterioration in functioning is associated with a decrease in the useful diameter of pipes and the emergence of new air routes. For example, through open doors and windows.

Natural systems fail under strong winds and sudden pressure changes. Another reason is the difference in temperature outside and in the extension. Therefore, they need to be compensated by compulsory devices. Check for normal rotation speed of the impeller. The first sign of a malfunction is the appearance of noise.

Incorrect operation of air exchange leads to a decrease in heating efficiency and interruptions. This may be one of the failure factors. Check for tightness and absence of dirt and debris.

Chimney for ventilation of a gas boiler room

The correct chimney for boiler room ventilation

A chimney is one of the most important elements of a competent ventilation system for a boiler room in a private home. Therefore, its design needs to be discussed separately.

SNiP ventilation in the boiler room are also developed for chimneys:

- The chimney does not allow gas and fumes to pass through. No combustion products should enter the air in the boiler room. To increase the tightness of the chimney, some owners plaster it or insert asbestos-cement inside the metal pipe. Its diameter depends on the power of the boiler;

- The chimney pipe must extend beyond the level of the ridge so that the draft is sufficient. The chimney outlet must rise above the roof ridge by 2 - 5 meters, otherwise suction is possible;

- The diameter of the ventilation chimney in a gas boiler room must be larger than the diameter of the chimney of the boiler itself and depends on its power. You can use the following proportions: with a boiler power of 24 kW - diameter 120 mm;

- at 30 kW – 130 mm;

- at 40 kW – 170 mm;

- at 55 kW – 190 mm;

- at 80 kW – 220 mm;

- at 100 kW – 230 mm.

For those who decide to equip the ventilation of the boiler room of their own private home with their own hands, simple rules will help:

- the cross-section of the chimney pipe is indicated in the boiler passport;

- the chimney is made of sheet metal (galvanized or stainless steel). The chimney has a circular cross-section of the same diameter along its entire length and an inspection window for cleaning;

- the chimney should have no more than three turns or bends.

Necessary calculations

Accurate and competent calculation of ventilation is an important stage in the design of a heating system. Professional engineering calculations take into account the dimensions of the furnace room, technical characteristics and location of equipment installation. Designing a boiler room for a private house is simpler. The following parameters need to be defined:

- Geometric dimensions of the room (length, width, height).

- Air flow speed. It should not be less than 1 m/s.

- The coefficient of air exchange enhancement, determined by the difference between the permissible room height (6 m) and its actual value.

Having determined them, you can calculate the optimal diameter of the supply and exhaust ducts of the ventilation system. For a room with dimensions of 4 × 3 × 2.8 m (length, width, height), the calculations look like this.

- By multiplying the parameters of a room, its volume is calculated. It is equal to 33.6 m3.

- The coefficient of increase in air exchange in the boiler room is determined: (6 - 2.8) * 0.25 + 3 = 3.8.

- The volume of air that must be replaced within an hour is found: V = 3.8 × 33.6 = 128 m³.

- The cross-sectional area of the channel that the exhaust ventilation in the cottage boiler room should have is calculated by the formula: F = 128/3600 = 0.035 m2.

- The resulting area value is converted into diameter, since in practice round-section ventilation pipes are more often used: D = 2 sqrt (S / π) = 211 mm.

DIY installation

Proper design of a boiler room ventilation system includes three mandatory stages: preparation of a technical project, installation of equipment and performance testing. When planning, the performance of the ventilation unit, the length of the air ducts and the thermal output of the boiler are taken into account. When installing air ducts, you must remember that their location depends on the type of air exchange used. Horizontal pipes should only be installed in forced-air systems. Moreover, their length is related to the power of the installed equipment. In any case, the channels must be straight, without bends or turns. Natural systems are allowed to be equipped only with vertical aerial types, the length of which cannot be less than 3 m.

Having completed the installation of the ventilation and heating system of a private house, it is necessary to check the functionality of all its functional elements. It is necessary to make sure that there are no coolant leaks, reverse draft and heat losses, to measure the efficiency of the boiler and the concentration of carbon monoxide in the combustion chamber. To ensure the reliability of measurements, they should be carried out only 24 hours after starting heating and air exchange. In order to increase the safety of the boiler room and effectively remove combustion products from it, it is useful to additionally use fire ventilation and a special smoke control system.

Prices

When installing turnkey ventilation, the cost of qualified preparation of boiler room design documentation and installation work depends on the size of the house, the type and characteristics of the heating equipment used, the type of air exchange, automation, and so on. The implementation of the first service averages 55 rubles per 1 m2, and installation itself in a building with an area of 100-800 m2 will cost 25,000 - 33,000.

Main technical characteristics and prices of the most popular air handling units:

| Model name | Max. air flow, m³/h | Heater power, kW | Dimensions, mm | Price, rubles |

| GlobalVent Economy-300 | 400 | 2,7 | 220x640x435 | 35 300 |

| 2vv Alfa-C-20VS-DP-2 | 2000 | 32,8 | 618x468x1200 | 172 300 |

| A-Clima ARL BOX 2.5 | 1970 | 34 | 1500x800x370 | 106 200 |

| GlobalVent Economy-1500 | 1900 | 11,1 | 390x770x635 | 63 900 |

| A-Clima Arl Box 1.5 | 1635 | 28 | 1270x670x370 | 103 900 |

| DVS OTA 160/5000 | 376 | 5 | 490x1000x490 | 42 500 |

Chimney outlet of a heating device in a private house

Chimneys and their installation require a specialized approach and compliance with certain requirements. The walls of the chimney are usually made resistant to temperature changes, corrosion and chemical compounds.

The hood for boilers in a private house must meet building regulations:

- SNiP 41-01-2003 “Ventilation and heating of residential premises.”

- SNiP 42-01-2002, 42-101-2003 “Recommendations and requirements for gas distribution complexes”

Thus, while maintaining these legislations, it is necessary to ensure that smoke removal corresponds to the required air exchange and air safety. And to do this you need to calculate the height and cross-section of the chimney and air duct. During installation, the following conditions must be observed:

- the pipe must be positioned strictly vertically;

- rise above the roof ridge no more than 0.5 m;

- the total height of the vein channel is no more than 5 m;

- The joints in the channel are insulated with heat-resistant sealant.

If the above requirements are met, you can install the ventilation pipe for the heating device yourself.

Installation of an open chimney system, taking into account the diameter

The standards governing the installation of this chimney exhaust option for a gas boiler are as follows:

- the chimney pipe should not have more than three elbows and not have many bends;

- the material used for the structure must be non-flammable;

- it is very important to equip the chimney with thermal insulation in order to reduce the amount of condensate that appears in it;

- a special hole with a damper should be installed in the pipe section, which is necessary for periodic cleaning of the system;

- another hole should serve to collect condensate;

- the height of the gas boiler chimney, as well as its diameter, must correspond to the parameters specified in the instructions for the equipment;

- the location of the open chimney must be strictly vertical, with a maximum permissible deviation of 30°;

- to prevent various external debris and precipitation from entering the pipe, it is necessary to equip a special protective cone-shaped umbrella at its end;

- the minimum height of the pipe above the ridge of a gable roof should be 0.5 m. If the roof is flat, this distance should increase to at least two meters.

Fire-resistant materials should be used as thermal insulation for a vertical chimney, such as, for example:

- brick;

- asbestos cement;

- lime based solution.

In addition to thermal insulation, the pipe should also be equipped with gas insulation so that combustion products do not pass through its walls. This will protect residents from poisoning and increase the safety performance of the equipment. It is extremely important to equip all chimney joints as tightly as possible.

You can build an open chimney system using one of the following methods:

- Brick chimney

. This material is widely used for various buildings, but it is least suitable for this particular system due to the fact that combustion products negatively affect the integrity of the brickwork, which inevitably shortens the service life of the entire structure. - Chimney made of steel sheets

. This material is perfect not only for the external, but also for the internal decoration of the walls of the chimney pipe. - Aluminum sheets are no more popular than steel

. They can also be used to equip the internal space of the system. - Enameled pipes

. Often, such material already has built-in thermal insulation, so if you use it as the main material, you will not have to additionally insulate the chimney.

Types of ventilation systems

The circulation of air masses in the room is natural or forced. The first is used for boiler units with a thermal power of up to 30 kW, if such a system is provided for this modification by the manufacturer.

The second scheme is installed in more powerful boilers with developed heating surfaces, several circulation circuits and a large length of smoke ventilation ducts. Such a heat supply system has large aerodynamic resistance along the path of the gas-air mixture, which the flue gases will need to overcome.

In this connection, their movement can only be ensured by force using a blower fan or smoke exhauster.

Natural

The least effective system, and at the same time simpler, is installed in one-story houses of a small area with low-power boilers. It is often used to organize air exchange in basements, attics, utility rooms and garages.

Natural exhaust in the boiler room

The intake of air masses in the furnace room is carried out through vents, window openings, ventilation grilles in the door panels, and exhaust ventilation is carried out through air ducts located at the top of the walls or in the ceilings with an outlet above the roof.

A professionally executed ventilation system changes the entire volume of air in the combustion chamber to fresh air. To do this, the inlet and outlet air holes are located opposite each other.

For example, the boiler unit is placed directly opposite the entrance, and the exhaust vent is located above the boiler. Air masses move from below, pass through the entire combustion chamber and go up to the hood. The window can be on any wall.

It is not recommended to place the air duct outlet near the boiler. In winter, a sharp drop in outside air temperatures can affect the operation of the boiler, which is why the hole is made at a distance of at least 1-1.5 m from the area where it is located.

Forced

Turbocharged heating devices or forced circulation boilers are installed only according to the recommendations of the equipment manufacturer. They are produced with closed combustion chambers, and the air is supplied by blowing centrifugal fans.

To increase the efficiency of boiler equipment and its repair, modern boilers are equipped with a combined air supply system using air filters, a heater, for air preheating and fans.

For gas boilers of higher power, smoke exhausters are additionally installed, which create a vacuum in the firebox, thereby forcing flue gases to move through the flues.

Innovative domestic boilers with a closed firebox, using gaseous fuel, are equipped with automation with a weather-dependent control and safety system.

It sets the mode depending on the outside temperature, and therefore regulates the supply of gas fuel volume. This function must be consistent with the amount of air entering the boiler to ensure complete gas combustion.

To ensure consistency between thermal engineering and aerodynamic processes, primary sensors for the temperature of the heating water and draft pressure in the combustion space are used.

Thus, the actuators in the fuel opening/closing mode will operate in proportion to the air flow entering the burner device.

Stainless metal exhaust pipe

Steel chimneys are available in different versions. A single-wall pipe is placed in brickwork. A similar scheme is also used for the restoration of a channel that worked with a boiler using solid fuel elements. Assembled from ready-made factory sections, each of them consists of an outer shell and an inner one. The space between them is filled with thermal insulation material. Such structures are intended for installation inside or outside the house. Specialized construction channels are not needed.

To protect the structure from destructive processes caused by acid that appears from sulfur contained in exhaust gases, a special stainless metal is used. The cost of similar structures is higher than brick and ceramic ones, but they have significant good qualities. They are assembled from some modules, the walls are perfectly flat and smooth, easy to clean, and not prone to condensation accumulation. Light weight does not require a base. To clean the channels that are inside, it is disassembled into its component parts.

The material is non-flammable and will withstand the temperature of the outgoing smoke. The factory configuration takes into account the expected purchase of tees and elbows, which makes it possible to create any configuration at the required angle. To make a chimney in an already built house, no major alterations are required, even if it is not included in the project. Can be attached to the wall. The diameter of the internal channel is selected to match the size of the hole for the gas boiler outlet.

The external placement of a single-wall structure leads to very high condensation formation, which interferes with normal draft. To avoid bad consequences, it is placed in a brick channel or a sandwich model with thermal insulation is used. In order to reduce the cost of such products, steel coated with a layer of zinc is used along with stainless steel. The inner tube has a thickness of 0.5–0.6 mm. Two-stage devices are more economical than other metal hoods due to good thermal insulation and do not require the construction of an external brick channel.

The ventilation column accumulates in this order:

- start from the lower segment, installing one pipe into another;

- suggest a large number of invisible hatches;

- holders for wall mounting are installed every 1.5 m;

- the length of horizontal sections cannot be more than 1 meter without mechanical ventilation.

When purchasing a double-circuit model, attention is paid to the material of the pipes. For the interior, only stainless steel is allowed, galvanized metal is not suitable

At a temperature of just over 400°, it begins to oxidize and toxic fumes appear. High humidity makes the situation worse. A similar design is very easy to make with your own hands. For insulation, basalt-based wool, expanded clay sand, and polyurethane are used.

How to choose material for the hood

To solve such problems, brick, stainless, galvanized steel or ceramic material is used. Let's analyze each of them in more detail.

Coaxial ventilation

This gas boiler hood in a private house consists of a short outer and a long inner pipe. In addition, it includes all sorts of accessories: clamps, elbows, gaskets, as well as a condensate receiver. This design is also called “pipe in pipe” and is used in gas heating appliances with a closed combustion chamber.

The design and principle of operation are the same for all boilers of this type:

- The pipe located inside is connected on one side to the boiler pipe, and its other side is led out to the street and combustion products exit through it. It is made of stainless steel and can withstand high temperature changes.

- The pipe, located outside, is connected at one end to the inlet, and the other end is taken outside the room. Fresh air enters through this channel.

- During operation of the unit, the exhaust combustion products are discharged outside due to draft through the internal channel, and at the same time fresh air is supplied to the combustion chamber through the external channel.

This coaxial device has the following advantages:

- The chimney is safe. This is possible because the escaping hot combustion products are immediately cooled by cold air coming from outside.

- Increased productivity. Fresh air heats up when supplied and increases the efficiency of the unit.

- Environmental friendliness of the system.

- Installation in the kitchen. Such a wall-mounted heating device does not spoil the overall interior of the room.

Another feature of installing such boilers with coaxial air circulation is that in a private home, the chimney can be installed both vertically and horizontally.

Brickwork

Nowadays brick is used less and less for ventilation shafts.

This is caused by two main reasons:

Firstly , due to its fragility, after 7-10 years the brick begins to crumble, and the masonry loses its tightness, which means it loses its purpose. It is destroyed due to the fact that the temperature in the channel changes and as a result condensation forms, which freezes in winter. It is more acceptable to make chimneys from this material when the walls are constantly in contact with hot waste.

Secondly , brickwork is a labor-intensive process; such a ventilation duct has a complex design and unjustified costs.

In this regard, a better option would be a brick shaft with a galvanized pipe inside for ventilation. It is assembled in parts from 2-meter contours, and the thickness of the walls is selected taking into account the temperature of the exhaust gases.

Steel hood

The exhaust gas during operation of a gas boiler has a temperature of about 430 degrees, and even more when operating solid fuel boilers. Therefore, the exhaust pipes for a gas boiler in a private house are made of stainless steel with a wall thickness of 0.7-1 mm. These products are quite stable to the action of condensation on the surface of the walls.

It should be noted that the service life of these ventilation pipes is significantly shorter than that of brick and ceramic ones. At the same time, standard steel hoods are easier to replace because they are lighter and do not require specialized foundations to provide strength.

Such channels are manufactured in different versions:

- Placement in a specially laid brick well;

- From factory circuits. In this case, each circuit is a sandwich pipe with two walls. Here one pipe is located inside another, and the gap is filled with heat-insulating material.

The use of such hoods simplifies installation, and they can be mounted both indoors and outdoors.

Ceramic gas outlet

This is the most versatile design that can be used with all types of boilers. The material is resistant to aggressive products formed during combustion. It is necessary to take into account the highest temperature for which the products are designed. For solid fuels, you need models that can withstand 600°; for boilers running on gas, 450° is sufficient. First of all, they provide for the installation of a condensate drain.

Ceramic pipes are installed mainly in brick structures or hollow cinder blocks. If they have two holes, one of them is used for ventilation or oxygen supply for a burner with a closed fuel chamber. The pipes are insulated with mineral wool to reduce the appearance of moisture and increase draft. Models are sold in a steel case. They can be placed in the middle of the house without the construction of specialized channels.

The smoke exhaust duct consists of individual elements 0.5–1 m long. On the upper part there is a coupling into which the next section is placed. Various product options are available:

- 1. Round for installation in concrete blocks. They have a cavity where a pipe and an asbestos seal are placed. To connect the components, reinforcement is placed in the holes.

- 2. With right angles for installation in brickwork. Their size is 20×20 cm.

- 3. With steel body. The pipes are connected with clamps.

- 4. Integral design with sleeve. It has ventilation channels and holes for installing fittings during installation.

The use of ceramic pipes for gas exhaust without enclosure and thermal insulation is not possible. They strongly absorb moisture, so a shell on the outside is required.

Air duct materials in gas boiler houses

Properly selected material for the air duct ensures longer operation of ventilation.

In accordance with current standards, the following can be used as a material for organizing the ventilation of rooms with gas equipment:

- brick;

- ceramics;

- asbestos;

- galvanized and stainless steel.

It is not advisable to use plastic for air ducts, because... this reduces the fire resistance of structures. Some regulations (for example, paragraph 7.11 of SNiP 41-01-2003) indicate that air ducts can be partially made of flammable materials.

When using plastic elements, you must remember that the presence of flammable elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employees

Regardless of what material is used, all ventilation ducts passing through cold areas must be insulated. In these places, draft may decrease, condensation may form, and the ventilation duct of a boiler room with a gas boiler may freeze and stop performing its functions. That is why it is better to stretch pipes along a warm circuit, eliminating the possibility of them freezing.

Brick exhaust ducts

Brick is not durable because... due to temperature changes, condensation forms on its surface, leading to the destruction of the material. If brickwork is taken as the material for the shaft, then the chimney is assembled from single-circuit galvanized metal pipes, the thickness of which depends on the temperature of the gases emitted.

Ceramic ventilation pipes

Air ducts made of ceramics are universal, easy to use and durable. The principle of their assembly is similar to the technology for constructing ceramic chimneys. Due to their high gas density, they are resistant to severe pollution of various types and aggressive chemical environments.

But in such hoods it is necessary to install condensate drains, because... ceramics absorb moisture well. Structurally, such a hood consists of 3 layers:

- ceramic inner layer;

- middle insulating layer of stone and mineral wool;

- outer expanded clay concrete shell.

This ventilation system cannot have more than three elbows. A drip and inspection are installed at the bottom of the ceramic chimney.

Steel air ducts

Steel exhaust ducts are convenient and practical.

A metal chimney in a gas boiler room can have a rectangular or round shape in cross-section, but in this case the width of one side should not exceed the width of the other by 2 times

When installing a steel ventilation system, you must adhere to the following recommendations:

- The collection of segments is carried out using the “pipe to pipe” method.

- Wall brackets are attached in increments of no more than 150 cm.

- The length of horizontal segments should be no more than 2 m, if the system does not provide forced draft.

According to standards, the thickness of steel walls should be at least 0.5-0.6 mm. The temperature of the gas produced by boilers is 400-450 0C, which is why thin-walled metal pipes can quickly burn out.

Ceramic hood

It should be appreciated that a ceramic channel is an ideal solution for all types of boilers in a private home. This material is resistant to high temperatures. It is also neutral towards toxic chemical compounds that can be formed during the combustion of various fuels. Ceramic hood channels are mainly arranged vertically in modules with one or two recesses.

In the latter version, the second channel is used to ventilate the boiler room or to supply air to the boiler burner. Typically, such sandwiches are insulated with mineral wool to protect them from cooling and condensation. In addition, natural draft increases in an insulated pipe. When installing such a ceramic hood, there must be a gap for free passage of air between the insulation and the surface of the well.

On the building materials market you can find sets of ceramic hoods in a metal casing. This model does not require ventilation gaps and is mounted on a heating device both inside and outside the house. They can be operated with exhaust gas temperatures up to 450 degrees.

At the same time, ceramics absorb moisture well, so they usually have a tray to collect condensed moisture. And the channel itself is provided with free access for airflow. Thanks to the smooth surface in the pipe, it is resistant to contamination and easy to clean during maintenance.

To operate solid fuel boilers in a private home, pipes are used that can withstand temperatures of 650 degrees. In addition, they must be neutral to soot combustion and operated in a dry condition.

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (clause 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If during commissioning tests defects in the ventilation system and technical inconsistencies with the design documentation are revealed, commissioning of the heating system will be refused.

The Gas Inspector's responsibilities include visual inspection of equipment, safety functions, controls, and carbon monoxide monitoring. If necessary, the owner of the premises may require the inspector to provide certificates-permits to work with an anemometer or SRO

Ventilation provides a constant intense flow of fresh air. The operation of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These legal acts include:

- Federal Law No. 384;

- Government Decree No. 1521 on ensuring mandatory compliance with 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on safety measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, so when installing ventilation equipment for a gas boiler room, you should monitor their latest editions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified with the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SP:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Project documentation must be drawn up on the basis of these regulations. To ensure that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the project development stage.

Certification of ventilation equipment

When purchasing exhaust and fresh air supply devices, you should check their documents. A declaration of conformity must be issued for ventilation equipment sold in the Russian Federation.

This document confirms that the devices comply with all current requirements of the Customs Union set out in the following technical regulations:

- TR CU 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of the product and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler room. It indicates all technical characteristics of the product

But voluntary certification requires additional capital investments, so they often save on it. In accordance with Federal Law No. 313 and Government Decrees No. 982 and No. 148, mandatory certification of ventilation equipment has been abolished.

Metal, ceramic or coaxial chimney?

In a private house, chimney pipes for gas-fired boilers can be metal, ceramic or coaxial. The preferred type of flue pipe material that is suitable for use with a particular boiler is usually indicated by the manufacturer in the technical documentation.

Chimney device

The most common option is a metal chimney that can withstand an operating temperature of 800 degrees. Typically, the pipes of such chimney structures are made of stainless steel; ferrous metal coated with zinc can also be used as a manufacturing material.

In general, the standard design consists of several components: the inner layer of the chimney is made of stainless steel, on top of which there is a layer of heat-resistant basalt wool and a thin iron casing. The advantages of metal chimneys include high resistance to mechanical damage, as well as increased reliability and a universal, presentable appearance.

Ceramic chimney pipe

Ceramics, which can withstand up to 1200 degrees, are in slightly less demand among consumers. The structure also consists of three layers: a ceramic component, a layer of insulation and a hard shell of expanded clay concrete. Chimneys made from this material are distinguished by their simplicity and reliability, ease of installation, as well as high fire safety.

The coaxial chimney is valued for its presentable appearance and fairly high performance characteristics

In general, this type of construction has a somewhat specific shape, due to which it has an important advantage - condensation does not form on its internal walls. This property is very important for gas equipment, so when choosing a suitable material you should consider purchasing a coaxial chimney

Diagram: coaxial chimney device Attention! Brick pipes are suitable for solid fuel, not gas equipment. Therefore, for gas boilers, an old brick chimney must be converted by inserting a liner made of metal, followed by insulation.

Recommendations for individual rooms

When installing any ventilation in a private home, air flows are arranged in such a way that clean street air first flows into the living room, bedrooms, study and library.

And then along the corridors he must go to the kitchen, bathroom and pantry with access to the exhaust ventilation shaft.

To ensure unhindered natural air flow through the cottage, all interior doors must have a clearance of 2–3 cm between the door leaf and the threshold

If the cottage is wooden, then an additional hood should also be provided in the bathroom. The humidity in this room is high, it will be difficult to get by without an exhaust fan.

In the kitchen, in addition to the ventilation hole, it is recommended to additionally install a hood above the stove in the ventilation duct. It will allow you to quickly remove cooking odors, preventing them from spreading to other rooms in the house.

A separate point is the boiler room and kitchen with gas equipment. They must be equipped with a separate channel for air flow directly from the street. Plus, don't forget about the chimney.

This will ensure that oxygen for combustion enters the firebox in the required volume, and carbon monoxide will immediately leave the room.