No matter how well the chimney laying work is done, time takes its toll, and even the most reliable buildings are unable to resist its influence.

Brick chimney repair

If the first pathological signs of deformation, shedding, or cracking appear, it is best to immediately take measures to eliminate them, otherwise fatal destruction of the pipe will further occur, and then it will have to be rebuilt. In other words, repairing a brick chimney becomes an urgent task.

Chimney repair work can be varied - from sealing small cracks to dismantling the entire structure and erecting a new one.

Causes and consequences of chimney destruction

The causes of chimney destruction can be artificial or natural. The first group includes poor-quality masonry (failure to comply with construction plans and rules), cheap materials, and violation of operating rules.

Because of this, for example, condensation can form in the chimney duct, which will accumulate, freeze in winter and destroy the pipes. The destruction of the masonry will worsen the draft and render the fireplace or stove completely unusable.

Natural causes of destruction include physical aging of the structure or a natural disaster, which a person cannot influence in any way.

When is a major overhaul necessary?

The need for a major overhaul of a brick chimney is indicated by the following points:

- The presence of extended cracks in the brickwork of the stove and sections of the chimney in the room.

- Destruction of the outer pipe masonry, crumbling of bricks.

- Significant reduction in thrust without visible air leakage from outside. This indicates serious destruction of the internal part of the chimney masonry, its clogging with combustion products or external debris.

Note! If the destruction of bricks in the chimney exceeds 15-20%, then the pipe requires major repairs. For steel pipe, the need for major repairs is indicated by the failure of one or more sandwich segments.

In what cases is repair necessary?

Repairs cannot be delayed if:

- there is obvious destruction of the outer part of the structure;

- numerous cracks in the masonry, cracks in the foundation;

- poor traction;

- blockage of the oven chamber with mortar or brick;

- severe blockage of the channel.

Repairs are required immediately so as not to worsen the situation.

Pipe condition assessment

The condition of the pipe is assessed after the inspection, when all possible defects are identified, the dimensions of the chimney are specified, if there are no drawings, the performance of the gas boiler, fireplace, etc. is checked.

In difficult cases, it is worth resorting to the help of experts, and in order to prevent this from happening, you should regularly conduct a visual examination yourself.

More details about assessment and diagnostics are written in the set of rules for construction and design SP 13-101-99.

What to do to make your chimney last long

The long service life of your chimney largely depends on following simple rules for operating the stove:

- The stove should be heated regularly, avoiding overheating. It is better to split the firebox twice a day, at regular intervals. This way the room will warm up more evenly, and the chimney will not have time to cool down or freeze.

- Use dry firewood or high-quality coal. For example, burning raw pine wood greatly increases the contamination of the chimney with soot.

- Regularly inspect the stove and chimney for cracks. Carry out minor repairs in a timely manner.

- Monitor the condition of the smoke exhaust duct and regularly clean it of soot and debris.

- Monitor the condition of the pipe head and protective cap.

The main malfunctions of brick chimneys and how to eliminate them

There are 4 types of main chimney faults:

- contamination of the channel with soot or other foreign objects;

- formation of condensation in the masonry;

- visible cracks on the surface of the pipe;

- blowing into the chimney channel.

Clogging

Clogging is likely due to the accumulation of soot, collapse of brick or plaster, or foreign objects entering the shaft. Due to the blockage, traction decreases. Strictly speaking, there is no need for repairs here. To correct the situation, a heavy metal weight is used to break through the resulting plug. A specialist (or you yourself), being on the roof, ties a weight to a rope and lets it into the shaft.

If this method does not work, you will have to disassemble the stove until the “thief” who “stole” your draft is found! If the cause of the blockage is soot, then, rolling up your sleeves, you need to clean it: with a brush on a long stick, with chemicals like “Chimney Sweep” or by burning potato peelings the old-fashioned way.

Condensate

The appearance of a burning smell in a heated room or tarry stains and excess moisture on the walls of the shaft indicates that condensation has appeared in the structure.

Its culprit is cracks in the masonry or freezing due to poor insulation of the chimney.

Insulation is usually necessary for buildings with a cold attic. In such cases, the pipe section is thermally insulated with basalt wool or other suitable material.

Cracks

Cracks, as I already said, are formed due to condensation. But the most common reasons for their appearance are:

- Significant temperature difference. Therefore, when the stove has not been heated for a long time, you need to heat it little by little with a gradual increase in the volume of firewood.

- Operating time. Make repairs on time!

To repair a chimney from small cracks use:

- clay – sold packaged in bags weighing from 1 kg;

- heat-resistant sealant;

- fireproof cement mortar.

To repair areas with large cracks, it will likely make more sense to replace the problem area entirely.

Blowing out

Backdraft, also known as blowing, occurs due to two reasons:

- Failure of the furnace head. Replacing the head solves the problem.

- Insufficient height of the chimney on the roof. In this case, you need to add a few rows and the traction will return.

Features of repair of steel chimneys

Steel smoke exhaust ducts are a more modern solution and have some advantages over brickwork. Let's consider the main advantages of using steel pipes for installing chimney communications:

- availability;

- resistance to corrosive influences;

- resistance to aggressive chemicals;

- resistance to temperature changes;

- ease of installation.

The most practical are steel chimneys; this design is easy to install and lasts a long time

From a constructive point of view, such channels are modular and consist of pipes that are interconnected. The joining of pipes in such structures is carried out using special connecting clamps.

Let's look at the step-by-step repair of a steel structure:

- First you need to clean the chimney.

- After cleaning, you need to conduct a preliminary inspection of the chimney. This event will help identify the reason that prevents the chimney from performing its functions properly. As a rule, the main reason for reduced draft in a steel chimney is the occurrence of cracks.

- If a crack is detected, the repair is quite simple: the damaged segment is replaced with another.

Repairing a steel chimney is considered very simple, since it does not require complete dismantling of the structure (damaged modules can be easily replaced with new ones).

Basic malfunctions of metal chimneys and methods for their repair

The main malfunctions of a metal chimney include:

- Wall corrosion. Repair will not help - the problem area needs to be replaced.

- Top element broken. In such a situation, you should quickly replace the head to prevent back draft in the room.

- Channel deformation. If possible, align the course of the chimney pipes and make additional fastenings, strengthening problem areas.

Do not forget to clean the shaft, because soot negatively affects the operation of the system.

What functions does the chimney duct perform?

The chimney is located in a vertical plane and is a channel, the shape of which can be different. Let's consider two main options for the cross-sectional shape of these structures:

- rectangular;

- round.

The most common materials for chimneys are usually:

- brick;

- steel (stainless or galvanized).

Each structure of this type must comply with certain building and fire codes, which are described in detail in the relevant documentation. Let's look at the main functions that these channels perform:

- removal of combustion products of raw materials that are processed in heating devices outside the residential building;

- ensuring the necessary traction indicators. The draft in the chimney communication is a very important indicator on which the efficiency of the heating system as a whole depends ;

- Some chimneys are rightfully considered an indispensable element of building decor.

Important! Any problems that arise during the operation of this heating communication can lead to disastrous consequences. In a faulty design, draft is disrupted, which leads to a decrease in the quality of heating. A phenomenon such as backdraft may occur and combustion products may enter living quarters, which undoubtedly poses a danger to the lives of residents.

In addition to its main function, the chimney can play the role of a decorative element in the exterior of the building

There are many factors that affect the chimney duct and contribute to its destruction. In particular, these factors pose a danger to brick structures, since they are less resistant to them.

Types of industrial chimney repairs

For industrial chimneys, the operating requirements are more stringent. Regular inspection of the chimney trunk and auxiliary systems (smoke removal systems and others) is carried out by company employees authorized for supervision. Based on the inspection, an act, a technical condition report and a map of defects are drawn up. After the inspection, a decision is made on repairs, which can be of two types:

- Current. It is usually carried out on its own, at least according to established standards. Repairs of this type do not involve heavy and complex work.

- Capital. Conducted by special companies.

Capital work includes: replacement, extension or strengthening of the trunk; foundation repair, replacement of worn-out elements.

Examination of chimney pipes

An examination of industrial pipes is appointed due to conservation, reconstruction, liquidation of the pipe or the enterprise itself, etc. With the help of an examination, you can establish its actual technical condition, draw up a repair plan and set a date for the next inspection.

According to safety rules for the operation of ventilation and industrial pipes PB 03-445-02, examination is required if:

- vertical cracks more than 10 mm thick;

- horizontal cracks of the wound 1/6 of the circumference of the pipe itself;

- destruction of masonry up to 2 cm deep;

- destruction of the solution up to 4 cm;

- peeling of the top finishing layer with an area of 1 m2.

Preparation for repair

Restoring brick households in particular is considered the most problematic. Considering the dimensions themselves, as well as the nature of possible malfunctions, you may need help. What to do first:

- Determine the extent of the problem, what exactly is faulty, perhaps the masonry has been damaged or cracks have appeared.

- Clean the entire area to identify hidden defects.

- Determine the scope of the work and how difficult it is to complete it yourself.

How to repair a brick chimney

In case of local destruction in the upper street part of the chimney, it is dismantled and re-laid. During repairs, special solutions and high-quality bricks are used.

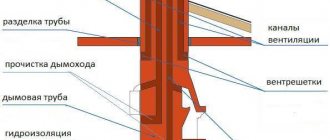

When the chimney shaft is damaged along its entire length, a metal, ceramic or polymer sleeve is inserted inside.

When the mortar cracks, the chimney channel is lined from the inside.

Restoration of masonry

Before restoring the masonry, it must be disassembled. Start at the top, gradually moving down. Having reached the desired place where the cracks end, a new trunk is erected from refractory bricks. It is very important that the inner surface after repair is smooth and does not interfere with smoke exhaust.

Installing the sleeve

If it is not possible to disassemble the channel, then it is restored using a sleeve that is inserted into the chimney. In such repairs, along with the installation itself, the preparatory stage is also extremely important.

Preparing for work

Before work on installing the liner begins, the shaft is cleared of soot, debris and other objects. The cross-sectional area of the sleeve is made smaller than the internal area of the channel in order to place thermal insulation in the resulting gap.

Installation

Initially, the masonry is partially dismantled. The sleeve that is going to be installed must correspond in height and cross-section to the shaft of the existing chimney. It should also have a cleaning door.

The sleeve is carefully lowered down in sections. At the junction of the parts, the masonry is dismantled to open access to the elements and reliably connect them together. This is how the whole structure is assembled.

After installation and thermal insulation of the sleeves, install an umbrella on the head of the pipe and seal the disassembled areas.

Lining of smoke channels

Lining a chimney is a quick and less labor-intensive process, unlike other methods. It consists of spraying a refractory solution with the addition of marble chips or perlite.

Apply, as a rule, in 3 layers with breaks, during which the previous layer must dry completely. The result is a smooth coating without roughness, which does not interfere with the free passage of combustion products.

Repair video

Now it’s worth taking a break and watching a few useful videos on the topic.

Smoke duct lining

Chimney lining or lining is a universal method for reconstructing smoke exhaust and ventilation ducts, which involves the use of special fire-resistant compounds. The most popular means used for the reconstruction of chimney ducts are:

- Mordax;

- Mosan.

The main element that is part of the first product is granite chips. This product is produced in Finland, so it has good quality characteristics. To obtain the necessary solution that will allow you to repair a chimney made of brick, this product is mixed with lime, as well as cement mortar and water. Mosan is a domestic analogue of Mordax, which is made on the basis of perlite.

Both of the above products are distinguished by the fact that they easily adhere to brick and concrete materials. The main advantage of this reconstruction method is that it is done without dismantling the brickwork. After reconstruction, the walls of the internal chimney channel become smooth. Thus, the traction in the system increases and its cleaning is simplified.

As a rule, lining is done very quickly. The entire reconstruction process takes no more than 3–4 hours. Let's consider the order of work during the lining:

- First of all, it is necessary to clean the internal channel of the old brick chimney, removing all soot and other foreign elements from it.

- Next, the canal is moistened.

- At the third stage, a blowing tool (brush) is immersed in the channel, which sprays the composition onto the inner walls of the channel.

- Spraying the mixture is repeated 3 times. Each of the previous layers must dry before applying the next one.

Maintenance of brick chimneys

In order for the brick to serve for 50 years or more, it is necessary to carry out timely repairs of the chimney, as well as its maintenance. Such maintenance means cleaning the internal cavity of the channel, timely sealing of small cracks, potholes and cavities, maintaining the lining layer in proper condition, etc.

Dismantling

Chimney dismantling can be partial or complete. The brickwork is dismantled in order from top to bottom. The volume of bricks to be dismantled must be calculated in advance in order to plan the number of vehicles for its removal. The surrounding area is cleared of machinery and equipment to prevent damage to them.

With the sequential dismantling method, the bricks are dismantled and thrown into the chimney shaft. Downstairs, the bricks are received and stored in the boiler room, after which they are taken out for disposal by prepared transport.

To avoid injury and property damage, it is important to assess the condition of the chimney in advance and develop a plan for dismantling the chimney. In some cases, instead of serial disassembly, disassembly in parts is used. This method requires a lot of mechanization and a truck crane.

Reduced cravings

Reduced draft is the most common case that leads to pipe repair or reconstruction. As a result of operation, soot accumulates in the chimney or construction debris gets there, which impairs draft. To break through the clog, use clearing weights. If this method does not bring the desired result, then you have to completely or partially disassemble the chimney.

Today, in order to avoid troubles with soot, fire-retardant compositions are used, which are added to the stove along with the fuel.

Masonry

In the design and laying of chimneys, there are several rules that must be followed:

- The outer walls must be at least half a brick thick (125 mm).

- The size of the channel is directly affected by the heat transfer value.

- When installing exhaust ventilation in one pipe with a smoke duct, they are combined.

- The material consumption is overestimated in order to maintain ligation of the sutures.

Reconstruction with polymer liners

This method of chimney reconstruction is the most modern today. Unlike previous methods of repairing a chimney, the use of polymer liners is not so common, however, you should pay attention to this method.

Reconstruction with polymer liners is suitable in cases where boilers operating on gas act as a heating device. This is due to the low temperature that occurs during gas processing. Accordingly, this method of chimney repair is not suitable if the heating device operates on solid fuel.

Let's look at chimney repairs step by step using the following liners:

- First, you need to immerse the polymer material liner inside the chimney.

- Next, you need to inflate the liner with air, which is under pressure, and then with steam.

- As a result, the liner, which is exposed to compressed air and steam, adapts to the shape of the internal channel of the chimney communication and hardens.

Thus, the surface of the channel is covered with a polymer layer, which is characterized by high strength characteristics, heat resistance and smoothness. Smooth internal walls will not allow soot deposits to accumulate, and will also contribute to more efficient removal of combustion products outside the residential building.

How to repair a reinforced concrete chimney

Reinforced concrete chimneys are usually repaired in the following situations:

- lining repair (protection of fire-resistant coating);

- anti-corrosion protection on the outside;

- replacement of bandage rings;

- strengthening of individual sections of the structure, etc.

Depending on the type of repair (simple or complex), the optimal method for eliminating defects is selected. Simple work includes repairing chips and cracks in concrete and protecting corroded reinforcement. Complex ones include restoration of pipe geometry with various repair compounds, protection of surfaces with special compounds from moisture and other aggressive environmental influences.

The protective material is applied using special equipment (spray gun, shotcrete machine, etc.)

What is needed for repair work?

To carry out repair work, you need to prepare consumable tools and materials. Their choice depends on several factors:

- the material from which the chimney is made;

- type of damage;

- complexity of the design.

Consumables, tools:

- components of the pipeline, if it is made of separate metal parts;

- bricks, mortar for masonry;

- trowel, trowel;

- fire-resistant composition;

- welding machine, grinder;

- spatulas of different sizes.

Additionally, you need to replace the pipe head with a new one.

Trowel (Photo: Instagram / italia.decorator)